Technical Contents

Engineering Guide: Open Cell Polyurethane Foam

Engineering Insight: Material Selection in Open Cell Polyurethane Foam

Open cell polyurethane foam is widely utilized across industrial, automotive, and consumer sectors due to its favorable balance of flexibility, acoustic absorption, and thermal insulation. However, its performance is highly dependent on precise material formulation and processing parameters. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf open cell foams frequently underperform in demanding applications because they are engineered for general use, not specific operational environments. This mismatch often leads to premature degradation, reduced efficiency, and increased lifecycle costs.

The core issue with generic foam products lies in their standardized chemical composition. Open cell polyurethane is formed through the reaction of polyols and isocyanates, with water acting as the primary blowing agent to generate carbon dioxide and create the cellular structure. The ratio of these components, the functionality of the polyol, catalyst selection, and surfactant type all dictate cell morphology, density, and mechanical behavior. Off-the-shelf foams typically use cost-optimized formulations that sacrifice performance consistency to meet price points. As a result, they may exhibit poor compression set resistance, inconsistent airflow characteristics, or inadequate flame retardancy when exposed to real-world stressors.

In industrial sealing, gasketing, or vibration damping applications, such shortcomings can lead to seal failure, noise transmission, or mechanical fatigue. For example, a standard foam may compress adequately at room temperature but lose resilience under sustained thermal cycling. Similarly, acoustic foams selected without analyzing frequency-specific absorption profiles often fail to meet noise reduction targets in automotive or HVAC systems.

Custom-engineered open cell polyurethane foams address these challenges by tailoring formulation variables to the application’s physical and environmental demands. At Baoshida, we collaborate with OEMs to adjust density, cell openness, tensile strength, and flame resistance to achieve optimal performance. This precision engineering ensures long-term reliability, compliance with industry standards (e.g., UL 94, ASTM E84), and compatibility with adjacent materials in complex assemblies.

The following table outlines key specifications that differentiate standard and engineered open cell polyurethane foams:

| Property | Standard Off-the-Shelf Foam | Engineered Industrial Foam |

|---|---|---|

| Density (kg/m³) | 15–25 | 20–60 (customizable) |

| Tensile Strength (kPa) | 80–120 | 150–250 |

| Elongation at Break (%) | 120–180 | 200–300 |

| Compression Set (50%, 22h) | 10–15% | <8% |

| Airflow Resistance (Pa·s/m) | 1,500–3,000 | 800–5,000 (tunable) |

| Flame Resistance (UL 94) | HB | HB, V-2, or V-0 achievable |

| Operating Temperature (°C) | -20 to 80 | -40 to 110 |

Material selection is not a commodity decision—it is an engineering imperative. By moving beyond generic solutions and adopting purpose-built open cell polyurethane foams, manufacturers can significantly enhance product durability, safety, and performance. At Suzhou Baoshida Trading Co., Ltd., we deliver engineered rubber solutions that meet the exacting demands of modern industrial applications.

