Technical Contents

Engineering Guide: Plexiglass Plates

Engineering Insight: plexiglass plates in Demanding Industrial Applications

In industrial environments where precision, durability, and optical clarity are paramount, plexiglass plates—commonly known as acrylic sheets—are frequently specified for enclosures, sight windows, protective barriers, and instrumentation components. While commercially available plexiglass plates may appear functionally equivalent across suppliers, significant performance disparities emerge under operational stress. At Suzhou Baoshida Trading Co., Ltd., our experience in industrial rubber solutions extends into hybrid material systems, where plexiglass interfaces with elastomeric seals, gaskets, and damping components. This integration reveals a critical insight: generic, off-the-shelf plexiglass plates often fail due to inadequate material selection for specific environmental and mechanical conditions.

The primary failure modes include stress cracking, UV degradation, thermal warping, and incompatibility with sealing systems. Standard extruded acrylic sheets, while cost-effective, exhibit lower molecular weight and internal stresses that predispose them to environmental stress cracking—especially when exposed to oils, solvents, or adhesives commonly found in industrial settings. Cast acrylic, by contrast, offers superior mechanical strength, optical clarity, and resistance to thermal and chemical attack. However, many suppliers default to extruded grades to reduce cost, compromising long-term reliability.

Moreover, thermal expansion characteristics of plexiglass must be carefully matched to adjacent materials. Acrylic has a coefficient of linear thermal expansion approximately eight times that of steel. In applications where plexiglass plates are mounted within metal frames or bonded to rubber gaskets, differential expansion can induce shear stress, leading to delamination, seal failure, or plate fracture. Off-the-shelf solutions rarely account for these system-level interactions, resulting in premature field failures.

Another overlooked factor is surface treatment. Untreated plexiglass is highly susceptible to scratching and static charge accumulation, which attracts contaminants in cleanroom or electronic environments. Anti-scratch and anti-static coated variants are available but are seldom included in generic product lines. Additionally, UV stabilization is essential for outdoor or high-exposure applications; without it, yellowing and embrittlement occur within months.

At Baoshida, we emphasize engineered material selection based on application-specific parameters. Our technical team evaluates load profiles, temperature ranges, chemical exposure, and sealing requirements to recommend the optimal grade of plexiglass—ensuring compatibility with integrated rubber components and long-term system integrity.

| Property | Cast Acrylic | Extruded Acrylic | Notes |

|---|---|---|---|

| Tensile Strength (MPa) | 70–75 | 60–65 | Higher strength improves crack resistance |

| Continuous Use Temp (°C) | 85–90 | 70–75 | Critical for thermal cycling environments |

| UV Resistance | Excellent (with stabilization) | Moderate | Affects outdoor longevity |

| Optical Clarity (% transmission) | 92–93 | 90–91 | Slight but measurable difference |

| Chemical Resistance | High | Moderate | Cast resists solvents and oils better |

| Coefficient of Thermal Expansion (10⁻⁶/K) | 70–90 | 70–90 | Must be matched to sealing system |

Material selection is not a commodity decision. In industrial applications, the performance of plexiglass plates is inseparable from the system in which they operate. A holistic engineering approach prevents failure and ensures reliability.

Material Specifications

Material Specifications: Industrial Rubber Solutions for Critical Sealing Applications

