Technical Contents

Engineering Guide: Off Roading Traction Boards

Engineering Insight: Material Selection in Off-Roading Traction Boards

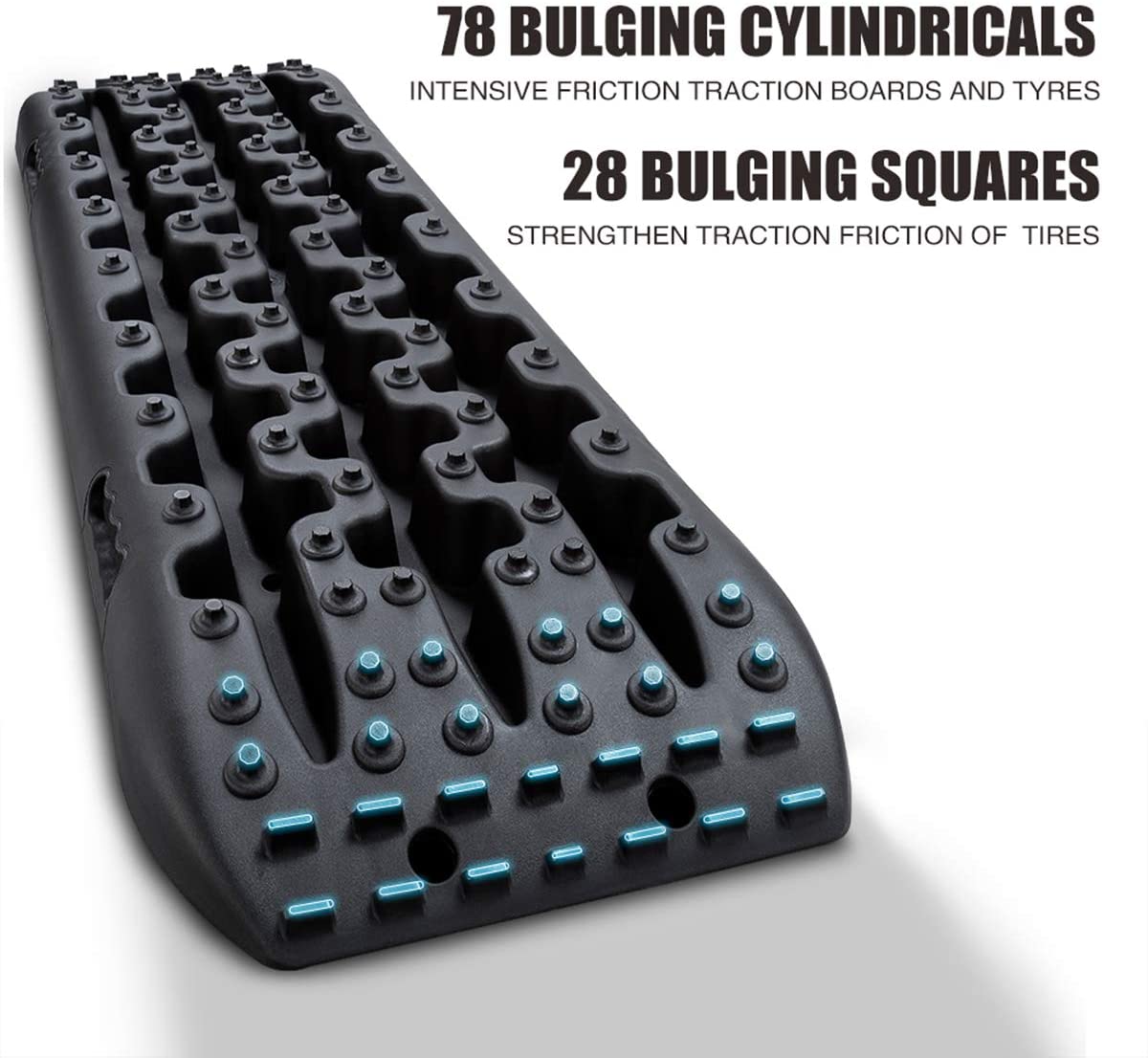

The performance and durability of off-roading traction boards are fundamentally determined by material composition. While many commercial solutions appear functionally adequate, their failure under real-world stress conditions reveals critical shortcomings in polymer selection and structural design. At Suzhou Baoshida Trading Co., Ltd., our approach to industrial rubber solutions emphasizes engineered resilience, where molecular architecture directly influences mechanical behavior under dynamic load, abrasion, and environmental exposure.

