Technical Contents

Engineering Guide: Ptfe Diaphragm Pump

Engineering Insight: Material Selection in PTFE Diaphragm Pumps

In the industrial handling of aggressive chemicals, high-purity fluids, or abrasive media, the PTFE diaphragm pump stands as a critical component in maintaining process integrity and operational safety. While many manufacturers offer off-the-shelf PTFE diaphragm pumps, a significant number of field failures can be traced back to inadequate material selection, particularly in the elastomeric and polymeric components beyond the primary PTFE diaphragm. At Suzhou Baoshida Trading Co., Ltd., our engineering focus centers on precision material compatibility to ensure long-term reliability under real-world operating conditions.

Standard catalog pumps often utilize generic elastomers for internal seals, valve components, or backup diaphragms. These materials—such as NBR, EPDM, or even standard silicone—may appear functionally adequate under laboratory conditions but degrade rapidly when exposed to halogenated solvents, strong acids, or elevated temperatures. PTFE, while chemically inert and thermally stable up to 260°C, is often paired with supporting materials that do not share its resilience. This mismatch creates a weak link in the system, leading to diaphragm rupture, seal extrusion, or valve clogging—failures that compromise both safety and uptime.

The root cause lies in the assumption that PTFE’s chemical resistance alone guarantees pump longevity. In reality, a diaphragm pump is a system of interacting materials. Even minor swelling or hardening of a secondary O-ring or check valve seat can alter stroke dynamics, reduce suction efficiency, or cause premature fatigue in the PTFE membrane. For instance, exposure to methylene chloride may not affect PTFE but can rapidly degrade FKM seals, leading to internal leakage and loss of prime.

Custom engineering is not a luxury—it is a necessity in critical applications. At Baoshida, we conduct full material compatibility audits based on fluid composition, temperature profile, and duty cycle. This includes selecting perfluoroelastomers (FFKM) for seals, reinforced PTFE composites for diaphragms, and chemically inert thermoplastics for valve bodies. Our approach ensures that every component operates within its compatibility envelope, not just the diaphragm.

The table below outlines key material performance characteristics relevant to PTFE diaphragm pump construction:

| Material | Max Temp (°C) | Key Chemical Resistances | Limitations |

|---|---|---|---|

| PTFE | 260 | Acids, bases, solvents, oxidizers | Creep under load, permeability to gases |

| FFKM | 327 | Aromatic/halogenated solvents, strong acids | High cost, limited availability |

| FKM (Viton®) | 230 | Aliphatic hydrocarbons, some acids | Poor resistance to ketones, amines, methanol |

| EPDM | 150 | Water, steam, alkalis | Swells in oils, hydrocarbons |

| PFA | 260 | Similar to PTFE, with better flow | Higher cost than standard PTFE |

Off-the-shelf pumps frequently sacrifice material integrity for cost and delivery speed. In contrast, engineered solutions from Baoshida integrate holistic compatibility, ensuring that every material in the wetted path supports the PTFE diaphragm’s performance. This precision extends service life, reduces maintenance frequency, and safeguards process continuity in demanding industrial environments.

