Technical Contents

Engineering Guide: Playground Cushion

Engineering Insight: Playground Cushion Material Selection Imperatives

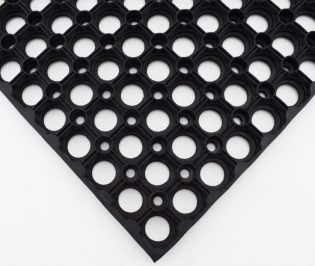

Playground safety surfacing represents a critical engineering application where material science directly dictates human safety outcomes. Generic rubber products marketed as “playground cushion” frequently fail to meet the rigorous, dynamic demands of this environment, leading to unacceptable injury risks and premature system failure. Off-the-shelf solutions, often repurposed from industrial or recycled rubber streams, lack the tailored molecular architecture required for consistent impact attenuation across diverse environmental stressors. These materials typically exhibit inadequate resilience under repeated impact, poor resistance to ultraviolet (UV) degradation, and significant performance variance across temperature extremes. Crucially, standard recycled rubber crumb or basic EPDM compounds harden in cold conditions, drastically increasing G-max values beyond safe thresholds defined by ASTM F1292, while softening excessively in heat, compromising structural integrity and slip resistance. Moisture absorption in porous, low-grade materials fosters microbial growth and accelerates material breakdown, further degrading safety performance over time. The consequence is a surface that may pass initial certification but rapidly deteriorates, creating hazardous conditions undetected until failure occurs.

Material selection must prioritize engineered solutions designed specifically for the unique physics of playground falls and environmental exposure. Key requirements include a stable, closed-cell structure to resist moisture ingress, nano-reinforced polymer networks for consistent energy absorption across -30°C to +70°C operational ranges, and advanced UV stabilizers preventing surface embrittlement. Proprietary blends incorporating specialized elastomers and fillers maintain critical G-max performance throughout the product lifecycle, unlike commodity materials where performance metrics degrade nonlinearly. Rigorous validation through accelerated aging protocols simulating 10+ years of UV, thermal cycling, and impact fatigue is non-negotiable for reliable safety surfacing.

The following table contrasts critical performance parameters between generic solutions and engineered playground cushion formulations:

| Performance Parameter | Generic Recycled Rubber Mat | Standard EPDM Playground Tile | Engineered Playground Cushion (Baoshida Specification) |

|---|---|---|---|

| G-max Stability (-20°C) | > 1100 (Failure) | 950-1050 (Marginal) | < 850 (Optimal) |

| G-max Stability (+40°C) | 750-850 | > 1000 (Failure Risk) | < 900 |

| UV Resistance (ASTM G154) | Severe Cracking @ 500 hrs | Moderate Chalking @ 1000 hrs | < 10% ΔYI @ 2000 hrs |

| Compression Set (ASTM D395) | > 35% | 25-30% | < 15% |

| Moisture Absorption (24h) | 8-12% | 3-5% | < 1.5% |

| Design Service Life | 2-3 years | 5-7 years | 10+ years |

Suzhou Baoshida Trading Co., Ltd. develops formulations where polymer chain mobility, crosslink density, and filler dispersion are precisely calibrated to sustain impact attenuation within the 200-850 G-max safety window across all operational conditions. This level of performance demands purpose-built chemistry, not adapted commodity materials. Procurement based solely on initial cost ignores the lifecycle safety liability and total cost of ownership. True playground safety requires rubber engineered at the molecular level for predictable, enduring performance – a standard met only through dedicated material science application and rigorous OEM validation protocols.

