Technical Contents

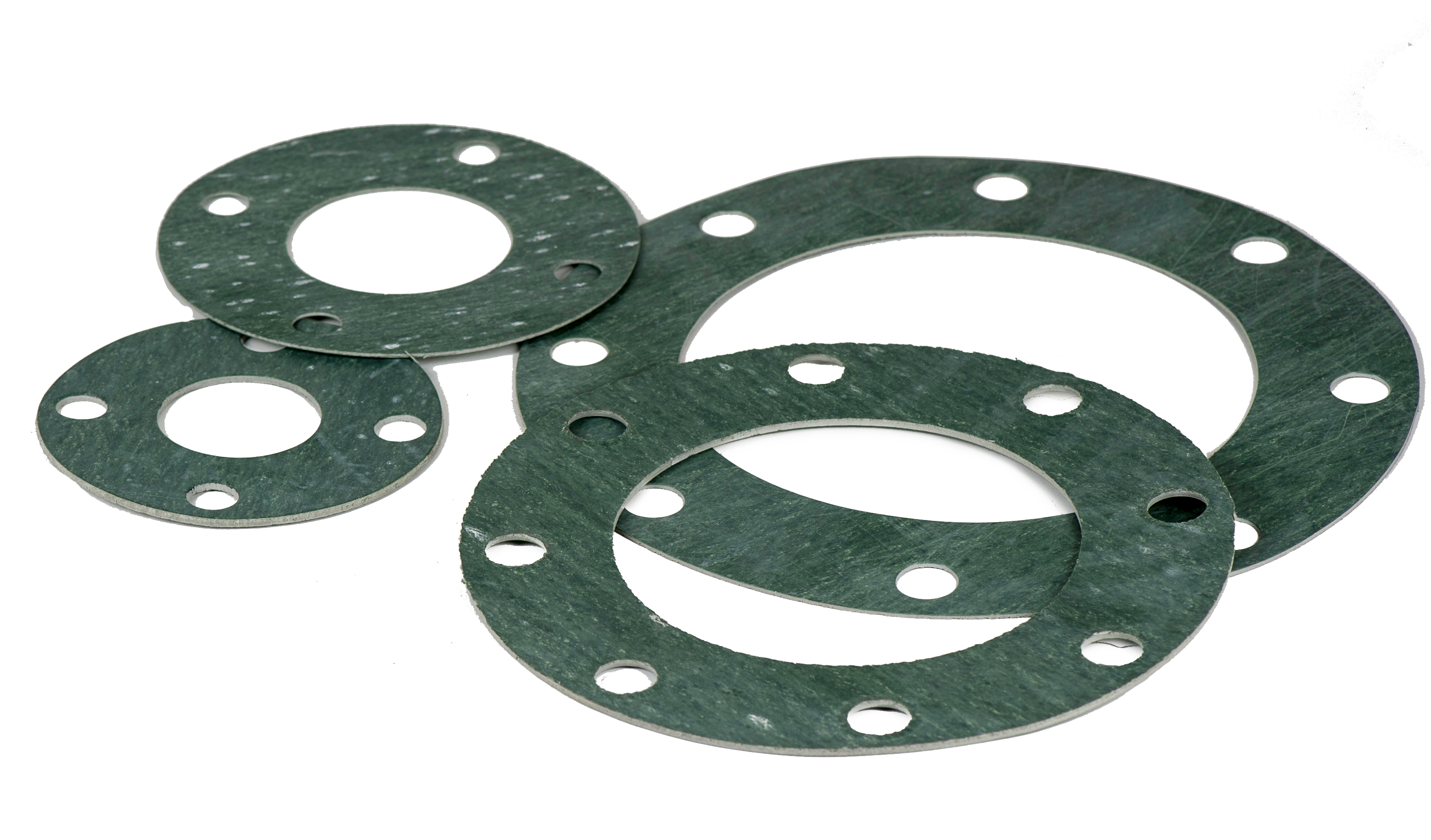

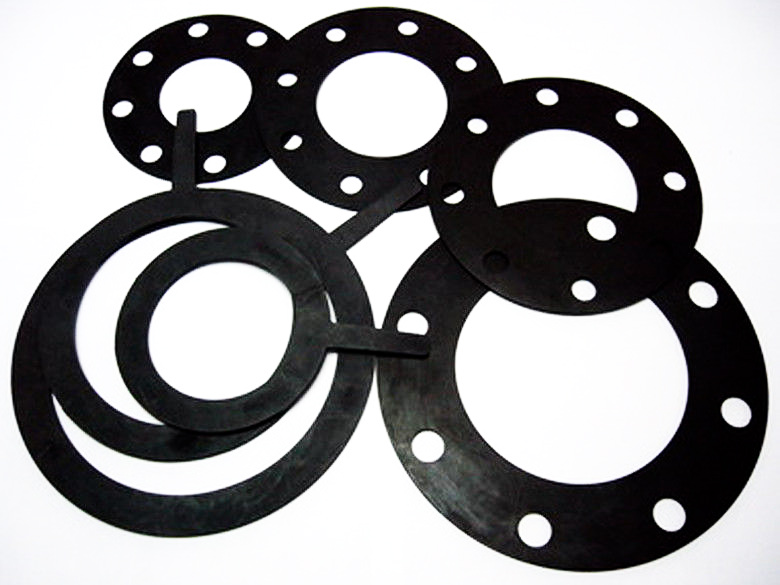

Engineering Guide: Pipe Flange Gasket

Engineering Insight: Material Selection in Pipe Flange Gasket Performance

The integrity of industrial piping systems hinges critically on the performance of pipe flange gaskets, where material selection dictates long-term reliability. Off-the-shelf gaskets frequently fail under demanding operational conditions due to generic compound formulations that ignore the specific chemical, thermal, and mechanical stresses of the application. These failures manifest as leaks, premature extrusion, or catastrophic seal degradation, leading to unplanned downtime, safety hazards, and significant financial losses. The root cause lies in the oversimplification of elastomer properties; a gasket material must maintain resilience across dynamic variables including fluid compatibility, cyclic pressure loads, temperature fluctuations, and flange surface imperfections.

Generic gaskets often utilize standard elastomers like basic NBR or EPDM, which lack the tailored resistance required for complex industrial media. For instance, exposure to aggressive chemicals such as amines or chlorinated solvents can cause severe swelling or hardening in non-formulated compounds, compromising the sealing interface. Similarly, elevated temperatures accelerate compression set in low-grade materials, permanently reducing the gasket’s ability to recover and maintain bolt load. ASTM F104 classifications for filler content or ASTM D2000 material grades provide baseline metrics, but they insufficiently address real-world synergies between stressors. A precision-engineered gasket requires molecular-level customization—such as peroxide-cured FKM for high-temperature acid resistance or specialty FFKM for semiconductor-grade purity—to sustain a dynamic sealing envelope under operational extremes.

