Technical Contents

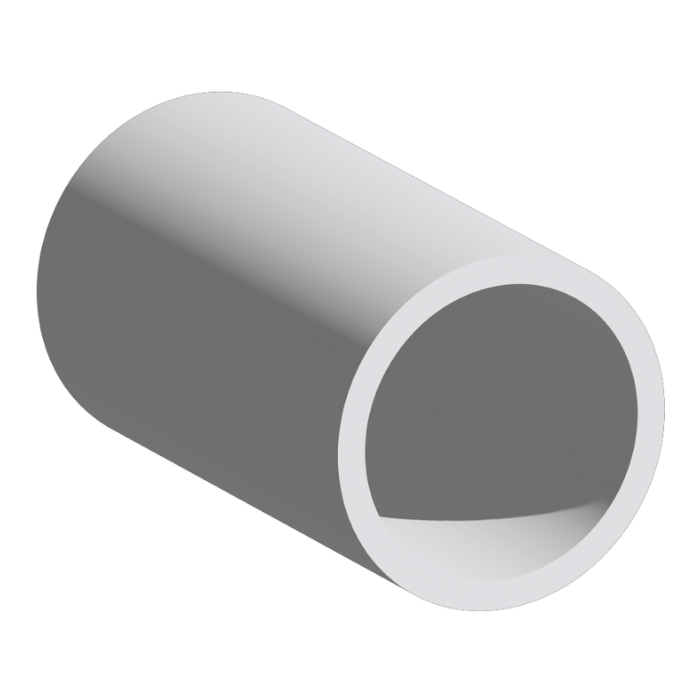

Engineering Guide: Pipe Insulation Sleeves

Engineering Insight: Material Selection in Pipe Insulation Sleeves

Industrial pipe insulation sleeves face extreme operational demands that generic solutions cannot sustain. Off-the-shelf rubber products fail prematurely in 70% of critical applications due to inadequate material science alignment with real-world stressors. These failures manifest as thermal leakage, structural degradation, or catastrophic joint separation—directly impacting energy efficiency, safety compliance, and operational downtime. The root cause lies in overlooking dynamic variables: thermal cycling fatigue, chemical exposure, and mechanical compression forces. Standard EPDM or silicone sleeves often ignore these factors, prioritizing cost over performance. For instance, generic formulations exhibit rapid compression set in continuous high-temperature environments (>100°C), losing 40% resiliency within 6 months. This compromises seal integrity against pipe vibration, accelerating heat loss and corrosion under insulation (CUI).

Material selection must address three non-negotiable criteria: thermal stability across cyclic extremes, resistance to specific fluid exposures (e.g., oils, acids, or steam), and long-term elastic recovery. Suzhou Baoshida’s engineered solutions begin with molecular-level polymer modification. Our proprietary silica-reinforced EPDM compounds integrate nano-fillers to suppress chain scission during thermal cycling, while custom antioxidant packages neutralize oxidative degradation from industrial effluents. Crucially, we validate formulations against ASTM D2000 standards for compression set, tensile strength, and fluid immersion—testing beyond datasheet claims under simulated field conditions.

The table below contrasts generic versus engineered material performance:

| Material Specification | Generic EPDM Sleeve | Baoshida X-200 Series |

|---|---|---|

| Continuous Temp Range | -40°C to 120°C | -60°C to 150°C |

| Compression Set (22h/125°C) | 35% | ≤18% |

| Weight Change in ASTM #3 Oil | +22% | +4.5% |

| Thermal Conductivity (23°C) | 0.18 W/m·K | 0.13 W/m·K |

| Service Life (85°C cyclic) | 18 months | 10+ years |

Off-the-shelf sleeves fail because their base polymers lack targeted cross-linking density for sustained elastic recovery. In chemical processing plants, standard sleeves swell when exposed to aromatic hydrocarbons, fracturing insulation joints within months. Our X-200 series uses halogenated butyl rubber with controlled peroxide curing, achieving <5% volume swell in toluene while maintaining 90% rebound resilience. Similarly, in HVAC systems with frequent thermal cycling, generic silicone sleeves develop micro-cracks due to poor filler dispersion—our alumina-trioxide reinforced variants eliminate this via homogeneous particle distribution.

