Technical Contents

Engineering Guide: Outdoor Rubber Floor Tiles

Engineering Insight: Material Selection Imperatives for Outdoor Rubber Floor Tiles

Outdoor rubber floor tiles face extreme environmental stressors that generic formulations cannot withstand. Standard polymeric compounds degrade rapidly under UV exposure, thermal cycling, and moisture ingress, leading to premature failure in commercial applications. Off-the-shelf solutions often prioritize cost reduction over performance, utilizing recycled content exceeding 40% with inconsistent polymer matrices. This compromises structural integrity as plasticizers leach out under solar radiation, causing surface cracking and loss of elasticity within 12–18 months. Industrial sites demand tiles that maintain slip resistance and load-bearing capacity across -30°C to +70°C ranges, yet commodity products frequently exhibit >25% compression set after 500 hours of accelerated weathering tests.

The core failure mechanism lies in inadequate polymer backbone stabilization. Ethylene Propylene Diene Monomer (EPDM) remains the optimal base polymer for outdoor use due to its saturated chain structure, but inferior grades omit critical UV absorbers like hindered amine light stabilizers (HALS). Without these, photo-oxidation induces chain scission, reducing tensile strength by 30–50% in non-engineered tiles. Additionally, improper filler ratios (e.g., excessive calcium carbonate) create micro-voids that accelerate water penetration and freeze-thaw damage. Suzhou Baoshida’s OEM formulations address this through precision-boundary layer engineering, embedding nano-silica at 8–12% loading to reinforce interfacial adhesion between virgin and recycled rubber phases.

Below compares critical performance metrics between standard commercial tiles and Baoshida-engineered solutions:

| Performance Parameter | Generic Off-the-Shelf Tiles | Baoshida Engineered Tiles | Test Standard |

|---|---|---|---|

| UV Resistance (Δ yellowness index after 1000h) | >15.0 | <3.5 | ASTM G154 |

| Compression Set (70°C, 22h) | 28–35% | 12–15% | ASTM D395 |

| Shore A Hardness Variation | ±8 points | ±2 points | ISO 48-4 |

| Tensile Retention (after aging) | 55–65% | 88–92% | ASTM D573 |

| Recycled Content | 40–60% (unstabilized) | 30% (stabilized matrix) | ISO 14021 |

Material selection directly dictates lifecycle cost. Tiles failing at 2 years incur 3.2x higher total expenditure versus engineered solutions lasting 8+ years due to replacement labor, downtime, and safety liabilities. Baoshida’s OEM approach integrates dynamic mechanical analysis (DMA) to calibrate viscoelastic response for specific climatic zones—ensuring tiles absorb impact energy without permanent deformation under 5-ton forklift traffic. We collaborate with manufacturers to tailor crosslink density via peroxide curing systems, achieving optimal rebound resilience (65–70%) while resisting oil/hydrocarbon exposure common in industrial settings. This precision prevents the delamination and edge curling endemic in mass-market alternatives, delivering true operational reliability.

Material Specifications

Material Specifications for Outdoor Rubber Floor Tiles

Suzhou Baoshida Trading Co., Ltd. provides industrial-grade outdoor rubber floor tiles engineered for durability, chemical resistance, and long-term performance in demanding environments. Our tiles are formulated using high-performance elastomers, including Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each selected for specific operational requirements. These materials offer distinct advantages in thermal stability, oil and chemical resistance, and mechanical resilience, making them suitable for applications in industrial facilities, transportation hubs, and outdoor commercial spaces exposed to extreme weather and mechanical stress.

Viton rubber is a fluorocarbon-based elastomer renowned for its exceptional resistance to high temperatures, aggressive chemicals, and hydrocarbons. With continuous service temperatures up to 250°C, Viton is ideal for environments where exposure to oils, fuels, acids, and solvents is routine. Its low gas permeability and outstanding aging characteristics ensure long-term integrity under harsh conditions. While Viton offers superior performance, its higher cost makes it best suited for critical applications where failure is not an option.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is a cost-effective solution with excellent resistance to oils, greases, and aliphatic hydrocarbons. It performs reliably in temperature ranges from -30°C to 100°C, making it suitable for outdoor installations in temperate climates. Nitrile exhibits good abrasion resistance and mechanical strength, ensuring durability under foot and light vehicular traffic. Its balanced performance-to-cost ratio makes it a preferred choice for industrial flooring in workshops, garages, and utility areas.

