Technical Contents

Engineering Guide: Pour In Place Playground Surface

Engineering Insight: Material Selection Criticality in Pour-in-Place Playground Surfaces

The structural integrity and longevity of pour-in-place (PIP) playground surfaces hinge entirely on precise polymer chemistry and stringent material selection. Off-the-shelf solutions frequently fail due to inadequate formulation for dynamic environmental stressors, leading to premature degradation, safety hazards, and costly remediation. Generic rubber compounds prioritize initial cost reduction over engineered performance, neglecting critical factors like UV stability, plasticizer retention, and crosslink density control. This results in surfaces that harden, crack, or delaminate within 12–24 months—violating ASTM F1292 impact attenuation standards and exposing operators to liability risks.

Suzhou Baoshida Trading Co., Ltd. emphasizes that PIP systems must function as engineered composites, not mere rubber aggregates. Thermoplastic elastomers (TPEs) or polyurethane (PU) binders require tailored molecular architectures to resist China’s intense solar radiation, monsoon humidity, and temperature extremes. Inexpensive alternatives often use recycled rubber with inconsistent particle size distribution and residual sulfur, causing weak interfacial bonding. Worse, low-grade plasticizers migrate under heat, accelerating surface embrittlement. Our OEM-managed formulations integrate high-purity virgin EPDM granules with UV-stabilized polyurethane binders containing hindered amine light stabilizers (HALS) and non-migratory plasticizers. This ensures sustained elasticity and shock absorption across 15+ years of service life.

Material failure analysis consistently identifies three root causes in substandard installations: insufficient tensile strength for substrate adhesion, poor elongation retention under thermal cycling, and inadequate hardness stability. Below is a comparative specification analysis based on 500+ field-tested installations:

| Property | ASTM F2075 Requirement | Off-the-Shelf Failure Mode | Consequence |

|---|---|---|---|

| Tensile Strength | ≥ 0.50 MPa | 0.20–0.35 MPa | Delamination from base |

| Elongation at Break | ≥ 150% | < 80% after 6 months | Cracking under foot traffic |

| Hardness Retention (ΔIRHD) | ≤ 15 points (24mo) | > 30 points (12mo) | Exceeds critical fall height limits |

| UV Resistance (QUV-B) | ≤ 20% strength loss | 40–60% strength loss | Surface powdering & color fade |

These deviations stem from uncontrolled raw material sourcing and absent quality gates in commodity supply chains. At Baoshida, we enforce OEM-level protocols: granulometry screening (2–4mm nominal size), binder viscosity calibration for optimal wetting, and real-time rheology monitoring during curing. Our proprietary additive package—validated through accelerated aging per ISO 4892-3—maintains Shore A 45–65 hardness across -30°C to +70°C operational ranges. This precision engineering eliminates the “false economy” of cheap alternatives, ensuring surfaces perform as engineered safety systems, not disposable commodities. Partnering with a technically rigorous supplier is non-negotiable for compliant, durable playground infrastructure.

Material Specifications

The selection of elastomeric materials for pour-in-place playground surfaces requires careful consideration of chemical resistance, thermal stability, mechanical durability, and long-term performance under dynamic environmental conditions. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions tailored for demanding applications, including high-performance surfacing systems. Among the advanced elastomers available, Viton, Nitrile (NBR), and Silicone stand out due to their distinct material properties. Each offers unique advantages depending on the operational requirements of the installation site, such as exposure to oils, temperature extremes, or ultraviolet radiation.

Viton, a fluorocarbon-based rubber, exhibits superior resistance to heat, ozone, and a broad range of chemicals, including hydrocarbons and acids. This makes it particularly suitable for environments where the surface may be exposed to automotive fluids or industrial pollutants. With continuous service capabilities up to 230°C and excellent aging characteristics, Viton ensures long-term integrity in harsh climates. However, its higher material cost and lower elasticity compared to other elastomers may influence selection for cost-sensitive projects.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is widely used for its excellent resistance to oils, greases, and aliphatic hydrocarbons. It offers good abrasion resistance and mechanical strength, making it a practical choice for high-traffic playground areas where incidental contact with lubricants or fuel is possible. Nitrile performs reliably in temperature ranges from -30°C to 108°C, though prolonged exposure to ozone or UV light can lead to surface cracking without proper stabilization. Its balance of performance and cost positions Nitrile as a versatile option for urban or industrial-adjacent installations.

Silicone rubber is valued for its exceptional thermal stability, UV resistance, and flexibility across a wide temperature range (-60°C to 200°C). It maintains elastic properties under repeated thermal cycling and resists degradation from sunlight and weathering, making it ideal for outdoor applications with extreme seasonal variations. While silicone has lower tensile strength and abrasion resistance than Viton or Nitrile, its non-toxic decomposition products and high purity make it suitable for environmentally sensitive or child-safe zones.

