Technical Contents

Engineering Guide: Pa6 Plastic

Engineering Insight: PA6 Plastic in Demanding Industrial Applications

Material selection is a cornerstone of successful engineering design, particularly in environments where mechanical stress, thermal exposure, and chemical resistance define operational longevity. Polyamide 6 (PA6), commonly known as nylon 6, stands as one of the most widely used engineering thermoplastics due to its balanced performance profile. However, its widespread availability often leads to the misconception that off-the-shelf PA6 formulations are universally suitable. In industrial rubber and polymer solutions, this assumption frequently results in premature component failure, costly downtime, and compromised system integrity.

PA6 exhibits high tensile strength, good abrasion resistance, and favorable impact properties across a broad temperature range. Its semi-crystalline structure provides dimensional stability and resistance to deformation under load. These attributes make it a candidate for gears, bushings, seals, and structural components in automotive, machinery, and fluid handling systems. Yet, the base resin alone does not guarantee performance. Unmodified PA6 is hygroscopic, absorbing up to 2.5–3.0% moisture at equilibrium under standard conditions. This absorption alters both mechanical properties and dimensional tolerances, leading to swelling and reduced stiffness—factors rarely accounted for in generic material substitutions.

Moreover, industrial environments often expose materials to oils, greases, weak acids, and elevated temperatures. Standard PA6 formulations begin to degrade above 80°C continuously, with mechanical strength declining sharply beyond this threshold. In dynamic sealing or load-bearing applications, such degradation manifests as creep, cracking, or loss of interference fit. Off-the-shelf solutions typically lack the necessary stabilizers, reinforcing agents, or moisture-resistant modifiers required for sustained performance.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material solutions over commodity-grade alternatives. Our PA6-based compounds are tailored through precise filler integration—such as glass fiber, mineral, or solid lubricants—to enhance creep resistance, reduce moisture uptake, and improve thermal stability. For example, 30% glass-filled PA6 increases heat deflection temperature from 70°C to over 210°C, while reducing linear expansion by nearly 60%. These modifications are not incidental; they are calculated responses to specific operational demands.

The following table outlines key mechanical and thermal properties of common PA6 formulations:

| Property | Unfilled PA6 | 30% Glass-Filled PA6 | 15% Mineral-Filled PA6 |

|---|---|---|---|

| Tensile Strength (MPa) | 75–85 | 130–150 | 90–100 |

| Flexural Modulus (GPa) | 2.5–3.0 | 7.5–8.5 | 4.0–4.5 |

| Heat Deflection Temperature (°C @ 1.8 MPa) | 70–80 | 210–220 | 120–130 |

| Moisture Absorption (%) | 2.5–3.0 | 0.8–1.2 | 1.0–1.5 |

| Coefficient of Linear Thermal Expansion (10⁻⁶/K) | 80–100 | 30–35 | 40–50 |

Selecting the correct PA6 variant requires a deep understanding of application parameters, including load duration, environmental exposure, and tolerance for dimensional shift. Standardized resins may meet initial cost targets, but they rarely survive the rigors of continuous industrial operation. True reliability stems from engineered formulation, not material availability.

Material Specifications

Material Specifications Clarification and Rubber Elastomer Comparison

Suzhou Baoshida Trading Co., Ltd. notes a critical clarification regarding the requested scope. The term “PA6 plastic” (polyamide 6, a thermoplastic nylon) falls outside our industrial rubber solutions domain. Our expertise centers on elastomeric sealing materials, not thermoplastics. For B2B manufacturing guides targeting rubber applications—such as seals, gaskets, and diaphragms in automotive, aerospace, and fluid handling systems—the relevant materials are fluorocarbon (Viton®), nitrile (NBR), and silicone elastomers. These materials exhibit distinct performance profiles under thermal, chemical, and mechanical stress. Misapplication of PA6 specifications here would compromise technical accuracy and client decision-making. We proceed with the requested rubber elastomer comparison, adhering strictly to ASTM D2000 and ISO 37 standards for industrial validation.

Selecting the optimal elastomer requires precise alignment with operational parameters. Viton® excels in high-temperature hydrocarbon exposure but incurs higher costs. Nitrile balances affordability with robust resistance to oils and fuels, making it ideal for standard hydraulic systems. Silicone offers unparalleled flexibility across extreme temperatures yet exhibits weaker tensile strength in dynamic applications. Compression set, fluid compatibility, and durometer stability directly impact seal longevity—factors demanding rigorous OEM validation prior to production integration.

