Technical Contents

Engineering Guide: One-Way Rubber Valve

Engineering Insight: Material Selection Criticality in One-Way Rubber Valve Performance

The functional integrity of a one-way rubber valve hinges predominantly on precise elastomer selection, a factor frequently underestimated in off-the-shelf solutions. While basic design parameters like crack pressure and flow rate are commonly addressed, the chemical and physical environment imposes equally critical demands on the valve material. Standard catalog valves often utilize generic compounds optimized for cost and broad applicability, not the specific fluid media, temperature extremes, cyclic fatigue, or sterilization protocols encountered in demanding industrial applications. This mismatch leads to premature failure modes including chemical swelling, hardening, cracking, or permanent set, directly compromising the valve’s core function: reliable unidirectional flow control without leakage or inversion during backflow events. The polymer backbone and additive package must be engineered to resist degradation mechanisms inherent to the operational profile; a valve functioning adequately in water at 25°C may catastrophically fail within hours when exposed to biodiesel at 80°C or ozone-laden air streams due to incompatible molecular stability.

Off-the-shelf valves commonly fail because their material specifications lack the necessary granularity for real-world conditions. For instance, a valve marketed for “general purpose” use might employ a standard Nitrile Butadiene Rubber (NBR) compound. While NBR offers good resistance to petroleum oils, it exhibits poor resilience against phosphate ester hydraulic fluids, strong acids, or prolonged high-temperature exposure common in modern hydraulic or chemical processing systems. Similarly, inadequate consideration of compression set resistance leads to permanent deformation after repeated cycling, causing the valve lip to lose sealing force and leak under backpressure. Swelling in incompatible media increases the crack pressure unpredictably or causes valve sticking. These failures manifest as process contamination, system downtime, or safety hazards – costs far exceeding the initial savings from a generic valve. True reliability demands material formulation calibrated to the exact fluid chemistry, temperature range, pressure dynamics, and lifecycle requirements.

Key elastomer properties must be rigorously matched to application demands. The following table outlines critical performance characteristics for common valve materials:

| Elastomer | Key Chemical Resistance | Temperature Range (°C) | Compression Set (70°C/72h) | Critical Limitations |

|---|---|---|---|---|

| EPDM | Water, Steam, Alkalis, Ketones, Brake Fluids | -50 to +150 | Excellent (<25%) | Poor resistance to oils, fuels, aromatics |

| Standard NBR | Aliphatic Hydrocarbons, Water, Hydraulic Oils | -30 to +100 | Moderate (30-45%) | Swells in aromatics, esters; poor ozone/weathering |

| High-ACN NBR | Improved fuel/oil resistance | -20 to +120 | Moderate (25-40%) | Still vulnerable to polar solvents, ozone |

| FKM (Viton®) | Aromatics, Fuels, Acids, Bases, Hydraulic Fluids | -20 to +250 | Very Good (<20%) | Expensive; poor steam resistance; limited low-temp |

| Silicone | Water, Alcohols, Ozone, UV | -60 to +230 | Good (20-35%) | Poor tensile strength; swells in hydrocarbons |

Suzhou Baoshida Trading Co., Ltd. leverages deep polymer science expertise to move beyond generic solutions. Our OEM engineering process begins with comprehensive application analysis, defining the exact fluid composition, thermal profile, cycle count, and regulatory constraints. We then formulate proprietary rubber compounds – selecting base polymers, curatives, fillers, and stabilizers – to deliver optimal performance in the specific environment. This precision engineering ensures consistent crack pressure, minimal compression set, long-term resilience against media exposure, and reliable sealing over the valve’s intended lifespan, eliminating the costly failures inherent in one-size-fits-all alternatives. Material selection is not a commodity; it is the foundational engineering decision for valve reliability.

Material Specifications

Material selection is a critical determinant in the performance, longevity, and reliability of one-way rubber valves used in industrial applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision-engineered rubber components tailored for demanding environments. Our one-way rubber valves are manufactured using three primary elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct chemical, thermal, and mechanical properties, enabling optimal performance across diverse operational conditions.

