Technical Contents

Engineering Guide: Polyurethane Extrusion

Engineering Insight: Polyurethane Extrusion Material Selection Criticality

Polyurethane extrusion demands rigorous material science alignment with application-specific stressors. Off-the-shelf polyurethane compounds frequently fail in industrial environments due to generic formulations prioritizing cost over performance parameters. These standard materials lack tailored molecular architecture to withstand dynamic variables such as extreme temperature cycling, aggressive chemical exposure, or sustained mechanical loading. Consequently, premature degradation occurs—evidenced by seal extrusion in hydraulic systems, surface cracking in mining conveyor belts, or catastrophic compression set in automotive suspension bushings. Such failures directly impact OEM equipment uptime and lifecycle costs, proving that material selection is not a procurement decision but a core engineering function.

The root cause lies in unmodified polyurethane chemistry. Generic polyethers or聚酯 polyesters exhibit narrow operational windows. For instance, standard polyester-based PU rapidly hydrolyzes in humid conditions above 40°C, while polyether variants suffer ozone-induced surface crazing. Aromatic isocyanate prepolymers yellow and lose tensile strength under UV exposure—unacceptable for outdoor applications. Crucially, off-the-shelf compounds rarely optimize the critical balance between hardness, elongation, and resilience. High-durometer grades often sacrifice flexibility, leading to brittle fracture during extrusion or in-service flexing. Conversely, low-durometer formulations may lack the modulus to resist extrusion gaps under pressure.

Suzhou Baoshida Trading Co., Ltd. addresses this through precision polymer engineering. We co-develop extrusion compounds by modifying isocyanate types (MDI, TDI, or aliphatic HDI), polyol selection, and additive packages to target OEM requirements. Our process begins with stressor mapping: defining peak operating temperatures, fluid compatibility, and dynamic load profiles. This informs custom crosslink density adjustments and nano-reinforcement strategies—such as silane coupling agents for adhesion or ceramic fillers for abrasion resistance. The result is a compound engineered for extrusion stability and end-use longevity, not merely baseline compliance.

Consider the performance divergence illustrated below between generic and engineered polyurethanes:

| Property | Generic PU Compound | Baoshida Engineered PU Compound |

|---|---|---|

| Hardness Range (Shore A) | 70–90 (fixed) | 55–95 (customizable) |

| Tensile Strength | 25–35 MPa | 40–65 MPa |

| Elongation at Break | 300–450% | 400–600% |

| Compression Set (70°C/22h) | 25–35% | 8–15% |

| Operating Temperature | -20°C to +80°C | -40°C to +120°C |

| Hydraulic Fluid Resistance | Moderate (swell >15%) | Excellent (swell <5%) |

This data underscores why standardized solutions falter. Generic compounds cannot simultaneously achieve low compression set and high elongation—critical for dynamic seals. Our engineered grades maintain structural integrity under hydraulic pressures exceeding 500 bar while resisting biodiesel and phosphate ester fluids. For extrusion processing, we optimize melt viscosity and cure kinetics to prevent surface defects like sharkskin or melt fracture, ensuring dimensional consistency in complex profiles.

Ultimately, polyurethane extrusion success hinges on material science rigor. Suzhou Baoshida Trading Co., Ltd. partners with OEMs to transform failure analysis into formulation blueprints, eliminating the cost of premature part replacement through chemistry-first engineering. The investment in custom material development yields direct returns in equipment reliability and operational efficiency.