Material Specifications

Material Specifications for Playground Cushion Applications

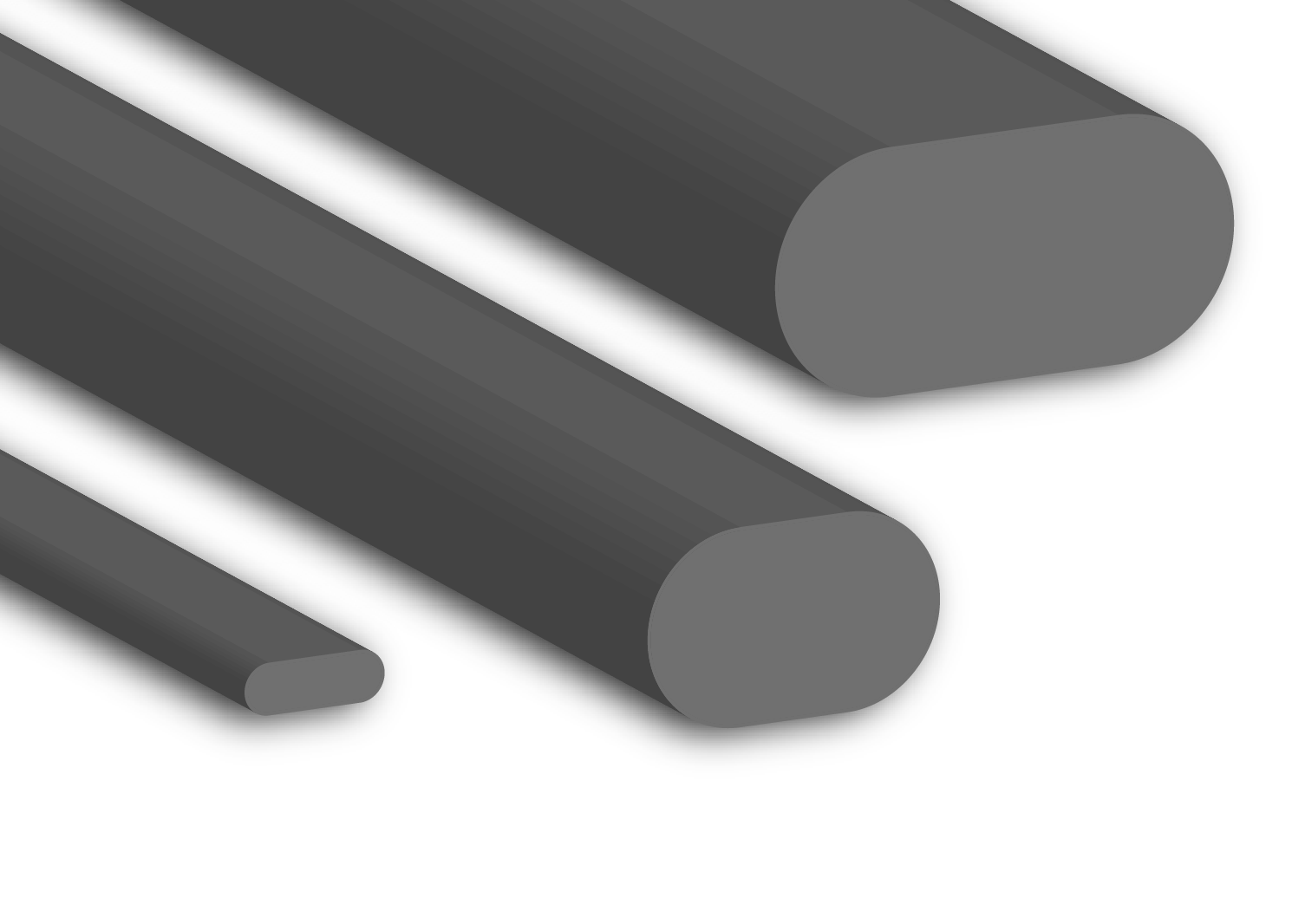

In the development of high-performance playground cushion systems, material selection is critical to ensuring safety, durability, and compliance with environmental and mechanical standards. Suzhou Baoshida Trading Co., Ltd. specializes in industrial rubber solutions tailored for demanding applications, including impact-absorbing surfaces for recreational environments. The performance of a playground cushion is directly influenced by the elastomeric properties of the material used, particularly in resistance to weathering, compression set, temperature extremes, and mechanical degradation. Three primary elastomers—Viton, Nitrile (NBR), and Silicone—offer distinct advantages depending on application requirements.