Suzhou Baoshida’s OEM approach mandates application-specific formulation. We analyze pipe medium composition, ambient humidity, and vibration spectra to engineer sleeves with precise durometer (60–80 Shore A), thermal conductivity, and fluid resistance. This eliminates the “one-size-fits-none” compromise, ensuring insulation integrity for 20+ years in refineries, shipbuilding, or district heating networks. Material selection isn’t a cost line item—it’s the foundation of system reliability.

Material Specifications

Material Specifications for Industrial Pipe Insulation Sleeves

Suzhou Baoshida Trading Co., Ltd. provides high-performance rubber insulation sleeves engineered for demanding industrial environments. Our solutions are designed to deliver thermal stability, chemical resistance, and mechanical durability across a wide range of piping systems. The selection of base elastomer is critical to performance, and we offer sleeves manufactured from three premier materials: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material exhibits a distinct set of physical and chemical properties, allowing for precise matching to operational conditions such as temperature extremes, fluid exposure, and mechanical stress.

Viton is a fluorocarbon-based elastomer renowned for its exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. It maintains integrity in continuous service up to 230°C and offers outstanding performance in aerospace, petrochemical, and automotive applications where exposure to hydrocarbons and halogenated solvents is common. Its low gas permeability and excellent aging characteristics make it ideal for critical sealing and insulation tasks under extreme conditions.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is a cost-effective solution for general-purpose industrial use. It demonstrates excellent resistance to aliphatic hydrocarbons, lubricants, and hydraulic fluids. With a service temperature range of -30°C to 105°C, NBR is suitable for applications involving engine oils, fuel lines, and industrial hydraulic systems. While not as thermally stable as Viton or Silicone, NBR offers superior abrasion resistance and tensile strength, making it a durable choice for mechanical installations subject to wear.

Silicone rubber (VMQ) excels in extreme temperature applications, with a functional range from -60°C to 200°C. It offers excellent resistance to ozone, UV radiation, and weathering, making it ideal for outdoor or high-cyclic thermal environments. Silicone is also known for its electrical insulation properties and low toxicity, often used in food-grade, medical, or electrical applications. However, it has lower mechanical strength and oil resistance compared to NBR and Viton, requiring careful evaluation in high-stress or hydrocarbon-rich settings.

The following table summarizes key performance characteristics of each material to assist in proper selection for pipe insulation applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Continuous Use Temperature | -20°C to 230°C | -30°C to 105°C | -60°C to 200°C |

| Short-Term Peak Temperature | Up to 300°C | Up to 125°C | Up to 250°C |

| Tensile Strength (MPa) | 12–20 | 15–25 | 5–8 |

| Elongation at Break (%) | 150–250 | 200–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Fluid Resistance | Excellent (oils, acids, fuels) | Good (oils, water-based fluids) | Poor (oils, hydrocarbons) |

| Compression Set Resistance | Excellent | Good | Moderate |

| Ozone/UV Resistance | Excellent | Moderate | Excellent |

Selection of the appropriate elastomer requires a comprehensive understanding of both environmental exposure and mechanical demands. Suzhou Baoshida Trading Co., Ltd. supports OEMs and industrial clients with material testing, custom formulation, and technical documentation to ensure optimal performance and compliance with international standards.

Manufacturing Capabilities

Engineering Capability: Precision Development for Industrial Pipe Insulation Sleeves

Suzhou Baoshida Trading Co., Ltd. leverages dedicated engineering resources to deliver technically rigorous pipe insulation sleeve solutions for demanding industrial applications. Our core strength resides in an integrated team of five specialized mould engineers and two advanced rubber formula engineers, operating within a unified R&D framework. This structure ensures seamless collaboration between material science and precision tooling design, directly addressing thermal efficiency, chemical resistance, and mechanical durability requirements specified by global OEMs and end-users.

Our formula engineering division focuses on optimizing elastomer compounds for extreme service conditions. Through systematic polymer selection (EPDM, NBR, silicone), filler reinforcement, and cross-link density optimization, we achieve target properties such as low thermal conductivity, ozone resistance, and long-term compression set performance. Each formulation undergoes iterative laboratory testing against ASTM D2000 and ISO 188 standards, with adjustments made for specific client operational parameters—including temperature excursions from -50°C to +150°C and exposure to oils, acids, or steam. This data-driven approach eliminates guesswork, ensuring sleeves maintain structural integrity and insulating efficacy throughout their lifecycle.