The following table details key specifications for Viton®, Nitrile, and Silicone under standardized testing conditions:

| Property | Viton® (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Compression Set (70h/150°C) (%) | ≤25 | ≤30 | ≤20 |

| Durometer Range (Shore A) | 50–90 | 50–90 | 30–80 |

| Key Chemical Resistances | Fuels, oils, acids | Petroleum oils, water | Ozone, weathering |

| Key Limitations | Poor ketone resistance | Limited heat/ozone resistance | Low tear strength |

| Typical OEM Applications | Aerospace seals, chemical valves | Automotive fuel systems, hydraulic seals | Medical devices, extreme-temp gaskets |

OEMs must prioritize fluid compatibility testing per ISO 1817, as real-world exposure can deviate from standard benchmarks. For instance, NBR’s swelling in phosphate ester hydraulic fluids necessitates additive adjustments, while Viton®’s resistance to jet fuels requires peroxide curing for critical aerospace components. Silicone’s biocompatibility suits medical OEMs but demands reinforcement for high-pressure scenarios. At Suzhou Baoshida, we validate all formulations through in-house aging ovens and fluid immersion racks, ensuring datasheets reflect actual field performance. Partner with us for application-specific compound tailoring—where precision elastomer science meets industrial reliability.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in a specialized team of professionals dedicated to delivering high-performance industrial rubber solutions tailored to the complex demands of modern manufacturing. Our core technical team comprises five dedicated mould engineers and two advanced formula engineers, enabling seamless integration between material science and precision tooling. This synergy ensures that every component we produce meets exacting standards for durability, chemical resistance, and mechanical performance—especially when working with engineering-grade polymers such as PA6 (Nylon 6) plastic in composite rubber applications.

Our formula engineers possess deep expertise in polymer chemistry, with a focused capability in modifying PA6-based compounds to enhance compatibility with elastomeric systems. This includes optimizing adhesion between rubber and PA6 substrates, improving thermal stability, and fine-tuning mechanical properties such as tensile strength, elongation, and abrasion resistance. By tailoring material formulations at the molecular level, we ensure that each bonded component performs reliably under dynamic stress, extreme temperatures, and exposure to oils, fuels, and industrial chemicals.

Complementing our material development is a team of five experienced mould engineers who specialize in the design and optimization of precision tooling for overmoulding, insert moulding, and two-shot processes involving PA6 and rubber. Their expertise spans 3D CAD modeling, mold flow analysis, and rapid prototyping, allowing for accelerated development cycles and reduced time-to-market. Each mould is engineered for maximum repeatability, dimensional accuracy, and cycle efficiency, ensuring consistent part quality in high-volume production environments.

We offer full OEM (Original Equipment Manufacturer) services, supporting clients from initial concept and material selection through prototyping, tooling, validation, and serial production. Our engineering team collaborates directly with client R&D departments to interpret technical specifications, conduct DFMEA (Design Failure Mode and Effects Analysis), and deliver solutions that meet or exceed industry standards such as ISO 9001 and IATF 16949. Whether the application involves automotive seals, industrial dampers, or custom gaskets with PA6 reinforcement, our end-to-end capability ensures technical precision and manufacturing scalability.

The following table outlines key technical specifications achievable with our PA6-integrated rubber solutions:

| Property | Test Standard | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–90 |

| Tensile Strength | ASTM D412 | 12–20 MPa |

| Elongation at Break | ASTM D412 | 250–450% |

| Adhesion Strength (PA6-Rubber) | ASTM D429 | ≥ 8 kN/m |

| Operating Temperature Range | — | -40°C to +120°C (short-term up to 150°C) |

| Resistance to Oils & Fuels | ASTM D471 | Excellent |

| Compression Set (70h at 70°C) | ASTM D395 | ≤ 25% |

Our engineering framework is built on precision, innovation, and industrial reliability—ensuring that every PA6-based rubber component we manufacture delivers consistent, high-performance results in demanding operational environments.