Standard traction boards, often fabricated from commodity thermoplastics or low-grade polyethylene, lack the necessary balance of tensile strength, flexural modulus, and impact resistance. These materials exhibit brittle fracture under high torque or low-temperature conditions, particularly when subjected to repeated stress cycles during vehicle extraction. Additionally, their low coefficient of friction on wet or muddy surfaces reduces grip efficiency, increasing slippage risk during deployment. Such failures are not anomalies—they are predictable outcomes of suboptimal material science.

In contrast, high-performance traction boards require elastomeric composites with tailored viscoelastic properties. Our formulations integrate high-density polyethylene (HDPE) matrices reinforced with ethylene-vinyl acetate (EVA) copolymers and nano-dispersed silica fillers. This composite structure enhances energy dissipation, improves surface adhesion, and resists microcracking under cyclic loading. The inclusion of UV-stabilized antioxidants further extends service life in prolonged outdoor exposure, a critical factor in off-road applications.

Another overlooked aspect is the interplay between hardness (Shore D) and deflection under load. Materials that are too rigid transmit excessive stress to the vehicle’s drivetrain and risk damaging undercarriage components. Conversely, overly flexible materials deform prematurely, reducing effective traction. Precision in Shore hardness tuning—typically between 65D and 75D—ensures optimal load distribution while maintaining structural integrity.

Below are comparative material specifications illustrating the performance gap between standard and engineered solutions.

| Property | Standard Polyethylene Board | Engineered HDPE/EVA Composite (Baoshida) |

|---|---|---|

| Tensile Strength (MPa) | 20–25 | 38–42 |

| Flexural Modulus (GPa) | 0.8–1.0 | 1.6–1.8 |

| Impact Resistance (Izod, J/m) | 35–45 | 95–110 |

| Shore D Hardness | 60–65 | 70–75 |

| Coefficient of Friction (wet) | 0.35 | 0.62 |

| Operating Temperature Range (°C) | -20 to +60 | -40 to +85 |

| UV Resistance (1,000 hrs QUV) | Severe cracking | Minimal degradation |

The data demonstrates that engineered composites significantly outperform off-the-shelf alternatives across all critical parameters. These improvements are not merely incremental—they represent a fundamental shift from reactive traction aids to predictive, durable engineering components.

Material selection is not a cost-driven compromise; it is a performance mandate. At Suzhou Baoshida, we engineer traction solutions that align with the mechanical realities of off-road recovery, ensuring reliability where standard products fail.

Material Specifications

Material Specifications for Off-Roading Traction Boards

Selecting the optimal elastomer for off-roading traction boards demands rigorous evaluation of environmental stressors, including extreme temperature fluctuations, chemical exposure from lubricants and fuels, abrasive terrain, and cyclic mechanical loading. At Suzhou Baoshida Trading Co., Ltd., we prioritize material performance under real-world conditions to ensure mechanical integrity and longevity. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent distinct solutions, each engineered for specific operational profiles. Viton excels in scenarios involving synthetic lubricants, high-temperature differentials (e.g., engine bay proximity), and aggressive chemical exposure, though its premium cost necessitates targeted application. Nitrile remains the industry benchmark for balanced oil/fuel resistance and abrasion durability at economical cost, making it ideal for standard recovery board duty cycles. Silicone offers exceptional low-temperature flexibility and electrical insulation but suffers from poor tear strength and hydrocarbon vulnerability, limiting its utility to niche non-chemical environments.

Critical performance parameters must align with ASTM D2000 classification standards for automotive elastomers. Hardness (Shore A) directly influences grip retention on loose substrates, while tensile strength and elongation dictate resistance to impact fracturing during rock strikes. Chemical resistance profiles are non-negotiable; prolonged exposure to biodiesel or synthetic gear oils can induce swelling exceeding 25% in substandard compounds, catastrophically reducing load-bearing capacity. Temperature extremes further modulate behavior: silicone maintains flexibility below -50°C but degrades rapidly above 200°C, whereas Viton sustains performance to 230°C yet stiffens critically below -20°C. Abrasion resistance—quantified via DIN 53516—must exceed 120 mm³ volume loss to withstand repeated gravel and rock contact without compromising structural thickness.