The table below illustrates why standardized solutions fall short, comparing critical performance thresholds across common elastomer families:

| Elastomer Type | Temperature Range (°C) | Key Chemical Resistance | Compression Set (ASTM D395, 22h/150°C) | Typical Failure Modes in Off-the-Shelf Gaskets |

|---|---|---|---|---|

| Standard NBR | -30 to +100 | Oils, aliphatic hydrocarbons | >45% | Swelling in polar solvents; rapid thermal degradation above 100°C |

| General EPDM | -50 to +150 | Water, steam, alkalis | >35% | Degradation in petroleum fluids; ozone cracking in outdoor exposure |

| Standard FKM | -20 to +200 | Acids, fuels, aromatics | >25% | Limited resistance to ketones/amines; hardening below -20°C |

| Precision FFKM | -20 to +327 | All chemicals, plasma | <15% | Rare in engineered solutions; generic versions lack thermal stability |

Material inadequacy is compounded by inconsistent manufacturing tolerances in mass-produced gaskets. Variations in durometer, filler dispersion, or cure state create weak points prone to extrusion under pressure spikes. At Suzhou Baoshida, we address this through OEM-driven compound development, leveraging dynamic mechanical analysis (DMA) and fluid immersion testing to simulate exact service conditions. Our precision rubber seals integrate application-specific parameters—such as flange bolt torque profiles, media pH, and thermal cycling rates—into the formulation phase. This eliminates the guesswork of off-the-shelf alternatives, ensuring the gasket’s stress-strain behavior aligns with the system’s operational envelope.

