Technical Contents

Engineering Guide: Polyurean Sound

Engineering Insight: Polyurethane Sound Damping Material Selection

Material selection for polyurethane sound damping applications represents a critical engineering decision far beyond basic hardness or density specifications. Generic, off-the-shelf polyurethane compounds frequently fail in demanding industrial acoustic environments due to insufficient consideration of dynamic mechanical behavior under operational stress. Sound energy dissipation relies fundamentally on the material’s ability to convert vibrational energy into heat through internal molecular friction, quantified by the loss factor (tan δ). Standard formulations often prioritize cost or static properties, neglecting the complex interplay between frequency, temperature, strain amplitude, and long-term environmental exposure inherent in real-world machinery. This oversight leads to inadequate damping performance, premature fatigue failure, or catastrophic resonance events when the material’s viscoelastic response does not align with the specific vibrational signature of the application.

Off-the-shelf polyurethanes commonly exhibit narrow effective damping bandwidths. A compound optimized for low-frequency isolation at room temperature may become glassy and ineffective at higher frequencies or sub-zero conditions, or overly soft and unstable at elevated temperatures. Hydrolysis resistance is another frequent failure point; standard polyester-based polyurethanes degrade rapidly in humid or wet environments common in marine, agricultural, or outdoor industrial settings, losing structural integrity and damping capability. Similarly, exposure to oils, fuels, or ozone can cause swelling, cracking, or hardening in non-formulated grades, drastically altering acoustic performance. The consequence is not merely reduced noise control but potential secondary damage from uncontrolled vibration transmission, leading to accelerated wear on bearings, shafts, or connected components, resulting in costly downtime and warranty claims.

The following table delineates key performance differentiators between generic and engineered polyurethane compounds for sound damping:

| Property | Generic Off-the-Shelf PU | Engineered PU (OEM Specification) |

|---|---|---|

| Hardness Range (Shore A) | Fixed Narrow Range (e.g., 70A ±5) | Precisely Tuned Range (e.g., 60A-95A) |

| Loss Factor (tan δ) Peak | Single Peak, Narrow Bandwidth | Multiple Peaks, Broad Bandwidth |

| Temperature Stability | Limited Range (-10°C to 60°C) | Extended Range (-40°C to 120°C+) |

| Hydrolysis Resistance | Poor (Polyester Base) | Excellent (Polyether or Specialized Polymer) |

| Dynamic Modulus Consistency | High Variability under Load | Stable Performance at Target Strain |

| Fluid Resistance | Basic Oil Resistance | Customized for Specific Fluids (Fuels, Coolants) |

| Service Life (Cyclic) | Short (High Fatigue) | Extended (Optimized Crosslink Density) |

Successful sound damping requires polyurethane formulations engineered at the molecular level to match the specific vibrational profile, environmental conditions, and lifecycle demands of the application. This involves precise control over polymer backbone chemistry (polyether vs. polyester vs. specialized hybrids), crosslink density, additive packages (antioxidants, plasticizers, fillers), and curing kinetics. Suzhou Baoshida Trading Co., Ltd. leverages deep OEM partnership experience to co-develop compounds where dynamic mechanical analysis (DMA) data directly informs the formulation. We move beyond catalog numbers to deliver precision-engineered solutions that maintain target damping performance across the operational envelope, ensuring long-term reliability and optimal acoustic control where generic materials consistently underperform. Material selection is not a component specification; it is the foundation of effective vibration management.

Material Specifications

Material Specifications for Industrial Rubber Solutions

Suzhou Baoshida Trading Co., Ltd. provides high-performance rubber compounds engineered for demanding industrial environments. In acoustic and sealing applications where durability, chemical resistance, and thermal stability are critical, selecting the appropriate elastomer is essential. Among the most widely used materials are Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each offers distinct advantages depending on operating conditions such as temperature extremes, exposure to oils and fuels, and long-term compression set resistance. Understanding the technical specifications of these materials enables OEMs and industrial designers to optimize component reliability and service life in applications related to polyurean sound systems and other precision equipment.

Viton, a fluorocarbon-based rubber, is renowned for its outstanding resistance to high temperatures, aggressive chemicals, and hydrocarbon fuels. With continuous service capability up to 230°C and intermittent exposure tolerance beyond 250°C, Viton is ideal for environments involving engine oils, lubricants, and industrial solvents. Its low gas permeability and excellent aging characteristics make it a preferred choice in high-reliability sealing applications, particularly where failure is not an option. However, Viton exhibits lower flexibility at sub-zero temperatures and higher material cost compared to alternatives.

