Technical Contents

Engineering Guide: Polyethelene Foam

Engineering Insight: Polyethylene Foam Material Selection Imperatives

In industrial applications demanding polyethylene (PE) foam, generic off-the-shelf solutions frequently compromise performance and longevity. Standard formulations prioritize cost efficiency over engineering rigor, leading to premature failure in demanding environments. Suzhou Baoshida Trading Co., Ltd. emphasizes that material selection must align with specific mechanical, thermal, and chemical exposure profiles. Failure to address these variables results in dimensional instability, loss of sealing integrity, or catastrophic compression set—directly impacting OEM product reliability and end-user safety.

The core deficiency of non-specialized PE foam lies in its unoptimized cellular structure and additive package. Commercial-grade foams often exhibit inconsistent cell density, inadequate cross-linking, and insufficient stabilizers for UV or ozone resistance. For instance, automotive gasketing exposed to engine bay temperatures exceeding 100°C rapidly degrades when using standard low-density PE foam, causing fluid leaks. Similarly, industrial packaging for precision electronics requires exact compression recovery rates; off-the-shelf variants with poor resilience fail to absorb repeated impact shocks, risking component damage. These failures stem from a one-size-fits-all approach ignoring application-specific stressors like dynamic load cycles, solvent exposure, or long-term creep resistance.

Critical material properties must be engineered at the molecular level. Key parameters include closed-cell integrity for moisture barrier performance, tailored density gradients for multi-axis load distribution, and proprietary antioxidant blends for extended service life. Below is a comparison of standard versus engineered PE foam specifications relevant to industrial use cases:

| Parameter | Standard PE Foam Limitation | Custom Solution Requirement |

|---|---|---|

| Density Range | Fixed 20-30 kg/m³ | 15-120 kg/m³ (application-specific) |

| Temperature Resistance | -20°C to +70°C (short-term) | -40°C to +110°C (continuous) |

| Compression Set (50%) | >35% after 24h @ 70°C | <15% after 168h @ 85°C |

| Tensile Strength | 0.1-0.3 MPa | 0.4-1.2 MPa (reinforced variants) |

| Chemical Resistance | Limited to water/glycol | Full resistance to oils, acids, fuels |

Suzhou Baoshida’s OEM partnership model addresses these gaps through co-engineered formulations. We analyze application data—including load duration, environmental exposure, and regulatory constraints—to modify base polymer viscosity, cross-link density, and additive synergies. For example, our PE foam for medical device shielding integrates gamma-stable antioxidants and achieves ISO 10993 biocompatibility, while aerospace variants meet FAR 25.853 flame spread requirements through halogen-free阻燃 systems.

Material selection is not a procurement decision but a foundational engineering process. Off-the-shelf PE foam sacrifices precision for accessibility, inevitably increasing total cost of ownership through field failures and warranty claims. Partnering with a specialist like Suzhou Baoshida ensures PE foam performs as an engineered component—not a disposable commodity. Contact our technical team to validate your application requirements against our ISO 9001-certified formulation protocols.

Material Specifications

Polyethylene foam is a versatile closed-cell material widely used in industrial sealing, insulation, and cushioning applications due to its excellent chemical resistance, low moisture absorption, and consistent mechanical properties. When integrated with high-performance elastomeric materials such as Viton, Nitrile, and Silicone, polyethylene foam composites achieve enhanced functionality in demanding environments. These combinations are engineered to meet rigorous OEM specifications across automotive, aerospace, electronics, and industrial equipment sectors. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision-formulated rubber solutions that ensure compatibility, durability, and performance under extreme thermal, chemical, and mechanical conditions.

Viton, a fluorocarbon-based elastomer, offers superior resistance to high temperatures, oils, fuels, and aggressive chemicals. It maintains integrity in continuous service up to 200°C and intermittent exposure up to 250°C, making it ideal for engine gaskets, fuel system seals, and chemical processing components. When bonded with polyethylene foam, Viton enhances the composite’s ability to withstand harsh operating environments while maintaining dimensional stability.

Nitrile rubber (NBR) is a cost-effective solution for applications involving petroleum-based oils and hydraulic fluids. With a service temperature range of -30°C to 100°C, and short-term resistance up to 120°C, Nitrile provides excellent abrasion resistance and tensile strength. Its compatibility with polyethylene foam enables the development of seals and dampening pads used in machinery, automotive under-hood systems, and fluid-handling equipment.