Ultimately, successful flange sealing demands moving beyond catalog specifications. It requires treating each gasket as a precision-engineered component, where elastomer chemistry, physical properties, and geometric design are co-optimized for the unique demands of the piping system. This approach transforms gaskets from failure points into reliable, maintenance-free assets.

Material Specifications

Material Specifications for Pipe Flange Gaskets

Selecting the appropriate elastomer for pipe flange gaskets is critical to ensuring long-term sealing performance under diverse industrial operating conditions. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered to meet rigorous chemical, thermal, and mechanical demands. Our primary gasket materials—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—are formulated to deliver optimal resilience, compression set resistance, and compatibility across a broad spectrum of media. Each material exhibits distinct performance characteristics that must be aligned with application parameters such as temperature range, fluid exposure, and mechanical stress.

Viton, a fluorocarbon-based rubber, offers exceptional resistance to high temperatures, oils, fuels, and a wide range of aggressive chemicals. With continuous service capability up to 230°C (446°F), Viton is ideal for demanding environments in petrochemical, aerospace, and automotive industries. Its low gas permeability and excellent aging characteristics make it a preferred choice for applications requiring long-term reliability under extreme conditions. However, Viton demonstrates limited flexibility at low temperatures and higher cost compared to other elastomers, necessitating careful evaluation of cost-performance trade-offs.

Nitrile rubber, or Buna-N, is a copolymer of butadiene and acrylonitrile, widely used for its outstanding resistance to petroleum-based oils, hydraulic fluids, and aliphatic hydrocarbons. It performs reliably in temperature ranges from -30°C to 120°C (-22°F to 248°F), making it suitable for industrial hydraulic systems, fuel handling, and general mechanical sealing. Nitrile offers good abrasion resistance and tensile strength, with formulation variability allowing optimization for oil resistance versus low-temperature flexibility. While not suitable for exposure to ozone, weathering, or polar solvents, Nitrile remains a cost-effective solution for oil and fuel sealing in moderate environments.

Silicone rubber, a polysiloxane polymer, excels in extreme temperature applications due to its serviceability from -60°C to 200°C (-76°F to 392°F). It maintains flexibility at cryogenic temperatures and resists degradation at elevated heat levels. Silicone demonstrates excellent electrical insulation properties and low toxicity, making it suitable for food, pharmaceutical, and medical applications when compounded to meet regulatory standards. However, its relatively low tensile strength and poor resistance to petroleum-based fluids limit its use in high-stress mechanical seals or oil-exposed environments.

The following table compares key physical and chemical properties of these materials to assist in material selection for pipe flange gaskets.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Temperature Range (°F) | -4 to 446 | -22 to 248 | -76 to 392 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Water Resistance | Excellent | Good | Excellent |

| Chemical Resistance | Broad (acids, bases, hydrocarbons) | Limited to oils and aliphatic hydrocarbons | Poor with solvents and acids |

Material selection must be based on comprehensive evaluation of operational demands. Suzhou Baoshida Trading Co., Ltd. provides customized gasket solutions with full technical support to ensure optimal performance and regulatory compliance.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Formulation and OEM Execution for Pipe Flange Gaskets

Suzhou Baoshida Trading Co., Ltd. delivers engineered sealing solutions for critical pipe flange applications through dedicated in-house engineering resources. Our core strength resides in the integrated expertise of five specialized Mould Engineers and two advanced Rubber Formula Engineers. This focused team operates at the intersection of material science and precision manufacturing, ensuring gaskets meet exacting industrial performance demands under extreme temperature, pressure, and chemical exposure conditions. We do not merely produce gaskets; we solve complex sealing challenges through scientific formulation and rigorous process control.