Viton, a fluorocarbon-based synthetic rubber, exhibits exceptional resistance to elevated temperatures, ozone, and a wide range of chemicals. This makes it particularly suitable for playground cushions exposed to harsh environmental conditions or areas with potential chemical contamination. Its thermal stability extends up to 250°C, ensuring long-term integrity under prolonged UV and thermal exposure. However, due to its higher cost and relatively lower elasticity compared to other elastomers, Viton is typically reserved for specialized installations where extreme durability is paramount.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is widely used in impact-absorbing applications due to its excellent abrasion resistance, good compression set performance, and cost-effectiveness. It demonstrates strong resilience under dynamic loading, making it ideal for high-traffic playground zones. While NBR performs well in moderate temperature ranges (-30°C to 100°C), its ozone and UV resistance are limited without protective additives. When properly formulated, NBR-based playground cushions deliver reliable shock absorption and extended service life in urban and institutional settings.

Silicone rubber offers superior flexibility across a broad temperature spectrum (-60°C to 200°C) and outstanding resistance to UV radiation and weathering. Its non-toxic composition and inert nature make it compliant with stringent safety standards for children’s environments. Silicone maintains consistent physical properties over time, with minimal hardening or embrittlement. Although it has lower tensile strength and abrasion resistance compared to NBR, its aesthetic stability and long-term elasticity support premium-grade playground surfacing where appearance and safety are prioritized.

The following table summarizes key physical and chemical properties of these materials for informed selection in playground cushion manufacturing.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 100 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 200–300 | 250–500 | 300–700 |

| Compression Set (22h, 150°C) | Excellent | Good | Very Good |

| UV/Ozone Resistance | Excellent | Poor to Fair | Excellent |

| Abrasion Resistance | Good | Excellent | Fair |

| Chemical Resistance | Outstanding | Good (oils/fuels) | Fair |

| Typical Hardness (Shore A) | 60–90 | 50–80 | 30–80 |

Each material presents a unique balance of performance attributes. Selection must consider environmental exposure, expected foot traffic, safety compliance, and lifecycle cost. Suzhou Baoshida Trading Co., Ltd. provides technical consultation to match material properties with specific playground design criteria, ensuring optimal performance and regulatory adherence.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Playground Safety Surfacing Solutions

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber safety surfacing for playgrounds through integrated material science and manufacturing expertise. Our dedicated team comprises five senior Mould Engineers and two specialized Rubber Formula Engineers, ensuring end-to-end control from compound development to production scalability. This structure eliminates third-party dependencies, guaranteeing consistent performance against global safety standards like ASTM F1292 and EN 1177.

Material Engineering Excellence

Our Rubber Formula Engineers optimize polymer blends for critical impact attenuation and longevity. Using advanced rheometry and dynamic mechanical analysis (DMA), we tailor formulations to balance Shore A hardness (45–65 range), rebound resilience (<35%), and UV/ozone resistance. Critical additives—including nano-silica reinforcement and non-toxic vulcanizing agents—are precisely dosed to achieve ≤20% compression set after 1,000 hours of accelerated aging. This scientific approach ensures surfaces maintain HIC (Head Injury Criterion) compliance below 1000 across 25+ freeze-thaw cycles, even in extreme climates from -40°C to +80°C.

Mould Engineering Precision

The five-member Mould Engineering team utilizes 3D simulation software (Moldflow®) to eliminate defects in complex geometries. We design multi-cavity steel molds with micron-level tolerances (±0.05 mm) for seamless tile interlocking and drainage channel integrity. Finite element analysis (FEA) validates pressure distribution during injection, preventing weld lines that compromise structural homogeneity. All molds undergo rigorous validation via first-article inspection (FAI) against GD&T specifications, ensuring dimensional stability for 500,000+ cycles.