Silicone rubber excels in extreme temperature applications, functioning reliably from -60°C to 200°C. It offers good electrical insulation properties and resistance to ozone and UV radiation, though it exhibits lower mechanical strength compared to Viton or Nitrile. Silicone-polyethylene foam composites are commonly used in electronic enclosures, medical devices, and outdoor sealing applications where thermal cycling and environmental aging are critical concerns.

Each elastomer brings distinct advantages, and the selection depends on the operational environment, regulatory requirements, and performance priorities. Our engineering team at Suzhou Baoshida ensures precise material pairing, adhesive bonding techniques, and quality control to deliver consistent, high-performance rubber-foam solutions tailored to OEM needs.

The following table summarizes key physical and chemical properties of Viton, Nitrile, and Silicone when used in combination with polyethylene foam:

| Property | Viton | Nitrile (NBR) | Silicone |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 intermittent) | -30 to 100 (up to 120 intermittent) | -60 to 200 |

| Tensile Strength (MPa) | 10–15 | 8–14 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–400 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–80 | 40–80 |

| Resistance to Oils/Fuels | Excellent | Very Good | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Compression Set (22 hrs, 150°C) | Low | Moderate | Low to Moderate |

| Common Applications | Aerospace seals, chemical gaskets | Automotive seals, hydraulic systems | Electrical insulation, medical devices, outdoor seals |

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. Engineering Capability: Polyethylene Foam Solutions

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered polyethylene foam products through integrated material science and advanced manufacturing expertise. Our Industrial Rubber Solutions division combines deep formulation knowledge with rigorous tooling design to meet the exacting demands of automotive, electronics, and industrial sealing applications. Central to this capability is a dedicated engineering team comprising five specialized mold engineers and two certified rubber formula engineers. This structure ensures seamless synergy between material composition and production tooling, eliminating traditional handoff delays and quality inconsistencies.

Our formula engineers focus exclusively on optimizing polyethylene foam cross-linking chemistry, cell structure uniformity, and additive integration. They develop custom formulations addressing specific client requirements for compression set resistance, thermal stability, and chemical compatibility. Concurrently, the mold engineering team leverages CAD/CAM simulation and finite element analysis to design tooling that achieves micron-level dimensional accuracy, critical for tolerance-critical assemblies. This dual-engineering approach enables rapid prototyping cycles and guarantees first-article conformity to ISO 9001 and IATF 16949 standards.

As a certified OEM partner, we manage the entire production lifecycle under one roof—from raw material sourcing to final validation. Clients benefit from end-to-end traceability, with real-time process monitoring during extrusion, cross-linking, and calendaring stages. Our facility supports low-volume custom runs and high-volume production, maintaining ±0.1mm thickness tolerances across densities up to 200 kg/m³. Every OEM project includes comprehensive material certification, including ASTM D3574 and ISO 1856 test reports, ensuring regulatory compliance for global supply chains.

The following table summarizes key technical capabilities for our polyethylene foam products:

| Property | Standard Range | Baoshida Capability | Testing Standard |

|---|---|---|---|

| Density | 20–200 kg/m³ | 15–220 kg/m³ | ASTM D3574 |

| Compression Set (50%) | ≤15% (70°C/22h) | ≤10% (70°C/22h) | ASTM D3574 |

| Temperature Resistance | -70°C to +80°C | -75°C to +85°C | ISO 188 |

| Tensile Strength | 0.1–0.5 MPa | 0.08–0.6 MPa | ASTM D412 |

| Closed-Cell Content | ≥85% | ≥92% | ASTM D2856 |

This technical rigor extends to sustainability initiatives, where our engineers formulate recyclable PE foam variants meeting UL 94 HF-1 flammability standards without halogenated additives. Suzhou Baoshida’s engineering framework transforms complex material challenges into reliable, scalable manufacturing outcomes—proving that precision in polyethylene foam begins with integrated scientific and industrial expertise. Clients gain not just a supplier, but a co-engineering partner committed to performance validation at every production phase.

