Introduction: Navigating the Global Market for oil seal dimensions chart

In today’s fast-evolving industrial landscape, precision and reliability are non-negotiable—especially when selecting components as fundamental as oil seals. For international B2B buyers across Africa, South America, the Middle East, and Europe, understanding and utilizing a comprehensive oil seal dimensions chart isn’t just beneficial—it’s essential. A single mismatched seal can jeopardize entire operations by causing leakage, contamination, or costly downtime. Yet, navigating a maze of global suppliers, technical variations, and fluctuating costs can be a significant challenge, particularly as manufacturing hubs in Asia and other regions expand their offerings.

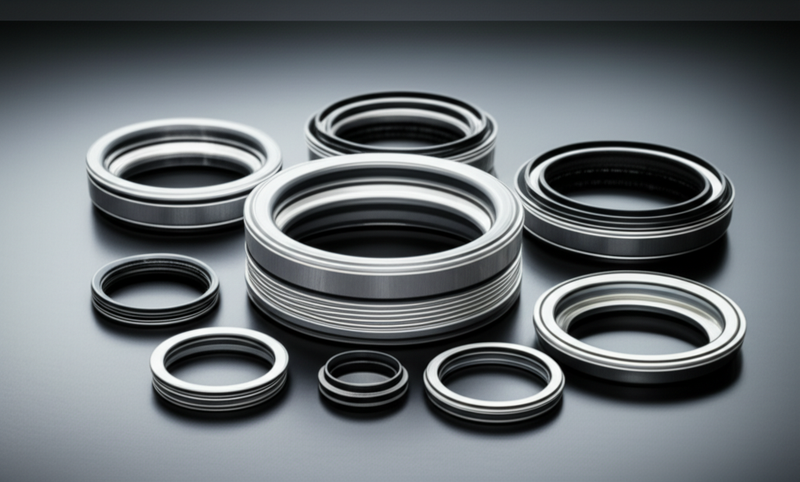

Oil seal dimensions charts serve as the critical foundation for informed procurement. They streamline the selection process, ensuring compatibility across machinery, compliance with international standards, and optimized performance for automotive, hydraulic, and industrial equipment. The right chart not only unlocks access to a wider range of suitable products—from single-lip to advanced double-lip designs—but also clarifies material choices (such as Nitrile, Viton, Silicone, or PTFE) and certifications required for local or export markets.

This guide delivers a 360-degree perspective, empowering buyers to make confident sourcing decisions. You’ll find in-depth coverage of:

- Types and configurations of oil seals

- Material properties and selection for diverse environments

- Key manufacturer and quality control benchmarks (ISO, TS certificates)

- Supplier assessment and international sourcing best practices

- Cost factors and market trends

- Frequently asked questions addressing practical procurement concerns

Whether you’re new to global B2B sourcing or looking to optimize complex supply chains, this resource equips you with practical knowledge and actionable strategies to mitigate risk, control costs, and maximize reliability when sourcing oil seals worldwide.

Understanding oil seal dimensions chart Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metric Oil Seal Chart | Dimensions listed in millimeters (ID, OD, width); aligns with ISO/DIN standards | Automotive, industrial machinery in global markets | + International interoperability – May require metric tooling |

| Inch (Imperial) Chart | Uses inches for all key dimensions; based on SAE/ASTM standards | North/South American equipment, legacy European assets | + Ideal for US legacy systems – Less global compatibility |

| TC-Type Double Lip Chart | Specifies double lip, spring-loaded design; enhanced sealing data | Heavy industry, automotive, high-contamination settings | + Superior sealing and lifespan – Typically higher cost |

| Material-Specific Chart | Categorized by material (NBR, FKM, Silicone); includes compatibility data | Marine, mining, chemical processing, food-grade uses | + Informs compatibility at a glance – May require cross-referencing |

| Custom/Non-Standard Chart | Tracks non-standard sizes, large diameters, and custom tolerances | Special projects, OEMs, infrastructure retrofits | + Enables bespoke solutions – Extended lead times, higher MOQ |

Metric Oil Seal Chart

This chart lists oil seal dimensions in millimeters, conforming to international (ISO/DIN) standards. It is the primary reference for buyers sourcing for modern machines or applications prioritizing international compatibility. B2B buyers in Africa, the Middle East, and Europe benefit considerably, as most contemporary machinery and suppliers utilize metric sizing. When procuring, ensure supplier adherence to tight tolerances and confirm metric labeling to avoid mismatches in multi-origin supply chains. The main limitation is compatibility with older or US-origin machinery, which may require imperial sizes.

Inch (Imperial) Chart

Inch-based dimension charts use the imperial system—still common in North and South America and among some legacy European equipment. These charts are critical for B2B buyers maintaining or retrofitting older assets, especially in industries like mining and oil and gas. When using an inch chart, confirm that your equipment specifications align to avoid conversion errors. Consider supplier ability to meet exact SAE/ASTM dimensional tolerances. While interoperability across new global assets may be a challenge, these charts remain indispensable for certain regions and industries.

TC-Type Double Lip Chart

TC-type double lip charts focus on a widely used, double-lip, spring-loaded oil seal, detailing both standard and special dimensions. These are vital for highly demanding applications—like heavy truck axles, agro-industrial machinery, and automotive powertrains—where enhanced sealing against dust, mud, and fluids is critical. B2B buyers should prioritize vendors with proven TC-type expertise, look for detailed spring and lip dimension listings, and consider total lifecycle cost versus standard single-lip options. The higher initial cost is offset by longer operational intervals and reduced downtime.