Our Rubber Formula Engineers possess deep expertise in polymer chemistry and compounding. They systematically develop and optimize elastomer formulations using base polymers including EPDM, NBR, FKM, and specialty blends. Each compound is engineered for specific service environments, balancing critical properties such as compression set resistance, tensile strength, fluid compatibility, and thermal stability. This involves precise control over filler systems, cure kinetics, and additive packages to achieve target cross-link density and long-term resilience. Material validation follows stringent ASTM and ISO protocols, with formulations tailored to resist degradation from oils, acids, steam, or aggressive industrial media encountered in petrochemical, power generation, and marine systems.

Complementing formulation science, our Mould Engineering team ensures dimensional precision and repeatability. Utilizing advanced CAD/CAM software and precision CNC machining, they design and maintain mould tooling to exact flange standards (ASME B16.20, B16.21, EN 1514). Critical attention is paid to cavity geometry, venting, and runner systems to eliminate flash, ensure uniform material flow, and achieve the required surface finish for optimal seal integrity. Process parameters for injection and compression moulding are scientifically determined and monitored, guaranteeing consistent durometer, thickness tolerance (±0.1mm typical), and absence of internal defects.

This integrated engineering capability directly enables superior OEM partnership. We collaborate closely with client technical teams from the initial design phase, translating operational requirements into validated gasket specifications. Our engineers support rapid prototyping, conduct Finite Element Analysis (FEA) for stress prediction under load, and provide comprehensive material test reports (MTRs). Crucially, we offer full customization without restrictive minimum order quantities, adapting compounds and geometries to unique flange configurations or performance criteria. This flexibility, backed by robust quality management systems (ISO 9001 certified), ensures seamless integration into global supply chains.

The following table summarizes key performance characteristics achievable through our engineered compounds for standard industrial flange gasket applications:

| Material Type | Temperature Range (°C) | Maximum Pressure (Bar) | Key ASTM Standards | Primary Chemical Resistance |

|---|---|---|---|---|

| High-Grade EPDM | -50 to +150 | 100 | D2000, D1418, F147 | Steam, Water, Alkalis, Ketones |

| Nitrile (NBR) | -30 to +120 | 120 | D2000, D1418, F147 | Oils, Fuels, Aliphatic Hydrocarbons |

| Fluorocarbon (FKM) | -20 to +230 | 150 | D2000, D1418, F147 | Aromatics, Acids, High-Temp Oils |

| Specialty Blends | Custom Range | Up to 200 | Client-Specific Protocols | Tailored to Aggressive Media |

Suzhou Baoshida’s engineering ecosystem guarantees that every pipe flange gasket is a precisely engineered component, not a generic commodity. Our commitment to scientific development and OEM agility provides industrial clients with reliable, high-performance sealing solutions that enhance system safety and operational uptime.

Customization Process

Drawing Analysis

The customization process for pipe flange gaskets begins with comprehensive drawing analysis. At Suzhou Baoshida Trading Co., Ltd., engineering teams evaluate client-submitted technical drawings to extract critical dimensional and performance parameters. These include inner and outer diameters, thickness, surface finish requirements, bolt hole patterns, and any groove or seating specifications. Tolerance analysis is performed in accordance with ISO 3601 or ASME B16.20 standards to ensure compatibility with existing flange systems. Our engineers verify sealing surface geometry, compression limits, and installation constraints to prevent over-compression or extrusion under operational conditions. This stage also identifies potential design risks such as insufficient squeeze, inadequate flange support, or mismatched hardness requirements. All geometric data is cross-referenced with material performance databases to guide optimal formulation selection.

Formulation Development

Based on the operational environment derived from the drawing and client input, a precise rubber compound is formulated. Key factors include temperature range, media exposure (e.g., oils, acids, steam), pressure cycles, and regulatory compliance (FDA, NSF, RoHS). Our in-house R&D laboratory develops custom elastomer formulations using base polymers such as NBR, EPDM, FKM, or silicone, tailored to deliver the required chemical resistance, compression set, tensile strength, and resilience. Additives are calibrated to enhance aging resistance, flame retardancy, or low-temperature flexibility where necessary. Each formulation undergoes predictive testing via accelerated aging and swelling analysis against target fluids. The Shore A hardness is optimized between 50 and 90 to balance sealing force and deformation recovery. Final compound specifications are documented and archived for batch traceability.

