Technical Contents

Engineering Guide: Polyurethane Snow Plow Blades

Engineering Insight Material Science Determines Snow Plow Blade Longevity

Material selection is the decisive factor in polyurethane snow plow blade performance and service life, yet it remains critically underestimated by many OEMs relying on generic off-the-shelf compounds. Standard polyurethane formulations, often designed for general industrial use, lack the specific molecular architecture required to withstand the extreme, multi-stress environment of snow removal operations. This oversight leads to premature failure modes including catastrophic edge chipping, rapid abrasive wear, and delamination from the steel mounting bracket, resulting in significant downtime and replacement costs for end-users. The fundamental flaw lies in the inability of commodity polyurethanes to simultaneously optimize the competing properties essential for this application: high abrasion resistance must coexist with exceptional low-temperature flexibility and robust adhesion to metal substrates under dynamic impact loading.

Generic polyurethane blades typically utilize rigid polymer chains and standard crosslink densities optimized for room-temperature applications. When exposed to sub-zero temperatures common during snow events, especially when combined with road salt residues that lower the effective freezing point, these materials experience a dramatic loss in polymer chain mobility. Their glass transition temperature (Tg) often exceeds operational conditions, causing the material to become brittle well above -20°F (-29°C). Impact with hidden obstacles like manhole covers or road debris at these temperatures induces immediate fracture rather than elastic deformation. Furthermore, standard formulations exhibit insufficient cut growth resistance; microscopic nicks from abrasive road grit propagate rapidly under cyclic stress, accelerating wear and edge degradation. Poor interfacial adhesion chemistry in off-the-shelf compounds fails to maintain bond integrity against the constant vibration and peeling forces encountered during plowing, leading to costly separation from the steel backing plate.

Suzhou Baoshida Trading Co., Ltd. addresses these failure points through precision-engineered thermoset polyurethane systems. Our proprietary formulations utilize specialized isocyanates and polyols selected to depress the Tg significantly below operational minima while maintaining high crosslink density for abrasion resistance. Advanced reactive plasticizers enhance low-temperature flexibility without permanent migration, and tailored adhesion promoters create covalent bonds with the steel substrate. The critical balance is achieved through rigorous laboratory simulation of real-world stressors, not merely meeting baseline hardness specifications.

The performance disparity between generic and engineered polyurethane is quantifiable under operational conditions:

| Critical Property | Generic Off-the-Shelf PU | Baoshida Engineered Snow Plow PU | Operational Impact of Difference |

|---|---|---|---|

| Shore A Hardness (23°C) | 90A ± 5 | 88A ± 3 | Maintains optimal edge conformity without excessive stiffness |

| Glass Transition Temp (Tg) | -35°C (-31°F) | -55°C (-67°F) | Retains flexibility and impact resistance at extreme cold |

| Abrasion Loss (DIN 53516) | 120 mm³ | 65 mm³ | 45% longer service life on abrasive surfaces |

| Tear Strength (ASTM D624) | 65 kN/m | 110 kN/m | Resists nick propagation and edge chipping |

| Adhesion to Steel (Peel) | 4.5 kN/m | 12.0 kN/m | Eliminates delamination under dynamic plowing loads |

Material science is not a cost center but a reliability imperative for snow plow blades. Generic polyurethane solutions compromise on the specific molecular requirements of this demanding application, guaranteeing premature failure. Suzhou Baoshida Trading Co., Ltd. provides OEMs with scientifically validated polyurethane compounds engineered to deliver maximum uptime and lowest total cost of ownership through superior material performance under real-world winter conditions. The selection of an appropriately formulated polyurethane is the foundational engineering decision determining blade success.