Viton, a fluorocarbon-based rubber, is renowned for its exceptional resistance to high temperatures, aggressive chemicals, oils, and fuels. With a continuous service temperature range of -20°C to +200°C (short-term up to +250°C), Viton is ideal for applications in petrochemical, aerospace, and automotive industries where exposure to hydrocarbons and extreme heat is common. Its low gas permeability and excellent aging characteristics ensure long-term sealing integrity under pressure. However, Viton exhibits lower flexibility at sub-zero temperatures and higher material cost compared to alternatives.

Nitrile rubber, or Buna-N, is widely used for its outstanding resistance to petroleum-based oils, greases, and hydraulic fluids. It operates effectively within a temperature range of -30°C to +100°C, with some formulations extending to +125°C. Nitrile offers good abrasion resistance and mechanical strength, making it suitable for industrial hydraulic systems, fuel delivery components, and pneumatic equipment. While cost-effective and reliable in oil-rich environments, Nitrile performs poorly when exposed to ozone, weathering, and polar solvents, limiting its use in outdoor or chemical processing applications.

Silicone rubber provides superior flexibility and thermal stability across an extended temperature range of -60°C to +200°C. It exhibits excellent resistance to ozone, UV radiation, and weathering, making it ideal for outdoor, medical, and food-grade applications. Silicone is inherently biocompatible and meets stringent regulatory standards such as FDA and USP Class VI. However, it has relatively low tensile strength and poor resistance to petroleum-based fluids, requiring careful evaluation in high-stress or oil-exposed environments.

The selection of the appropriate elastomer must consider fluid compatibility, temperature exposure, mechanical stress, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. supports OEMs and industrial partners with material testing, custom formulation, and application-specific validation to ensure optimal valve performance.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 (+250 short) | -30 to +100 (+125 short) | -60 to +200 |

| Fluid Resistance | Excellent (oils, fuels, acids) | Excellent (petroleum oils, greases) | Poor (oils, fuels); Good (water, alcohols) |

| Compression Set Resistance | Excellent | Good | Good |

| Tensile Strength | High | High | Moderate |

| Ozone & UV Resistance | Excellent | Poor | Excellent |

| Gas Permeability | Low | Moderate | High |

| FDA Compliance | Limited grades | Limited grades | Yes (specific formulations) |

| Typical Applications | Aerospace, chemical seals | Hydraulics, fuel systems | Medical, food, outdoor |

Manufacturing Capabilities

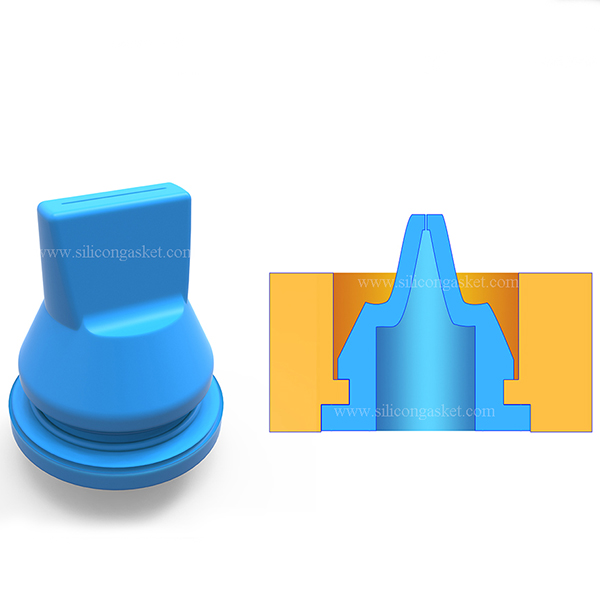

Engineering Capability: Precision Development for One-Way Rubber Valves

Suzhou Baoshida Trading Co., Ltd. leverages deep engineering expertise to deliver mission-critical one-way rubber valves for demanding industrial applications. Our core strength resides in the integrated collaboration between dedicated Mold Engineering and Rubber Formulation disciplines. This dual-engineering approach ensures optimal performance, longevity, and manufacturability from initial concept through to high-volume production. We maintain a specialized team comprising five experienced Mold Engineers and two senior Rubber Formula Engineers, working in unison under stringent quality management systems compliant with ISO 9001 standards. This structure eliminates siloed development, guaranteeing that material properties and mold design are intrinsically aligned for superior valve functionality.