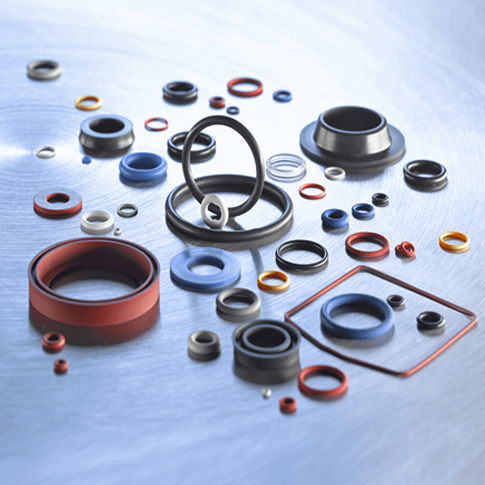

Suzhou Baoshida Trading Co., Ltd. clarifies a critical distinction for precision manufacturing partners: plexiglass (acrylic) plates fall outside our core competency in industrial rubber solutions. As an OEM specialist in elastomeric components, we exclusively engineer and supply rubber-based materials for dynamic sealing, vibration damping, and chemical resistance in demanding industrial environments. Confusion between acrylic plastics and specialty rubbers can lead to catastrophic field failures. Our expertise centers on Viton, Nitrile, and Silicone compounds—each rigorously formulated to meet ISO 3601, ASTM D2000, and OEM-specific performance criteria.

These elastomers are selected based on fluid compatibility, thermal stability, and mechanical stress requirements. Viton fluorocarbon rubber excels in aerospace and chemical processing due to its unparalleled resistance to aggressive fuels, acids, and high temperatures. Nitrile butadiene rubber (NBR) remains the cost-effective standard for hydraulic systems and automotive fuel handling, offering robust oil resistance. Silicone provides exceptional flexibility across extreme temperature ranges, making it indispensable for medical devices and semiconductor manufacturing. All compounds undergo stringent batch testing for compression set, tensile strength, and durometer consistency per ISO 48-4 standards.

The following table details key technical specifications for precision application engineering:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Durometer Range (Shore A) | 50–90 | 40–90 | 30–80 |

| Fluid Resistance | Excellent (fuels, acids) | Good (oils, water) | Poor (oils) |

| Compression Set (ASTM D395) | ≤20% (200°C/70h) | ≤25% (100°C/70h) | ≤20% (150°C/70h) |

| Tensile Strength (MPa) | 8–15 | 10–25 | 4–12 |

OEM clients must prioritize material selection against specific operational stressors. For instance, Viton’s resistance to aromatic hydrocarbons prevents seal degradation in jet engine systems, while NBR’s balance of resilience and cost efficiency suits transmission seals in commercial vehicles. Silicone’s biocompatibility and low-temperature flexibility are non-negotiable for pharmaceutical diaphragm pumps. Misapplication—such as using NBR in high-temperature fuel cells—results in rapid extrusion failure. Our engineering team validates material suitability through fluid immersion testing per ISO 1817 and thermal aging per ASTM D573, ensuring compliance with SAE AS568 or custom OEM drawings.

Suzhou Baoshida’s value proposition extends beyond standard compounds. We offer custom formulation services to modify tear strength, electrical conductivity, or FDA compliance for niche applications. All materials include full traceability via CoA (Certificate of Analysis) with lot-specific mechanical data. For mission-critical projects, we implement APQP protocols and PPAP submissions to de-risk production scaling. Partnering with us guarantees that rubber components meet the exacting demands of automotive, energy, and industrial machinery sectors—where material failure is never an option. Engage our technical team early in the design phase to optimize performance and lifecycle costs.

Manufacturing Capabilities

At Suzhou Baoshida Trading Co., Ltd., our Engineering Capability forms the backbone of our industrial rubber solutions, enabling us to deliver precision-engineered products tailored to the exacting demands of global OEMs. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we integrate material science with advanced tooling design to ensure consistent performance, durability, and manufacturability across all applications involving plexiglass plates and associated sealing or damping components.

Our mould engineers possess extensive expertise in designing and optimizing injection, compression, and transfer moulds used in the production of rubber-to-plastic bonded components. This is particularly critical in applications where plexiglass plates interface with elastomeric seals or vibration-damping elements. By leveraging 3D CAD software and finite element analysis (FEA), our team ensures dimensional accuracy, optimal material flow, and minimal cycle times. Each mould design undergoes rigorous simulation and validation protocols to prevent defects such as flash, incomplete filling, or stress concentration—common challenges when integrating rubber with rigid transparent substrates like plexiglass.