Material Specifications

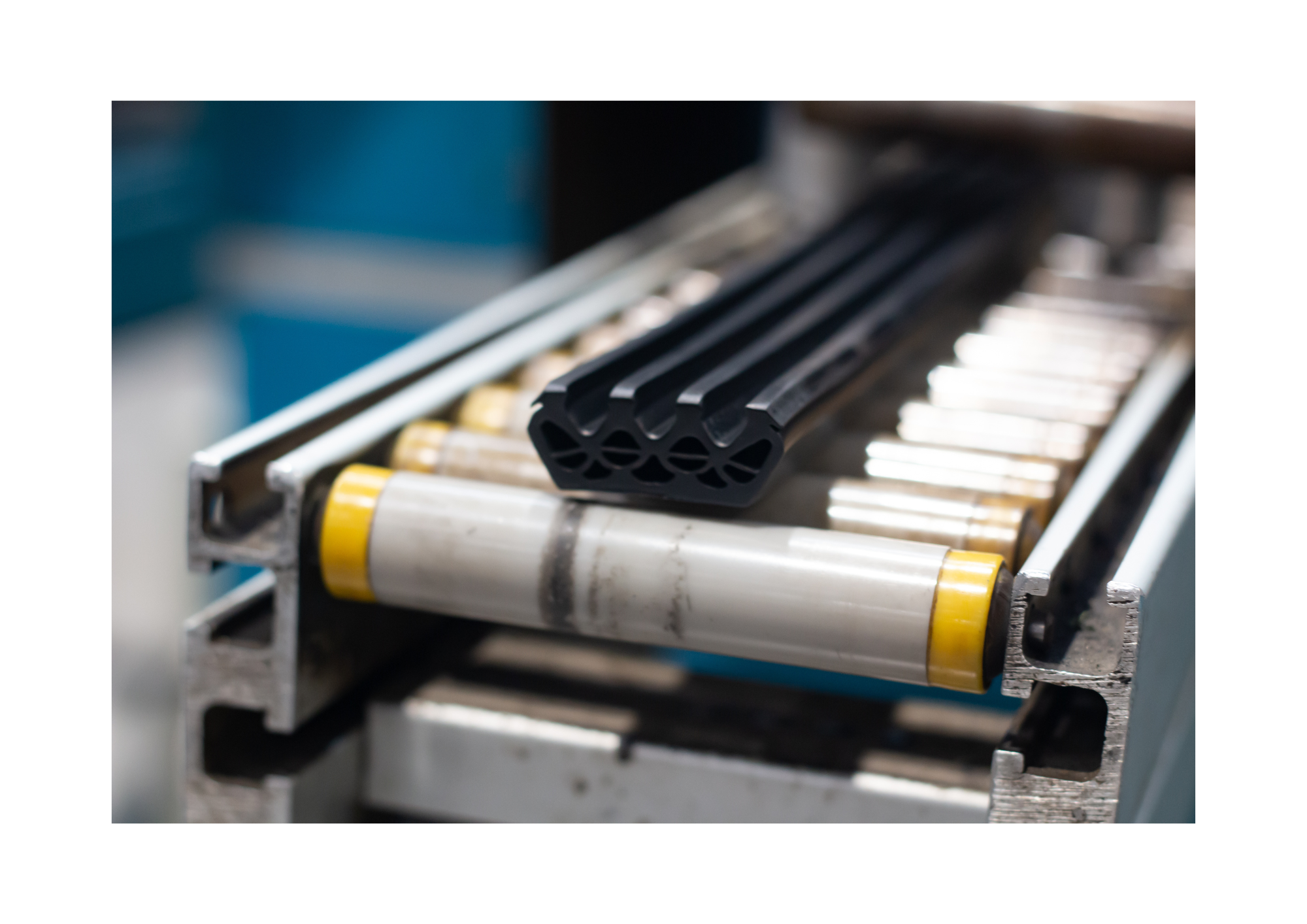

Polyurethane extrusion is a critical process in industrial rubber manufacturing, delivering high-performance seals, gaskets, and protective profiles for demanding environments. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision extrusion solutions using advanced elastomeric materials, including Viton, Nitrile (NBR), and Silicone. Each material offers distinct chemical, thermal, and mechanical properties, making them suitable for specific operational conditions. Understanding these differences is essential for selecting the optimal compound for your application.

Viton, a fluorocarbon-based rubber (FKM), is renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. It performs reliably in continuous service temperatures up to 230°C (446°F), with short-term exposure capability exceeding 300°C. This makes Viton ideal for aerospace, automotive fuel systems, and chemical processing equipment where long-term stability under extreme conditions is required. Its low gas permeability and excellent aging characteristics further enhance its suitability for critical sealing applications.

