Technical Contents

Engineering Guide: Pineapple Doormat

Engineering Insight: Material Selection in Pineapple Doormat Manufacturing

In industrial rubber applications, even seemingly simple products such as the pineapple doormat demand rigorous engineering consideration. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is not a secondary design factor—it is the foundation of performance, durability, and lifecycle cost. Off-the-shelf rubber doormats frequently fail in commercial or high-traffic environments due to inappropriate elastomer choices, inadequate hardness profiles, and poor resistance to environmental stressors. These failures manifest as cracking, premature wear, loss of tread definition, and reduced slip resistance—issues that compromise safety and increase replacement frequency.

The distinctive pineapple texture, characterized by deep, pyramid-like protrusions, places unique mechanical demands on the base compound. This geometry concentrates stress at the peaks during compression and foot traffic, requiring a rubber formulation with high tensile strength and excellent fatigue resistance. Standard SBR (Styrene-Butadiene Rubber) blends, commonly used in low-cost mats, lack the resilience needed for sustained deformation recovery. Over time, these materials undergo permanent set, leading to flattened treads and diminished dirt-scraping efficiency.

We advocate for the use of compounded EPDM (Ethylene Propylene Diene Monomer) or high-abrasion NR (Natural Rubber) formulations tailored to the service environment. EPDM offers superior ozone and UV resistance, making it ideal for outdoor installations where exposure to sunlight and atmospheric pollutants accelerates degradation. NR, when properly vulcanized with reinforcing fillers such as N330 carbon black, delivers exceptional tear strength and dynamic mechanical properties, critical for maintaining structural integrity under repeated loading.

Additive integration further defines performance. Anti-static agents, mold inhibitors, and UV stabilizers must be homogenously dispersed during mixing to ensure long-term functionality. Poor dispersion—common in mass-produced mats—leads to localized weak points and inconsistent aging behavior.

Below is a comparative specification table highlighting key material properties relevant to engineered pineapple doormats:

| Property | Standard SBR Blend | Engineered EPDM | High-Abrasion NR |

|---|---|---|---|

| Hardness (Shore A) | 55–65 | 60–70 | 65–75 |

| Tensile Strength (MPa) | 8–10 | 14–18 | 20–25 |

| Elongation at Break (%) | 250–300 | 350–450 | 400–500 |

| Abrasion Loss (mm³) | 120–150 | 80–100 | 60–80 |

| Ozone Resistance | Poor | Excellent | Good |

| Operating Temperature Range (°C) | -10 to +70 | -40 to +120 | -20 to +80 |

The data underscores why generic solutions underperform. An engineered rubber compound ensures the pineapple profile retains its functional geometry over years of service, even in demanding environments such as factory entrances, transportation hubs, or coastal facilities.

At Baoshida, we apply OEM-level formulation science to every mat, ensuring material properties align precisely with operational requirements. This precision engineering approach eliminates the hidden costs of frequent replacement and enhances safety through consistent performance.

Material Specifications

Material Specifications for Industrial Pineapple Pattern Doormats

Suzhou Baoshida Trading Co., Ltd. engineers industrial rubber doormats with a pineapple surface texture for optimal debris retention and slip resistance. This textured profile—achieved via precision steel mold engraving—requires elastomers balancing abrasion resistance, environmental stability, and molding fidelity. Contrary to consumer misconceptions, these mats utilize synthetic rubber compounds, not natural pineapple fibers, to withstand commercial foot traffic, chemical exposure, and extreme temperatures. Material selection directly impacts service life in demanding settings like factories, airports, and chemical handling facilities.

Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent our core formulations for pineapple-pattern mats, each engineered for distinct operational hazards. Viton excels in aerospace and chemical plants due to unparalleled resistance to fuels, acids, and ozone. Nitrile provides cost-effective durability against oils and greases in automotive workshops. Silicone delivers flexibility in cryogenic or high-heat food processing environments but requires reinforcement for heavy abrasion zones. All compounds undergo rigorous Shore A hardness calibration (60–85) to maintain texture definition while ensuring user comfort. Critical additives include silica for tear strength, carbon black for UV stability, and proprietary plasticizers to prevent hardening below -40°C.