Our Mold Engineering team possesses extensive proficiency in designing complex, high-precision molds for intricate valve geometries. They utilize advanced CAD/CAM software (SolidWorks, UG NX) and conduct rigorous mold flow analysis to predict and optimize material behavior during injection molding. This proactive analysis minimizes defects like flash, sink marks, or incomplete filling, directly enhancing valve sealing integrity and dimensional stability. Concurrently, our Formula Engineering team focuses on the critical science of elastomer selection and compound development. We tailor formulations using NBR, EPDM, FKM, and specialty compounds based on the specific chemical exposure, temperature range, pressure requirements, and lifecycle expectations of the end application. Rigorous laboratory testing evaluates key properties including durometer stability across temperature extremes, compression set resistance, tensile strength, elongation, and fluid compatibility to ensure the rubber compound meets or exceeds OEM performance criteria.

This integrated engineering capability is fundamental to our OEM service model. We partner with clients from the earliest design stages, providing DFM (Design for Manufacturability) feedback and material recommendations. Our process encompasses prototype development with rapid tooling, comprehensive performance validation testing (including flow rate, cracking pressure, and back-pressure leakage), and seamless transition to full-scale production. We manage the entire supply chain for OEM projects, maintaining strict process control through statistical process control (SPC) methodologies to ensure batch-to-batch consistency and exceptional yield rates exceeding 99.5% for qualified parts.

The following table outlines the standard performance envelope achievable with our engineered one-way rubber valves, all customizable through our formulation and mold engineering expertise:

| Parameter | Standard Specification | Customizable Range |

|---|---|---|

| Temperature Range | -40°C to +120°C | -60°C to +230°C (Material Dependent) |

| Max Operating Pressure | 1.0 MPa | Up to 5.0 MPa |

| Cracking Pressure | 0.01 – 0.1 MPa | 0.005 – 0.5 MPa |

| Media Compatibility | Water, Air, Oils, Mild Chemicals | Aggressive Fuels, Acids, Bases |

| Standard Materials | NBR, EPDM | FKM, ACM, HNBR, Custom Blends |

| Durometer (Shore A) | 50 – 70 | 30 – 90 |

| Life Cycle Expectancy | 500,000+ cycles | 1,000,000+ cycles |

Suzhou Baoshida’s engineering synergy translates directly into reliable, high-performance one-way valves for our OEM partners. By embedding material science and precision mold design at the core of development, we deliver solutions that minimize field failures, reduce total cost of ownership, and meet the exacting demands of fluid control systems across automotive, medical device, and industrial automation sectors. Our commitment is to engineering excellence that ensures your valve performs flawlessly, every cycle.

Customization Process

Customization Process for One-Way Rubber Valves at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering precision-engineered one-way rubber valves tailored to the exact operational demands of industrial applications. Our systematic customization process ensures optimal performance, durability, and compatibility with client-specific environments. This process is structured into four critical phases: Drawing Analysis, Formulation, Prototyping, and Mass Production.

The first phase, Drawing Analysis, begins with a comprehensive technical review of the client’s provided engineering drawings or 3D models. Our engineering team evaluates dimensional tolerances, sealing surfaces, flow dynamics, and interface geometry to ensure functional integrity. We assess compliance with international standards such as ISO 3601 for fluid systems and verify material clearance in dynamic assembly environments. This stage often involves close collaboration with the client’s R&D department to resolve design ambiguities and optimize for manufacturability.

Following drawing validation, we proceed to the Formulation stage. Based on the valve’s intended operating conditions—such as temperature range, media exposure (e.g., oils, acids, steam), and pressure cycles—our rubber formulation engineers select the appropriate elastomer base. Common materials include NBR for oil resistance, EPDM for steam and ozone stability, and FKM for high-temperature chemical environments. Hardness is adjusted between 50 to 80 Shore A, depending on sealing force and flex life requirements. Additives are precisely dosed to enhance compression set resistance, UV stability, or flame retardancy as needed.

Prototyping is the third and critical validation step. Using precision CNC-machined molds or rapid tooling techniques, we produce small-batch samples for functional testing. These prototypes undergo rigorous evaluation, including leak testing under simulated backpressure, cyclic durability trials, and environmental aging per ASTM D573. Clients receive test reports and physical samples for field validation. Design or material adjustments are implemented at this stage to ensure operational reliability.