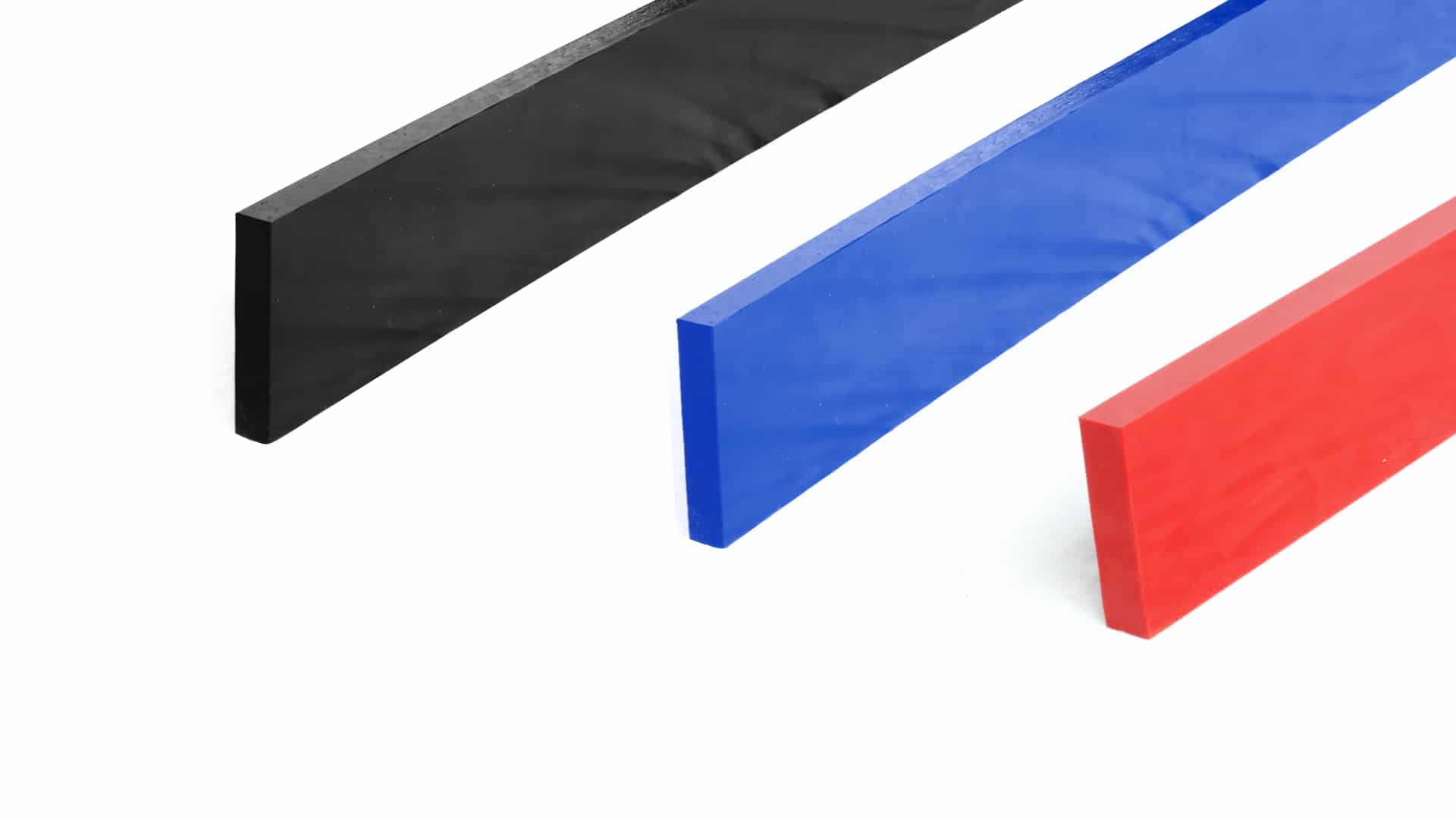

Material Specifications

Material selection is a critical engineering decision in the manufacturing of polyurethane snow plow blades, particularly when integrating high-performance elastomers for sealing, wear resistance, and environmental durability. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions tailored for demanding applications, including winter maintenance equipment. When specifying elastomeric components for snow plow systems, three materials stand out due to their distinct chemical and mechanical properties: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each offers unique advantages depending on operating temperature, exposure to oils and fuels, and mechanical stress conditions.