The comparative analysis below details key performance metrics for B2B procurement decisions. Specifications adhere to ASTM D2000 and ISO 37 standards, with tolerances controlled to ±2 Shore A units and ±0.5mm dimensional accuracy.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range | -25°C to +230°C | -40°C to +120°C | -60°C to +200°C |

| Tensile Strength (MPa) | 15–20 | 10–18 | 6–10 |

| Abrasion Resistance | Excellent | Good | Fair |

| Oil/Fuel Resistance | Exceptional | Very Good | Poor |

| Compression Set (22h/150°C) | 15–25% | 20–35% | 30–50% |

| Key Industrial Use Case | Chemical transfer zones | Automotive service bays | Food processing cold storage |

Material viability hinges on application-specific stressors. For example, Viton’s superior chemical inertness justifies its premium cost in pharmaceutical cleanrooms where solvent exposure degrades NBR within months. Conversely, NBR remains the optimal choice for warehouse entrances with hydraulic fluid spills, offering 40% lower material cost without compromising 5-year service life. Silicone formulations require specialized fillers like fumed silica to mitigate inherent abrasion vulnerability in high-traffic zones, making them suitable only for controlled environments with thermal extremes.

Suzhou Baoshida’s OEM capabilities include custom durometer tuning, FDA-compliant pigment integration, and mold-depth adjustments (1.5–3.0mm texture profile) to match client facility requirements. All compounds undergo 72-hour accelerated aging tests per ISO 188 prior to shipment, ensuring dimensional stability and texture retention under operational loads. Partner with our engineering team to select the precise formulation aligning with your environmental stressors and lifecycle cost targets.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber engineering, delivering precision-engineered solutions tailored to the functional and durability demands of commercial and industrial applications. Our Engineering Capability division integrates advanced material science with precision mold design, enabling us to develop high-performance rubber products such as the pineapple doormat—a product that exemplifies both functional design and material resilience. At the core of our technical strength are five dedicated mold engineers and two specialized rubber formula engineers, working in synergy to ensure every product meets exacting OEM standards.

Our mold engineering team employs state-of-the-art CAD/CAM software and CNC machining techniques to design and fabricate molds with micron-level accuracy. This precision ensures consistent replication of the intricate pineapple texture, which is critical for optimal dirt-scraping performance and long-term wear resistance. Each mold is subjected to rigorous simulation and stress testing to validate structural integrity under high-volume production cycles. The team’s expertise spans multi-cavity configurations, rapid tooling iterations, and modular designs that support scalability and fast time-to-market for client-specific projects.

Complementing mold precision is our advanced rubber compounding capability. Our two in-house formula engineers specialize in developing custom EPDM, SBR, and recycled rubber blends optimized for abrasion resistance, UV stability, and compression set performance. For the pineapple doormat, this translates into formulations that maintain flexibility across temperature extremes (-30°C to +80°C), resist degradation from moisture and ozone exposure, and deliver consistent texture definition over extended service life. Each compound is validated through accelerated aging tests, tensile analysis, and Shore A hardness profiling to ensure compliance with international quality benchmarks.

We operate as a full-service OEM partner, offering end-to-end development from concept to mass production. Clients benefit from our integrated workflow where material formulation and mold design are co-developed, minimizing trial iterations and reducing prototyping lead time by up to 40%. Our facility supports low-volume pilot runs and high-volume manufacturing, with annual production capacity exceeding 2 million units for standard doormat configurations.