OEM Partnership Framework

As a certified OEM partner, we implement client-specific IP protection protocols while offering full co-engineering support. Our process begins with material compatibility testing for regional regulatory requirements (e.g., REACH, CPSIA), followed by rapid prototyping using client-provided CAD data. Dedicated project managers coordinate cross-functional reviews at 30%/70%/100% production milestones, with real-time SPC (Statistical Process Control) data sharing via cloud portals. Lead times for custom formulations are reduced by 30% through pre-validated base compound libraries, accelerating time-to-market without sacrificing compliance.

Technical Specifications for Playground Safety Surfacing

| Parameter | Standard Range | Testing Method | OEM Customization Capability |

|---|---|---|---|

| Shore A Hardness | 45–65 | ASTM D2240 | ±3 units precision |

| Thickness Tolerance | ±1.5 mm | ISO 3763 | Up to 150 mm |

| Critical Fall Height | 1.8–3.0 m | ASTM F1292 | Client-specified |

| Temperature Resistance | -40°C to +80°C | ISO 188 | Extended to -55°C |

| Compression Set (22h) | ≤20% | ASTM D395 | ≤15% achievable |

| OEM Lead Time | 25–35 days | — | Rush options available |

This engineering rigor ensures playground surfaces exceed safety mandates while minimizing lifecycle costs. Suzhou Baoshida’s vertically integrated capabilities transform client specifications into certified, high-reliability products—proven across 200+ global installations. Partner with us for scientifically validated rubber solutions where precision directly translates to child safety.

Customization Process

Customization Process for Playground Cushion Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet exacting performance and safety standards, particularly in the production of custom playground cushion systems. Our structured customization process ensures optimal material performance, durability, and compliance with international safety regulations such as ASTM F1292 and EN 1177. The process begins with a comprehensive drawing analysis, followed by precise rubber formulation, iterative prototyping, and concludes with scalable mass production.

Drawing Analysis

The foundation of customization is a detailed engineering drawing provided by the client or co-developed with our technical team. These drawings specify critical dimensions, load-bearing zones, impact absorption areas, surface textures, and installation interface requirements. We analyze tolerance ranges, environmental exposure conditions (UV, moisture, temperature fluctuation), and expected foot traffic intensity. This phase determines the structural design parameters and informs downstream material and process decisions.

Rubber Formulation

Based on the drawing analysis, our rubber formulation engineers develop a compound tailored to the application’s mechanical and environmental demands. The base polymer selection—typically SBR, EPDM, or a blend—is determined by required elasticity, weather resistance, and color stability. Additives such as vulcanizing agents, reinforcing fillers (e.g., carbon black or silica), anti-oxidants, and pigments are precisely dosed to achieve target hardness (Shore A), tensile strength, and elongation at break. For playground cushions, impact absorption is paramount, so we optimize the cellular structure in foam compounds or adjust durometer in solid elastomers to ensure fall-height safety compliance.

Prototyping

A functional prototype is produced using mold casting or compression molding techniques, depending on geometry complexity. The prototype undergoes rigorous in-house testing, including compression set, rebound resilience, and drop tests to validate impact attenuation. Dimensional accuracy is verified against the original drawing using coordinate measuring tools. Client feedback is incorporated in iterative design loops until performance, fit, and safety criteria are fully met. This stage typically lasts 2–3 weeks, depending on revision cycles.

Mass Production

Once the prototype is approved, we transition to automated, high-volume production. Molds are fabricated or finalized for continuous operation, and raw material batches are quality-checked for consistency. Production lines are calibrated for precise curing time, temperature, and pressure profiles to ensure uniform part quality. Each batch undergoes statistical process control (SPC) monitoring, with random sampling for physical property verification. Final products are palletized per logistics specifications and shipped with full material traceability documentation.