Viton is a fluorocarbon-based elastomer renowned for its exceptional resistance to high temperatures, ozone, and a broad range of chemicals, including hydrocarbons and automotive fluids. With a continuous service temperature range up to 230°C, Viton is ideal for components exposed to engine heat or de-icing agents containing aggressive solvents. Its low gas permeability and long-term stability under thermal cycling make it suitable for dynamic sealing applications near hydraulic systems in snow plow assemblies. However, Viton exhibits lower flexibility at sub-zero temperatures compared to other elastomers, which must be considered in extreme cold environments.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is widely used in industrial applications due to its excellent resistance to oils, greases, and water. It offers good abrasion resistance and mechanical strength, making it a cost-effective choice for seals and gaskets in hydraulic rams and actuation systems within snow plow mechanisms. Nitrile performs reliably in temperature ranges from -30°C to 100°C, with some formulations extending to 120°C intermittently. While it provides superior fuel and oil resistance, its performance degrades under prolonged UV or ozone exposure, necessitating protective housing or coatings in outdoor applications.

Silicone rubber (VMQ) excels in extreme temperature environments, with operational stability from -60°C to 200°C. This makes it particularly valuable for low-temperature flexibility in arctic or high-altitude snow removal operations. Silicone also demonstrates excellent resistance to UV radiation and ozone, ensuring long-term outdoor durability. However, it has relatively poor resistance to petroleum-based fluids and lower tensile strength compared to NBR or Viton, limiting its use in high-wear or oil-exposed zones. It is best suited for static seals, protective boots, or non-load-bearing components.

The following table summarizes key physical and chemical properties for informed material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 100 (up to 120) | -60 to 200 |

| Oil/Fuel Resistance | Excellent | Excellent | Poor |

| Ozone/UV Resistance | Excellent | Fair to Poor | Excellent |

| Tensile Strength | High | High | Moderate |

| Low-Temperature Flexibility | Moderate | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Typical Applications | Dynamic seals, fuel systems | Hydraulic seals, gaskets | Static seals, boots |

Material choice must align with the operational profile of the snow plow system, balancing chemical exposure, thermal demands, and mechanical loading. Suzhou Baoshida Trading Co., Ltd. supports OEMs with precision-engineered rubber components, ensuring optimal performance and longevity in severe winter conditions.

Manufacturing Capabilities

Engineering Capability: Precision Formulation and OEM Excellence for Polyurethane Snow Plow Blades

Suzhou Baoshida Trading Co., Ltd. leverages deep engineering expertise as the cornerstone of our polyurethane snow plow blade manufacturing. Our dedicated technical team, comprising five specialized mould engineers and two advanced formula engineers, ensures every component meets the exacting demands of winter operations. This integrated capability allows us to translate complex performance requirements into robust, field-proven solutions, directly supporting our core strength in OEM partnerships for industrial rubber applications.

Our formula engineers possess mastery in polyurethane chemistry, specifically optimizing formulations for the extreme conditions encountered by snow plow blades. They meticulously engineer the molecular architecture to achieve critical balance: exceptional abrasion resistance against concrete and asphalt, sustained flexibility at temperatures as low as -40°C, and minimized ice adhesion properties. This scientific approach ensures blades maintain cutting edges longer, resist cracking during impact, and shed compacted snow efficiently, directly enhancing equipment uptime and operator safety. Material selection and additive integration are rigorously validated through accelerated wear testing and thermal cycling protocols before any production release.