Customization Process

Drawing Analysis

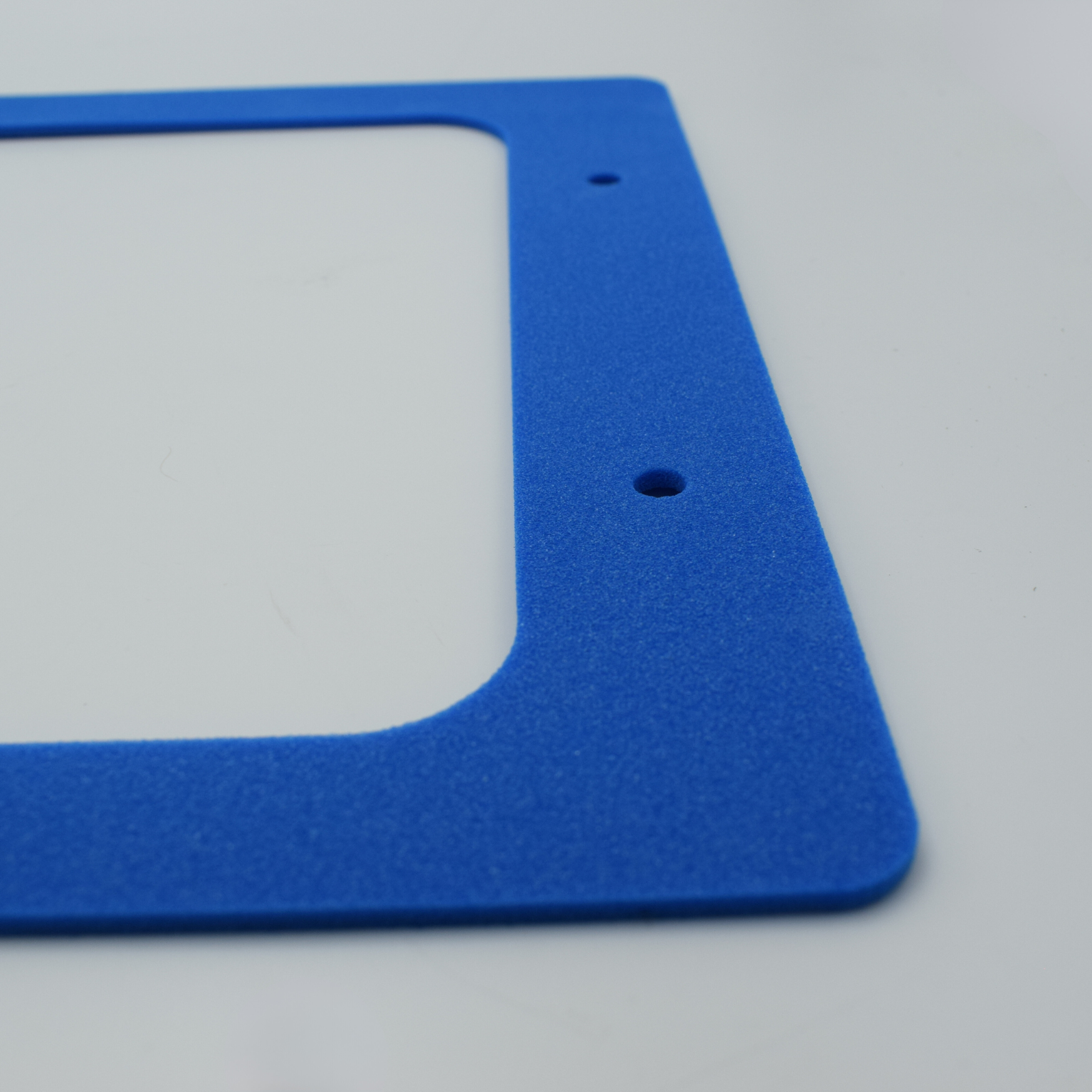

The customization process for polyethylene foam begins with a comprehensive drawing analysis, where technical blueprints provided by the client are evaluated for dimensional accuracy, tolerance requirements, and application-specific performance criteria. Our engineering team at Suzhou Baoshida Trading Co., Ltd. conducts a detailed review of cross-sectional profiles, geometric complexity, and interfacing components to ensure compatibility with downstream manufacturing processes. This phase includes assessing environmental exposure factors such as UV resistance, temperature range, and mechanical stress, which directly influence material selection and structural design. Any discrepancies or optimization opportunities are communicated to the client for clarification or design refinement prior to formulation.

Formulation Development

Following drawing validation, our rubber formula engineers initiate the formulation stage, tailoring the polyethylene foam compound to meet precise physical and chemical performance targets. The base resin is selected based on density, melt flow index, and branching structure, while additives such as cross-linking agents, blowing agents, antioxidants, and flame retardants are precisely dosed to achieve desired characteristics. Our in-house laboratory utilizes rheological testing and thermal analysis to optimize cure kinetics and foam expansion behavior. Formulation adjustments are documented and verified through controlled small-batch mixing, ensuring repeatability and compliance with industry standards such as ASTM D2856 and ISO 1926. This stage is critical in aligning the material properties with the functional demands of the end-use environment.