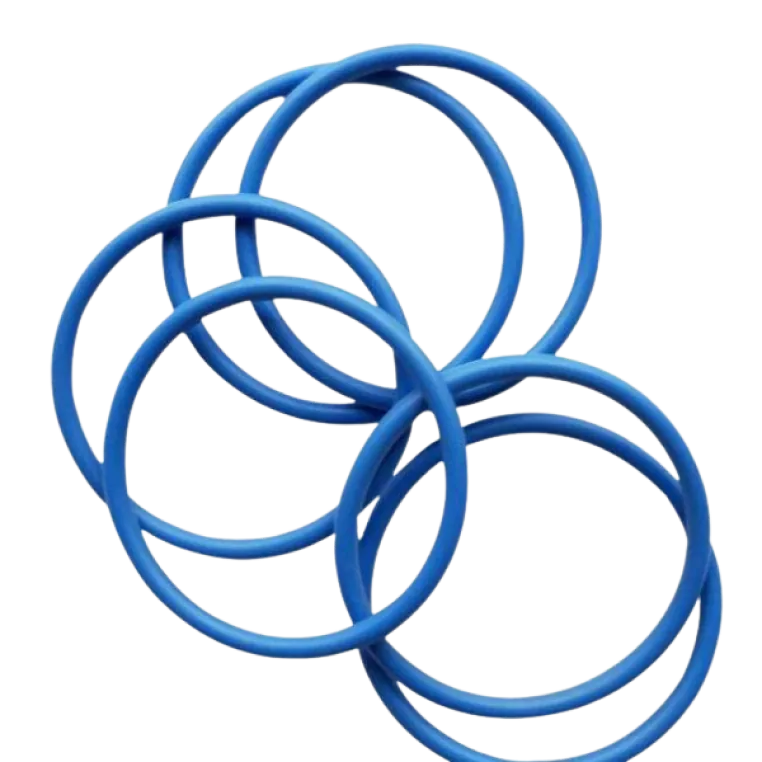

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is one of the most widely used elastomers in industrial applications due to its excellent resistance to petroleum-based oils and fuels. With a standard operating temperature range of -30°C to 105°C (-22°F to 221°F), Nitrile provides a balanced performance profile for hydraulic systems, O-rings, and gaskets in machinery and automotive sectors. While not as thermally stable as Viton, Nitrile offers superior abrasion resistance and tensile strength, particularly in dynamic sealing environments. It is also more cost-effective, making it a preferred choice for general-purpose applications.

Silicone rubber (VMQ) excels in extreme temperature applications, with continuous service capabilities from -60°C to 200°C (-76°F to 392°F), and brief exposure up to 250°C. It demonstrates outstanding resistance to ozone, UV radiation, and weathering, making it ideal for outdoor, medical, and high-purity environments. Silicone is inherently inert and meets stringent regulatory standards, including FDA and USP Class VI. However, it has lower mechanical strength and poor resistance to petroleum-based fluids, limiting its use in high-stress or oil-exposed applications.

The selection of the appropriate elastomer for polyurethane extrusion must consider the interplay between temperature, chemical exposure, mechanical stress, and regulatory requirements. Our engineering team at Suzhou Baoshida supports OEMs with material testing, formulation customization, and extrusion optimization to ensure performance consistency and regulatory compliance.

Below is a comparative overview of the key specifications for Viton, Nitrile, and Silicone:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 105 | -60 to 200 |

| Temperature Range (°F) | -4 to 446 | -22 to 221 | -76 to 392 |

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–8 |

| Elongation at Break (%) | 200–300 | 200–500 | 200–700 |

| Hardness (Shore A, typical) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| FDA Compliance | Select Grades | Limited | Yes (Standard) |

Material selection directly impacts extrusion quality, service life, and system reliability. Suzhou Baoshida Trading Co., Ltd. ensures precision in every extruded profile through rigorous material control and process engineering.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. Polyurethane Extrusion Engineering Capability

Suzhou Baoshida Trading Co., Ltd. delivers precision polyurethane extrusion solutions underpinned by rigorous engineering expertise. Our dedicated team comprises five specialized mold engineers and two advanced formula engineers, collectively ensuring seamless integration from molecular design to final profile geometry. This integrated approach addresses the core challenges of polyurethane extrusion: managing viscoelastic behavior, thermal stability, and dimensional accuracy under high-pressure processing. Our formula engineers optimize polymer chemistry—fine-tuning isocyanate indices, chain extenders, and additive packages—to achieve targeted mechanical properties while maintaining extrusion stability. Concurrently, mold engineers design and validate tooling that compensates for die swell, minimizes flow-induced defects, and ensures consistent cross-sectional integrity across complex profiles. This synergy eliminates iterative prototyping delays, reducing development cycles by up to 40% for demanding industrial applications.