Nitrile rubber, or Buna-N, is one of the most commonly used elastomers in industrial sealing due to its excellent resistance to petroleum-based oils and fuels. It performs reliably within a temperature range of -30°C to 120°C, with some formulations extending to 150°C for short durations. Nitrile offers good abrasion resistance and mechanical strength, making it suitable for dynamic sealing applications such as gaskets, O-rings, and diaphragms. While cost-effective and widely available, Nitrile is less resistant to ozone, UV radiation, and polar solvents, limiting its use in outdoor or highly oxidative environments.

Silicone rubber excels in extreme temperature applications, functioning effectively from -60°C to 200°C, with specialized grades capable of withstanding brief exposures up to 300°C. It demonstrates excellent resistance to UV, ozone, and weathering, along with low toxicity and good electrical insulation properties. Silicone is frequently used in acoustic dampening components and seals exposed to wide thermal cycling. However, it has relatively poor resistance to petroleum oils and lower tensile strength compared to Nitrile or Viton, necessitating careful design consideration in high-stress environments.

The following table summarizes key technical properties of these materials for comparative evaluation.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–20 | 5–8 |

| Elongation at Break (%) | 200–300 | 200–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set (22h, 150°C) | 15–25% | 20–40% | 10–20% |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Electrical Insulation | Good | Fair | Excellent |

Selection of the appropriate elastomer must balance performance requirements with cost, environmental exposure, and mechanical demands. Suzhou Baoshida Trading Co., Ltd. supports OEM partners with material data sheets, sample testing, and custom formulation services to ensure optimal integration into industrial systems.