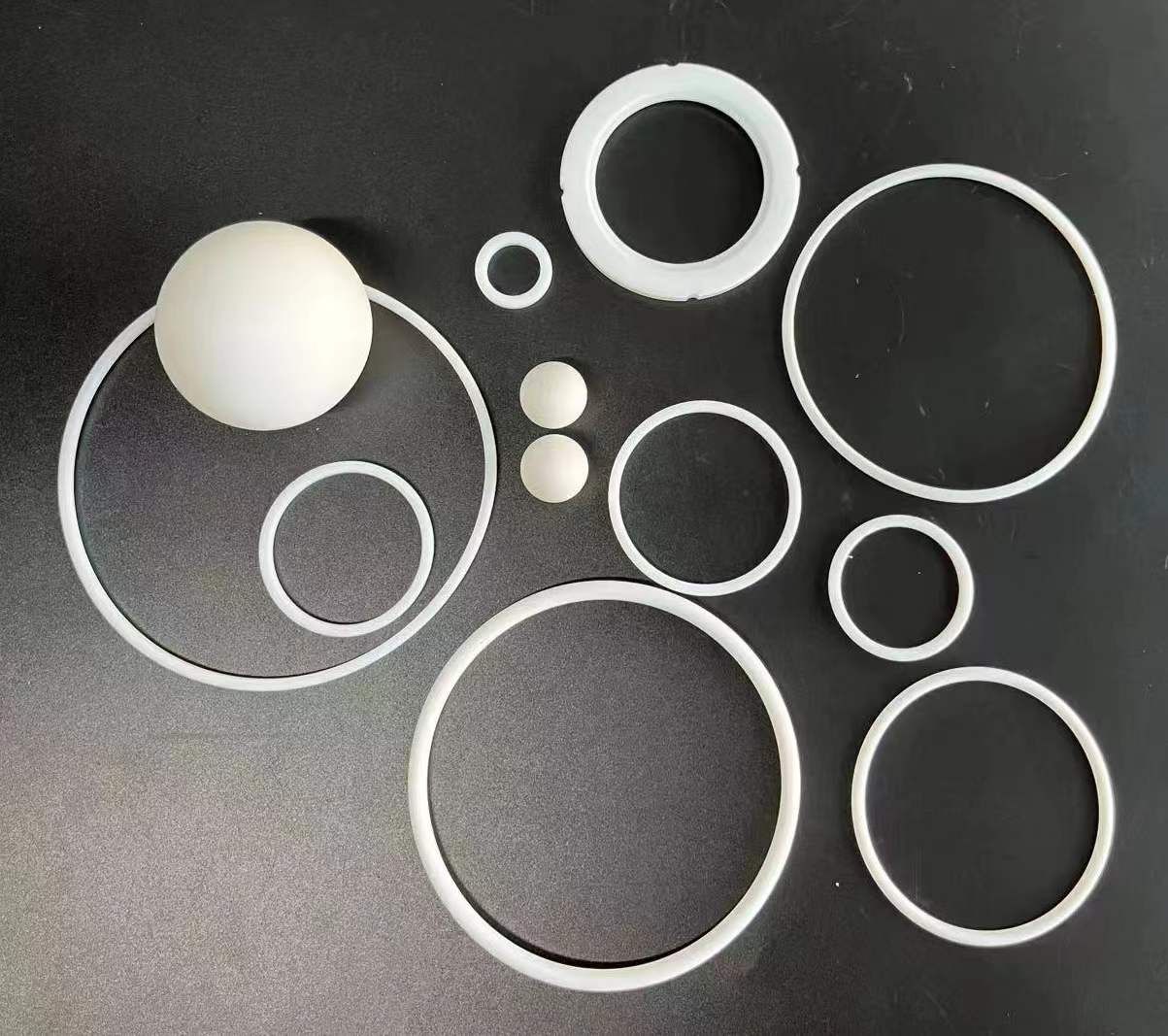

Material Specifications

Material Specifications for PTFE Diaphragm Pump Sealing Components

Precise elastomer selection is critical for PTFE diaphragm pump longevity and performance in aggressive chemical handling applications. While the diaphragm itself utilizes PTFE for its exceptional chemical inertness and low friction, the dynamic seals, valve seats, and auxiliary components rely on specialized elastomers to maintain integrity under pressure, temperature fluctuations, and chemical exposure. Inappropriate material choice directly leads to premature swelling, hardening, cracking, or permeation, causing leaks, reduced flow rates, and unplanned downtime. Suzhou Baoshida Trading Co., Ltd. rigorously evaluates Viton (FKM), Nitrile (NBR), and Silicone (VMQ) based on quantifiable industrial parameters to match OEM requirements with optimal sealing solutions. Each material presents distinct advantages and limitations that must align with the specific process fluid and operating environment.

Viton (FKM) represents the premium choice for severe service conditions demanding maximum chemical resistance. Its fluorocarbon structure provides outstanding stability against a broad spectrum of aggressive chemicals, including aromatic hydrocarbons, chlorinated solvents, acids, and fuels. Viton maintains reliable performance across a wide temperature range from -20°C to +200°C, with short-term excursions possible. It exhibits excellent resistance to compression set and high-pressure environments, making it suitable for demanding industrial processes involving strong oxidizers or high-purity chemicals. However, its high cost and susceptibility to ketones, esters, and amines necessitate careful fluid compatibility verification. Nitrile (NBR) offers a cost-effective solution for applications involving petroleum-based oils, aliphatic hydrocarbons, and water. It provides good abrasion resistance and mechanical strength at moderate pressures. Its primary limitation is poor resistance to ozone, weathering, polar solvents like ketones and esters, and strong acids or bases. Nitrile is generally restricted to temperatures between -30°C and +100°C, beyond which significant degradation occurs. Silicone (VMQ) excels in extreme temperature applications, functioning reliably from -60°C to +200°C, and offers good resistance to water, alcohols, and some acids. Its low toxicity makes it suitable for certain food or pharmaceutical segments. However, Silicone possesses poor tensile strength, high gas permeability, and very limited resistance to petroleum oils, fuels, and many solvents, restricting its use in general chemical pumping.