The following table outlines the technical specifications achievable for our pineapple doormat series under standard OEM configurations:

| Parameter | Specification |

|---|---|

| Material Options | EPDM, SBR, Recycled Rubber Compound |

| Shore A Hardness | 55 ± 5 |

| Tensile Strength | ≥ 8.0 MPa |

| Elongation at Break | ≥ 250% |

| Compression Set (22h, 70°C) | ≤ 20% |

| Operating Temperature | -30°C to +80°C |

| UV Resistance | ASTM G154 Compliant (5000h exposure) |

| Mold Tolerance | ±0.1 mm |

| Production Cycle Time | 90–120 seconds per unit |

Suzhou Baoshida Trading Co., Ltd. combines deep material expertise with precision engineering to deliver rubber solutions that perform under real-world conditions. Our OEM framework is built on collaboration, technical transparency, and scalable manufacturing—ensuring every pineapple doormat exceeds functional expectations while maintaining cost efficiency.

Customization Process

Customization Process for Engineered Rubber Pineapple-Patterned Doormats

Suzhou Baoshida Trading Co., Ltd. executes a stringent four-phase customization protocol for OEM partners requiring industrial-grade rubber pineapple-patterned doormats. This process ensures dimensional accuracy, material resilience, and production scalability while adhering to global performance benchmarks.

Drawing Analysis initiates the workflow. Our engineering team deconstructs client-provided CAD files or technical sketches, verifying critical parameters including nub height tolerance (±0.3mm), overall thickness uniformity (±0.5mm), and edge geometry. We cross-reference ISO 2768-mK standards for general tolerances and identify potential molding challenges such as undercuts or insufficient draft angles. Material flow simulations predict vulcanization behavior, preventing defects like short shots or knit lines in the intricate pineapple texture. Non-conformities trigger immediate collaborative redesign with the client.

Formulation Development follows, leveraging our proprietary rubber compounding expertise. Based on the doormat’s end-use environment (e.g., commercial entryways, marine decks, or chemical exposure zones), we select base polymers—typically SBR for cost efficiency or EPDM for UV/ozone resistance. Critical additives include silica for abrasion resistance, calcium carbonate as a reinforcing filler, and specialized anti-aging agents. The sulfur cure system is precisely calibrated to balance scorch safety (≥10 minutes at 125°C) with optimal crosslink density. Shore A hardness is targeted between 60–70 to ensure debris-scraping efficacy without compromising flexibility.

Prototyping employs aluminum cavity molds for rapid validation. Three physical samples undergo accelerated lifecycle testing: 50,000 cycles on a Taber Abraser (ASTM D4060), 1,000-hour QUV weathering (ASTM G154), and dynamic flex testing at -20°C. Dimensional reports compare molded samples against CAD data using CMM verification. Client feedback on texture depth, color fastness (ISO 105-A02), and surface finish dictates final formulation adjustments before tooling sign-off.

Mass Production commences only after prototype approval. We deploy hydraulic press molding at 160°C ±2°C with automated demolding to preserve nub integrity. In-line quality control includes: real-time durometer checks, visual inspection under 500-lux lighting, and batch traceability via QR-coded material logs. Every 500 units undergo destructive testing per ASTM D412 for tensile strength and elongation.

Key Performance Specifications for Pineapple Doormats

| Parameter | Standard Requirement | Test Method |

|---|---|---|

| Shore A Hardness | 65 ± 5 | ASTM D2240 |

| Tensile Strength | ≥12.0 MPa | ASTM D412 |

| Abrasion Resistance | ≤120 mg loss | ASTM D5963 |

| Compression Set (22h/70°C) | ≤25% | ASTM D395 |

| Color Fastness (Grade) | ≥4 | ISO 105-A02 |

This phased methodology minimizes time-to-market while guaranteeing that every doormat meets the mechanical and aesthetic demands of high-traffic industrial applications. Suzhou Baoshida’s integration of material science with precision manufacturing delivers OEM solutions that exceed ISO 9001 quality thresholds. Rigorous validation protocols at each stage eliminate costly field failures, ensuring client ROI through product longevity and consistent performance.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Industrial Rubber Doormat Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber manufacturing, delivering high-performance, durable, and precision-engineered rubber solutions to global OEMs and commercial clients. As specialists in rubber compounding, extrusion, and custom molding, we apply our technical expertise to develop functional rubber products—including the innovative pineapple-patterned rubber doormat—designed for maximum durability, slip resistance, and long-term performance in high-traffic environments. Whether for industrial facilities, commercial entrances, or public infrastructure, our rubber doormats are formulated to meet exact mechanical, chemical, and environmental requirements.