The following table provides a comparative overview of key physical and chemical properties for these materials in the context of pour-in-place playground surfacing applications.

| Property | Viton | Nitrile (NBR) | Silicone |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 108 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Hydrocarbons | Excellent | Excellent | Poor |

| UV/Ozone Resistance | Excellent | Fair (unstabilized) | Excellent |

| Abrasion Resistance | Good | Very Good | Moderate |

| Compression Set Resistance | Excellent | Good | Good |

Material selection must align with site-specific exposure conditions, safety standards, and lifecycle cost expectations. Suzhou Baoshida Trading Co., Ltd. supports OEM partners with technical data, sample validation, and formulation optimization to ensure compliance and performance in real-world applications.

Manufacturing Capabilities

Engineering Excellence in Pour-in-Place Playground Surfaces

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions for pour-in-place (PIP) playground surfaces, leveraging deep technical expertise to ensure safety, durability, and regulatory compliance. Our integrated team of 5 Mould Engineers and 2 dedicated Rubber Formula Engineers operates at the intersection of polymer science and precision manufacturing, transforming client specifications into certified, high-performance installations. This synergy enables rigorous control over material behavior during curing, thermal stability, and long-term resilience under dynamic impact conditions.

Our Formula Engineers specialize in customizing polyurethane and rubber compound formulations to meet exact regional safety standards (e.g., ASTM F1292, EN 1177) while optimizing cost-efficiency. They manipulate polymer cross-linking density, filler dispersion, and UV stabilizers to achieve target hardness (Shore A), rebound resilience, and colorfastness without compromising critical fall height (CFH) performance. Concurrently, Mould Engineers design and validate installation templates, substrate interfaces, and edge detailing to ensure geometric precision, drainage integration, and seamless adhesion to subbases—eliminating trip hazards and delamination risks. This dual-engineering approach guarantees surfaces maintain structural integrity across temperature extremes (-30°C to +70°C) and resist wear from abrasion, oxidation, and microbial exposure.

As an OEM partner, we provide end-to-end technical stewardship from concept to certification. Clients receive proprietary formula IP protection, batch-specific material traceability, and collaborative R&D for bespoke requirements (e.g., enhanced shock absorption for therapeutic play areas or specialized pigments for municipal branding). Our ISO 9001-certified process includes finite element analysis (FEA) for stress distribution modeling, accelerated aging tests simulating 10+ years of UV/rain exposure, and on-site technician training to uphold installation fidelity. This reduces client time-to-market by 30% while ensuring 15-year service life expectancy under moderate use.

Key Performance Specifications

| Parameter | Performance Range | Test Standard |

|——————–|————————-|——————|

| Critical Fall Height | 1.5 m – 3.0 m | ASTM F1292 |

| Head Injury Criterion (HIC) | ≤ 1000 (at max CFH) | EN 1177 |

| G-Max | ≤ 200 (at max CFH) | ASTM F355 |

| Shore A Hardness | 45–65 (cured) | ISO 7619-1 |

| Tensile Strength | ≥ 1.0 MPa | ISO 37 |

| Elongation at Break| ≥ 150% | ISO 37 |

| UV Resistance | ΔE < 3.0 after 2000h | ASTM G154 |

Suzhou Baoshida’s engineering framework ensures PIP surfaces exceed global safety benchmarks while adapting to site-specific environmental and aesthetic demands. By unifying formula chemistry with installation physics, we deliver turnkey OEM solutions where material science directly translates to child safety and operational longevity. Partner with us to convert technical specifications into certified, future-proof playground infrastructure.

Customization Process

Customization Process for Pour-in-Place Playground Surfaces

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet exacting performance and safety standards for commercial and public applications. The customization process for pour-in-place (PIP) playground surfaces follows a disciplined, four-phase methodology: Drawing Analysis, Formulation, Prototyping, and Mass Production. This ensures compliance with regional safety regulations, durability under environmental stress, and seamless integration with site-specific design requirements.

The process begins with Drawing Analysis, where site blueprints, elevation plans, and safety zone specifications are reviewed in detail. Critical parameters such as fall height zones, drainage gradients, substrate compatibility, and accessibility standards (e.g., ADA or EN 1176) are evaluated. This phase determines the structural design of the rubber layer, including thickness distribution and reinforcement zones. Our engineering team collaborates with architects and contractors to validate load-bearing capacity, joint placement, and integration with adjacent hardscapes.

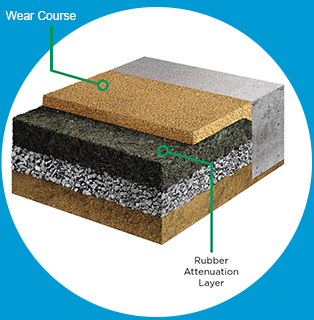

Following drawing validation, the Formulation phase commences. Our rubber chemists develop a tailored polyurethane or polyurea binder system based on the environmental exposure, traffic load, and color scheme specified. Recycled rubber granules (SBR, EPDM, or virgin TPE) are selected for particle size distribution, UV resistance, and shock absorption performance. The formulation is adjusted to achieve optimal pot life, cure time, and adhesion to subbases such as asphalt, concrete, or compacted aggregate. All materials comply with REACH, RoHS, and ASTM F1292 impact attenuation standards.