Material-Specific Chart

Material-specific charts categorize oil seals by their elastomer composition (such as nitrile, Viton, or silicone), highlighting chemical and thermal compatibility. This is essential for buyers in sectors facing extreme conditions: marine, mining, chemical processing, and food and pharma industries. These charts streamline procurement by allowing immediate selection based on exposure risks and compliance needs. The best suppliers provide charts that cross-reference material codes with dimensional data and resistance ratings. B2B considerations include verifying food or FDA grades, and balancing upfront cost against service life.

Custom/Non-Standard Chart

Custom or non-standard charts capture dimensions not widely available in catalog offerings—covering oversize seals, specialized tolerances, or OEM-specified profiles. For B2B buyers managing infrastructure retrofits, unique machinery, or specialized production lines, these charts are invaluable in ensuring precise fit and function. Product availability may involve longer lead times and higher minimum order quantities (MOQs). Strong technical collaboration with suppliers is necessary, as is attention to post-order support for installation and warranty. Custom charts empower buyers to future-proof their operations and address challenging engineering needs.

Related Video: List of All Oil Seal , its Sizes [ in mm and inches ] and its description

Key Industrial Applications of oil seal dimensions chart

| Industry/Sector | Specific Application of oil seal dimensions chart | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Engine assembly, transmission systems, wheel hubs | Accurate fit, reduced downtime, warranty compliance | Adherence to global standards (ISO/TS 16949), custom sizing, material certification |

| Heavy Machinery & Mining | Hydraulic cylinders, gearboxes, drive shafts | Minimized leakage, improved equipment lifespan | Extreme temperature/material compatibility, supplier reliability, robust documentation |

| Oil & Gas | Pumps, compressors, pipeline maintenance | Leak prevention, compliance, safety | Chemical resistance, pressure specification, certifications (API/ISO) |

| Food & Beverage Processing | Conveyor equipment, filling machines, mixers | Contamination control, hygiene, regulatory safety | FDA/EC-approved materials, ease of cleaning, traceability |

| Power Generation & Utilities | Turbines, cooling pumps, generator housings | Operational reliability, maintenance cost reduction | High-performance materials, rapid availability, long lifecycle |

Automotive Manufacturing

In the automotive sector, oil seal dimensions charts are vital for specifying seals in engines, transmissions, and wheel assemblies. These charts enable engineers and buyers to match exact shaft and bore sizes across diverse vehicle models, preventing mismatched components that might increase warranty claims or cause mechanical failures. For global buyers, especially in regions such as Turkey and South America, aligning with internationally recognized standards (like ISO/TS 16949) ensures compatibility with global OEMs. Reliable suppliers should offer flexible customization, traceability, and proof of compliance for quality assurance.

Heavy Machinery & Mining

Heavy equipment, including excavators and mining vehicles, operates in harsh conditions demanding robust sealing solutions. Oil seal dimensions charts guide maintenance teams in selecting seals that fit hydraulic cylinders, gearboxes, and large rotary shafts. Key challenges such as temperature extremes, abrasive environments, and irregular maintenance intervals are addressed by verifying the correct seal size and material before sourcing. Buyers from Africa and the Middle East should prioritize suppliers who can demonstrate material resilience, consistent lead times, and comprehensive technical documentation to minimize operational interruptions.

Oil & Gas

Oil seals are essential in the oil and gas industry for pumps, compressors, and pipeline applications where they prevent leaks and ensure safety. Dimensions charts are used to cross-check compatibility before large-volume procurement, minimizing the risk of costly shutdowns due to improper fit. Requirements in this sector include high chemical and pressure resistance, as well as adherence to strict international certifications (e.g., API, ISO). Buyers in Europe and Saudi Arabia must validate that suppliers can provide precise dimensional data and ensure documentation meets rigorous industry standards.

Food & Beverage Processing

Machinery in food and beverage production, such as conveyors and mixers, requires oil seals that meet stringent hygiene and contamination-control norms. Reference to the dimensions chart ensures that seals used on food-contact surfaces maintain a precise fit that withstands frequent cleaning and sterilization. International buyers should look for suppliers offering FDA or EC-approved materials, detailed compliance information, and robust traceability systems to meet both local and export market regulatory demands, ensuring product integrity and consumer safety.

Power Generation & Utilities

In power generation, accurate oil seal sizing is imperative for equipment like turbines and cooling pumps, which operate continuously and require minimized maintenance. The dimensions chart assists technical teams in specifying seals that support long lifecycle performance and easy replacement during scheduled outages. For utility operators worldwide, including those in Africa and Eastern Europe, working with responsive suppliers who offer fast turnaround, ready access to a wide range of sizes, and technical support can significantly reduce downtime and operating costs.

Related Video: how oil seal works ( animation )

Strategic Material Selection Guide for oil seal dimensions chart

Choosing the Right Materials for Oil Seal Dimensions: A Global B2B Perspective

Selecting the optimal material for oil seals is a critical decision for international B2B buyers. The right material ensures reliable sealing performance across diverse operating environments and meets market-specific requirements. Here are four widely used oil seal materials—Nitrile (NBR), Viton (FKM), Silicone (VMQ), and PTFE (Teflon)—each analyzed with key properties, performance pros and cons, and targeted considerations for global buyers, especially across Africa, South America, the Middle East, and Europe.

Nitrile Rubber (NBR)

Key Properties:

Nitrile offers a balanced profile with good resistance to oils, greases, and moderate chemicals. It handles temperatures from -30°C to 120°C and is moderately resistant to abrasion and wear. Pressure limits are suitable for most medium-duty applications.

