Technical Contents

Engineering Guide: Poppy Doormat

Engineering Insight: The Critical Role of Material Selection in poppy doormat Performance

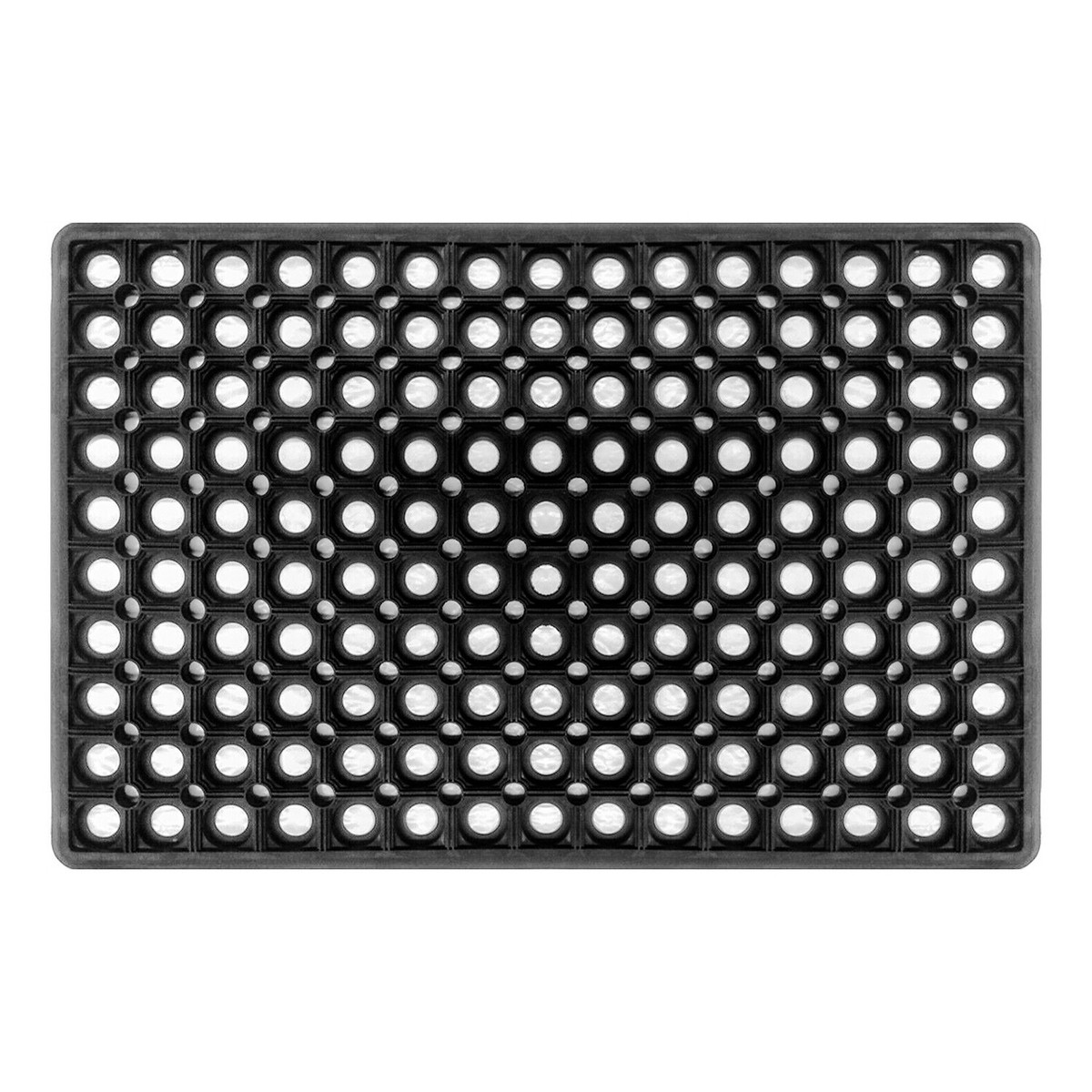

In industrial environments, the functionality of a doormat extends far beyond aesthetics. The poppy doormat, often deployed in high-traffic commercial and manufacturing zones, serves as a first line of defense against debris, moisture, and slip hazards. However, widespread reliance on off-the-shelf rubber solutions frequently leads to premature degradation, safety risks, and increased maintenance costs. The root cause lies in inadequate material selection—a factor that determines resilience, longevity, and environmental compatibility.

Standard consumer-grade rubber compounds, typically based on reclaimed rubber or low-grade SBR (styrene-butadiene rubber), lack the molecular stability required for industrial applications. These materials exhibit poor resistance to ozone, UV exposure, and temperature fluctuations. In outdoor or semi-exposed installations, such as factory entrances or warehouse access points, these mats rapidly crack, harden, or delaminate. Furthermore, their surface texture diminishes quickly under mechanical stress, reducing traction and increasing slip potential.