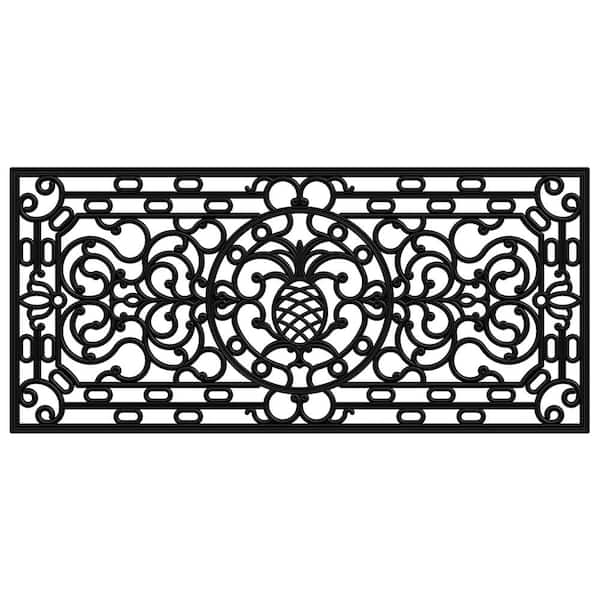

Our pineapple doormat design is not merely aesthetic; it is an engineered solution. The raised diamond-lattice pattern mimics the natural grip and water-channeling properties of pineapple skin, optimizing surface traction and debris clearance. This design enhances cleaning efficiency at entryways by scraping dirt, moisture, and particulates from footwear, reducing indoor contamination and maintenance costs. Manufactured from high-density SBR or EPDM rubber compounds, these mats exhibit superior resistance to abrasion, UV degradation, ozone, and temperature extremes—ensuring consistent performance across diverse climates and operational conditions.

Each doormat is produced under strict quality control protocols, with attention to dimensional accuracy, durometer consistency, and adhesion strength. We offer customization in thickness, color, size, and backing options—including anti-slip latex, fabric, or adhesive layers—to meet specific architectural or safety standards. In addition, our rubber formulations can be tailored to comply with fire retardancy (e.g., UL94), low-emission (VOC), or recyclability requirements, supporting sustainable building initiatives.

For technical collaboration or sourcing inquiries, we invite manufacturers, distributors, and project engineers to contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. With over 15 years of experience in rubber product development and international supply chain management, Mr. Boyce provides expert guidance on material selection, prototype development, and volume production planning. He supports clients through every stage—from initial specification and sample validation to just-in-time logistics and after-sales technical support.

Reach out today to request material data sheets, order samples, or discuss custom tooling for your next project. Partnering with Suzhou Baoshida ensures access to advanced rubber technology, rigorous quality assurance, and responsive engineering support—all backed by competitive pricing and reliable delivery from our Jiangsu-based manufacturing network.

Technical Specifications – Pineapple Pattern Rubber Doormat

| Parameter | Specification |

|---|---|

| Material | SBR, EPDM (custom compounds available) |

| Standard Thickness | 8 mm, 10 mm, 12 mm (custom up to 20 mm) |

| Standard Sizes | 600×900 mm, 900×1500 mm, 1200×1800 mm |

| Durometer (Shore A) | 60–75 ±5 |

| Operating Temperature | -40°C to +100°C (EPDM: up to +135°C) |

| Flame Resistance | Optional UL94 HF-1 or ASTM E662 compliance |

| Backing Options | Latex, fabric, adhesive, or open-back |

| Color Options | Black, gray, red, blue, custom (Pantone match) |

| Lead Time (Bulk Orders) | 25–35 days after sample approval |

Contact Mr. Boyce directly at [email protected] to initiate a technical discussion or request a quotation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).