Pros & Cons:

NBR’s core advantage is affordability and broad availability worldwide, enabling scalable and cost-effective procurement. However, its chemical resistance is inferior compared to other elastomers, and it suffers in applications with aggressive fuels, solvents, or higher temperatures. UV/ozone aging may also be a concern in outdoor or tropical environments.

Application Impact:

NBR remains a solid choice for automotive, agricultural, and light industrial machinery with standard lubrication. Its performance may degrade with exposure to aggressive chemicals or extreme ambient conditions.

Buyer Considerations:

Most NBR seals adhere to global standards such as ASTM D2000 and DIN 3760, simplifying cross-border sourcing. Suitable for B2B buyers seeking economical, proven solutions for non-critical environments. Popular in Africa and South America where cost sensitivity is high and applications are less demanding.

Viton (FKM)

Key Properties:

Viton, a fluoroelastomer, excels in chemical and temperature resistance, withstanding continuous exposure up to 250°C. It tolerates a wide range of aggressive fluids including fuels, synthetic oils, and many chemicals common in modern industrial settings.

Pros & Cons:

Viton provides exceptional durability, long-term sealing, and resistance to most oils, acids, and even some oxidizers. The main drawback is its higher cost, making it less suitable for price-sensitive or low-value equipment. Some manufacturing complexity may impact lead times for custom dimensions.

Application Impact:

Ideal for high-value or critical systems—such as process pumps in oil & gas, chemical processing, and export-focused automotive applications—where long service life and resistance to harsh fluids are required.

Buyer Considerations:

Accepted by most global standards (ASTM D1418, DIN 3760), Viton is well-regarded in Europe and the Middle East’s petrochemical and heavy industry sectors. Buyers should ensure suppliers can certify performance to international norms, especially for regulated or export equipment.

Silicone (VMQ)

Key Properties:

Silicone seals function across the broadest temperature range of elastomers (-70°C to 260°C), featuring excellent flexibility and ozone/UV resistance. However, they exhibit moderate resistance to oils and limited strength in abrasive environments.

Pros & Cons:

Silicone’s chief advantages are low-temperature flexibility, resilience in outdoor settings, and suitability for food-grade or medical applications. Drawbacks include higher tendency to swell in certain oils and relatively poor abrasion resistance, limiting use in dynamic or high-wear environments.

Application Impact:

Preferred for applications with wide-ranging temperatures, such as industrial equipment in cold climates (Europe, high-altitude regions), medical devices, and food-processing machinery.

Buyer Considerations:

Silicones often meet FDA, EC1935/2004, and relevant ISO standards, making them suitable for buyers targeting regulated markets. In Middle Eastern or tropical markets, their ozone/UV resistance is valuable, but fluid compatibility must be checked for each case.

PTFE (Teflon)

Key Properties:

PTFE seals lead the field in chemical resistance and withstand a massive temperature range (-200°C to 300°C). They are inert to nearly all fluids (except fluorine and molten alkali metals), have minimal friction, and are non-aging under most conditions.

Pros & Cons:

The premium advantages of PTFE are non-reactivity and suitability for high-speed, high-temperature, or highly aggressive chemical environments. The downside includes high material and processing costs, less flexibility, and potential leakage if shaft tolerances or surface finishes are not optimized.

Application Impact:

PTFE is indispensable in pharmaceuticals, food processing, and corrosive industrial environments—anywhere traditional rubbers fail. Its attributes justify the investment for buyers prioritizing reliability over upfront costs.

Buyer Considerations:

PTFE seals comply with a broad range of standards, such as FDA, EU 10/2011, and ISO 3601, facilitating global trade. Buyers should verify manufacturing precision, as PTFE seals are less forgiving of dimensional or surface inaccuracies—a critical point for Middle Eastern and European buyers demanding top-tier process reliability.

Summary Comparison Table

| Material | Typical Use Case for oil seal dimensions chart | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nitrile (NBR) | Automotive, general industrial, pumps, and gearboxes | Cost-effective and widely available | Limited chemical & temperature resistance | Low |

| Viton (FKM) | Petrochemical, export automotive, heavy process equipment | Superior chemical & heat resistance | High cost, customization needed | High |

| Silicone (VMQ) | Food-grade, medical devices, very low/high temperature applications | Excellent flexibility, wide temperature range | Poor wear & oil resistance in some fluids | Medium |

| PTFE (Teflon) | Aggressive chemical, pharma, food processing, high-speed shafts | Ultimate chemical & thermal stability | Expensive, less flexible, needs precision | High |

In-depth Look: Manufacturing Processes and Quality Assurance for oil seal dimensions chart

Overview of Oil Seal Manufacturing: Key Stages and Techniques

The manufacture of oil seals—especially those referenced in dimension charts for industrial, automotive, and heavy equipment applications—involves a precise and multi-stage process. Understanding these stages is crucial for international B2B buyers in Africa, South America, the Middle East, and Europe, where resource constraints and operational reliability often drive procurement decisions.

1. Material Preparation

The foundation of oil seal quality lies in material selection and preparation. Manufacturers source elastomers such as Nitrile (NBR), Viton (FKM), Silicone (VMQ), PTFE (Teflon), and Polyacrylate (ACM) to suit specific temperature, chemical, and mechanical requirements. Raw materials are rigorously tested for purity, hardness (durometer), and uniformity to ensure compliance with global standards.