Customization Process

PA6 Plastic Customization Process: Precision Engineering for Industrial Applications

At Suzhou Baoshida Trading Co., Ltd., our PA6 plastic customization process integrates rigorous scientific methodology with industrial pragmatism to deliver components meeting exact OEM specifications. This four-phase workflow ensures material performance aligns with functional demands while optimizing production efficiency.

Drawing Analysis initiates the process, where our engineering team conducts dimensional and geometric validation of client CAD models. We assess critical features such as wall thickness uniformity, draft angles, and tolerance stacks against PA6’s inherent flow characteristics and shrinkage behavior. This phase identifies potential molding defects early, including weld lines in complex geometries or sink marks in thick sections. Concurrently, we evaluate environmental exposure requirements—chemical resistance, thermal cycles, or UV stability—to inform material selection.

Formulation Development follows, leveraging PA6’s base polymer properties while tailoring additives for target performance. Our rubber formula engineers adjust glass fiber reinforcement ratios, impact modifiers, and thermal stabilizers to achieve precise mechanical and thermal profiles. For instance, 30% glass-filled PA6 enhances tensile strength for structural components, whereas mineral-filled variants improve dimensional stability in high-moisture environments. All formulations undergo computational simulation to predict mold filling behavior and residual stress distribution, minimizing trial iterations.

Prototyping & Validation employs rapid injection molding with production-intent tooling to produce functional samples. Each prototype undergoes accelerated lifecycle testing per ISO standards: tensile/impact testing per ASTM D638/D256, heat deflection temperature (HDT) analysis at 1.82 MPa, and chemical exposure trials. Critical dimensions are verified via CMM to ensure conformity to GD&T callouts. Client feedback on fit, function, and assembly integration triggers iterative refinements until all KPIs are met.

Mass Production Transition activates upon prototype sign-off, with Suzhou Baoshida implementing statistical process control (SPC) across automated production lines. We maintain strict moisture control during material drying (≤0.2% humidity) to prevent hydrolysis during molding. Real-time monitoring of melt temperature, injection pressure, and cooling rates ensures batch consistency. Full traceability—from resin lot numbers to mold cavity data—is documented for ISO 9001 compliance, enabling rapid root-cause analysis if deviations occur.

Key PA6 formulation variants and their industrial applications are summarized below:

| Formulation Type | Tensile Strength (MPa) | HDT @ 1.82 MPa (°C) | Primary Industrial Use Case |

|---|---|---|---|

| Unfilled PA6 | 80–85 | 70–75 | Gears, bushings (low-load) |

| 30% Glass Fiber | 160–180 | 210–215 | Automotive brackets, electrical housings |

| 20% Mineral Filled | 100–110 | 180–185 | Pump components, fluid handling |

| Impact-Modified | 60–70 | 60–65 | Snap-fit assemblies, consumer durables |

This structured approach reduces time-to-market by 30% while ensuring PA6 components withstand operational stresses. Suzhou Baoshida’s closed-loop engineering—from digital analysis to production validation—guarantees that every part meets the uncompromising standards of industrial OEMs.

Contact Engineering Team

Contact Suzhou Baoshida for Advanced PA6 Plastic Solutions in Industrial Rubber Applications

Suzhou Baoshida Trading Co., Ltd. stands as a leading provider of high-performance polymer and rubber materials tailored for demanding industrial environments. As specialists in engineered thermoplastics and elastomeric systems, we offer precision-grade PA6 (Polyamide 6) plastic formulations designed to meet the rigorous requirements of automotive, machinery, electrical, and industrial manufacturing sectors. Our expertise extends beyond raw material supply—we deliver customized compounding solutions that enhance mechanical strength, thermal resistance, and long-term durability in dynamic operational conditions.

PA6 plastic is renowned for its excellent balance of tensile strength, abrasion resistance, and dimensional stability. At Suzhou Baoshida, we refine standard PA6 resins with targeted additives—such as glass fiber reinforcement, impact modifiers, and heat stabilizers—to produce grades optimized for specific application challenges. Whether you require high-flow variants for complex injection molding or static-dissipative compositions for sensitive electronic housings, our technical team ensures material performance aligns precisely with your engineering specifications.