Manufacturing Capabilities

Engineering Capability: Precision Polyurethane Sound Dampening Solutions

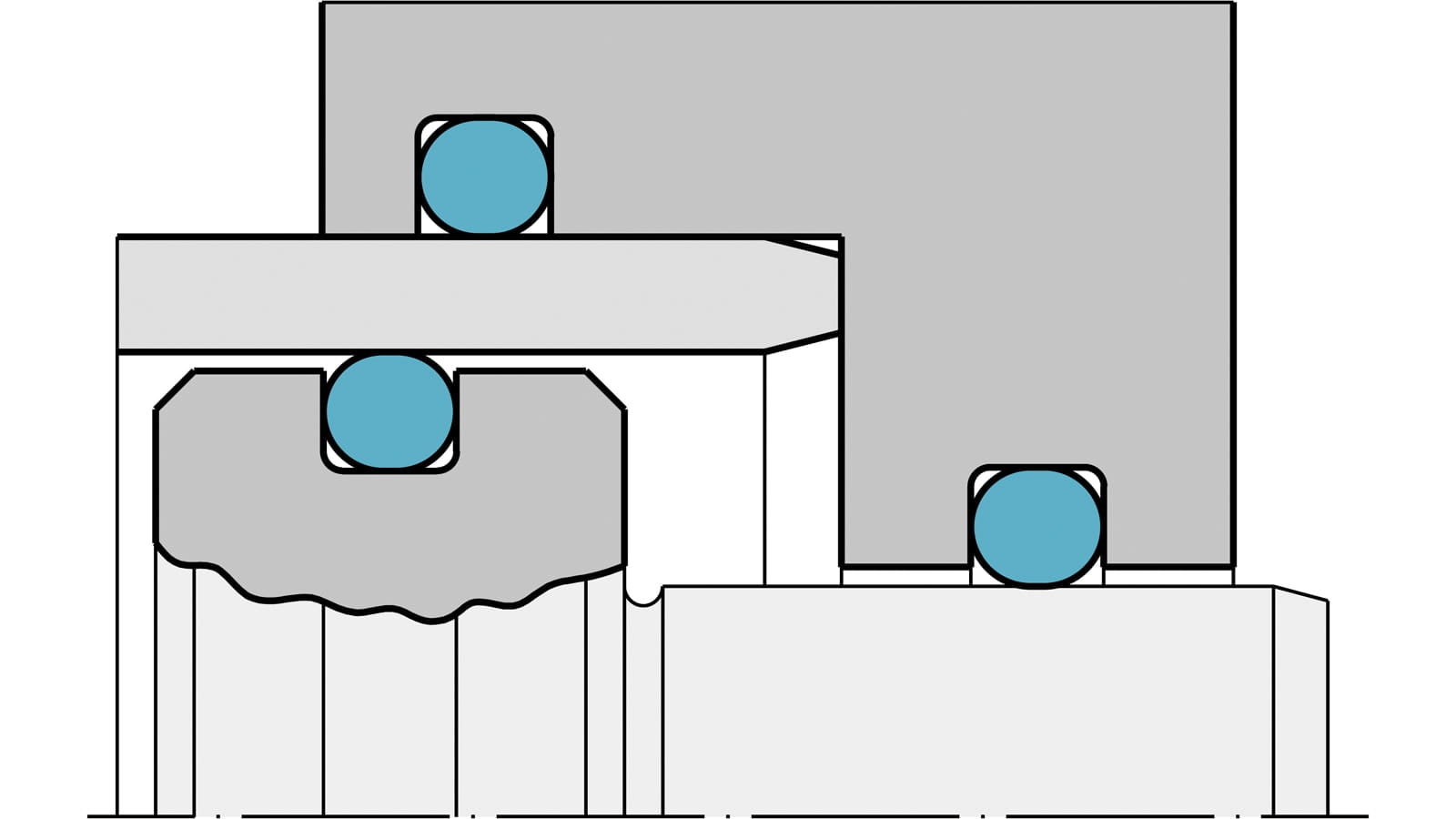

Suzhou Baoshida Trading Co., Ltd. leverages deep material science expertise and advanced manufacturing engineering to deliver superior polyurethane sound dampening solutions for industrial applications. Our core strength lies in the integrated capabilities of our dedicated engineering team, comprising five specialized Mold Engineers and two certified Rubber Formula Engineers. This structure ensures seamless translation of acoustic performance requirements into precise, manufacturable rubber components. Our Formula Engineers possess extensive knowledge of polyurethane chemistry, specifically optimizing viscoelastic behavior, density gradients, and cell structure for targeted noise absorption and vibration isolation. Concurrently, our Mold Engineering team focuses on precision tooling design, critical for achieving the complex geometries and tight tolerances demanded by modern sound management systems, particularly in controlling cavity resonance and ensuring consistent part integrity across production runs.

This dual-engineering approach enables us to solve complex acoustic challenges where standard off-the-shelf materials fail. We systematically analyze the noise frequency spectrum, environmental exposure (temperature, fluids, UV), and mechanical stress profiles of the application. Our Formula Engineers then develop bespoke polyurethane compounds, adjusting isocyanate/prepolymer ratios, catalyst systems, and filler packages to achieve the exact balance of hardness, resilience, and sound transmission loss required. The Mold Engineering team validates these formulations through rigorous prototyping, utilizing advanced flow simulation to eliminate weld lines and optimize cure profiles, ensuring the final part delivers the predicted acoustic performance consistently. This closed-loop development process minimizes iteration cycles and accelerates time-to-market for our clients.

Our OEM capabilities are built upon this engineering foundation, offering true partnership from concept to mass production. We manage the entire process in-house, including proprietary compound development, precision mold fabrication, and high-volume molding under stringent ISO 9001 controls. Clients benefit from complete IP protection, with formulations and tooling held under strict confidentiality agreements. We excel at producing complex acoustic components such as engine mounts, HVAC duct insulation, machinery enclosures, and transportation interior panels, where dimensional stability and long-term acoustic performance retention are non-negotiable.

Key performance parameters for our engineered polyurethane sound dampening materials are detailed below, illustrating the range achievable through our formulation expertise:

| Property | Standard Formulation Range | Custom Solution Capability |

|---|---|---|

| Density (kg/m³) | 300 – 800 | 200 – 1200 (Closed-cell focus) |

| Hardness (Shore A) | 30 – 90 | 15 – 95 (Dynamic tuning) |

| Sound Transmission Loss | 15 – 25 dB (1-4 kHz) | >30 dB (Targeted frequencies) |

| Compression Set (22h/70°C) | <20% | <10% (Critical for longevity) |

| Operating Temperature | -40°C to +100°C | -55°C to +130°C (Extended range) |

Suzhou Baoshida functions as a true engineering extension for global OEMs, providing not just parts, but validated acoustic performance solutions. Our commitment to scientific rigor in both material formulation and precision manufacturing ensures components that meet the most demanding specifications for noise reduction in automotive, industrial machinery, and HVAC systems. Partner with us for zero-knowledge transfer development of polyurethane sound dampening products where performance and reliability are paramount.

Customization Process

Customization Process for Polyurean Sound Applications

At Suzhou Baoshida Trading Co., Ltd., our approach to delivering high-performance industrial rubber solutions for polyurean sound applications follows a rigorous, science-driven customization pathway. This ensures that every component meets exact acoustic, mechanical, and environmental requirements. The process begins with Drawing Analysis, where engineering blueprints and 3D models are scrutinized for dimensional tolerances, load conditions, and interface specifications. Our technical team evaluates substrate compatibility, dynamic stress points, and acoustic damping zones to determine optimal material behavior under operational conditions. This stage is critical in identifying potential failure modes and aligning design intent with material capabilities.

Following drawing validation, we proceed to Formulation Design. Our rubber chemists develop proprietary polyurethane elastomer compounds tailored to the acoustic and mechanical demands of the application. Key parameters such as Shore hardness, rebound resilience, compression set, and dynamic modulus are precisely controlled. Additives for UV resistance, thermal stability, and hydrolysis resistance are incorporated as needed. The formulation phase leverages our in-house rheological and dynamic mechanical analysis (DMA) testing to simulate real-world performance under variable temperature and frequency conditions. Each compound is optimized not only for sound absorption or vibration damping but also for long-term durability in industrial environments.