Mixing and compounding occur in controlled environments, using batch mixers to blend base polymers with fillers, plasticizers, curing agents, and colorants. Documentation and traceability at this early stage are critical for downstream quality assurance and regulatory compliance—a nuance B2B buyers must consider when evaluating suppliers.

2. Forming Processes

Filed as one of the most technology-dependent stages, forming defines the seal’s dimensional accuracy and performance attributes:

- Compression and Injection Molding: The prepared rubber compound is molded to form the oil seal’s basic shape. Advanced CNC molds and high-pressure injection processes are commonly deployed for intricate profiles, such as TC double lip or custom configurations.

- Metal Component Fabrication: For oil seals with reinforcement rings or springs (typically in double-lip or spring-loaded variants), precise metal stamping and coiling are utilized. Stainless or carbon steel cores are produced to tight tolerances for optimal concentricity and fit.

3. Assembly and Secondary Processing

After forming, components (rubber body, metal spring, and metal case) are assembled automatically or semi-automatically. For complex seals, a secondary bonding or over-molding step ensures robust adhesion between materials.

Surface finishing treatments, such as trimming excess flash, deburring, and coating (for corrosion resistance or enhanced lubricity), are vital. Advanced surface treatments can significantly impact lifespan in harsh climates or high-load environments—relevant for buyers facing extreme operational conditions.

4. Inspection and Sorting

Seals are visually and mechanically inspected for surface defects, voids, or inclusions. Automated vision systems are increasingly employed for dimensional conformance, matching actual product dimensions against reference charts and CAD specifications.

Quality Control Systems in Oil Seal Manufacturing

Building reliability into oil seals requires a layered approach to quality control (QC), governed both by international standards and industry-specific requirements.

International and Industry-Specific Standards

B2B buyers should expect reputable manufacturers to adhere to:

- ISO 9001: The benchmark for quality management systems, assuring control over the entire manufacturing lifecycle, documentation, and traceability.

- ISO/TS 16949: Essential for automotive applications, emphasizing defect prevention and consistent quality in mass production.

- CE Marking, API, and Others: While not always required, some European and sectoral standards (such as CE for safety or API for oil & gas) add assurance for specific end-use applications.

Critical QC Checkpoints

A robust supplier QC program typically encompasses:

- Incoming Quality Control (IQC): Raw materials are tested for identity, physical properties, and contamination. For buyers, documentation of these checks—such as Certificates of Analysis (COA)—are crucial for due diligence.

- In-Process Quality Control (IPQC): During forming and assembly, dimensions, temperature profiles, and material consistency are continuously monitored. Random batch sampling and Statistical Process Control (SPC) methodologies help identify deviations early.

- Final Quality Control (FQC): The finished seals are checked for appearance, dimensions (using coordinate measuring machines or laser scanners), hardness, and functional attributes. Comprehensive reports matching batches to oil seal dimension charts enhance transparency.

Advanced Testing Techniques

Suppliers committed to quality will perform a suite of standard and specialized tests, including:

- Dimensional Checks: Employing calipers, micrometers, and optical measuring equipment, seals are validated against published size charts for inside diameter (ID), outside diameter (OD), and width.

- Material and Performance Testing: Hardness (Shore A), tensile strength, compression set, and elongation tests ensure conformity to specification and application demands.

- Leakage and Pressure Testing: Simulated in real-use conditions (temperature, pressure, rotational speed) to confirm sealing integrity.

- Chemical Resistance and Aging: Accelerated life testing is used to assess durability against oils, fuels, and environmental contaminants.

Audit trails, batch traceability, and retention of test samples are hallmarks of best practice manufacturers.

Verifying Supplier Quality Assurance: Actions for B2B Buyers

International buyers face additional challenges: language barriers, extended logistics chains, and varying regulatory regimes. To mitigate these, structured supplier evaluation and ongoing verification are essential.

Supplier Audits and Assessment

- Onsite Factory Audits: Whenever feasible, conduct or commission audits (self or via third parties) focusing on manufacturing controls, housekeeping, calibration records, and sample traceability.

- Review of Certifications: Insist on up-to-date ISO 9001 (or sector-specific) certificates, with validity directly verifiable via standard bodies.

- Sample Evaluation: Request pre-shipment or golden samples for independent measurement against dimension charts and specification sheets.

Production and QC Documentation

- Batch Reports: Ask for comprehensive QC reports for delivered batches, including records of dimensional and performance testing, lot traceability, and any NCR (non-conformance report) logs.

- Certificates of Conformance (CoC) and Analysis (CoA): These provide additional verification of material compliance and are a must for regulated sectors or safety-critical applications.

Third-Party Inspections

Especially for international buyers from Africa, South America, the Middle East, or non-EU Europe where local technical resources may be limited:

- Pre-shipment Inspection: Employ reputable third-party agencies (e.g., SGS, TÜV, Intertek) for independent verification, including random sampling, visual checks, dimensional measurement, and packaging verification.

- Ongoing Supplier Performance Reviews: Develop a supplier scorecard tracking quality, delivery, and responsiveness; use it for continuous improvement or alternative sourcing decisions.

Regional Certification and Compliance Considerations

Buyers targeting specific markets must be cautious about regional compliance nuances:

- Africa and South America: Verify the suitability of seals for local climate factors (heat, dust, humidity) and compatibility with locally prevalent equipment standards.

- Middle East: For Saudi Arabia and neighbors, ensure compatibility with SASO standards, and request evidence of performance in high-temperature or sand-laden environments.

- Europe (including Turkey): CE conformity may apply for certain equipment; expect RoHS and REACH compliance for material safety. Demand full technical documentation and access to harmonized technical files.