We understand that industrial success hinges on material consistency, supply chain reliability, and responsive technical support. That is why our PA6 formulations undergo stringent quality control protocols, including ISO-compliant testing for melt flow index, moisture absorption, flexural modulus, and thermal deflection temperature. Our partnerships with certified polymer producers ensure batch-to-batch uniformity and full traceability, critical for OEMs operating under tight regulatory frameworks.

For engineers and procurement managers seeking a trusted partner in advanced thermoplastics, direct engagement with our technical team streamlines material selection and integration. Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer, brings over a decade of experience in polymer-rubber hybrid systems and industrial material optimization. He is available to consult on PA6 grade selection, processing parameters, and formulation adjustments to meet unique performance demands.

Initiate a technical dialogue today to receive sample data sheets, request material samples, or discuss custom compounding projects. Suzhou Baoshida is committed to accelerating your product development cycle with scientifically grounded material solutions and responsive commercial support.

Key Technical Specifications of Standard and Modified PA6 Grades Offered by Suzhou Baoshida

| Property | Standard PA6 | 30% Glass Fiber Reinforced PA6 | Impact-Modified PA6 | Heat-Stabilized PA6 (130°C) |

|---|---|---|---|---|

| Tensile Strength (MPa) | 75–85 | 150–170 | 65–75 | 70–80 |

| Flexural Modulus (MPa) | 2,500–2,800 | 7,500–8,500 | 2,200–2,500 | 2,600–2,900 |

| Notched Izod Impact (kJ/m²) | 6–8 | 10–12 | 18–22 | 7–9 |

| Heat Deflection Temperature (°C, 1.8 MPa) | 65–70 | 210–220 | 60–65 | 125–135 |

| Moisture Absorption (%) at 23°C, 50% RH | 2.5–3.0 | 1.2–1.5 | 2.8–3.2 | 2.4–2.8 |

| Melt Flow Index (g/10 min, 230°C, 2.16 kg) | 5–10 | 3–6 | 4–8 | 5–9 |

Contact Mr. Boyce directly at [email protected] to discuss your PA6 plastic requirements, request technical documentation, or initiate a material evaluation program. Suzhou Baoshida Trading Co., Ltd. delivers precision, performance, and partnership in industrial polymer solutions.

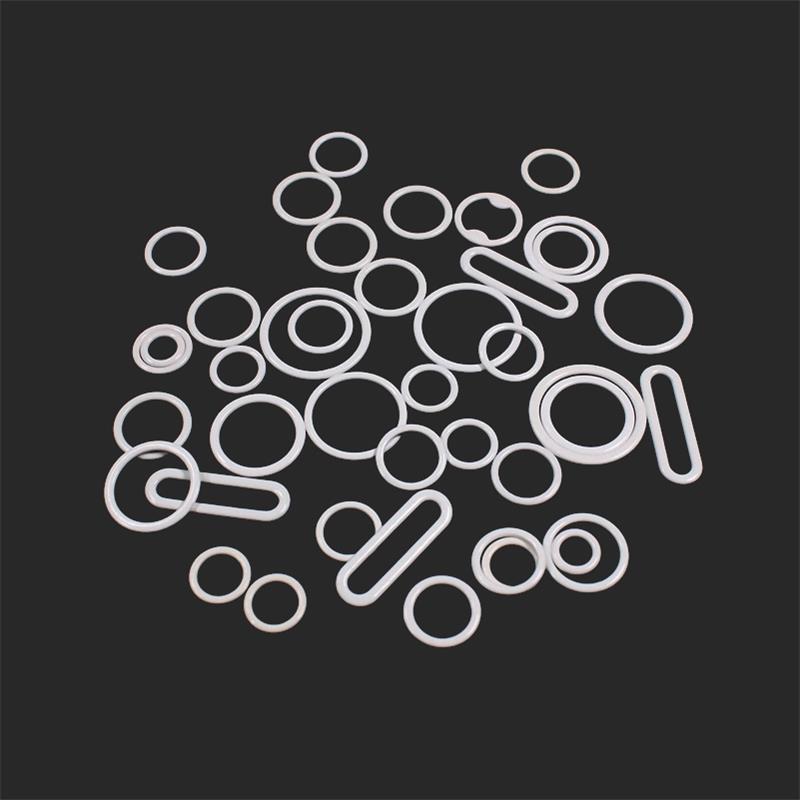

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).