Material Specifications

Material Specifications: Open Cell Polyurethane Foam for Industrial Applications

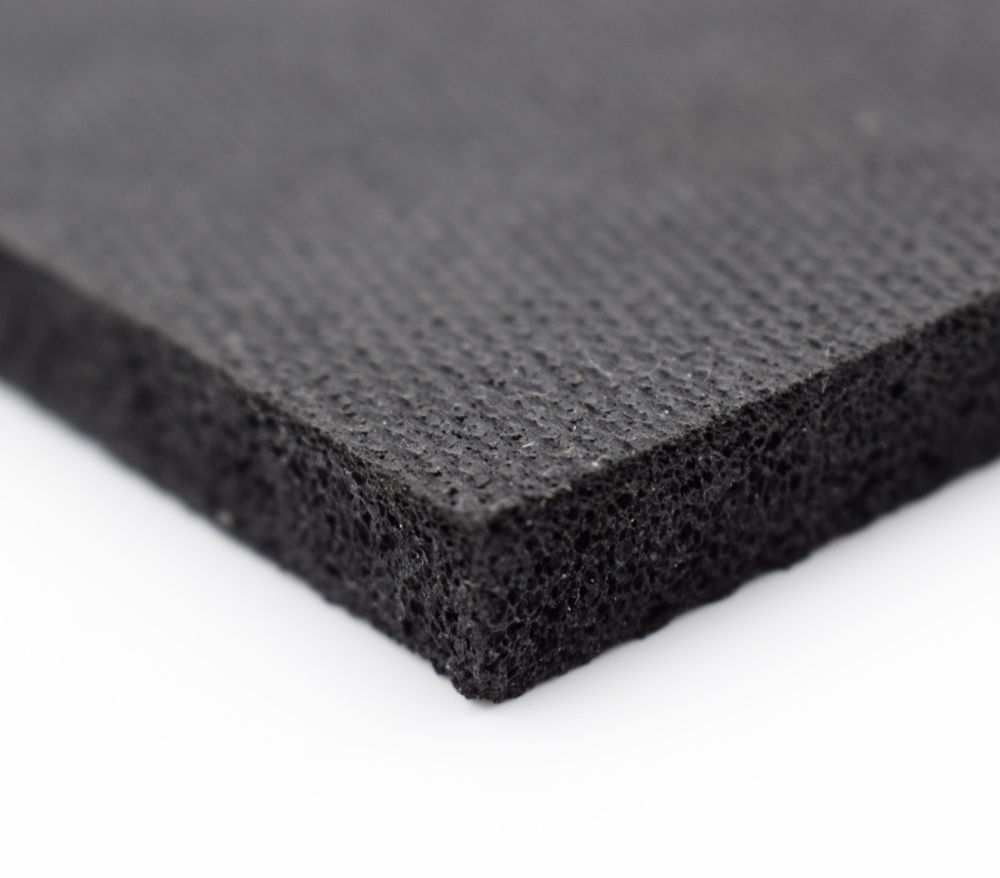

Open cell polyurethane foam represents a critical material solution within industrial sealing, gasketing, and vibration damping systems. Its defining characteristic is a highly interconnected cellular structure where cells are predominantly open, facilitating controlled air and fluid permeability. This structure directly influences key performance metrics including compression set, resilience, and thermal insulation properties. At Suzhou Baoshida Trading Co., Ltd., we rigorously control foam density, typically ranging from 15 kg/m³ to 120 kg/m³, to meet precise OEM requirements for cushioning, acoustic absorption, or filtration. Critical specifications adhere to ASTM D3574 standards, encompassing tensile strength (100-300 kPa), elongation at break (100-250%), and compression deflection force (10-50% ILD). Consistency in cell morphology is paramount, as irregular cell structure compromises sealing integrity and fatigue resistance in dynamic applications. Our formulations prioritize low compression set (<15% per ASTM D3574 Method F after 22 hours at 70°C), ensuring long-term dimensional stability under continuous load—a non-negotiable parameter for automotive and aerospace clients.

While open cell polyurethane foam serves distinct functional roles, its integration often necessitates complementary elastomeric components. Below is a comparative specification table for Viton®, Nitrile (NBR), and Silicone—commonly paired materials in integrated sealing systems where chemical exposure, temperature extremes, or biocompatibility dictate selection. Note this comparison addresses elastomer properties, not the polyurethane foam itself.

| Material | Temperature Range (°C) | Key Chemical Resistance | Typical Hardness (Shore A) | Primary Industrial Applications |

|---|---|---|---|---|

| Viton® (FKM) | -20 to +230 | Exceptional: Fuels, oils, acids, aromatics | 60-90 | Aerospace seals, chemical processing O-rings |

| Nitrile (NBR) | -40 to +120 | Excellent: Petroleum oils, greases, water | 40-90 | Automotive fuel systems, hydraulic seals |

| Silicone (VMQ) | -60 to +200 | Good: Water, oxygen, ozone; Poor: Fuels | 30-80 | Medical devices, food processing, electronics |

Polyurethane foam performance must be evaluated alongside these elastomers in system design. For instance, NBR gaskets may interface with polyurethane foam spacers in fuel system housings, demanding compatibility testing per SAE J2236. Viton® components often shield polyurethane elements from aggressive jet fuels in aerospace assemblies, leveraging its superior hydrocarbon resistance. Silicone’s biocompatibility makes it ideal for medical device housings where open cell foam provides cushioning without leaching extractables.

Suzhou Baoshida emphasizes material synergy in OEM partnerships. Our technical team validates polyurethane foam specifications against elastomer interfaces through accelerated aging per ASTM D573 and fluid immersion testing. Density gradients within the foam matrix are calibrated to balance permeability requirements with structural support—critical for HVAC filtration media or battery pack cushioning in EVs. Strict lot traceability ensures repeatability across production runs, directly supporting our clients’ Six Sigma manufacturing objectives. Understanding the interplay between polyurethane foam characteristics and complementary elastomer properties is fundamental to engineering robust, failure-resistant industrial systems.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Open Cell Polyurethane Foam

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in open cell polyurethane foam manufacturing is anchored in deep technical expertise and a systematic approach to material science and mold design. Our team comprises five dedicated mold engineers and two specialized rubber formula engineers, enabling us to deliver fully integrated OEM solutions that meet exacting industrial standards. This multidisciplinary structure ensures seamless coordination between material formulation and mold functionality, resulting in optimized production efficiency and superior product consistency.