Complementing this material science expertise, our five mould engineers focus on precision tooling and manufacturing process control. They design and refine moulds to guarantee consistent part geometry, critical for uniform pressure distribution across the plow edge and seamless integration with mounting systems. Their work encompasses cavity pressure monitoring, thermal management optimization, and tolerance analysis to eliminate flash, sink marks, or dimensional drift – common failure points in inferior blades. This precision engineering ensures every unit off the line meets the tight specifications demanded by OEM equipment manufacturers.

Our OEM capability is built upon this dual-engineering foundation. We engage early in the design phase, utilizing client specifications and application data to co-develop blades tailored to specific vehicle models, regional snow conditions, and performance targets. This includes iterative prototyping, finite element analysis (FEA) for stress prediction, and comprehensive field validation testing under real-world winter scenarios. Suzhou Baoshida manages the entire process from concept to serial production, providing full documentation, material traceability, and rigorous quality assurance per ISO 9001 standards.

The resulting performance characteristics of our engineered polyurethane snow plow blades are quantifiable and reliable, as demonstrated in the key specifications below:

| Property | Test Standard | Target Value | Performance Benefit |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 85 ± 3 | Optimal balance of edge retention and impact absorption |

| Abrasion Resistance | ASTM D5963 | ≤ 85 mm³ loss | Extended service life on abrasive surfaces |

| Low Temperature Flex | ASTM D1329 | Pass @ -40°C | Prevents brittle fracture in extreme cold |

| Tensile Strength | ASTM D412 | ≥ 35 MPa | Resists tearing during heavy snow loads |

| Tear Strength | ASTM D624 (Die B) | ≥ 75 kN/m | Maintains integrity against sharp impacts |

This commitment to scientific material development, precision manufacturing, and collaborative OEM engineering ensures Suzhou Baoshida delivers polyurethane snow plow blades that exceed industry expectations for durability, safety, and operational efficiency in the harshest winter environments. Rigorous validation protocols underpin every shipment, guaranteeing consistent performance for our manufacturing partners.

Customization Process

Customization Process for Polyurethane Snow Plow Blades

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered for performance, durability, and application-specific precision. The customization process for polyurethane snow plow blades follows a rigorous four-stage workflow: Drawing Analysis, Formulation, Prototyping, and Mass Production. This structured approach ensures that every blade meets the mechanical, environmental, and operational demands of winter maintenance equipment.

The process begins with Drawing Analysis, where client-provided technical drawings are evaluated for dimensional accuracy, mounting interface compatibility, and structural integrity. Our engineering team conducts a thorough review of blade geometry, including curvature, edge profile, and attachment points. Finite element analysis (FEA) may be applied to simulate stress distribution under load, particularly at high-impact zones such as the cutting edge and mounting brackets. This stage ensures that the design aligns with both functional requirements and manufacturing feasibility.

Following drawing validation, we proceed to Formulation Development. Polyurethane selection is critical—its hardness, abrasion resistance, and low-temperature flexibility directly influence blade performance. For snow plow applications, we typically formulate with aliphatic or aromatic polyurethane systems tailored to balance elasticity and wear resistance. The target Shore A hardness ranges between 85 and 95 to resist ice abrasion while maintaining flexibility at sub-zero temperatures. Additives such as UV stabilizers and anti-hydrolysis agents are incorporated to extend service life in harsh winter conditions. All formulations are developed in-house using controlled lab-scale synthesis and tested per ASTM D412 (tensile strength), ASTM D624 (tear resistance), and ASTM D790 (flexural properties).

Once the formulation is approved, Prototyping commences. Using precision casting molds derived from the validated drawings, we produce a small batch of prototype blades. These prototypes undergo rigorous physical testing, including low-temperature impact resistance (-40°C), edge durability on simulated icy surfaces, and fatigue testing under cyclic loading. Client feedback is integrated at this stage, allowing for geometric or material adjustments before tooling finalization.