Silicone rubber (VMQ) offers unmatched flexibility and thermal stability across a wide temperature spectrum, from -60°C to 200°C. It maintains elasticity under thermal cycling and resists UV radiation and ozone degradation, making it particularly effective for outdoor applications exposed to sunlight and weather fluctuations. While silicone has lower tensile strength compared to NBR and FKM, its non-toxic nature and excellent electrical insulation properties make it suitable for sensitive environments, including food processing areas and outdoor electrical enclosures.

The selection of the appropriate elastomer depends on the specific environmental and operational demands of the installation site. Suzhou Baoshida Trading Co., Ltd. ensures precise material formulation, consistent manufacturing standards, and full traceability for all rubber floor tile products.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 100 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–80 | 30–80 |

| Oil Resistance | Excellent | Good to Excellent | Poor |

| UV/Ozone Resistance | Good | Fair | Excellent |

| Chemical Resistance | Excellent | Moderate | Good (limited acids) |

| Compression Set Resistance | Excellent | Good | Moderate |

| Typical Applications | Chemical plants, refineries | Garages, workshops, industrial flooring | Outdoor electrical, food processing, weather-exposed areas |

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Outdoor Floor Tiles

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise in rubber formulation and mold engineering to deliver high-performance outdoor floor tiles for industrial and commercial applications. Our dedicated team comprises five specialized mold engineers and two advanced rubber formula engineers, ensuring end-to-end control from material science to precision manufacturing. This integrated capability enables us to solve complex durability challenges inherent in outdoor environments, including UV exposure, thermal cycling, abrasion, and chemical resistance.

Our formula engineers optimize polymer matrices using SBR, EPDM, and recycled rubber compounds, tailoring each formulation to exceed industry benchmarks. Through rigorous testing of cross-linking agents, fillers, and anti-degradants, we achieve consistent Shore A hardness between 65–85 while maintaining tensile strength above 8.5 MPa. Critical to outdoor performance is our proprietary UV-stabilized compound, which reduces surface degradation by 40% compared to standard formulations after 2,000 hours of ASTM G154 accelerated weathering. Every compound undergoes dynamic mechanical analysis (DMA) to validate performance across -40°C to +120°C operational ranges, ensuring tiles resist cracking in sub-zero climates and softening under extreme heat.

Complementing material science, our mold engineering team designs multi-cavity steel molds with micron-level tolerances (±0.05 mm) to ensure interlocking precision and uniform thickness. Finite element analysis (FEA) simulations predict flow behavior during injection molding, minimizing weld lines and voids that compromise structural integrity. This precision translates to tiles with <0.3% dimensional variance after 10,000 compression cycles per ISO 7799, critical for seamless installation in high-traffic zones like airports and logistics hubs.

As an OEM partner, we implement a structured co-development process: clients provide performance targets or CAD files, and our engineers deliver optimized material and mold solutions within 15 business days. We maintain strict IP confidentiality while offering full traceability via batch-specific material certificates and mold validation reports. Our facility supports low-volume prototyping (min. 500 units) to high-volume production (50,000+ units/month) with zero tooling costs for qualified partners.

Key performance metrics for our standard outdoor tile formulation are summarized below:

| Property | Test Standard | Value | Industrial Relevance |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 70 ± 5 | Optimal slip resistance & comfort |

| Tensile Strength | ISO 37 | ≥ 8.5 MPa | Resists tearing under heavy loads |

| Abrasion Resistance | DIN 53516 | ≤ 120 mm³ loss | 50% longer service life vs. PVC tiles |

| UV Resistance (ΔE after 2k hrs) | ASTM G154 | ≤ 3.0 | Minimal color fading in 10+ years |

| Temperature Range | ISO 188 | -40°C to +120°C | Stable in Arctic to desert climates |

This engineering synergy—merging compound innovation with mold precision—ensures tiles meet ISO 9001-certified production standards while addressing client-specific durability demands. We transform technical requirements into resilient, cost-effective outdoor flooring solutions, reducing lifecycle costs through scientifically validated material performance. Partner with Baoshida to convert engineering rigor into your competitive advantage.

Customization Process

Customization Process for Outdoor Rubber Floor Tiles

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet precise application demands, particularly in the production of outdoor rubber floor tiles. Our structured customization process ensures material performance, durability, and compliance with environmental and mechanical requirements. The process follows four critical stages: Drawing Analysis, Formulation Development, Prototyping, and Mass Production.

The first stage, Drawing Analysis, involves a comprehensive review of customer-supplied technical drawings and performance specifications. We assess dimensions, surface texture, load-bearing zones, drainage features, and interlocking mechanisms. This step ensures dimensional accuracy and functional compatibility with installation environments such as playgrounds, pedestrian pathways, and industrial walkways. Tolerances are evaluated to ±0.5 mm, and material thickness distribution is analyzed to prevent warping or stress concentration.