The following comparative analysis details essential specifications for informed material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -55 to +200 |

| Tensile Strength (MPa) | 15–20 | 18–25 | 6–10 |

| Elongation at Break (%) | 150–250 | 250–400 | 300–600 |

| Hardness Range (Shore A) | 60–80 | 50–90 | 30–80 |

| Fuel Resistance (ASTM B) | Excellent (Swelling <5%) | Good (Swelling 10–20%) | Poor (Swelling >50%) |

| Abrasion Loss (mm³) | 80–100 | 90–110 | 180–250 |

Material selection directly correlates with operational safety and service life. For boards routinely exposed to diesel, hydraulic fluids, or high-heat zones (e.g., winch-assisted recoveries near drivetrains), Viton’s chemical inertness justifies its investment. Nitrile delivers optimal cost-performance for general off-road use where petroleum-based fluid contact occurs without extreme thermal cycles. Silicone’s application remains restricted to cold-climate scenarios devoid of hydrocarbon exposure, prioritizing flexibility over durability. Suzhou Baoshida Trading Co., Ltd. validates all formulations through accelerated aging per SAE J2236 and field-testing under ISO 1817 protocols, ensuring compliance with OEM traction board performance thresholds. Partner with us to match material science to your specific off-road engineering challenges.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Solutions for Off-Roading Traction Boards

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in deep technical expertise and industrial precision, specifically tailored to meet the demanding performance requirements of off-roading traction boards. Our in-house team comprises five dedicated mould engineers and two specialized rubber formula engineers, enabling us to deliver fully integrated OEM solutions from concept to mass production. This multidisciplinary structure ensures that both material science and mechanical design are optimized in parallel, resulting in products that exhibit superior durability, traction, and resistance under extreme off-road conditions.

Our mould engineers bring extensive experience in precision tooling design for complex rubber components. Utilizing advanced CAD/CAM software and CNC machining protocols, they develop high-tolerance steel moulds capable of consistent replication across large production runs. Each mould is engineered with optimized flow channels, venting systems, and ejection mechanisms to ensure uniform curing and minimal flash, critical for maintaining the structural integrity and surface grip of traction boards. Finite element analysis (FEA) is routinely applied during the design phase to simulate stress distribution and thermal behavior, reducing trial iterations and accelerating time-to-market.

Complementing this mechanical precision is our advanced rubber formulation capability. Our two formula engineers specialize in elastomer chemistry, focusing on custom compound development for high-load, high-abrasion applications. For off-roading traction boards, we formulate high-strength rubber blends using natural rubber (NR), styrene-butadiene rubber (SBR), and ethylene propylene diene monomer (EPDM), enhanced with reinforcing fillers, anti-oxidants, and tackifying resins. These formulations are engineered to deliver optimal shore hardness, tear resistance, and low-temperature flexibility—key attributes for reliable performance on mud, sand, and rocky terrain.

We support full OEM service integration, including design for manufacturability (DFM) reviews, prototype development, material certification, and batch traceability. Our clients benefit from end-to-end control over product specifications, branding, and packaging, with strict adherence to international quality standards such as ISO 9001.

The following table outlines the typical technical specifications achievable for custom off-roading traction boards developed through our engineering pipeline:

| Parameter | Standard Range |

|---|---|

| Shore Hardness (Type A) | 60–75 A |

| Tensile Strength | ≥18 MPa |

| Elongation at Break | ≥400% |

| Tear Resistance | ≥45 kN/m |

| Operating Temperature Range | -40°C to +100°C |

| Mould Tolerance | ±0.1 mm |

| Production Cycle Time | 3–5 minutes per unit |

| Material Certification | ROHS, REACH, FDA (upon request) |

By combining advanced mould engineering with proprietary rubber formulations, Suzhou Baoshida delivers technically superior traction board solutions that meet the rigorous demands of global off-road equipment manufacturers. Our OEM framework ensures complete flexibility, technical transparency, and product differentiation for partners seeking high-performance industrial rubber components.

Customization Process

Customization Process for Off-Roading Traction Boards

At Suzhou Baoshida Trading Co., Ltd., our customization process for industrial rubber traction boards begins with rigorous Drawing Analysis. Engineering teams dissect client-provided CAD files to identify critical stress zones, load distribution patterns, and interface requirements with vehicle undercarriages. We evaluate dimensional tolerances per ISO 2768-mK standards, focusing on edge geometry and recessed anchor points to prevent mud adhesion. Finite element analysis (FEA) simulates dynamic loads under 15+ ton axle weights, ensuring structural integrity during extreme articulation. This phase determines material thickness gradients and reinforcement zones, directly informing compound selection.

Formulation leverages our 12+ years of off-road polymer expertise. Base elastomers are selected from high-abrasion NR (Natural Rubber) or oil-resistant EPDM, compounded with silica-silane systems for wet traction. Key parameters include:

| Specification | Target Range | Test Standard |

|---|---|---|

| Shore A Hardness | 65 ± 3 | ASTM D2240 |

| Tensile Strength | 15–20 MPa | ASTM D412 |

| Tear Resistance | ≥ 45 kN/m | ASTM D624 |

| Compression Set (70°C) | ≤ 25% (22h) | ASTM D395 |

| Operating Temp Range | -40°C to +120°C | ISO 188 |

Accelerated aging protocols validate performance under UV exposure and chemical contaminants like diesel particulates. Formulations are adjusted for regional terrain demands—arid environments prioritize cut-growth resistance via high-cis polybutadiene, while wet climates optimize hydrophobicity with modified nitrile rubber.