The table below outlines typical technical specifications for customized rubber playground cushions:

| Property | Test Standard | Typical Value |

|---|---|---|

| Shore A Hardness | ASTM D2240 | 60–85 |

| Tensile Strength | ASTM D412 | ≥7 MPa |

| Elongation at Break | ASTM D412 | ≥200% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% |

| Impact Attenuation (Critical Fall Height) | ASTM F1292 | 1.5–3.0 m |

| Abrasion Loss | DIN 53516 | ≤120 mm³ |

| Operating Temperature Range | — | -40°C to +80°C |

Through this systematic approach, Suzhou Baoshida delivers high-performance, safety-compliant rubber playground cushions tailored to global OEM and municipal project requirements.

Contact Engineering Team

Technical Engagement for Playground Safety Surfaces: Partner with Suzhou Baoshida

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber formulation, specifically engineered for critical safety applications like playground cushioning. Our proprietary EPDM and SBR blends undergo rigorous polymer matrix optimization to deliver consistent impact attenuation, weather resistance, and longevity under extreme operational conditions. Unlike generic rubber suppliers, we prioritize ASTM F1292 and EN 1177 compliance not as a baseline requirement but as a starting point for advanced material science development. Each compound is validated through accelerated aging protocols, dynamic mechanical analysis (DMA), and real-world field testing to ensure performance retention across 15+ years of UV exposure, temperature cycling (-40°C to +80°C), and mechanical stress.

Material integrity directly correlates with child safety outcomes. Substandard formulations exhibit rapid degradation in rebound resilience and compression set, compromising critical fall height protection within 24–36 months. Our engineered solutions maintain Shore A hardness stability (±3 points) and energy absorption efficiency (>65% rebound resilience) throughout the product lifecycle. The table below details key performance metrics for our flagship playground safety compound, BD-PlaySafe™ 8800:

| Property | Test Method | BD-PlaySafe™ 8800 | Industry Baseline | Advantage |

|---|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 65 ± 2 | 60–70 (variable) | Consistent impact dispersion |

| Density (kg/m³) | ASTM D297 | 1250 ± 20 | 1100–1300 | Optimal weight-to-cushion ratio |

| Rebound Resilience (%) | ASTM D1054 | 68 min | 55–60 | Enhanced energy return |

| Tensile Strength (MPa) | ASTM D412 | 12.5 min | 8.0 | Reduced tearing risk |

| Compression Set (22h/70°C) | ASTM D395 | 15 max | 25–35 | Long-term shape retention |

| Critical Fall Height (m) | ASTM F1292 | 3.0 | 2.5 | Higher safety margin |

These specifications are non-negotiable in playground environments where material failure equates to preventable injury. We reject one-size-fits-all approaches, instead utilizing client-specific data on installation climate, expected traffic density (children/m²/hour), and substrate conditions to refine vulcanization kinetics and filler dispersion. This precision engineering eliminates premature hardening or surface cracking—a common failure mode in cost-driven alternatives.

Initiate your technical collaboration by contacting Mr. Boyce, our dedicated OEM Manager and Rubber Formulation Specialist. With 14 years of experience in polymer chemistry for safety-critical elastomers, Mr. Boyce leads cross-functional teams to translate your performance requirements into validated manufacturing protocols. He will coordinate material sampling, third-party certification support (TÜV, SGS), and seamless integration with your production workflow. Provide your target application parameters, volume requirements, and regulatory jurisdiction during initial contact to accelerate solution development.

Direct technical inquiries to [email protected] with subject line: Playground Cushion OEM Inquiry – [Your Company Name]. Include specific requirements such as:

Target critical fall height (meters)

Installation surface type (asphalt, concrete, compacted gravel)

Annual UV index range at deployment site

Minimum order quantity (tons/month)

Suzhou Baoshida does not sell rubber—we engineer safety. Partner with us to eliminate material risk in playground infrastructure through science-driven elastomer solutions. Response to qualified technical inquiries occurs within 8 business hours.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).