Prototyping and Validation

A prototype batch is manufactured using precision compression or injection molding, depending on complexity and volume. Prototypes are subjected to dimensional inspection via coordinate measuring machines (CMM) and optical comparators to ensure conformance to drawing tolerances. Functional testing includes compression-deflection analysis, leak rate measurement under simulated operating conditions, and thermal cycling. Clients receive test reports and physical samples for field evaluation. Feedback is integrated into design or material adjustments before final approval.

Mass Production

Upon prototype validation, the project transitions to mass production. Our automated production lines ensure consistent curing time, temperature, and pressure across batches. In-process quality checks and final 100% visual inspection guarantee defect-free output. Each lot is tested for hardness, tensile properties, and dimensional stability per ASTM D2000 standards.

| Parameter | Standard Range | Testing Method |

|---|---|---|

| Inner Diameter | 25–2000 mm | ISO 3601 |

| Thickness | 1.5–6.0 mm | ASTM D395 |

| Hardness (Shore A) | 50–90 ±5 | ASTM D2240 |

| Operating Temp | -40°C to +250°C | ASTM D573 |

| Compression Set (22h, 100°C) | ≤25% | ASTM D395 B |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Flange Gasket Solutions

When flange sealing failures occur in high-pressure, high-temperature industrial systems, the cost extends beyond immediate downtime. Suboptimal gasket performance risks fluid leakage, environmental non-compliance, and catastrophic equipment damage. Suzhou Baoshida Trading Co., Ltd. provides engineered rubber sealing solutions where generic gaskets fail. Our technical team specializes in material science and precision manufacturing for critical flange applications across petrochemical, power generation, and semiconductor industries. We do not sell standard off-the-shelf products; we develop application-specific gasket formulations that meet exact OEM specifications and stringent international standards.

Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer, leads client technical engagements. With 18 years of experience in elastomer compounding and flange dynamics, he translates your operational challenges—whether extreme thermal cycling, aggressive chemical exposure, or vacuum integrity requirements—into validated gasket performance. Contact him directly to initiate a technical consultation where we analyze your flange dimensions, media compatibility, pressure-temperature profiles, and failure history. This diagnostic phase precedes any quotation, ensuring our solution addresses root causes, not symptoms. Our ISO 9001-certified process includes finite element analysis (FEA) for stress distribution modeling and accelerated aging tests per ASTM D2000 protocols.

The table below summarizes key performance parameters achievable through our custom formulations. These values represent baseline capabilities; actual specifications are tailored to your project requirements and validated through joint testing protocols.

| Property | Test Standard | Typical Range (Customizable) |

|---|---|---|

| Temperature Resistance | ASTM D573 | -55°C to +350°C |

| Compression Set (22h/150°C) | ASTM D395 | ≤15% |

| Tensile Strength | ASTM D412 | 12–25 MPa |

| Fluid Resistance (Oil IRM 903) | ASTM D471 | Volume Swell ≤15% |

| Hardness (Shore A) | ASTM D2240 | 60–90 |

Initiate your technical partnership by contacting Mr. Boyce at [email protected]. Include your flange drawing (ASME B16.5/B16.47), operating conditions, and any historical failure data. For urgent sealing emergencies, reference your project timeline in the subject line to expedite our response. All technical inquiries receive a detailed engineering assessment within 24 business hours—not a generic sales reply. We require no non-disclosure agreement for initial consultations, demonstrating confidence in our ability to solve complex sealing challenges transparently.

Suzhou Baoshida operates from a 12,000m² manufacturing facility in Suzhou Industrial Park, equipped with state-of-the-art mixing, molding, and testing laboratories. Our gaskets undergo 100% dimensional inspection via CMM and batch-level material certification. When system integrity is non-negotiable, partner with an engineering-led supplier who treats your sealing challenge as a precision science. Contact Mr. Boyce today to convert flange leakage risks into operational reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).