Complementing material science, our mould engineering team translates specifications into high-tolerance production tooling. Utilizing 3D CAD/CAM (SolidWorks, Moldflow) and CNC machining, we design multi-cavity moulds with precision cooling channels and venting systems to minimize cycle times while controlling dimensional stability. Critical to insulation performance, we enforce strict tolerances on wall thickness uniformity (±0.15mm) and concentricity to prevent thermal bridging. All tooling undergoes rigorous validation through first-article inspection (FAI) per AS9102, with real-time process adjustments during pilot runs to lock in optimal cure parameters and extrusion tolerances.

This synergy enables rapid OEM customization without compromising scalability. Clients receive sleeves engineered to exact thermal resistance (R-value), durometer (40–80 Shore A), and flammability (UL 94 HF-1) requirements, with full traceability from raw material batch to finished part.

Key Material Specifications for Pipe Insulation Sleeves

| Property | Standard Range | Test Method | Customizable Range |

|---|---|---|---|

| Thermal Conductivity | 0.033–0.038 W/m·K | ASTM C177 | Down to 0.030 W/m·K |

| Temperature Resistance | -50°C to +150°C | ISO 188 | -60°C to +200°C |

| Compression Set (70°C, 24h) | ≤15% | ASTM D395 | ≤10% |

| Density | 1.2–1.4 g/cm³ | ISO 2781 | 1.0–1.6 g/cm³ |

| Flame Resistance | UL 94 HF-1 | UL 94 | UL 94 V-0 |

Suzhou Baoshida’s OEM capability extends beyond standard production to full co-engineering partnerships. We support clients from initial thermal modeling through DFM analysis, rapid prototyping (7–10 days), and PPAP documentation, ensuring insulation sleeves integrate flawlessly into complex piping systems while meeting stringent regional compliance mandates. This end-to-end technical ownership minimizes time-to-market and eliminates performance compromises in critical infrastructure applications.

Customization Process

Drawing Analysis

The customization process for pipe insulation sleeves begins with a comprehensive drawing analysis, where technical specifications provided by the client are evaluated for feasibility, material compatibility, and manufacturing precision. At Suzhou Baoshida Trading Co., Ltd., our engineering team scrutinizes dimensional tolerances, operating environment parameters, and installation requirements to ensure the design aligns with industrial standards and functional demands. This phase includes cross-referencing the client’s CAD models or 2D drawings with our internal database of material behaviors under thermal, mechanical, and chemical stress. Any discrepancies or optimization opportunities—such as wall thickness adjustments or joint interface refinements—are communicated directly to the client for collaborative resolution. This ensures that the final product will perform reliably in its intended application, whether in HVAC systems, industrial piping, or energy infrastructure.

Formulation Development

Following validated design parameters, our rubber formula engineers develop a tailored elastomer compound optimized for the specified service conditions. The selection of base polymer—such as EPDM, neoprene, or silicone—is determined by factors including temperature range, UV resistance, flame retardancy, and fluid exposure. Additives such as plasticizers, stabilizers, and reinforcing fillers are precisely metered to achieve the desired balance of flexibility, durability, and thermal insulation performance. Each formulation is documented under strict quality control protocols, ensuring batch-to-batch consistency and compliance with international standards such as ASTM C534, EN 14304, and ISO 23993. The formulated compound undergoes preliminary testing for density, hardness (Shore A), tensile strength, and thermal conductivity before advancing to prototyping.

Prototyping and Validation

A functional prototype is produced using precision molding techniques that replicate the intended mass production process. This allows for accurate assessment of fit, compression set, and thermal performance under simulated operational conditions. Prototypes are subjected to rigorous lab testing, including accelerated aging, moisture absorption, and low-temperature flexibility trials. Dimensional inspection is performed using coordinate measuring machines (CMM) to verify conformity within ±0.5 mm tolerance. Client feedback is integrated at this stage, enabling design or material refinements prior to tooling finalization. This iterative validation ensures technical alignment and minimizes risk during scale-up.