Once the formulation is finalized, Prototyping is initiated using precision casting or injection molding techniques. Prototypes are subjected to a battery of tests including impedance tube analysis for sound absorption coefficient, vibration transmissibility testing, and accelerated aging. These physical validations confirm that the material performs as predicted in both acoustic and mechanical domains. Feedback from prototype testing is used to refine the formulation or geometry if necessary, ensuring a robust design before scale-up.

The final stage is Mass Production, executed in our ISO-certified manufacturing facility with full traceability and process control. Automated batching systems ensure formulation consistency, while inline quality monitoring maintains dimensional and physical property specifications. All production batches undergo final inspection and are certified with material test reports.

Below are key technical specifications achievable with our customized polyurethane solutions for polyurean sound applications:

| Property | Test Method | Typical Range |

|---|---|---|

| Shore Hardness (A/D) | ASTM D2240 | 60A to 70D |

| Tensile Strength | ASTM D412 | 15 – 45 MPa |

| Elongation at Break | ASTM D412 | 300 – 800% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤ 25% |

| Sound Absorption Coefficient (NRC) | ASTM C423 | 0.35 – 0.75 |

| Dynamic Modulus (10 Hz, 23°C) | ISO 4664-1 | 2 – 15 MPa |

| Operating Temperature Range | — | -40°C to +100°C |

This structured customization process ensures that Suzhou Baoshida delivers engineered rubber solutions with precision, consistency, and superior acoustic performance for industrial clients worldwide.

Contact Engineering Team

Technical Collaboration for Precision Polyurethane Sound Solutions

Industrial noise management remains a critical engineering challenge across manufacturing sectors, from automotive assembly lines to precision machinery operations. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered polyurethane compounds designed to address acoustic inefficiencies through material science innovation. Our formulations leverage viscoelastic damping properties to absorb and dissipate vibrational energy, directly targeting resonance frequencies that compromise operational safety and regulatory compliance. Unlike generic rubber alternatives, our polyurethane solutions undergo rigorous ASTM D1054 and ISO 18437-1 validation to ensure consistent performance under dynamic stress conditions. This precision engineering translates to measurable reductions in decibel levels—typically 15–22 dB(A) across 500–5000 Hz spectra—without sacrificing mechanical integrity or thermal stability.

To facilitate seamless integration into your production ecosystem, we provide fully documented material specifications aligned with OEM requirements. The table below summarizes core parameters for our standard acoustic polyurethane series, all customizable to meet project-specific acoustic profiles and environmental constraints.

| Property | Test Standard | Value Range | Units |

|---|---|---|---|

| Density | ASTM D792 | 1.10–1.25 | g/cm³ |

| Hardness (Shore A) | ASTM D2240 | 45–90 | — |

| Sound Absorption Coefficient | ISO 10534-2 | 0.65–0.92 | — |

| Operating Temperature | ASTM D2240 | -40°C to +120°C | °C |

| Tensile Strength | ASTM D412 | 15–35 | MPa |

| Compression Set (22h/70°C) | ASTM D395 | ≤18% | % |

These metrics reflect batch-tested data from our ISO 9001-certified production facilities, where raw material traceability and in-process quality control are non-negotiable. Each compound is formulated to balance acoustic efficacy with durability—critical for applications demanding 10,000+ hour service life under continuous vibration. Our engineering team collaborates directly with OEMs to refine formulations based on spectral analysis of target noise sources, ensuring optimal damping at problem frequencies rather than broad-spectrum compromises. This approach minimizes material waste and accelerates time-to-compliance for clients facing stringent EU Machinery Directive 2006/42/EC or OSHA 1910.95 regulations.

Initiating a technical partnership with Suzhou Baoshida begins with a granular assessment of your acoustic challenge. Forward your noise spectrum reports, environmental conditions, and dimensional constraints to Mr. Boyce, our dedicated OEM Solutions Manager. He will coordinate a formulation review within 48 hours, providing data-driven recommendations for material selection and integration protocols. Mr. Boyce’s expertise spans 12+ years in polymer acoustics, with direct involvement in projects for Tier-1 automotive suppliers and industrial robotics manufacturers. Contact him exclusively at [email protected] to schedule a confidential consultation. Include reference code SB-PS-2024 in your correspondence to prioritize engineering resource allocation.

Suzhou Baoshida operates at the intersection of polymer chemistry and industrial pragmatism. We do not sell standardized products—we deliver validated noise control outcomes. Partner with us to transform acoustic liabilities into engineered advantages, backed by Suzhou Baoshida’s commitment to precision, scalability, and technical accountability. Your next decibel reduction milestone starts with a single email.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).