Our OEM capabilities extend beyond manufacturing to full co-engineering partnerships. We manage intellectual property protection rigorously while collaborating on material specification, tolerance validation, and process parameter optimization. Clients benefit from our in-house DOE (Design of Experiments) framework, which systematically evaluates formulation variables against extrusion performance metrics. This methodology guarantees reproducibility across production scales—from pilot batches to high-volume runs—while adhering to ISO 9001:2015 and IATF 16949 standards. Critical to our success is the ability to tailor polyurethane systems for extreme service conditions, including dynamic sealing, abrasion resistance, and chemical exposure, without compromising extrusion efficiency.

The table below summarizes key extrudable polyurethane specifications achievable through our engineered systems:

| Property | Standard Range | Custom Capability | Testing Standard |

|---|---|---|---|

| Hardness (Shore A/D) | 60A to 95A, 40D to 75D | 55A to 98A, 35D to 80D | ASTM D2240 |

| Tensile Strength | 25–50 MPa | Up to 65 MPa | ASTM D412 |

| Elongation at Break | 300–600% | 250–700% | ASTM D412 |

| Compression Set (70°C) | ≤25% (22h) | ≤18% (22h) | ASTM D395 |

| Operating Temperature | -40°C to +100°C | -55°C to +120°C | ISO 188 |

Formula engineers leverage real-time rheological data from our twin-screw extrusion lines to adjust crosslink density and phase separation kinetics, directly influencing extrudate surface finish and internal cohesion. Mold engineers utilize 3D flow simulation (Moldflow) to predict and correct flow imbalances, ensuring uniform material distribution even in multi-cavity or asymmetric profiles. This technical mastery allows us to consistently produce extrusions with ±0.05mm dimensional tolerances and surface roughness (Ra) below 1.6μm—critical for automotive seals, hydraulic wipers, and industrial conveyor components.

As your OEM partner, we prioritize technical transparency and scalability. Our engineering team provides comprehensive process documentation, including FMEA reports and material traceability logs, enabling seamless integration into your supply chain. By combining deep formulation science with precision tooling expertise, Suzhou Baoshida transforms polyurethane extrusion from a manufacturing process into a strategic advantage for global industrial clients.

Customization Process

Customization Process for Polyurethane Extrusion at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet the exact performance and dimensional requirements of our global OEM partners. In polyurethane extrusion, customization is not a one-size-fits-all process. We follow a rigorous, four-phase development pathway: Drawing Analysis, Formulation, Prototyping, and Mass Production. This structured approach ensures precision, repeatability, and compliance with technical standards across industries such as automotive, construction, and industrial machinery.

The process begins with Drawing Analysis, where our engineering team evaluates customer-provided technical drawings, 2D/3D models, and performance specifications. We assess critical parameters including cross-sectional geometry, dimensional tolerances, surface finish requirements, and environmental exposure conditions. Our engineers conduct a Design for Manufacturability (DFM) review to identify potential extrusion challenges such as wall thinning, die swell, or material flow inconsistencies. This phase ensures that the design is optimized for seamless transition into production.

Next, we proceed to Formulation, a core competency in our polyurethane extrusion services. Based on the operational environment—such as temperature range, UV exposure, abrasion resistance, or chemical contact—our rubber chemists develop a custom polyurethane compound. We utilize both polyester and polyether-based polyurethanes, selecting additives for enhanced UV stability, flame retardancy, or low-temperature flexibility. The formulation is validated through laboratory testing for hardness (Shore A 60–95), tensile strength, elongation at break, and compression set.