Complementing our mould engineering strength is our in-house rubber formulation capability. Our two formula engineers specialize in developing custom elastomeric compounds tailored for optical clarity compatibility, UV resistance, thermal stability, and adhesion performance—key factors when bonding rubber to plexiglass. Using advanced spectrometry and rheometric testing, they formulate compounds based on silicone, EPDM, NBR, and TPE platforms that meet specific environmental and mechanical requirements. This control over material chemistry allows us to solve complex interfacial challenges, such as differential thermal expansion between rubber and acrylic substrates, while maintaining long-term bond integrity.

Our OEM capabilities are built on a foundation of collaborative engineering. We work directly with clients during the design phase to optimize part geometry, select appropriate materials, and ensure manufacturability. This proactive approach reduces time-to-market and minimizes costly design iterations. From prototype development to high-volume production, we maintain full traceability and process control, adhering to ISO 9001 standards and customer-specific requirements.

The following table outlines key engineering parameters we manage in plexiglass-integrated rubber component manufacturing:

| Parameter | Capability | Testing Standard |

|---|---|---|

| Hardness Range (Shore A) | 30–90 | ASTM D2240 |

| Temperature Resistance | -40°C to +150°C (up to +200°C intermittent) | ASTM D573 |

| Adhesion Strength (Plexiglass) | ≥ 4.5 kN/m | ASTM D429 (Method B) |

| UV and Weathering Resistance | 1,000+ hrs QUV | ASTM G154 |

| Tolerance Control (Moulded Parts) | ±0.1 mm | ISO 2768 |

| Production Lead Time (Prototype) | 15–20 days | – |

By combining deep technical expertise in both rubber formulation and precision mould engineering, Suzhou Baoshida Trading Co., Ltd. delivers engineered solutions that meet the highest standards of performance and reliability in demanding industrial environments.

Customization Process

Customization Process for Rubber Components in Plexiglass Plate Systems

At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber solutions for industrial applications involving plexiglass (acrylic) plate assemblies. Our customization process ensures rubber components—such as seals, gaskets, and vibration dampeners—perfectly interface with acrylic substrates under demanding operational conditions. This integration is critical for maintaining structural integrity, optical clarity, and environmental resistance in end-use applications like display enclosures, medical devices, and transportation glazing systems.

The process begins with Drawing Analysis, where our engineering team scrutinizes OEM technical specifications, focusing on dimensional tolerances, load distribution, and thermal expansion coefficients between rubber and acrylic. We assess critical interfaces such as compression zones, adhesion requirements, and chemical exposure risks. This phase identifies potential stress points where rubber deformation could compromise plexiglass integrity, ensuring material selection aligns with ASTM D624 and ISO 37 standards for elastomer performance.

Next, Formulation leverages our proprietary compound database to develop a rubber matrix optimized for acrylic compatibility. Key considerations include Shore A hardness (typically 50–80) to balance sealing force without inducing acrylic stress cracking, low compression set (<20% per ASTM D395), and thermal stability matching acrylic’s expansion rate (70–100°C continuous service). We prioritize non-staining, low-extractable compounds to prevent hazing or yellowing of optical-grade plexiglass. Accelerated aging tests validate resistance to UV, ozone, and common solvents like isopropyl alcohol.

Prototyping employs CNC-machined molds to produce functional samples within 15 business days. Each prototype undergoes rigorous validation:

Dimensional verification via CMM against acrylic mating surfaces (±0.1mm tolerance)

Compression stress-deflection testing to confirm seal force uniformity

Adhesion peel tests per ASTM D903 for bonded assemblies

Thermal cycling from -40°C to 85°C to detect interfacial delamination

Upon OEM approval, Mass Production initiates under IATF 16949-certified protocols. We implement statistical process control (SPC) for critical parameters like durometer (±2 Shore A) and flash thickness (<0.15mm). Every batch undergoes 100% visual inspection for surface defects and抽样 testing for tensile strength, elongation, and compression set. Traceability is maintained via laser-etched lot codes, with full material certifications provided.