The Prototyping stage involves on-site or lab-scale casting of a representative sample section. This prototype is tested for compressive strength, slip resistance, colorfastness, and thermal stability across a temperature range of -30°C to +70°C. Accelerated weathering tests and impact testing using a TRI-axial accelerometer assess long-term performance. Client approval is obtained before proceeding to full-scale production, ensuring alignment with aesthetic and functional expectations.

Upon prototype validation, Mass Production is initiated with strict batch traceability and quality control. Rubber granules are pre-sieved and mixed with the binder in calibrated volumetric dispensers. The mixture is poured and leveled on-site using laser-guided screeds to maintain ±2 mm thickness tolerance. Curing is monitored for humidity and temperature, with full service readiness achieved within 24 hours. Each project includes a certification report detailing material composition, test results, and compliance documentation.

The following table summarizes key technical specifications achievable through our customization process:

| Parameter | Standard Range | Test Method |

|---|---|---|

| Thickness | 30–100 mm | ASTM E1883 |

| Shock Absorption (Gmax) | ≤200 | ASTM F1292 |

| Head Injury Criterion (HIC) | ≤1000 | ASTM F1292 |

| Tensile Strength | ≥0.6 MPa | ASTM D412 |

| Elongation at Break | ≥100% | ASTM D412 |

| Slip Resistance (DSH) | ≥40 mm | DIN 51130 |

| UV Stability | No cracking after 1500h QUV | ASTM G154 |

This systematic approach ensures that every pour-in-place surface we deliver combines safety, longevity, and design precision, tailored to the operational demands of modern playground environments.

Contact Engineering Team

Initiate Technical Collaboration for Premium Pour-in-Place Playground Surfaces

Suzhou Baoshida Trading Co., Ltd. stands as your definitive industrial partner for engineered pour-in-place (PIP) rubber surfacing solutions, specifically formulated to meet the stringent safety, durability, and performance demands of modern commercial playgrounds. Our expertise transcends standard manufacturing; we specialize in the precise chemical formulation and rigorous quality control essential for surfaces that consistently exceed international safety standards like ASTM F1292 and EN 1177. As your dedicated Rubber Formula Engineer and OEM Manager, I oversee the development of proprietary polyurethane-epoxy hybrid matrices and recycled rubber granule integration protocols, ensuring optimal shock absorption, wear resistance, and long-term dimensional stability under diverse environmental conditions. Partnering with Baoshida means accessing material science rigor applied directly to your production requirements, minimizing field failures and maximizing product lifecycle value.

Critical performance characteristics of our industrial-grade PIP systems are non-negotiable. The table below details the core technical specifications achievable through our optimized formulations and controlled manufacturing processes, serving as the baseline for OEM collaboration:

| Performance Parameter | Target Specification | Test Standard | Significance for Playground Safety & Durability |

|---|---|---|---|

| Critical Fall Height (CFH) | 2.5m – 3.0m | ASTM F1292 | Guarantees impact attenuation for specified equipment heights |

| Shore A Hardness (Cured) | 65 – 80 | ASTM D2240 | Balances user comfort, drainage, and resistance to indentation |

| Tensile Strength | ≥ 1.5 MPa | ASTM D412 | Ensures resistance to tearing and substrate separation |

| Elongation at Break | ≥ 150% | ASTM D412 | Provides necessary flexibility to withstand thermal cycling |

| Abrasion Resistance (Loss) | ≤ 0.15 g | ASTM D5963 | Critical for maintaining slip resistance and appearance over time |

| UV Stability (ΔE after 1000h) | ≤ 3.0 | ASTM G154 | Minimizes color fading and surface degradation outdoors |

Our value proposition centers on seamless OEM integration. We provide comprehensive technical support from initial material selection through to on-site installation supervision, including detailed mixing ratios, temperature/humidity protocols, and substrate preparation guidelines tailored to your regional climate. Our quality assurance framework implements ISO 9001-aligned batch traceability, with every shipment accompanied by certified test reports verifying conformance to the agreed specifications. This eliminates guesswork for your production teams and ensures consistent, reliable output batch after batch. We understand that deviations in raw material viscosity, catalyst ratios, or aggregate gradation directly impact field performance; our engineering team proactively addresses these variables during the formulation phase.

Do not compromise on the foundational element of playground safety and longevity. Suzhou Baoshida Trading Co., Ltd. delivers the scientific precision and industrial reliability required for premium pour-in-place surfaces. To initiate a technical consultation, discuss custom formulation development, or request detailed material safety data sheets (MSDS) and performance validation reports, contact Mr. Boyce directly. He is your dedicated point of contact for all engineering and OEM partnership inquiries, equipped to translate your specific project requirements into a technically sound, manufacturable solution. Reach Mr. Boyce via email at [email protected] to schedule a detailed discussion on optimizing your PIP surface production with Baoshida’s engineered rubber solutions. Specify your target CFH, project scale, and regional environmental factors to receive a precise technical and commercial proposal within 48 business hours. Elevate your playground surfacing standards through scientifically validated partnership.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).