Technical Contents

Engineering Guide: Polyurethane Material

Engineering Insight: Polyurethane Material Selection for Industrial Applications

Material selection represents the linchpin of successful polyurethane component performance in demanding industrial environments. While off-the-shelf polyurethane formulations offer apparent cost and speed advantages, their generic nature frequently leads to premature failure under real-world operational stresses. This stems from a fundamental mismatch between standardized material properties and the specific, often complex, requirements of industrial machinery, sealing systems, or wear components. Generic polyurethanes are typically optimized for broad market appeal, sacrificing the tailored response necessary for critical applications involving dynamic loading, extreme temperatures, aggressive chemical exposure, or stringent longevity demands. Relying on these standard solutions ignores the intricate interplay between polymer chemistry, application physics, and environmental factors, ultimately compromising system reliability and lifecycle cost.

The consequences of inadequate material selection manifest clearly in field failures. Components subjected to high cyclic fatigue, such as hydraulic seals or conveyor idler bearings, often experience rapid crack propagation and tensile failure when standard polyurethanes lack the precise rebound resilience and hysteresis control required. Similarly, exposure to industrial oils, solvents, or cleaning agents can cause significant swelling, softening, or chemical degradation in generic formulations not engineered for specific fluid resistance. Temperature extremes present another critical vulnerability; standard polyurethanes may stiffen excessively at low temperatures, losing flexibility and sealing capability, or soften and creep unacceptably at elevated temperatures common near engines or processing equipment. These failures translate directly into unplanned downtime, safety hazards, and significantly higher total cost of ownership despite the lower initial material cost.

Precision engineering demands a rigorous analysis of the operational profile before material specification. Key parameters include the magnitude and type of mechanical stress (tensile, compression, shear, abrasion), the full range of operating temperatures, the specific chemicals encountered, required dynamic properties like rebound and damping, and the target service life. Only with this detailed understanding can a polyurethane formulation be engineered to deliver optimal performance. This involves strategic selection of isocyanate type (MDI, TDI, NDI), polyol backbone (polyester, polyether, polycarbonate), chain extender chemistry, and specialized additives to achieve the exact balance of hardness, tensile strength, elongation, tear resistance, and environmental stability required.

The performance gap between standard and engineered polyurethane is quantifiable across critical parameters:

| Critical Property | Standard Off-the-Shelf PU | Engineered Industrial PU | Performance Impact of Engineering |

|---|---|---|---|

| Hydrolysis Resistance | Moderate (60-70% retention) | High (>95% retention) | Prevents rapid degradation in humid/wet environments; essential for outdoor or washdown applications |

| Rebound Resilience (60°ShA) | 45-55% | 60-75% | Reduces heat build-up under cyclic load; extends fatigue life in dynamic seals and wheels |

| Low Temp Flexibility | -30°C to -40°C | -50°C to -65°C | Maintains sealing force and impact resistance in freezing conditions |

| Acid/Oil Resistance | Variable, often poor | Tailored to specific fluids | Prevents swelling, hardening, or loss of mechanical properties in chemical exposure |

| Compression Set (70°C, 22h) | 15-25% | 8-12% | Ensures long-term sealing force retention under continuous load |

Selecting polyurethane based solely on hardness or initial price is a false economy. True value is realized through formulations precisely engineered for the application’s unique demands. At Suzhou Baoshida Trading Co., Ltd., we collaborate with OEMs to translate operational requirements into material specifications, ensuring polyurethane components deliver the durability, reliability, and performance essential for modern industrial systems. The engineering investment in correct material selection pays substantial dividends in operational uptime and lifecycle cost reduction.