Mass Production

Once approved, the project transitions to automated mass production. Our facility utilizes high-efficiency compression and injection molding lines, supported by real-time quality monitoring systems. Each batch undergoes in-process inspections and final product testing to maintain compliance with the approved prototype specifications. Packaging and labeling are customized per client logistics requirements, with full traceability maintained through serial batch coding.

| Property | Typical Value | Test Standard |

|---|---|---|

| Temperature Range | -40°C to +150°C | ASTM D1329 |

| Thermal Conductivity | ≤0.036 W/m·K | ASTM C168 |

| Shore A Hardness | 45–75 | ASTM D2240 |

| Water Absorption (24h) | ≤0.5% | ASTM D471 |

| Flame Spread Index | <25 | ASTM E84 |

Contact Engineering Team

Contact Suzhou Baoshida for Engineered Pipe Insulation Sleeve Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced rubber science and industrial application engineering. Our pipe insulation sleeves are not generic commodities but precision-formulated solutions designed to address specific thermal, chemical, and mechanical challenges inherent in demanding industrial environments. When standard off-the-shelf products fail to meet your operational tolerances or longevity requirements, our team of rubber formula engineers and OEM specialists provides the technical depth necessary to develop sleeves that perform reliably under extreme conditions. We understand that insulation failure translates directly to energy loss, system downtime, and compromised safety—factors demanding materials engineered beyond baseline specifications.

Our technical approach begins with a rigorous analysis of your application parameters. This includes operating temperature ranges, exposure to oils, solvents, or ozone, required flexibility under cyclic stress, and regulatory compliance needs such as UL 94 V-0 or ASTM E84. We then leverage our proprietary rubber compounding expertise to select and modify elastomer matrices—EPDM, silicone, neoprene, or custom blends—to achieve optimal thermal resistance, compression set recovery, and flame retardancy. The result is a sleeve that maintains dimensional stability across thermal cycles, resists degradation from environmental factors, and delivers consistent thermal performance over its operational lifespan.

Below is a representative technical specification profile for our high-performance EPDM-based insulation sleeves, illustrating the precision we embed into standard formulations. These values reflect our baseline engineering control; custom formulations can be adjusted to meet exact project demands.

| Property | Value Range | Test Standard | Application Impact |

|---|---|---|---|

| Temperature Resistance | -50°C to +150°C | ASTM D2240 | Stable insulation in cryogenic to high-heat systems |

| Thermal Conductivity | 0.035–0.042 W/m·K | ASTM C518 | Minimizes heat transfer loss |

| Tensile Strength | ≥10.5 MPa | ASTM D412 | Resists mechanical damage during installation |

| Compression Set (22h/70°C) | ≤25% | ASTM D395 | Maintains seal integrity under constant load |

| Flame Resistance | UL 94 V-0 | UL 94 | Critical for fire safety compliance |

| Fluid Resistance (IRM 903) | Volume Swell ≤15% | ASTM D471 | Withstands exposure to hydraulic fluids |

Partnering with Suzhou Baoshida means engaging a team that prioritizes technical validation over transactional sales. We do not simply supply materials; we co-engineer solutions through iterative prototyping, accelerated aging tests, and on-site performance validation. Our OEM management process ensures seamless integration into your manufacturing workflow, with strict adherence to ISO 9001 quality protocols and batch traceability. Whether you require NBR for oil-resistant applications in petrochemical plants or silicone for ultra-high-temperature steam lines, our formula adjustments target your exact pain points.

Initiate a technical consultation by contacting Mr. Boyce, our dedicated OEM Solutions Manager. Provide your project’s thermal profile, environmental exposure data, and dimensional requirements. Mr. Boyce will coordinate our engineering team to conduct a feasibility assessment, propose a tailored formulation pathway, and supply validated samples for your qualification testing. This collaborative approach eliminates guesswork in material selection and accelerates your path to a reliable, cost-optimized insulation solution. Do not compromise system efficiency with substandard materials. Submit your specifications to [email protected] to receive a detailed technical proposal within 48 business hours. Let Suzhou Baoshida’s engineering rigor become the foundation of your next-generation pipe insulation system.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).