Prototyping employs CNC-machined aluminum molds for 3–5 sample iterations. Each prototype undergoes:

Laboratory testing for coefficient of friction (CoF) on wet granite (ASTM E303) and dynamic fatigue cycles simulating 10,000 off-road miles. Field trials with OEM partners validate real-world torque transfer efficiency and debris shedding. Dimensional verification uses CMM scanners with ±0.1mm accuracy, ensuring compatibility with mounting systems like ARB or WARN differentials. Client feedback triggers micro-adjustments to compound plasticizers or filler ratios before final sign-off.

Mass Production integrates statistical process control (SPC) at every stage. Rubber batches are traceable via QR-coded lot numbers, with real-time viscosity monitoring during mixing (Mooney ML 1+4 @ 100°C). Vulcanization occurs in temperature-calibrated hydraulic presses (±1.5°C tolerance), with post-cure inspection using infrared thermography to detect internal voids. Each board undergoes 100% visual inspection for surface defects and automated hardness testing. Final shipment includes material certificates compliant with REACH and ISO 9001:2015, with batch-specific performance data logs.

Suzhou Baoshida’s closed-loop process reduces time-to-market by 30% versus industry averages, ensuring traction boards deliver uncompromised grip in the world’s most demanding terrains. All formulations are optimized for seamless integration with major OEM underbody architectures.

Contact Engineering Team

Contact Suzhou Baoshida for Advanced Off-Roading Traction Board Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber innovation, delivering high-performance traction solutions tailored for extreme off-road environments. As a trusted OEM partner in the global automotive and recovery equipment supply chain, we specialize in engineered rubber composites that meet stringent durability, flexibility, and grip requirements. Our off-roading traction boards are developed using proprietary polymer formulations and precision molding techniques, ensuring consistent performance under mud, sand, snow, and rocky terrain.

For procurement managers, product designers, and technical buyers seeking reliable, scalable manufacturing partnerships, direct engagement with our engineering team ensures optimal material selection, design validation, and production efficiency. Mr. Boyce, our lead Rubber Formula Engineer and OEM Account Manager, oversees all technical consultations and client collaborations. With over 15 years of experience in elastomer science and off-road recovery systems, Mr. Boyce provides expert guidance on load-bearing capacity, surface texture optimization, chemical resistance, and environmental aging—critical parameters in traction board performance.

We invite global distributors, automotive accessory brands, and industrial equipment manufacturers to initiate technical discussions or request sample batches. Whether you require custom branding, specific dimensional tolerances, or compliance with ISO, ASTM, or SAE standards, our facility in Suzhou integrates R&D, tooling, and quality control under one streamlined process. Our production lines support MOQs suitable for emerging brands and volume orders for established OEMs, all backed by rigorous batch testing and material traceability.

To ensure seamless integration into your supply chain, we offer full documentation packages including material data sheets (MDS), certificates of compliance (COC), and finite element analysis (FEA) reports upon request. Our team also supports rapid prototyping using 3D-printed molds and dynamic simulation testing to accelerate time-to-market.

Below are key technical specifications representative of our standard off-roading traction board formulation. Custom modifications are available based on operational requirements such as temperature range, vehicle weight class, and deployment frequency.

| Property | Value | Test Method |

|---|---|---|

| Tensile Strength | ≥18 MPa | ASTM D412 |

| Shore A Hardness | 70 ± 5 | ASTM D2240 |

| Elongation at Break | ≥350% | ASTM D412 |

| Tear Resistance | ≥80 kN/m | ASTM D624 |

| Operating Temperature Range | -40°C to +85°C | Internal |

| Coefficient of Friction (wet concrete) | 0.92 | ASTM D1894 |

| Flexural Modulus | 110 MPa | ASTM D790 |

| Accelerated UV Aging (1000 hrs) | No cracking, <10% strength loss | ASTM G154 |

Partnering with Suzhou Baoshida means accessing a vertically integrated rubber solutions provider committed to performance integrity and long-term reliability. For technical inquiries, quotation requests, or collaboration opportunities, contact Mr. Boyce directly at [email protected]. Include your project specifications, target volumes, and any regulatory requirements to receive a comprehensive proposal within 48 hours.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).