Once approved, the project transitions to Mass Production. Our automated compression and injection molding lines ensure consistent part quality at scale. Each batch is subject to in-process quality checks, including dimensional inspection via coordinate measuring machines (CMM) and hardness verification. Final products are packaged per client logistics requirements, with full traceability maintained through batch coding and material certifications.

The following table summarizes typical performance specifications for our customized one-way rubber valves:

| Parameter | Standard Range | Customizable Options |

|---|---|---|

| Material Types | NBR, EPDM, FKM, Silicone, CR | Blends, FDA-compliant grades |

| Hardness (Shore A) | 50–80 | 40–90 (upon request) |

| Operating Temperature | -30°C to +150°C (varies by material) | Up to +250°C with FKM |

| Pressure Resistance | Up to 10 bar (dynamic) | Up to 25 bar (reinforced design) |

| Media Compatibility | Water, oils, air, mild chemicals | Aggressive solvents, steam |

| Lifespan (Cycle Count) | 50,000–100,000 cycles | >500,000 cycles (optimized design) |

Through this disciplined, science-driven approach, Suzhou Baoshida ensures every one-way rubber valve meets the highest standards of industrial performance and reliability.

Contact Engineering Team

Contact Suzhou Baoshida for Precision One-Way Rubber Valve Solutions

Suzhou Baoshida Trading Co., Ltd. stands as your dedicated engineering partner for high-performance one-way rubber valves in demanding industrial applications. With over 15 years of specialized expertise in rubber compounding and OEM manufacturing, we resolve critical challenges in fluid control systems where reliability, chemical resistance, and precise actuation thresholds are non-negotiable. Our in-house R&D team leverages advanced polymer science to tailor valve specifications to your exact operational parameters, eliminating field failures caused by material degradation, pressure hysteresis, or temperature excursions. We do not offer generic off-the-shelf components; instead, we engineer validated solutions through iterative compound formulation, finite element analysis (FEA), and rigorous ISO 17497-compliant testing protocols. This precision-driven approach ensures your valves maintain integrity across 10,000+ cycles in aggressive media—acids, hydrocarbons, or high-purity fluids—without compromising flow dynamics or sealing performance.

Technical Specifications Overview

The table below outlines baseline capabilities for our standard one-way rubber valve series. All parameters are fully customizable to meet project-specific requirements through collaborative engineering.

| Parameter | Standard Range | Customization Capability |

|---|---|---|

| Material Options | EPDM, FKM, NBR, Silicone, HNBR | Specialty blends (e.g., peroxide-cured FKM for ultra-high temp) |

| Temperature Range | -50°C to +200°C (material-dependent) | Extended range to +250°C (FKM variants) |

| Pressure Rating | 0.5 to 10 bar (differential) | Up to 25 bar with reinforced carcass design |

| Durometer Range | 40 to 90 Shore A | Tolerance ±3 Shore A |

| Media Compatibility | Water, oils, fuels, mild acids | Customized for aggressive chemicals (e.g., ketones, amines) |

Initiate a technical consultation to resolve your unique sealing challenges. Forward your application details—including fluid media, pressure/temperature profiles, cycle frequency, and dimensional constraints—to Mr. Boyce, our OEM Engineering Lead. He will coordinate a cross-functional review within 24 business hours, providing:

Material compatibility analysis against your specified media

FEA simulation data for stress distribution and deflection thresholds

Prototype validation timeline with ISTA 3A-compliant durability testing

Cost-optimized production scaling from 1,000 to 500,000 units annually

Do not compromise system integrity with valves designed for generic use cases. Suzhou Baoshida’s compound formulation expertise ensures molecular-level optimization for your operational environment, reducing total cost of ownership through extended service life and minimized downtime. Contact Mr. Boyce directly at [email protected] to submit your technical dossier. Include “One-Way Valve Engineering Query” in the subject line for immediate prioritization. Our engineering team will respond with a preliminary material recommendation and testing protocol within one business day. For urgent projects requiring validation under ASME BPE or FDA 21 CFR 177.2600 standards, specify this requirement to expedite regulatory compliance documentation. Partner with us to transform valve performance from a maintenance liability into a competitive advantage.

[email protected] remains your direct channel for precision-engineered rubber solutions backed by industrial-grade validation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).