Practical Takeaways for B2B Buyers

- Prioritize suppliers with visible, well-documented QC practices, not just certifications.

- Request clear mapping of seal dimensions (ID, OD, width) to international size charts used in your country or sector.

- Leverage third-party inspections and periodic supplier audits for higher-value or mission-critical applications.

- Engage with suppliers offering strong technical support, customizable documentation, and proactive communication—especially where engineering expertise is required for custom or large-volume orders.

A careful, standards-driven approach not only guarantees the performance and longevity of oil seals in diverse international environments but also minimizes operational and reputational risk. B2B buyers who integrate these insights into their sourcing strategy will be better positioned to secure high-quality, cost-effective, and reliable oil seal solutions for their markets.

Related Video: How Things Are Made | An Animated Introduction to Manufacturing Processes

Comprehensive Cost and Pricing Analysis for oil seal dimensions chart Sourcing

Key Cost Elements in Oil Seal Sourcing

International B2B buyers considering oil seal sourcing based on dimension charts must understand the multi-layered cost structure behind each unit price. At the core, material costs—nitrile (NBR), Viton (FKM), silicone (VMQ), PTFE, or polyacrylate (ACM)—constitute a significant portion of expenses. Material prices fluctuate based on global petrochemical markets and the chosen compound’s technical properties; for example, Viton or PTFE seals are notably costlier due to advanced chemical or temperature resistance.

Labor and manufacturing overhead are next, capturing wages, utility bills, plant operations, and maintenance. Labor costs are typically lower in manufacturing hubs like China, but higher labor standards or automation can enhance quality and are priced accordingly. Tooling and setup charges factor heavily during custom or non-standard dimensions, with one-time costs distributed over projected order quantities.

Quality control (QC) and testing expenses rise with higher expectations for certification (ISO, TS) or application in regulated sectors (automotive, oil & gas). Investment in inspection systems and batch traceability enhances reliability but also marginally increases unit prices. Finally, packaging, inland transportation, and international shipping (logistics) can represent a significant cost for buyers in Africa, South America, the Middle East, and Europe, especially when incoterms move the liability to the buyer earlier in the supply chain.

Supplier margin rounds off the price, reflecting the business model, value-added services, and overall competitiveness. Aggressive pricing may signal quality or service trade-offs, so careful assessment of value is crucial.

Top Pricing Drivers for B2B Buyers

Several essential factors shape the final price on oil seal dimensions charts:

- Order Volume and MOQ (Minimum Order Quantity): Higher volumes command lower unit pricing due to economies of scale, while small lots (especially for custom dimensions) attract higher per-piece costs or setup surcharges.

- Specification and Customization: Standardized dimensions are more affordable, while custom/thickened lips, special coatings, or premium elastomer blends can substantially add to costs.

- Material Selection: Seals in ordinary rubber (e.g., NBR) are budget-friendly; specialized grades (high-temperature, chemical resistance) are premium-priced.

- Quality Standards and Certifications: Products adhering to ISO/TS or industry-specific norms carry higher costs owing to enhanced QC and documentation requirements.

- Supplier Profile and Location: Established exporters or brand-name suppliers often price higher but offer better service levels, technical support, and warranty structures. Proximity to industrial clusters or ports influences logistics costs and delivery times.

- Trade Terms (Incoterms): EXW (Ex-Works), FOB, CIF, and DDP terms each distribute cost and risk differently. Buyers in regions like Africa or South America must quantify local import duties and inland transportation when comparing quotes.

Actionable Strategies for Cost Control and Value Maximization

- Engage Multiple Suppliers: Solicit quotes from various qualified manufacturers—both from major hubs like China and regional players—to benchmark costs and terms.

- Leverage Volume Negotiations: Where possible, consolidate orders across projects or subsidiaries to exceed MOQs and secure volume discounts.

- Clarify All-In Pricing: Instruct suppliers to provide clear breakdowns covering tooling, QC, packing, and logistics. This minimizes hidden charges and simplifies landed cost assessments.

- Optimize Specifications: Select materials and designs aligning with operational requirements—avoid over-specifying for non-critical applications to keep costs rational.

- Request Quality Audits: For high-value or critical-use cases, invest in third-party audits or sample-inspection batches before shipment.

- Negotiate Incoterms Wisely: Factor in total landed costs, not just ex-factory prices—opt for CIF or DDP to better predict total outlay and reduce logistics headaches.

- Assess Total Cost of Ownership (TCO): Consider product lifespan, failure rates, and supplier support quality. Sometimes a higher upfront unit cost is justified by reduced downtime and maintenance throughout the seal’s service life.

International Pricing Nuances

For buyers in Africa, South America, the Middle East, and select European regions, be alert to:

- Currency Fluctuations: Exchange rates can impact final cost structures, especially with suppliers quoting in USD, RMB, or EUR.

- Local Tariffs and Compliance: Import duties and compliance regulations vary widely—consult with local agents or customs brokers early in the procurement process.

- Logistics Reliability: Ensure suppliers can coordinate with reputable global freight forwarders, as delays or damages in transit can erode potential cost advantages.

- Supplier Communication: Language support, time zone compatibility, and responsiveness form the backbone of a successful B2B relationship—prioritize suppliers with strong multilingual support and clear communication protocols.

Disclaimer: The information above provides a strategic framework for oil seal sourcing cost analysis. Actual prices and cost components are subject to change based on supplier, region, and market conditions; always request up-to-date, written quotations, and conduct due diligence before placing orders.