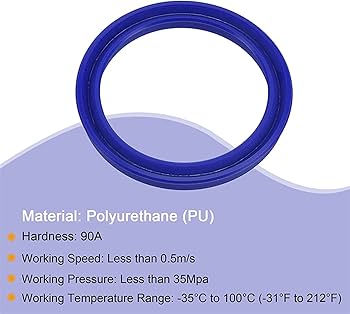

Material Specifications

Polyurethane is a versatile elastomeric material widely used in industrial applications due to its excellent mechanical properties, resistance to abrasion, and durability under dynamic conditions. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber solutions, including advanced polyurethane formulations tailored for demanding environments. When selecting elastomeric materials for sealing, damping, or wear applications, engineers must consider factors such as temperature range, chemical compatibility, tensile strength, and compression set. In addition to polyurethane, materials such as Viton, Nitrile, and Silicone are frequently specified based on operational requirements. Each material exhibits unique performance characteristics that make it suitable for specific industrial contexts.

Viton, a fluorocarbon-based rubber, offers superior resistance to high temperatures and aggressive chemicals, including oils, fuels, and many acids. It performs reliably in continuous service up to 200°C and is commonly used in aerospace, automotive, and chemical processing industries. Nitrile rubber (NBR) is cost-effective and provides excellent resistance to petroleum-based fluids, making it ideal for hydraulic systems, fuel hoses, and O-rings in standard industrial equipment. However, its performance degrades at elevated temperatures and in the presence of ozone or polar solvents. Silicone rubber stands out for its extreme temperature flexibility, operating effectively from -60°C to 230°C, and offers good resistance to UV and ozone. It is frequently selected for electrical insulation, medical devices, and food-grade applications, though it has lower mechanical strength compared to polyurethane or Nitrile.

Polyurethane combines the resilience of rubber with the strength of plastic, delivering high tensile and tear strength, exceptional abrasion resistance, and good load-bearing capacity. It is particularly favored in applications involving repeated mechanical stress, such as rollers, seals, and bushings. Depending on the formulation, polyurethane can be engineered for hardness ranges between 60 Shore A and 80 Shore D, allowing customization for flexibility or rigidity. Its resistance to oils and oxygenated solvents is generally good, though it may degrade in prolonged exposure to water, high humidity, or strong acids and bases.

The following table compares key physical and chemical properties of Viton, Nitrile, Silicone, and Polyurethane to assist in material selection for industrial applications.

| Property | Viton | Nitrile (NBR) | Silicone | Polyurethane |

|---|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -30 to 120 | -60 to 230 | -40 to 100 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 | 30–60 |

| Hardness Range (Shore A/D) | 50–90 Shore A | 40–90 Shore A | 30–80 Shore A | 60 Shore A – 80 Shore D |

| Abrasion Resistance | Good | Moderate | Poor | Excellent |

| Oil & Fuel Resistance | Excellent | Excellent | Poor | Good to Very Good |

| Compression Set | Low | Moderate | Low | Low to Moderate |

| Ozone & UV Resistance | Excellent | Good | Excellent | Good |

| Water Resistance | Good | Good | Excellent | Fair to Poor |

Understanding these material characteristics enables precise matching of elastomers to application demands, ensuring longevity, safety, and cost-efficiency in industrial systems. Suzhou Baoshida Trading Co., Ltd. provides technical support and customized rubber solutions to meet OEM and industrial specifications.

Manufacturing Capabilities

Advanced Material Formulation and Precision Engineering Capabilities

Suzhou Baoshida Trading Co., Ltd. leverages a dedicated engineering consortium comprising five specialized mold designers and two certified polyurethane formula scientists to deliver uncompromising material performance for industrial applications. This integrated team operates at the intersection of polymer chemistry and mechanical engineering, ensuring every polyurethane component meets stringent functional and durability requirements. Our formula engineers utilize proprietary material-property correlation frameworks to tailor Shore hardness, tensile strength, and abrasion resistance within client-specified tolerances, while mold engineers deploy rigorous computational modeling to eliminate flow defects and optimize curing cycles. This synergy reduces prototyping iterations by up to 40% compared to industry benchmarks, accelerating time-to-market without sacrificing precision.