Once the compound is finalized, we move to Prototyping. Using precision extrusion dies manufactured in-house, we produce short-run samples under production-intent conditions. These prototypes undergo dimensional verification via coordinate measuring machines (CMM) and are subjected to application-specific performance tests, including dynamic flexing, weathering, and sealing pressure evaluation. Customer feedback is integrated at this stage, allowing for die adjustments or material refinement before final approval.

The final phase is Mass Production, where we scale to high-volume output with strict process control. Our extrusion lines operate under ISO 9001-certified protocols, with real-time monitoring of temperature profiles, line speed, and cooling parameters. All finished profiles are inspected for dimensional consistency and surface defects before packaging and shipment.

The following table outlines key technical specifications achievable through our polyurethane extrusion process:

| Parameter | Range/Value |

|---|---|

| Material Types | Polyester, Polyether PU |

| Hardness (Shore A) | 60–95 |

| Cross-Sectional Tolerance | ±0.1 mm to ±0.3 mm (based on size) |

| Standard Lengths | Cut-to-length or continuous reels |

| Temperature Resistance | -40°C to +100°C (up to +120°C intermittent) |

| Standard Colors | Black, Gray, Custom (Pantone match) |

| Certifications Available | RoHS, REACH, UL (upon request) |

Through this systematic customization process, Suzhou Baoshida ensures that every polyurethane extruded profile delivers optimal performance, durability, and compatibility with the end application.

Contact Engineering Team

Optimizing Polyurethane Extrusion Outcomes Through Precision Engineering Partnerships

Suzhou Baoshida Trading Co., Ltd. delivers engineered polyurethane extrusion solutions for demanding industrial applications where material performance directly impacts product lifecycle and operational safety. Our technical team specializes in formulating custom polyurethane compounds that address extrusion challenges such as thermal degradation, inconsistent durometer distribution, and surface defects inherent in high-volume production. By integrating proprietary catalyst systems and real-time rheological monitoring, we achieve dimensional tolerances within ±0.05 mm and Shore A hardness consistency of ±3 points—critical for automotive seals, conveyor components, and hydraulic wipers operating under extreme pressure or temperature fluctuations.

Our extrusion process leverages dual-stage metering screws and laser-calibrated die geometries to eliminate common failure modes like melt fracture or vulcanization scorch. The table below summarizes core technical capabilities validated across 120+ OEM projects:

| Parameter | Standard Range | Precision Tier (OEM) | Testing Standard |

|---|---|---|---|

| Shore Hardness | 55A–95A | 60A–90A (±1.5 pts) | ISO 7619-1 |

| Extrusion Speed | 0.5–2.0 m/min | 1.2–1.8 m/min (±3%) | ASTM D2240 |

| Temp Tolerance | 80–110°C | 95±2°C (barrel) | ISO 22313 |

| Tensile Strength | 25–45 MPa | 35–42 MPa (min) | ISO 37 |

| Elongation at Break | 300–550% | 400–500% (±5%) | ISO 37 |

These specifications reflect our ISO 9001-certified production environment, where every compound batch undergoes pre-extrusion DSC analysis and post-production FTIR verification to ensure molecular crosslink density meets application-specific stress requirements. Unlike generic rubber suppliers, Baoshida’s engineers collaborate during the design phase to model extrusion flow dynamics using Moldflow simulation, preemptively resolving issues like die swell or cure inhibition that cause costly scrap rates in high-mix manufacturing.

Initiate a technical consultation with Mr. Boyce, our OEM Technical Director, to receive a data-driven extrusion feasibility assessment for your next project. Mr. Boyce holds 14 years of polyurethane formulation experience across Tier-1 automotive and industrial machinery sectors, with documented success reducing customer rework costs by 22–37% through compound optimization. Contact him directly at [email protected] with your material datasheet, dimensional drawings, and operational parameters. Specify “PU Extrusion Technical Query” in the subject line to expedite engineering resource allocation. We respond to all qualified submissions within 8 business hours with actionable process recommendations—not generic sales literature.

Partnering with Baoshida transforms extrusion from a production bottleneck into a competitive advantage. Our closed-loop quality system ensures every meter of extruded polyurethane meets your functional requirements while maintaining cost efficiency at scale. Forward your technical challenge today to validate how our material science expertise delivers measurable performance gains in your supply chain.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).