Spotlight on Potential oil seal dimensions chart Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘oil seal dimensions chart’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Oil Seal Size Chart (www.globaloring.com)

Global O-Ring and Seal, via its Oil Seal Size Chart offering, positions itself as a leading supplier for precise oil seal dimension requirements worldwide. The company specializes in providing a comprehensive, searchable chart with over 15,000 standard and metric size combinations, enabling B2B buyers to efficiently identify suitable shaft, bore, and width specifications. This robust, interactive tool supports both imperial and metric users, catering to international markets where dimensional accuracy and fast selection are essential. Global O-Ring and Seal’s multilingual resources and apparent after-hours support indicate a strong focus on serving diverse global clients, including those in Africa, South America, the Middle East, and Europe. While detailed public information on certifications and manufacturing is limited, their depth in cataloging and digital accessibility make them a valuable sourcing partner for industrial, automotive, and MRO procurement teams needing trusted oil seal data.

Hengoseal (hengoseal.com)

Hengoseal is a specialized supplier focused on supporting global MRO teams and industrial buyers with oil seal replacements and dimension identification. The company’s core strength lies in its advanced Oil Seal Cross Reference Chart, a digital tool designed to help buyers, engineers, and technicians quickly match obsolete, unmarked, or cross-brand seals using precise dimensional data (ID, OD, width), type, and material. Hengoseal’s platform enables rapid localization of alternatives compatible with leading brands such as SKF, National, NOK, Toyota, and Mitsubishi—minimizing downtime and reducing procurement risks.

The company demonstrates an understanding of practical field challenges, offering actionable, self-service resources to streamline international sourcing. Evidence suggests a strong track record in serving global markets, making Hengoseal particularly attractive for buyers in Africa, the Middle East, South America, and Europe seeking reliable replacements and efficient inventory management. While details about manufacturing certifications or facilities are limited, Hengoseal distinguishes itself through its commitment to accuracy, breadth of catalog, and responsive B2B support for cross-border customers.

Oil Seal Size Chart (www.nokcn-seals.com)

Oil Seal Size Chart, available via NOKCN-Seals, is a specialized resource and supplier for precision oil seal solutions with an extensive, searchable database featuring over 15,000 standard and metric size combinations. The platform enables B2B buyers to quickly identify oil seals by shaft diameter, bore, and width in both metric and imperial units, streamlining specification and procurement processes. Their offering covers a diverse range of industrial applications, emphasizing compatibility with global equipment standards and facilitating seamless international sourcing.

Key strengths include an intuitive online selection tool and robust product data, enabling engineering teams to match seals to exact requirements for machinery across industries. While there is limited public detail on certifications or in-house manufacturing, their internationalized online tools and support for global inquiries suggest readiness to serve buyers in Africa, South America, the Middle East, and Europe. Notably, Oil Seal Size Chart distinguishes itself by making oil seal selection transparent and efficient for cross-border industrial projects.

Quick Comparison of Profiled Manufacturers

| Manufacturer | Brief Focus Summary | Website Domain |

|---|---|---|

| Oil Seal Size Chart | Extensive searchable size chart for oil seals | www.globaloring.com |

| Hengoseal | Advanced cross-brand seal matching tool | hengoseal.com |

| Oil Seal Size Chart | Large searchable database; global sourcing support | www.nokcn-seals.com |

Essential Technical Properties and Trade Terminology for oil seal dimensions chart

Key Technical Properties in Oil Seal Dimension Charts

Selecting the right oil seal for industrial applications hinges on understanding core technical properties found in dimension charts. These properties directly impact product performance, lifespan, and procurement success across diverse operating environments.

-

Material Grade

The seal’s material (e.g., Nitrile/NBR, Viton/FKM, Silicone/VMQ, PTFE) defines its temperature, pressure, and chemical resistance. For buyers, material selection must align with specific industrial fluids, operating conditions, and regulatory standards. Mismatching can result in premature seal failure or costly downtime. -

Dimensional Tolerance

Indicating how precisely the actual size of a seal matches its nominal dimensions (inner diameter, outer diameter, width), tolerance levels are crucial for system compatibility, especially in high-precision equipment. Stringent tolerance ensures tight fits, minimizes leaks, and supports global interchangeability. -

Temperature Range

The specified operating temperatures for each material help buyers assess suitability for local climatic extremes or process requirements. For instance, Viton and PTFE seals withstand higher temperatures, vital for heavy-duty or Middle Eastern applications where ambient heat is a factor. -

Pressure Rating

Pressure handling capacity determines whether a seal can prevent leaks under static or dynamic loads. Overlooking this specification can jeopardize machinery integrity and breach warranty terms. -

Hardness (Shore A/D)

Measured via the Shore scale, hardness affects seal flexibility and resilience. Softer seals conform better to mating surfaces but may wear faster; harder seals offer durability but need tighter surface finishes. -

Chemical Compatibility

Noted in charts or product catalogs, this property spells out which oils, greases, or process chemicals the seal can tolerate. In sectors exposed to aggressive substances (refineries, agriculture), this factor is paramount for safety and operational reliability.

Understanding and confirming these specifications early ensures the chosen oil seal meets both functional and compliance requirements, reducing operational risks and long-term costs.

Common Trade Terms and Jargon in International Oil Seal Procurement

Procurement professionals encounter specific trade terminology throughout the sourcing and negotiation of oil seals, particularly when dealing with suppliers across borders. Familiarity with these terms improves communication, manages expectations, and streamlines the buying process.