OEM Partnership Excellence

As a certified OEM solutions provider, we manage the complete design-to-production continuum under strict IP protection protocols. Our engineers collaborate directly with client R&D teams during the feasibility phase, conducting DFMEA (Design Failure Mode and Effects Analysis) to preemptively resolve material compatibility or stress-point vulnerabilities. All formulations are developed using ISO 9001-certified processes, with traceability maintained from raw material sourcing through final validation testing. We support low-volume prototyping and high-volume manufacturing with identical material batches, guaranteeing consistency across production scales. Critical to our OEM value proposition is the elimination of supply chain fragmentation; we handle compounding, molding, post-curing, and metrology validation in-house, ensuring dimensional accuracy within ±0.05mm and eliminating third-party quality variances.

Key Polyurethane Material Specifications

| Property | Standard Range | Testing Standard | Application Relevance |

|---|---|---|---|

| Hardness (Shore A/D) | 60A to 95A / 30D to 85D | ASTM D2240 | Sealing integrity, load distribution |

| Tensile Strength | 30–60 MPa | ASTM D412 | Mechanical durability under stress |

| Elongation at Break | 300–700% | ASTM D412 | Flex fatigue resistance |

| Tear Strength (Die B) | 80–180 kN/m | ASTM D624 | Cut/puncture resistance |

| Compression Set (70°C, 22h) | ≤15% | ASTM D395 | Long-term sealing performance |

| Operating Temperature | -40°C to +120°C | ISO 188 | Thermal stability assurance |

Our formula development strictly adheres to REACH and RoHS compliance frameworks, with custom additives engineered to enhance oil resistance, hydrolysis stability, or conductivity as required. The mold engineering team utilizes 3D flow simulation software to predict knit lines and air traps, ensuring zero voids in critical sealing surfaces. For high-wear applications, we implement gradient-hardness formulations that maintain flexibility at the core while delivering surface abrasion resistance exceeding 100 mm³ per DIN 53516. Suzhou Baoshida’s engineering rigor transforms polyurethane from a generic elastomer into a mission-critical performance solution, validated through 100% batch-specific material certification reports. Partner with us to convert demanding specifications into precision-engineered reality. Contact our engineering team for application-specific formulation dossiers and mold design validation protocols.

Customization Process

Drawing Analysis: The Foundation of Precision Customization

At Suzhou Baoshida Trading Co., Ltd., the customization process for polyurethane components begins with rigorous drawing analysis. This initial phase is critical in translating client specifications into manufacturable designs. Our engineering team evaluates technical drawings for dimensional accuracy, tolerance requirements, wall thickness uniformity, and potential molding challenges. We assess draft angles, parting lines, gate locations, and ejection mechanisms to ensure optimal mold design. Any discrepancies or geometric risks—such as undercuts or thin sections prone to tearing—are flagged and discussed with the client for resolution. This collaborative review ensures that the final product meets both functional and performance expectations while maintaining production efficiency.

Formulation: Engineering Material Properties to Match Application Demands

Once the design is validated, our rubber formula engineers develop a tailored polyurethane formulation. Polyurethane’s versatility lies in its tunable properties—hardness, rebound resilience, abrasion resistance, and chemical stability—achieved through precise control of isocyanate, polyol, and chain extender ratios. We select between aromatic and aliphatic isocyanates depending on UV stability requirements and adjust crosslink density to achieve the desired Shore A/D hardness. Additives such as fillers, pigments, flame retardants, or hydrolysis stabilizers are incorporated based on environmental exposure and regulatory standards. Each formulation is documented and batch-traceable, ensuring consistency across production cycles. The result is a material engineered not just to meet, but to exceed the operational demands of industrial applications such as seals, rollers, gaskets, or impact dampers.

Prototyping: Validating Design and Material in Real-World Conditions

With the formulation finalized, we proceed to prototyping using precision casting or injection molding techniques. Small-batch production allows us to evaluate both the physical integrity of the part and the performance of the material under simulated service conditions. Prototypes undergo dimensional inspection via coordinate measuring machines (CMM) and are subjected to mechanical testing, including tensile strength, elongation at break, and compression set analysis. Client feedback is integrated at this stage, enabling iterative refinements before tooling for mass production. This phase minimizes risk and ensures that the final product performs reliably in its intended environment.