The comparative performance characteristics are summarized below for critical selection criteria.

| Material | Chemical Resistance Profile | Temperature Range (°C) | Typical Pressure Limit (Bar) | Key Applications & Limitations |

|---|---|---|---|---|

| Viton (FKM) | Exceptional: Acids, bases, aromatics, solvents, fuels. Poor: Ketones, esters, amines, low MW organic acids. | -20 to +200 | 25-35 | Chemical processing, semiconductor, high-purity fluids. High cost. Avoid ketones. |

| Nitrile (NBR) | Good: Aliphatic hydrocarbons, oils, water. Poor: Ozone, aromatics, ketones, esters, strong acids/bases. | -30 to +100 | 15-25 | Hydraulic systems, fuel transfer, general industrial oils. Cost-effective. Avoid solvents. |

| Silicone (VMQ) | Good: Water, alcohols, some acids/bases. Poor: Petroleum oils, fuels, solvents, concentrated acids. | -60 to +200 | 10-20 | High/low temp water, steam, food/pharma (specific grades). Low strength, high permeability. Avoid oils. |

Selection must prioritize the specific chemical composition, concentration, temperature profile, and pressure demands of the application. Suzhou Baoshida Trading Co., Ltd. provides comprehensive material compatibility data sheets and engineering support to ensure the optimal elastomer specification for PTFE diaphragm pump assemblies, minimizing total cost of ownership through extended service life and operational reliability in demanding industrial environments.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in industrial rubber solutions is anchored in deep material science expertise and precision tooling design, specifically tailored for demanding applications such as PTFE diaphragm pumps. Our team comprises five dedicated mould engineers and two specialized rubber formula engineers, enabling us to deliver fully integrated OEM solutions from concept to final production. This multidisciplinary structure ensures that both material performance and dimensional accuracy are optimized for long-term reliability in aggressive chemical, thermal, and mechanical environments.

Our formula engineers focus on custom elastomer development, with extensive experience in fluoropolymer composites, including modified PTFE, PFA, and FFKM blends. They rigorously evaluate filler dispersion, cross-link density, and thermal stability to produce diaphragm compounds that maintain integrity under cyclic stress and exposure to corrosive media. By controlling raw material sourcing and compounding in-house, we ensure batch-to-batch consistency and compliance with international standards such as FDA, NSF, and REACH.

Parallel to material development, our five mould engineers specialize in high-precision tooling for complex diaphragm geometries. Utilizing 3D CAD/CAM systems and finite element analysis (FEA), they design multi-cavity molds with tight tolerances (±0.05 mm) to support high-volume OEM production. Mold flow simulations are routinely conducted to optimize gating, cooling channels, and ejection systems, minimizing defects and extending tool life. All molds undergo rigorous in-house validation, including first-article inspection and accelerated life cycle testing under simulated operating conditions.

We offer full OEM support, including reverse engineering of legacy diaphragms, rapid prototyping, and design for manufacturability (DFM) feedback. Our clients benefit from accelerated time-to-market, with typical development cycles from sample to mass production completed within 8–10 weeks. With ISO 9001-certified processes and traceability down to individual batches, we ensure complete quality control and documentation transparency.

The following table outlines key technical specifications achievable through our engineering and manufacturing platform:

| Parameter | Specification |

|---|---|

| Material Types | PTFE, Modified PTFE, FFKM, PFA, Viton® |

| Hardness Range (Shore A) | 50–90 |

| Temperature Resistance | -40°C to +260°C (continuous) |

| Tensile Strength | Up to 28 MPa (FFKM compounds) |

| Elongation at Break | Up to 350% |

| Mould Tolerance | ±0.05 mm |

| Cycle Life (Dynamic Testing) | >10 million strokes (typical) |

| Regulatory Compliance | FDA, NSF, REACH, RoHS |

Our engineering synergy between rubber formulation and precision moulding positions Suzhou Baoshida as a trusted OEM partner for critical components in chemical processing, semiconductor manufacturing, and pharmaceutical transfer systems. We enable performance-driven design with industrial-grade scalability.