At Suzhou Baoshida Trading Co., Ltd., our engineered poppy doormat solutions utilize high-density EPDM (ethylene propylene diene monomer) rubber, formulated for superior durability and chemical resistance. EPDM’s saturated polymer backbone provides exceptional resistance to weathering, oxidation, and thermal cycling—critical for maintaining structural integrity across seasons. Unlike generic alternatives, our proprietary compound retains elasticity between -40°C and +135°C, ensuring consistent performance in extreme conditions.

Additionally, the geometry of the poppy profile must be matched to the elastomer’s durometer and tensile strength. A poorly balanced design—such as overly deep treads in a soft matrix—leads to tread collapse under load. Our engineering team optimizes the poppy height, spacing, and base thickness in conjunction with material hardness (Shore A 65–75), ensuring effective debris expulsion without compromising mat stability.

Another overlooked factor is adhesion between the rubber compound and reinforcing scrim. Off-the-shelf mats often use weak bonding agents or lack scrim reinforcement entirely, resulting in delamination under shear stress. Our manufacturing process integrates a high-tensile polyester scrim with chemically bonded adhesion, distributing load evenly and preventing edge curling.

The consequences of substandard material selection are not merely operational—they are financial. Frequent replacement, downtime for cleaning or reinstallation, and liability from slip incidents accumulate rapidly. A technically sound poppy doormat is not a commodity; it is a precision-engineered component of facility safety and efficiency.

Below is a comparative specification of standard off-the-shelf rubber versus Baoshida’s engineered EPDM solution:

| Property | Off-the-Shelf SBR Mat | Baoshida Engineered EPDM Mat |

|---|---|---|

| Base Polymer | Reclaimed SBR | Virgin EPDM |

| Shore A Hardness | 55–60 | 65–75 |

| Temperature Range (°C) | -10 to +70 | -40 to +135 |

| Tensile Strength (MPa) | 8–10 | 15–18 |

| Elongation at Break (%) | 200–250 | 400–450 |

| Ozone Resistance | Poor | Excellent |

| UV Stability | Low (cracks within 6 months) | High (5+ years outdoor use) |

| Scrim Reinforcement | None or low-grade | High-tensile polyester, bonded |

| Expected Service Life (years) | 1–2 | 5–7 |

Material selection is not a cost-saving opportunity—it is a risk management imperative. At Baoshida, we engineer rubber solutions that perform under real-world industrial demands.

Material Specifications

Material Specifications for Industrial Rubber Doormats

Suzhou Baoshida Trading Co., Ltd. engineers industrial rubber doormats for demanding commercial and industrial environments where standard textile or coir mats fail. Our formulations prioritize chemical resistance, thermal stability, and mechanical durability under continuous foot traffic. Unlike consumer-grade mats, these solutions must withstand hydrocarbon exposure, ozone degradation, and extreme temperature fluctuations common in manufacturing facilities, laboratories, and transportation hubs. Viton, Nitrile, and Silicone elastomers are selected based on rigorous ASTM D2000 classification standards, ensuring compliance with OEM performance thresholds for compression set, tensile strength, and abrasion resistance. Each material addresses specific operational hazards while maintaining dimensional stability after repeated cleaning cycles.

Viton (FKM) excels in aerospace and petrochemical facilities due to its unparalleled resistance to jet fuels, hydraulic fluids, and aromatic hydrocarbons. Its molecular structure maintains integrity from -15°C to 230°C, with a Shore A hardness of 70–85. Nitrile (NBR) offers optimal cost-performance balance for automotive workshops and machine shops, resisting oils, greases, and aliphatic solvents at temperatures between -30°C and 120°C. Shore A hardness ranges from 60–90, customizable for high-abrasion zones. Silicone (VMQ) serves cleanroom and food processing environments requiring extreme temperature resilience (-60°C to 200°C) and non-toxic compliance, though its lower tensile strength necessitates reinforced formulations for heavy-traffic areas. All compounds incorporate proprietary fillers to enhance tear strength and reduce permanent deformation below 15% per ASTM D395.