Our formula engineers possess advanced knowledge in polymer chemistry, specifically tailored to open cell polyurethane systems. They are responsible for developing custom foam formulations that achieve precise physical properties such as density, compression set, tensile strength, and airflow resistance. By adjusting isocyanate indices, catalyst types, surfactants, and blowing agents, we fine-tune foam structures to meet application-specific requirements, whether for acoustic insulation, filtration, or cushioning in automotive, HVAC, or industrial equipment sectors. Rigorous lab-scale prototyping and environmental aging tests ensure long-term performance under real-world conditions.

Complementing our formulation expertise, the mold engineering team specializes in designing and validating tooling systems for continuous, high-yield foam production. With extensive experience in low-pressure pour molding, slabstock, and batch processes, our engineers utilize CAD/CAM software and thermal simulation tools to optimize mold geometry, venting, and temperature distribution. This precision reduces cycle times, minimizes material waste, and ensures uniform cell structure development during foaming. All molds are manufactured to tight tolerances and subjected to functional testing before deployment in production.

Our OEM capabilities are built on a foundation of collaborative engineering. From initial concept to final validation, we work closely with clients to translate functional requirements into manufacturable designs. This includes DFM (Design for Manufacturing) reviews, material selection guidance, and full-scale prototyping. We support low-volume pilot runs and scale seamlessly to high-volume production, maintaining consistent quality through in-process controls and statistical process monitoring.

The integration of formula and mold engineering allows us to resolve complex challenges—such as cell anisotropy, shrinkage, or surface defects—through coordinated adjustments in both material and process parameters. This holistic approach reduces development time and accelerates time-to-market for client products.

Below is a summary of typical engineering specifications we achieve with open cell polyurethane foam:

| Property | Typical Range | Test Standard |

|---|---|---|

| Density | 15–60 kg/m³ | ISO 845 |

| Tensile Strength | 80–250 kPa | ISO 1798 |

| Elongation at Break | 100–300% | ISO 1798 |

| Compression Set (50%, 22h) | ≤10% | ISO 1856 |

| Airflow Resistance | 50–500 Pa·s/m | ASTM D3574 |

| Cell Size (average) | 200–600 µm | Microscopy Analysis |

| Hardness (Indentation, 40%) | 1.5–5.0 kPa | ISO 2439 |

This combination of formulation mastery, precision tooling, and OEM agility positions Suzhou Baoshida as a trusted engineering partner in the industrial rubber solutions sector.

Customization Process

Customization Process for Open Cell Polyurethane Foam Solutions

At Suzhou Baoshida Trading Co., Ltd., we execute a rigorous, science-driven customization pathway for open cell polyurethane foam, ensuring precise alignment with demanding industrial application requirements. Our process eliminates guesswork, transforming client specifications into high-performance, manufacturable solutions through four critical, interdependent phases.

Drawing Analysis: Translating Requirements into Engineering Parameters

The foundation of successful customization begins with meticulous interpretation of client technical drawings and performance mandates. Our engineering team conducts a deep-dive analysis, scrutinizing dimensional tolerances, environmental exposure conditions (temperature, humidity, chemical resistance), mechanical load profiles, airflow specifications, and regulatory compliance needs. We identify potential manufacturing conflicts early, such as unrealistic density gradients within complex geometries or conflicting compression set requirements under specific thermal cycles. This phase involves collaborative dialogue with the client to clarify ambiguities and establish unambiguous, measurable success criteria before any chemistry is developed. Understanding the end-use application context is paramount; a filter medium requires vastly different airflow dynamics than a vibration-damping gasket, directly influencing subsequent formulation strategy.

Formulation: Precision Chemistry for Targeted Performance

Leveraging the insights from drawing analysis, our Rubber Formula Engineering team designs the proprietary polyol-isocyanate system. This is not a generic adjustment but a precise recalibration of multiple interdependent variables: polyol molecular weight and functionality, isocyanate index, catalyst types and concentrations (balancing gelation and blowing reactions), surfactant selection for optimal cell structure and openness, and additive packages for flame retardancy, UV stability, or antimicrobial properties. We rigorously model the impact of each component on final foam characteristics like density distribution, compression force deflection (CFD), resilience, and thermal conductivity. Critical attention is paid to the catalyst-to-surfactant ratio, as this directly governs the delicate balance between cell opening (essential for airflow and absorption) and structural integrity. Every formulation is validated through small-batch predictive testing before prototyping.