Prototyping and Validation

Once the formulation is finalized, a prototype run is executed using calibrated extrusion or molding equipment that simulates full-scale production conditions. The prototypes are subjected to a battery of performance tests, including compression set, tensile strength, elongation at break, and thermal conductivity. Dimensional inspection is performed using coordinate measuring machines (CMM) to verify conformity with the original drawings. Clients receive physical samples along with a full test report for evaluation. Feedback is incorporated into final adjustments, ensuring that both form and function meet exact specifications before transitioning to mass production.

Mass Production

Upon client approval of the prototype, the project advances to mass production. Our automated production lines operate under strict quality control protocols, with real-time monitoring of extrusion temperature, die pressure, and foam density. Each batch undergoes inline inspection and periodic laboratory verification to maintain consistency. Finished polyethylene foam products are packaged according to client logistics requirements and shipped with full material traceability documentation.

| Property | Test Method | Typical Range |

|---|---|---|

| Density | ASTM D3574 | 20–200 kg/m³ |

| Tensile Strength | ASTM D412 | 0.3–1.8 MPa |

| Elongation at Break | ASTM D412 | 150–500% |

| Compression Set (50%, 22h, 70°C) | ASTM D3574 | ≤30% |

| Thermal Conductivity | ASTM C518 | 0.032–0.042 W/m·K |

Contact Engineering Team

Technical Collaboration Pathway for Polyethylene Foam Manufacturing

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial scalability, specializing in engineered polyethylene (PE) foam solutions for demanding B2B applications. Our engineering team leverages 15+ years of OEM partnership experience to transform material specifications into high-performance, cost-optimized products. Whether your project requires ultra-low-density insulation for automotive NVH reduction, closed-cell marine buoyancy cores, or precision-tolerance gasketing for industrial machinery, our formulation protocols ensure repeatability under ISO 9001-certified production. We do not merely supply foam—we co-engineer material systems that resolve thermal, acoustic, and mechanical challenges while adhering to stringent regulatory frameworks including REACH, RoHS, and UL 94 flammability standards.

The following critical parameters define our PE foam performance envelope, validated through in-house ASTM D3574, D1667, and ISO 844 testing:

| Property | Range | Application Relevance |

|---|---|---|

| Density | 20–200 kg/m³ | Weight-sensitive structural components |

| Hardness (Shore OO) | 10–90 | Sealing force optimization for dynamic joints |

| Tensile Strength | 0.1–1.8 MPa | Durability in flex-critical environments |

| Compression Set (25%) | ≤15% (70°C/22h) | Long-term sealing integrity assurance |

| Thermal Conductivity | 0.032–0.045 W/m·K | Precision thermal management systems |

These values represent baseline capabilities; our true differentiation lies in proprietary crosslinking modifiers and nucleation control that enable client-specific tuning of cell structure morphology. For instance, aerospace clients requiring ASTM D1002-compliant adhesion have utilized our surface-energy-modified PE foam to eliminate primer layers in composite bonding, reducing assembly steps by 30%. Similarly, medical device manufacturers leverage our gamma-stable formulations for sterilizable packaging that maintains dimensional stability after 50 kGy exposure.

Initiate your technical engagement by contacting Mr. Boyce, our dedicated OEM Solutions Manager, who will coordinate a cross-functional engineering review within 24 business hours. Mr. Boyce holds a Master of Science in Polymer Engineering from Tongji University and has managed 200+ successful PE foam commercializations across automotive, renewable energy, and electronics sectors. His team will provide:

Material compatibility analysis against your substrate and environmental profile

Prototyping support with 72-hour turnaround for critical dimensions

Full supply chain transparency from raw material sourcing to JIS-compliant packaging

Direct all technical inquiries, RFQs, or DFM consultations to [email protected]. Include your target application, performance thresholds, and annual volume requirements to expedite our response. Suzhou Baoshida operates dual production facilities in Jiangsu Province with 12,000 tons/year capacity and automated slitting lines accommodating widths up to 2,000 mm. We enforce zero-lot-rejection protocols through real-time FTIR batch verification and maintain strategic raw material reserves of LDPE, LLDPE, and EVA copolymers to mitigate supply chain volatility. Partner with us to convert material challenges into competitive advantage—where scientific rigor meets manufacturing excellence.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).