The comparative analysis below details critical performance parameters for OEM integration:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -15 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 6–12 |

| Compression Set (%) | ≤20 (24h, 150°C) | ≤30 (70h, 100°C) | ≤25 (22h, 200°C) |

| Key Chemical Resistance | Jet fuels, acids | Oils, greases | Steam, oxygen |

| Abrasion Resistance | Excellent | Very Good | Fair |

| OEM Cost Tier | Premium | Standard | High |

Material selection directly impacts lifecycle cost in industrial settings. Viton is mandatory for FAA-certified facilities handling aggressive solvents but incurs 40% higher material costs. Nitrile remains the strategic choice for 80% of automotive OEMs due to its abrasion resistance and rapid return on investment. Silicone requires careful application vetting—its low surface energy prevents staining in medical labs but necessitates textured surface engineering to mitigate slip risks when wet. Suzhou Baoshida’s OEM team conducts site-specific hazard assessments to match elastomer grades with facility workflows, ensuring mats exceed ISO 188 aging requirements while minimizing replacement frequency. All compounds are free of regulated phthalates and meet REACH Annex XVII compliance for global deployment.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber manufacturing, delivering engineered solutions tailored to the functional and performance demands of commercial and industrial applications. Within our core competency lies the development and production of high-performance rubber-based products, including specialized items such as the poppy doormat—a product engineered not only for aesthetic appeal but for durability, slip resistance, and long-term resilience in high-traffic environments. Our engineering capability is anchored by a dedicated team of five mould engineers and two advanced rubber formulation specialists, enabling full in-house control from concept to mass production.

The integration of mould engineering and material science is central to our design philosophy. Our five mould engineers possess extensive experience in precision steel tooling, cavity design, and flow dynamics optimization for rubber injection and compression moulding. This expertise ensures consistent part replication, tight dimensional tolerances, and efficient cycle times—critical factors in maintaining cost-effectiveness and scalability. Mould designs are developed using CAD/CAM software and rigorously tested through prototyping phases to validate venting, parting lines, and ejection mechanisms, minimizing defects and maximizing product integrity.

Complementing this is our team of two certified rubber formula engineers who specialize in elastomer compounding for application-specific performance. For the poppy doormat, this involves formulating EPDM or SBR-based compounds that balance weather resistance, tensile strength, and surface friction. These formulations are engineered to withstand UV exposure, thermal cycling, and repeated mechanical loading without degradation. Additives such as anti-aging agents, reinforcing fillers, and processing oils are precisely dosed to achieve target hardness (typically 50–65 Shore A), abrasion resistance, and color stability. Each formula undergoes laboratory testing for compression set, elongation at break, and slip resistance (measured via DIN 51130 ramp test) before approval.

Our OEM capabilities allow clients to co-develop customized doormat solutions with proprietary design, branding, and performance parameters. From 2D artwork to 3D tooling, we manage the entire product realization process, ensuring intellectual property protection and rapid time-to-market. With in-house tooling, compound development, and quality validation, Suzhou Baoshida provides a vertically integrated manufacturing model that reduces dependency on external suppliers and enhances process control.

The following table outlines key technical specifications achievable for OEM poppy doormat production:

| Parameter | Specification |

|---|---|

| Material Options | EPDM, SBR, Recycled Rubber Blends |

| Hardness Range | 50–65 Shore A |

| Operating Temperature | -40°C to +100°C |

| Tensile Strength | ≥ 8 MPa (ASTM D412) |

| Elongation at Break | ≥ 250% |

| Compression Set (22h, 70°C) | ≤ 25% (ASTM D395) |

| Slip Resistance (DIN 51130) | R9–R11 classification |

| Mould Tolerances | ±0.15 mm (cavity-dependent) |

| Production Lead Time (Tooling) | 25–35 days |

| Minimum Order Quantity (MOQ) | 500 pcs |

Suzhou Baoshida Trading Co., Ltd. combines deep technical expertise with scalable manufacturing infrastructure to deliver OEM rubber solutions that meet rigorous industrial standards. Our engineering team ensures every poppy doormat is not only fit for purpose but exceeds expectations in performance and longevity.

Customization Process

Customization Process for Industrial Rubber Poppy Doormats

At Suzhou Baoshida Trading Co., Ltd., our OEM customization workflow for industrial rubber poppy doormats prioritizes technical rigor and repeatability. We transform client specifications into high-performance products through four tightly integrated phases, ensuring compliance with ISO 9001 quality management standards.

Drawing Analysis Phase

Our engineering team conducts a granular review of client CAD files or physical samples, focusing on geometric tolerances, pattern depth consistency, and demolding angles critical for poppy petal definition. We verify adherence to ASTM D3182 processing guidelines, identifying potential stress points in intricate floral contours. This phase includes material flow simulation to preempt sink marks or incomplete cavity filling during molding, reducing tooling iterations by up to 40%.

Formulation Development

Based on performance requirements, our rubber chemists design proprietary SBR/NR (Styrene-Butadiene/Natural Rubber) compounds optimized for outdoor durability. Key parameters include ozone resistance (per ASTM D1149), UV stability, and controlled durometer to maintain poppy pattern sharpness while ensuring slip resistance. All formulations undergo accelerated aging tests per ISO 188, with adjustments made to plasticizer and antioxidant packages to achieve target service life in harsh environments.