Upon successful prototype validation, the project transitions to Mass Production. Our automated casting lines ensure batch consistency, with real-time monitoring of temperature, cure time, and material viscosity. Each blade is inspected for dimensional conformity and surface integrity. Final products are packaged with protective coatings and shipped in stackable configurations to minimize transit damage.

The following table summarizes key performance specifications for our standard polyurethane snow plow blade formulation:

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 90 ± 3 |

| Tensile Strength | ASTM D412 | ≥35 MPa |

| Elongation at Break | ASTM D412 | ≥500% |

| Tear Resistance (Die C) | ASTM D624 | ≥120 kN/m |

| Flexural Modulus | ASTM D790 | 1,100 MPa |

| Operating Temperature Range | — | -40°C to +80°C |

| Abrasion Loss (Taber Wheel) | ASTM D1044 | ≤80 mg (1,000 cycles) |

This systematic customization process ensures that every polyurethane snow plow blade we deliver meets the highest standards of industrial performance and reliability.

Contact Engineering Team

Technical Partnership for Polyurethane Snow Plow Blade Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber innovation, specializing in engineered polyurethane components for extreme-condition applications. Our polyurethane snow plow blades represent the culmination of advanced polymer science and rigorous field validation, designed explicitly to address the durability, efficiency, and safety demands of municipal, commercial, and heavy-equipment operators. Unlike conventional rubber or steel alternatives, our proprietary formulations deliver superior abrasion resistance, low-temperature flexibility, and consistent edge retention across diverse snow and ice conditions. This technical superiority translates directly to reduced downtime, extended service life, and lower total cost of ownership for end-users.

Central to our offering is a material composition optimized for the unique stresses encountered in snow removal operations. The table below details critical performance specifications validated through ASTM-standardized testing protocols and real-world deployment:

| Material Property | Performance Value | Testing Standard |

|---|---|---|

| Shore A Hardness | 85 ± 3 | ASTM D2240 |

| Tensile Strength | ≥ 42 MPa | ASTM D412 |

| Elongation at Break | ≥ 450% | ASTM D412 |

| Abrasion Resistance | ≤ 85 mm³ (loss) | ASTM D5963 |

| Low-Temperature Flexibility | -40°C (no cracking) | ISO 1432 |

| Tear Strength | ≥ 90 kN/m | ASTM D624 |

These metrics are not theoretical benchmarks but proven operational thresholds achieved through our controlled manufacturing processes and stringent quality assurance systems. Each blade undergoes batch-specific mechanical property verification and dimensional tolerance checks to ensure compatibility with major plow mounting systems (e.g., Meyer, Fisher, Boss). Our engineering team further supports clients through custom formulation adjustments for region-specific challenges, such as high-salt environments or extreme sub-zero climates, ensuring optimal performance under localized conditions.

Engaging Suzhou Baoshida initiates a collaborative technical partnership, not merely a transactional supply arrangement. We integrate seamlessly into your production or procurement workflow, providing comprehensive material certifications, technical datasheets, and on-demand engineering consultation. Our OEM-focused approach includes mold design support, accelerated life-cycle testing, and just-in-time logistics coordination to minimize inventory burdens while guaranteeing supply chain resilience. For municipal fleet managers and equipment manufacturers, this translates to reliable, high-performance blades that maintain cutting-edge integrity season after season, directly enhancing operational safety and reducing winter maintenance costs.

To resolve persistent snow plow blade failures, inconsistent wear patterns, or suboptimal cold-weather performance, direct technical engagement is essential. Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineering lead, possesses 15 years of specialized expertise in polyurethane compounding for impact-resistant applications. He will conduct a thorough analysis of your operational parameters, material requirements, and integration challenges to deliver a tailored solution. Contact Mr. Boyce immediately at [email protected] to initiate a technical consultation. Include your specific application details, current pain points, and volume requirements to expedite a precise engineering response. Partner with Suzhou Baoshida to transform snow removal reliability through scientifically validated polyurethane technology—where material precision meets industrial endurance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).