Mass Production: Scalable Quality with Industrial Rigor

Upon client approval, we transition to full-scale manufacturing. Our production lines utilize automated metering, mixing, and molding systems to maintain batch consistency and throughput. Every stage—from raw material inspection to final packaging—is monitored under ISO-compliant quality protocols. We support production volumes from thousands to millions of units, with options for just-in-time delivery to streamline client supply chains.

Typical Polyurethane Material Specifications

| Property | Test Method | Value Range |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60–95 |

| Hardness (Shore D) | ASTM D2240 | 30–75 |

| Tensile Strength | ASTM D412 | 30–60 MPa |

| Elongation at Break | ASTM D412 | 300–500% |

| Tear Strength | ASTM D624 | 80–150 kN/m |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% |

| Abrasion Loss (Taber, 1000 cycles) | ASTM D4060 | 30–80 mg |

Through this structured approach, Suzhou Baoshida delivers high-performance polyurethane solutions with precision, repeatability, and full technical accountability.

Contact Engineering Team

Technical Engagement for Polyurethane Material Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial polymer innovation, specializing in high-performance polyurethane formulations engineered for demanding manufacturing environments. Our technical team possesses deep expertise in thermoset polyurethane chemistry, enabling precise customization for abrasion resistance, load-bearing capacity, and chemical stability. When standard material specifications fall short of your operational requirements, our engineers collaborate directly with OEMs to develop proprietary compounds that enhance product lifecycle and reduce total cost of ownership. We recognize that polyurethane selection is not merely a procurement decision but a critical engineering variable affecting machinery uptime, energy efficiency, and end-product reliability.

Below we present key technical parameters for our baseline industrial polyurethane grades. These values represent typical production benchmarks; all formulations are adjustable to meet your exact mechanical and environmental constraints.

| Property | Test Method | Grade PU-75A | Grade PU-90A | Grade PU-55D |

|---|---|---|---|---|

| Hardness (Shore A/D) | ASTM D2240 | 75A | 90A | 55D |

| Tensile Strength (MPa) | ASTM D412 | 35 | 48 | 62 |

| Elongation at Break (%) | ASTM D412 | 550 | 420 | 280 |

| Tear Strength (kN/m) | ASTM D624 | 95 | 110 | 135 |

| Compression Set (22h/70°C) | ASTM D395 | 12% | 9% | 7% |

| Operating Temperature Range | — | -40°C to 90°C | -30°C to 100°C | -20°C to 110°C |

These specifications illustrate our capacity to balance flexibility with structural integrity across diverse Shore scales. However, real-world applications often necessitate deviations from standard profiles—whether incorporating flame retardants for mining equipment seals, enhancing UV resistance for outdoor agricultural components, or optimizing rebound resilience for high-cycle conveyor systems. Our laboratory utilizes advanced rheometry and accelerated aging protocols to validate performance under your specific stress conditions before full-scale production.

As your strategic OEM partner, Suzhou Baoshida delivers more than raw materials. We provide comprehensive technical stewardship from prototype validation through high-volume manufacturing, ensuring seamless integration into your production lines. Our quality management system adheres to ISO 9001:2015 standards with batch traceability down to individual catalyst lots. For projects requiring rapid iteration, we offer expedited formulation adjustments within 72 hours of receiving application data.

Initiate your custom polyurethane development process by contacting Mr. Boyce, our dedicated Technical OEM Manager. With 14 years of experience in polymer compounding for automotive, robotics, and heavy machinery sectors, Mr. Boyce will coordinate material testing, feasibility analysis, and scalable production planning. Direct technical inquiries to [email protected] with subject line “PU Formulation Request: [Your Application]” for priority engineering review. Include critical parameters such as dynamic load profiles, fluid exposure environments, and dimensional tolerances to accelerate solution design. Response time for technical submissions is guaranteed within 4 business hours during China Standard Time working hours. Partner with Suzhou Baoshida to transform polyurethane from a commodity specification into a competitive engineering advantage.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).