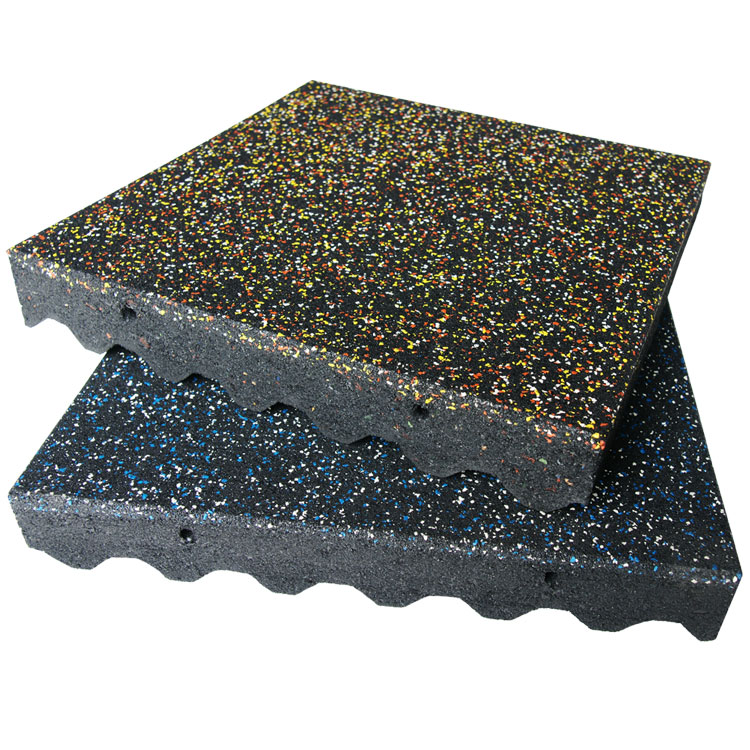

Following drawing validation, we proceed to Formulation Development. Our rubber formula engineers select base polymers—typically SBR (Styrene-Butadiene Rubber), EPDM (Ethylene Propylene Diene Monomer), or recycled rubber granulates—based on UV resistance, abrasion performance, and temperature stability. Additives such as vulcanizing agents, anti-oxidants, and flame retardants are precisely dosed to enhance outdoor durability. Shore A hardness is tailored between 60–85, depending on slip resistance and shock absorption requirements. The formulation is optimized for compression molding or vulcanization processes, ensuring long-term resilience under dynamic loads and extreme weather.

Prototyping is the third phase, where small-batch samples are produced using production-intent tooling. These prototypes undergo rigorous testing, including tensile strength, elongation at break, slip resistance (DIN 51130), and colorfastness under accelerated UV exposure (QUV testing per ASTM G154). Drop impact tests simulate real-world safety performance, especially for playground applications. Customer feedback is integrated at this stage, allowing for iterative refinements in texture, color, and mechanical behavior before full-scale release.