Key Rubber Properties for Plexiglass Interface Applications

| Property | Target Range | Test Standard | Significance for Plexiglass Systems |

|---|---|---|---|

| Shore A Hardness | 55–75 | ASTM D2240 | Prevents acrylic stress cracking under load |

| Compression Set (22h/70°C) | ≤18% | ASTM D395 | Ensures long-term seal retention |

| Linear Thermal Expansion | 1.8–2.5 x 10⁻⁴/°C | ASTM E831 | Matches acrylic expansion to avoid gaps |

| Tensile Strength | ≥10 MPa | ISO 37 | Resists tearing during assembly/service |

| Extractables (70°C/24h) | <1.5% | ASTM D1203 | Eliminates risk of acrylic surface hazing |

This systematic approach guarantees rubber components that enhance plexiglass plate functionality while meeting automotive, medical, and industrial OEM requirements. Suzhou Baoshida’s expertise in material science and precision manufacturing delivers solutions where rubber-acrylic synergy is non-negotiable. All processes are documented for full regulatory compliance, including REACH and RoHS directives.

Contact Engineering Team

For industrial manufacturers and OEMs seeking precision-engineered rubber components and polymer-based materials, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in high-performance industrial solutions. While our core expertise lies in advanced rubber formulations and sealing technologies, we also support complementary material needs, including plexiglass (PMMA) plates, through strategic sourcing and technical integration services. Our engineering team ensures that every material specification aligns with operational demands—whether for transparency, impact resistance, thermal stability, or chemical compatibility.

At Suzhou Baoshida, we understand that plexiglass plates are not merely aesthetic substitutes for glass; they are functional elements in control panels, protective enclosures, optical systems, and industrial machinery. That is why we apply the same rigorous standards to auxiliary materials as we do to our rubber compounds. Each plexiglass sheet is evaluated for optical clarity, surface hardness, UV resistance, and dimensional accuracy, ensuring compatibility with demanding industrial environments. Our technical team collaborates directly with clients to determine the optimal grade—whether standard, impact-modified, UV-stabilized, or anti-static—based on application parameters such as exposure to weathering, mechanical stress, or cleaning agents.

We do not merely supply materials—we engineer solutions. Our OEM clients benefit from value-added services including precision die-cutting, custom lamination, edge finishing, and co-formulation with elastomeric seals or gaskets where hybrid material systems are required. This integrated approach reduces assembly steps, enhances sealing performance, and improves long-term reliability in end-use applications.

Below are typical technical specifications for standard cast plexiglass plates we support through our supply network:

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 70–75 MPa | ISO 527 |

| Flexural Strength | 100–110 MPa | ISO 178 |

| Izod Impact Strength | 12–18 kJ/m² | ISO 180 |

| Heat Deflection Temperature (HDT) | 90–100°C at 1.8 MPa | ISO 75 |

| Light Transmission | ≥ 92% | ISO 13468 |

| Refractive Index | 1.49 | ISO 489 |

| Coefficient of Linear Thermal Expansion | 70–90 × 10⁻⁶ /K | ISO 11359 |

| Dielectric Strength | 18–22 kV/mm | IEC 60243 |

All materials are traceable, RoHS-compliant, and available in thicknesses ranging from 1 mm to 200 mm, with custom sheet sizes up to 2440 mm × 1830 mm. We also offer laser-cutting and CNC machining upon request.

For technical consultation or material sourcing support, contact Mr. Boyce, Rubber Formula Engineer and OEM Manager at Suzhou Baoshida Trading Co., Ltd. He leads our industrial solutions team and specializes in cross-material system integration. Reach out via email at [email protected] to discuss your plexiglass plate requirements, request samples, or initiate a joint development project. Our engineering desk provides full technical data sheets, compatibility assessments, and rapid prototyping coordination to accelerate your product development cycles. Partner with Suzhou Baoshida for precision, performance, and industrial-grade reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).