-

OEM (Original Equipment Manufacturer)

This refers to seals produced for use in branded equipment. OEM-grade products adhere to exact specifications required by the machinery manufacturer—important for buyers seeking guaranteed compatibility and warranty support. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier will accept per order. MOQs affect pricing and inventory strategies, especially for distributors or buyers wishing to test new suppliers with smaller trial orders. -

RFQ (Request for Quotation)

A standard document or process buyers use to solicit price and availability information based on precise technical and commercial requirements. Clear, detailed RFQs reduce misunderstandings and ensure accurate, comparable quotations from multiple vendors. -

Incoterms (International Commercial Terms)

These define shipping responsibilities, risks, and costs between buyers and sellers. Popular terms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Choosing the right Incoterm impacts logistics, customs clearance, and budgeting. -

Lead Time

The interval between placing an order and receiving goods. Accurate lead-time information is vital for planning production schedules, especially given varying distances and customs procedures for shipments to Africa, South America, the Middle East, or Europe. -

COC (Certificate of Conformity)

A document attesting that supplied oil seals meet specified standards or regulations, typically required for export, import clearance, or end-user quality assurance—critical for regulated industries or government procurement.

Acquiring a strong grasp of these properties and terms not only empowers B2B buyers to make informed decisions but also fosters more transparent, productive supplier relationships across international markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the oil seal dimensions chart Sector

Global Market Overview and Key Sourcing Trends

Oil seals are foundational elements in industrial equipment, automotive assemblies, and a diverse range of machinery—today’s global market for oil seal dimensions charts is shaped by dynamic industrialization and regional investment patterns. For B2B buyers in Africa and South America, demand is fueled by the ongoing expansion of automotive production, mining activities, and infrastructural development. In the Middle East and Europe, needs are centered on energy, heavy industries, and OEM (original equipment manufacturer) supply chains, with particular emphasis on reliability, lifecycle costs, and compliance with regional regulations.

One of the key drivers is the rapid evolution of global supply chains and the impact of digitization. Modern B2B procurement platforms now provide real-time access to extensive oil seal dimensions databases, technical drawings, and compatibility charts. This digital transparency is reducing traditional barriers, enabling buyers from Turkey, Saudi Arabia, and beyond to compare offerings from global and regional manufacturers—especially those in China, which has emerged as a leading production hub due to scalability, cost-competitiveness, and the ability to offer custom dimensions.

Technical innovation is also reshaping sourcing: advanced materials such as fluorinated elastomers (Viton/FKM), PTFE, and silicone are becoming more accessible, with manufacturers providing full documentation on performance characteristics by dimension and type. Customization options—critical for markets facing unique temperature, pressure, or chemical challenges—are now standard, with manufacturers supporting tailored solutions and rapid prototyping supported by CAD and online engineering consultation.

B2B buyers should monitor secondary trends, including a move toward integrated supplier partnerships that combine product supply with aftersales engineering support, and the rapid growth of local warehousing and regional distribution (especially in North and West Africa, the GCC, and Eastern Europe). By leveraging digital sourcing, technical standardization (such as ISO or DIN compliance), and direct supplier communication, international buyers can secure reliable supply, reduce lead times, and optimize total cost of ownership for oil seal solutions.

Sustainability and Ethical Sourcing in Oil Seal Procurement

As environmental standards grow more stringent worldwide, sustainability is increasingly central in B2B sourcing decisions concerning oil seal dimensions charts. Buyers are now expected to evaluate not simply the technical and commercial merits of oil seals, but also the environmental impact of their materials, manufacturing process, and supply chain.

Modern oil seals offer better performance with less environmental burden due to advances in ‘green’ elastomers, extended wear life, and improved resistance to degradation. For example, seals made with advanced FKM or silicone often last longer and mitigate the risk of lubricant leakage—directly contributing to reduced maintenance frequency and minimizing environmental contamination.

Ethical sourcing is another critical requirement. The most reputable manufacturers in China, Europe, and emerging markets now publicize adherence to key international standards (such as ISO 14001 for environmental management and ISO 9001 for quality). B2B buyers should prioritize suppliers who provide transparency about their raw material origin, chemical formulations, and labor practices, and who hold third-party certifications like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals).

Growing numbers of buyers in regions like the EU, Saudi Arabia, and South Africa mandate supplier declarations regarding conflict mineral sourcing, carbon footprint, and recycling initiatives. Partnering with suppliers who invest in resource-efficient manufacturing (e.g., reduced water and energy use, closed-loop waste management) is now a differentiator, and often a prerequisite for participation in public or multi-national procurement.

To deliver sustainable value, B2B buyers should integrate environmental and ethical criteria into their RFQs (Requests for Quotation) and contract terms—helping future-proof their supply chains as global compliance requirements intensify.

Evolution and Historical Context

The landscape of oil seal procurement has undergone noteworthy transformation over recent decades. Historically, oil seal selection relied on legacy catalogues, bespoke engineering relationships, and lengthy lead times for sourcing rarer dimensions or materials. The proliferation of standardized oil seal dimensions charts—defined by ISO, DIN, and regional standards—brought critical efficiencies, enabling interchangeability and multi-source procurement.

The rise of Asian manufacturing, spearheaded by Chinese firms, has driven innovation in cost-effective large-scale production while maintaining or surpassing international quality and environmental benchmarks. Concurrently, the digital revolution has democratized access to technical documentation, with multilingual databases and cross-reference tools enabling seamless international sourcing.

For B2B buyers today, these developments mean that securing the optimal oil seal is no longer constrained by geography or legacy supplier networks. Instead, a new era of agility, transparency, and sustainability is shaping sourcing strategies across markets worldwide.