Prototyping & Validation

We produce 3–5 physical prototypes using client-approved tooling steel (typically H13 grade). Each prototype undergoes dimensional verification via CMM (Coordinate Measuring Machine) against original drawings, with tolerance checks at ±0.2 mm for petal edges. Functional testing includes:

Abrasion resistance (ASTM D5963)

Compression set (ASTM D395) at 70°C for 22 hours

Tensile strength validation after 500-hour QUV exposure

Critical mechanical properties are summarized below for standard poppy doormat compounds:

| Property | Test Standard | Target Value | Unit |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 | — |

| Tensile Strength | ASTM D412 | ≥12.0 | MPa |

| Elongation at Break | ASTM D412 | ≥300 | % |

| Tear Strength | ASTM D624 | ≥45 | kN/m |

| Compression Set (22h) | ASTM D395 | ≤25 | % |

Mass Production Execution

Upon client sign-off, we initiate production under strict SPC (Statistical Process Control) protocols. Each batch undergoes real-time monitoring of vulcanization parameters (150–180°C, 8–12 MPa pressure) via embedded thermocouples. Random samples from every 500-unit lot are tested for colorfastness (ISO 105-B02) and dimensional stability. All production logs are digitally archived for full traceability, with certificates of conformance provided per shipment. This closed-loop system ensures zero deviation in pattern fidelity or mechanical performance across volumes from 1,000 to 50,000 units.

Suzhou Baoshida’s process eliminates guesswork in rubber customization, delivering poppy doormats that meet exact aesthetic and functional specifications while minimizing time-to-market for industrial clients.

Contact Engineering Team

For industrial-grade rubber solutions tailored to high-performance applications, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in precision manufacturing and material engineering. Specializing in custom rubber formulations and OEM production, our expertise extends to durable, weather-resistant products such as the poppy doormat—an innovative fusion of functional design and industrial resilience. Engineered for commercial and industrial environments, our doormats are not merely aesthetic floor coverings but engineered rubber composites designed to withstand extreme abrasion, moisture, and temperature fluctuations while maintaining structural integrity over extended service life.

At Suzhou Baoshida, we apply rigorous material science protocols to ensure every product meets exacting performance benchmarks. Our poppy doormat is formulated using a proprietary blend of styrene-butadiene rubber (SBR) and recycled EPDM granules, optimized for superior traction, UV resistance, and dimensional stability. This composite structure resists mold, mildew, and chemical degradation—critical for facilities in maritime, automotive, food processing, and pharmaceutical industries where hygiene and safety are paramount. Each mat undergoes compression molding at 170°C under 150 tons of pressure, ensuring uniform density and edge-to-edge durability.

We invite technical buyers, procurement managers, and OEM partners to engage directly with our engineering team to discuss customization, volume production, and compliance certification. Mr. Boyce, our Lead Rubber Formula Engineer and OEM Manager, oversees all client technical integrations and is available to support your project from concept to delivery. Whether you require specific Shore A hardness values, color-matched pigmentation, flame-retardant additives, or anti-static properties, our R&D pipeline supports rapid prototyping and material validation testing per ASTM, ISO, and DIN standards.

To ensure seamless collaboration, we provide full technical data sheets, material safety data sheets (MSDS), and sample batches upon request. Our facility in Suzhou operates under ISO 9001 and IATF 16949 certifications, with in-house quality control labs equipped for tensile strength, elongation at break, compression set, and abrasion resistance testing. Lead times for bulk orders are optimized through automated production lines and strategic raw material sourcing, ensuring on-time delivery without compromise to quality.

For immediate technical consultation or quotation requests, contact Mr. Boyce at [email protected]. Please include your application requirements, annual volume estimates, and any regulatory standards applicable to your industry.

Below are the standard technical specifications for our industrial poppy doormat:

| Property | Specification | Test Method |

|---|---|---|

| Material Composition | 70% SBR / 30% Recycled EPDM | ASTM D395 |

| Shore A Hardness | 65 ± 5 | ASTM D2240 |

| Tensile Strength | ≥ 10 MPa | ASTM D412 |

| Elongation at Break | ≥ 250% | ASTM D412 |

| Compression Set (22 hrs, 70°C) | ≤ 20% | ASTM D395 |

| Operating Temperature Range | -40°C to +100°C | ISO 1817 |

| Specific Gravity | 1.15 ± 0.05 | ASTM D297 |

| Flame Resistance | UL94 HB Rated | UL 94 |

| Available Thicknesses | 8 mm, 10 mm, 12 mm | Custom |

| Standard Sheet Size | 900 x 600 mm | OEM Sizes Available |

Partner with Suzhou Baoshida for engineered rubber solutions that meet the demands of modern industrial environments. Contact Mr. Boyce today to initiate technical discussions and receive a tailored proposal for your application.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).