Prototyping: Validating Performance Under Real Conditions

Physical prototypes are manufactured using near-production tooling and processes to accurately simulate final part behavior. We subject these samples to comprehensive in-house testing per ASTM D3574 and client-specific protocols. Key metrics include density profile mapping, compression set at elevated temperatures, airflow resistance (ASTM D737), tensile/tear strength, and aging performance. Prototypes undergo functional validation within simulated application environments – for instance, testing filtration efficiency under actual flow rates or assessing damping characteristics under dynamic loads. Client feedback on prototype performance is integrated iteratively; minor formulation tweaks or process parameter adjustments are implemented until all specifications are consistently met. This phase mitigates risk before capital commitment to full tooling.

Mass Production: Guaranteeing Consistency and Scalability

Upon prototype approval, we transition seamlessly to high-volume manufacturing within our ISO 9001-certified facility. Strict process control parameters established during prototyping – including raw material lot traceability, temperature/humidity-controlled mixing environments, precise metering ratios, and demold times – are enforced via automated systems and real-time SPC monitoring. Every production batch undergoes stringent first-article and in-process inspection against the agreed quality plan. Our closed-loop feedback system ensures immediate corrective action for any parameter drift, guaranteeing that the 10,000th part exhibits identical performance characteristics to the approved prototype. Dedicated project management ensures on-time delivery while maintaining the highest standards of repeatability demanded by Tier-1 industrial OEMs.

Key Performance Characteristics Achievable Through Customization

| Property | Standard Range (Open Cell PU Foam) | Baoshida Customization Capability | Critical Application Impact |

|---|---|---|---|

| Density (kg/m³) | 15 – 150 | 10 – 200 (Precise Gradient) | Weight, Support, Filtration Efficiency |

| Compression Set (% @ 50% def, 22h, 70°C) | 10 – 30% | < 8% (High Resilience Grades) | Long-Term Sealing, Recovery |

| Airflow Resistance (Pa·s/m) | 50 – 5000 | 20 – 10,000 (Tunable Profile) | Filtration Efficiency, Venting |

| Tensile Strength (kPa) | 50 – 250 | 30 – 400 | Durability, Handling Strength |

| Thermal Conductivity (W/m·K) | 0.030 – 0.040 | 0.025 – 0.050 (Optimized) | Insulation Performance |

Contact Engineering Team

For industrial manufacturers seeking high-performance open cell polyurethane foam solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the development and supply of precision-engineered rubber materials. With a deep specialization in industrial rubber solutions, our team delivers tailored formulations that meet the rigorous demands of automotive, aerospace, HVAC, filtration, and acoustic insulation applications. Open cell polyurethane foam, known for its excellent breathability, sound absorption, and compression resilience, requires exacting control over cell structure, density, and chemical resistance—parameters we optimize through advanced compounding and quality assurance protocols.

Our engineering team works closely with OEMs and Tier suppliers to match material properties with functional requirements, ensuring consistent performance under dynamic thermal, mechanical, and environmental conditions. Whether you require low-density foam for lightweight insulation or high-resilience variants for sealing and gasketing, Suzhou Baoshida provides scalable production capacity with strict adherence to international quality standards, including ISO 9001 and RoHS compliance. All formulations are subject to in-house testing for tensile strength, elongation at break, compression set, airflow resistance, and aging characteristics.

To support seamless integration into your manufacturing process, we offer comprehensive technical documentation, batch traceability, and on-demand formulation adjustments. Our global logistics network ensures timely delivery to North America, Europe, and Southeast Asia, backed by responsive customer service and engineering support.

For immediate technical consultation or material sampling, contact Mr. Boyce, Rubber Formula Engineer and OEM Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce specializes in open cell polyurethane foam development and has over a decade of experience in industrial elastomer applications. He will work directly with your engineering team to assess performance criteria, recommend optimal formulations, and facilitate prototype validation.

Reach out via email at [email protected] to initiate a technical dialogue. Include details such as required density range, thickness, operating temperature, regulatory certifications, and intended application environment to accelerate the evaluation process. We respond to all inquiries within 12 business hours and can provide sample kits within 5–7 working days upon confirmation of specifications.

Below are typical technical specifications for our standard open cell polyurethane foam series. Custom modifications are available upon request.

| Property | Test Method | Typical Value Range |

|---|---|---|

| Density | ISO 845 | 15–60 kg/m³ |

| Tensile Strength | ISO 1798 | 80–250 kPa |

| Elongation at Break | ISO 1798 | 100–300% |

| Compression Set (50%, 22h, 70°C) | ISO 1856 | ≤ 10% |

| Airflow Resistance | ISO 9053 | 1.5–15 kPa·s/m |

| Cell Structure | Microscopic Analysis | Open cell content > 90% |

| Operating Temperature Range | — | -40°C to +120°C |

| Flame Resistance | UL 94 | HB rated (customizable to V-0) |

Partner with Suzhou Baoshida for technically superior open cell polyurethane foam solutions engineered for reliability and performance. Contact Mr. Boyce today at [email protected] to schedule a technical review.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).