Related Video: Incoterms® 2020 Explained for Import Export Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of oil seal dimensions chart

-

How can I effectively vet international suppliers for oil seals, particularly in China or other Asia-based markets?

Thorough supplier vetting is critical for minimizing risk. Start by requesting proof of international quality certifications like ISO 9001 or IATF 16949. Ask for client references, particularly with other international buyers, and verify their export history and trade compliance. Assess production capacity by requesting factory audit reports or video walkthroughs. Utilize third-party inspection agencies where possible, and always insist on documented quality control processes specific to oil seal dimensions. Platforms like Alibaba or industry associations can help identify credible, export-focused suppliers. -

What level of customization is available for oil seal dimensions, and how should I approach custom orders?

Reputable manufacturers offer a range of customization options, from specific dimension tolerances to tailored material compounds for unique operating environments. Provide application details—such as operating temperature, pressure, fluid type, and rotational speed—alongside dimensional drawings or sample products. Clarify standards of measurement (metric or imperial), and discuss prototype or pre-production sampling capabilities with your supplier. Ensure there is mutual understanding on tolerance limits, labeling, and packaging to streamline your supply chain. -

What is the typical minimum order quantity (MOQ) and lead time for international B2B oil seal purchases?

MOQs can vary significantly; established suppliers may set lower MOQs for standard sizes—ranging from 500 to 1,000 units—while customized seals usually require higher MOQs. Lead times for standard items are generally 2–4 weeks, while custom orders may take 4–8 weeks, depending on complexity and supplier workload. Discuss your logistics timeline upfront with potential suppliers and negotiate buffer stock or safety inventory arrangements for critical orders. Supply chain disruptions can occur, so always plan conservatively. -

Which payment terms are advisable and commonly accepted when sourcing oil seals internationally?

Standard payment terms include Telegraphic Transfer (T/T), often with a 30% upfront deposit and the remaining 70% upon shipment. Letters of Credit (L/C) are preferred for higher-value or first-time trades due to the security they provide both parties. Some suppliers accept PayPal or credit card for small sample orders, but these carry higher fees. Wherever possible, consolidate orders to streamline transaction costs and build a history of timely payments to negotiate more favorable terms in the future. -

How can I ensure consistent quality and compliance with industry standards for oil seals from overseas suppliers?

Request material certificates (such as those for NBR, Viton, or PTFE), dimensional inspection reports, and sample batch testing before full-scale production. Insist on adherence to recognized standards such as DIN 3760 or ISO 6194, as these denote consistent dimensions and materials. Regular third-party pre-shipment inspections and ongoing random sampling help mitigate quality risks. Request clear product identification (e.g., batch numbers or QR codes) to support traceability and any future warranty claims. -

What documentation and certifications should accompany my oil seal shipments to satisfy local regulations and customs clearances?

Essential documents include a commercial invoice, packing list, certificate of origin, bill of lading (or airway bill), and conformity certificates (CE, ROHS, or local equivalents if required). For some markets, additional safety data sheets or test reports for certain materials (e.g., silicone or fluoroelastomer) may be necessary. Confirm with your customs broker or local chamber of commerce the specific documentation required in your destination country to minimize delays and avoid regulatory issues. -

What are the most efficient logistics options for importing oil seals to Africa, South America, the Middle East, or Europe?

Choose between sea freight for bulk, less time-sensitive orders and air freight for urgent or smaller shipments. Consider using international freight forwarders who offer DDP (Delivered Duty Paid) or DAP (Delivered at Place) terms to simplify customs clearance. Consolidating shipments can yield better freight rates and reduce handling risks. Always factor in port handling fees, inland transportation, and import duties when budgeting. Reliable suppliers provide shipment tracking and proactive documentation for smooth arrivals. -

How should I handle disputes or quality issues with overseas suppliers regarding oil seal dimension or performance discrepancies?

Address disputes promptly with photographic evidence, inspection reports, and full documentation referencing the agreed specification or dimension chart. Most reputable suppliers will offer replacements or credits for verified defects; establish these terms contractually before order placement. If resolution cannot be reached, utilize arbitration services provided by trade platforms or international chambers of commerce. To prevent issues, always document every agreement in writing and maintain detailed communication records for audit trails.

Strategic Sourcing Conclusion and Outlook for oil seal dimensions chart

The global landscape for oil seal sourcing is evolving rapidly, with increasing demand for robust sealing solutions across diverse regions such as Africa, South America, the Middle East, and Europe. For international B2B buyers, mastering oil seal dimensions charts is central to effective procurement—facilitating compatibility, minimizing operational risks, and optimizing inventory across multiple industrial sectors.

Key takeaways include prioritizing supplier relationships with established quality certifications, a proactive approach to design and material selection based on intended use and environmental conditions, and a comprehensive analysis of oil seal dimension standards. For strategic sourcing, it’s vital to evaluate manufacturers on their technical support, customization capabilities, and supply chain reliability—not just on price. Leading suppliers can offer tailored advice and support in navigating global standards, ensuring fit-for-purpose solutions delivered on time.

Looking ahead, as industrialization accelerates and machinery complexity increases, the importance of agile, data-driven sourcing decisions will only grow. Embrace digital sourcing tools, maintain open communication with manufacturers, and consistently review your oil seal dimension requirements to stay ahead of maintenance or production disruptions. Seize the opportunity now to build resilient supplier networks and specification-driven procurement strategies—your competitive edge in the evolving global marketplace for oil seals.