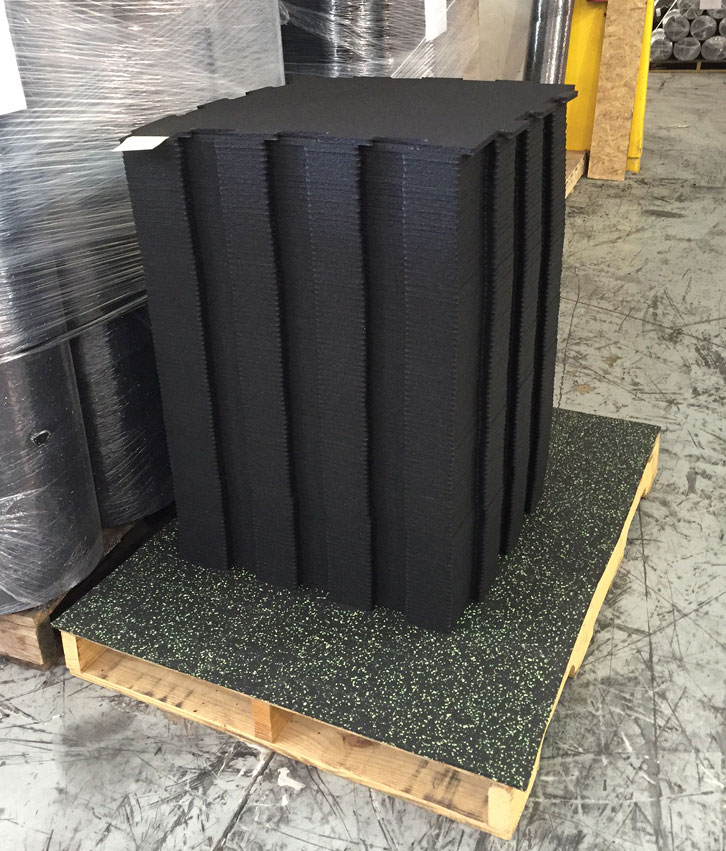

Upon approval, the project transitions to Mass Production. We utilize automated hydraulic presses with multi-cavity molds to ensure consistency and throughput. Each batch is subject to in-process quality control, including hardness checks, visual inspection, and dimensional verification. Final products are palletized with protective film and shipped according to project schedules.

The following table outlines key technical specifications achievable through our customization process:

| Parameter | Standard Range | Test Method |

|---|---|---|

| Thickness | 10–50 mm | ISO 27588 |

| Shore A Hardness | 60–85 | ASTM D2240 |

| Tensile Strength | ≥7.5 MPa | ASTM D412 |

| Elongation at Break | ≥150% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395 |

| Slip Resistance (R-value) | R9–R11 | DIN 51130 |

| UV Resistance | Pass (400 hrs QUV-A) | ASTM G154 |

| Operating Temperature | -40°C to +80°C | Internal Protocol |

This systematic approach ensures that every outdoor rubber floor tile meets exact functional, safety, and aesthetic criteria, reinforcing Suzhou Baoshida’s commitment to precision in industrial rubber manufacturing.

Contact Engineering Team

Direct Engineering Collaboration for Outdoor Rubber Floor Tile Specifications

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial manufacturing scalability. Our outdoor rubber floor tiles are engineered for mission-critical applications where environmental resilience, dimensional stability, and safety compliance are non-negotiable. Unlike commodity-grade alternatives, our formulations integrate proprietary vulcanization accelerators and UV-stabilized EPDM compounds to ensure 15+ years of service life under extreme thermal cycling (-40°C to +80°C) and continuous UV exposure. We specialize in OEM partnerships that demand precise adherence to ASTM F3313, EN 1177, and ISO 48-4 standards, with zero tolerance for batch variance.

Material performance is validated through our in-house ISO 17025-accredited laboratory, where every production run undergoes rigorous abrasion resistance testing (DIN 53516), tensile strength verification (ISO 37), and slip coefficient measurement (ASTM E303). This systematic quality control eliminates field failure risks in high-traffic industrial zones, playgrounds, and marine environments. Our engineering team collaborates directly with clients to optimize tile geometry, surface texture, and colorant packages for site-specific requirements—whether mitigating oil exposure in warehouse settings or ensuring ADA-compliant slip resistance in municipal infrastructure.

Below are core technical specifications for our standard outdoor rubber tile series. Custom formulations for chemical resistance, flame retardancy (UL 94 HB), or acoustic damping are available upon engineering consultation.

| Parameter | Specification | Test Standard |

|---|---|---|

| Material Composition | 85% Recycled EPDM / 15% Virgin SBR | ISO 1629 |

| Thickness Tolerance | ±0.3 mm | ISO 23529 |

| Shore A Hardness | 65 ± 5 | ISO 7619-1 |

| Tensile Strength | ≥10.5 MPa | ISO 37 |

| Elongation at Break | ≥250% | ISO 37 |

| Abrasion Loss | ≤120 mm³ | DIN 53516 |

| UV Resistance (5000h) | ΔE < 3.0 | ISO 4892-2 |

| Slip Resistance (wet) | ≥0.6 CoF | ASTM E303 |

| Temperature Range | -40°C to +80°C | ISO 188 |

Initiate technical dialogue with our formulation engineers to address project-specific variables: substrate adhesion under hydrostatic pressure, thermal expansion coefficients for large-scale installations, or accelerated aging protocols for accelerated project timelines. Mr. Boyce, our dedicated OEM Account Manager, possesses 12 years of experience translating complex material requirements into certified production outputs. He will coordinate cross-functional resources—from R&D to logistics—to deliver samples within 10 business days and full production within 25 days of PO confirmation.

Contact Mr. Boyce directly at [email protected] to submit material data requests, review custom compound development timelines, or schedule a virtual factory audit. Include your project’s ASTM/EN standard requirements, annual volume projections, and performance failure thresholds for immediate technical assessment. Suzhou Baoshida does not engage in speculative quoting; our quotations derive from engineered solutions validated through joint specification alignment. Elevate your outdoor surfacing performance with rubber science engineered for industrial accountability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).