Customization Process

Customization Process for PTFE Diaphragm Pump Components

At Suzhou Baoshida Trading Co., Ltd., our PTFE diaphragm pump customization follows a rigorous, science-driven methodology to ensure optimal performance in demanding industrial environments. This process eliminates material failure risks while meeting exact OEM specifications for chemical resistance, temperature stability, and mechanical endurance.

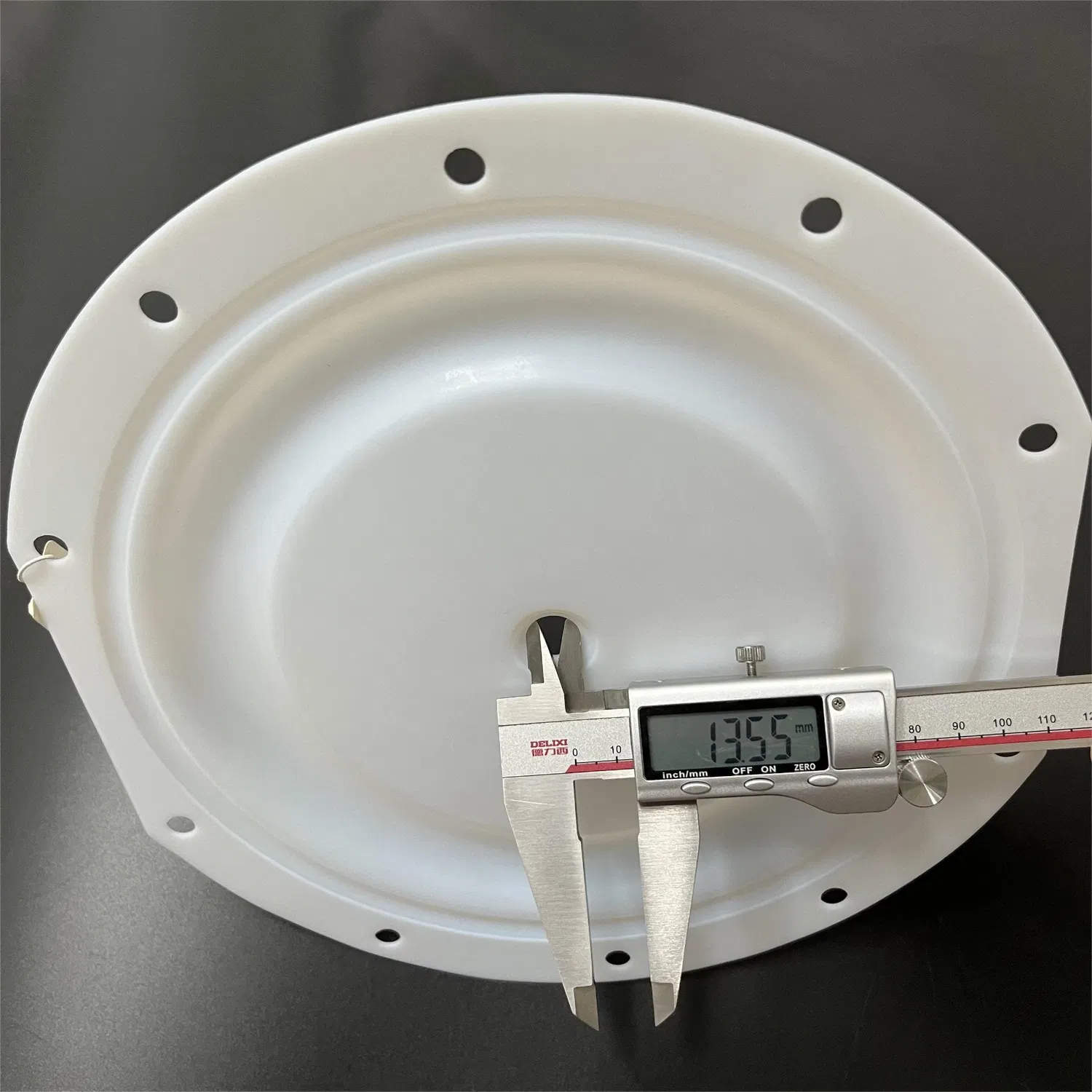

Drawing Analysis

We initiate with a granular review of engineering drawings, focusing on critical dimensional tolerances, stress concentration zones, and fluid contact surfaces. Finite element analysis (FEA) validates structural integrity under cyclic pressure loads, identifying potential fatigue points. Key parameters scrutinized include diaphragm thickness uniformity (±0.05 mm tolerance), edge sealing geometry, and flex-point radius. This phase ensures the design aligns with PTFE’s inherent low-friction properties and avoids excessive strain during 200+ million cycle operations. Non-conformities trigger immediate collaboration with the client’s engineering team for iterative refinement.

Formulation Development

Material science drives our proprietary PTFE compound design. Standard virgin PTFE (ASTM D4894) provides baseline chemical inertness, but most industrial applications require enhanced mechanical properties. Our engineers formulate custom grades by incorporating controlled percentages of high-purity fillers:

15–25% carbon fiber for tensile strength (≥30 MPa) and thermal conductivity

5–10% graphite for improved dry-run resilience

Specialty additives for acid/alkali resistance (e.g., fluorinated ethylene propylene copolymers)

Each formulation undergoes accelerated aging tests per ISO 22088-3 and dynamic mechanical analysis (DMA) to verify modulus retention at -70°C to +260°C.

Prototyping & Validation

Precision-machined prototypes are produced using ISO 13000-certified molding equipment. We conduct three-tier validation:

1. Dimensional verification via CMM (Coordinate Measuring Machine) against GD&T callouts

2. Functional testing in simulated process conditions (e.g., 10 bar pressure cycles with 98% sulfuric acid at 80°C)

3. Failure mode analysis using SEM (Scanning Electron Microscopy) on flexed samples

Clients receive comprehensive test reports including fatigue life curves and chemical compatibility matrices before sign-off.

Mass Production Execution

Upon approval, we transition to serial production under ISO 9001:2015 protocols. Each batch undergoes:

Real-time rheology monitoring during sintering (±2°C temperature control)

100% visual inspection for voids/inclusions per ASTM D3307

Statistical process control (SPC) tracking of durometer (55–65 Shore D) and elongation (≥300%)

Finished diaphragms are packaged in nitrogen-sealed containers to prevent moisture absorption prior to OEM integration.

Critical Performance Specifications Comparison

| Parameter | Standard Virgin PTFE | Baoshida Custom Grade BPT-7 | Test Standard |

|---|---|---|---|

| Continuous Temp. Range | -200°C to +260°C | -70°C to +260°C | ASTM D149 |

| Tensile Strength | 20–30 MPa | 32–40 MPa | ASTM D638 |

| Chemical Resistance | Excellent (pH 0–14) | Enhanced (HF, Cl₂, HNO₃) | ISO 175 |

| Flex Life (cycles) | 50 million | 200+ million | Internal BOST-TP-09 |

| Compression Set (24h) | 15% | ≤8% | ASTM D395 |

This systematic approach guarantees diaphragms that exceed OEM durability requirements in pharmaceutical, semiconductor, and chemical processing applications. Suzhou Baoshida’s vertical integration—from raw material sourcing to final validation—ensures batch-to-batch consistency critical for mission-critical fluid handling systems.

Contact Engineering Team

For industrial manufacturers seeking high-performance PTFE diaphragm pumps, Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions designed for durability, chemical resistance, and operational precision. As a trusted OEM partner in the industrial rubber sector, we specialize in custom-formulated elastomeric components that meet the rigorous demands of chemical processing, pharmaceuticals, semiconductor manufacturing, and wastewater treatment. Our PTFE diaphragm pumps are built to withstand aggressive media, extreme temperatures, and continuous cycle operations, ensuring minimal downtime and maximum process reliability.

Each PTFE diaphragm pump produced under our technical oversight integrates advanced fluoropolymer materials with precision-molded construction. These pumps leverage the inert nature of PTFE (polytetrafluoroethylene) to resist corrosion from acids, solvents, and halogens, making them ideal for handling highly corrosive or ultra-pure fluids. Our engineering team applies decades of rubber compounding expertise to optimize diaphragm flexibility, fatigue resistance, and seal integrity—critical factors in maintaining pump efficiency over extended service life.

We understand that industrial applications vary significantly in pressure, flow rate, and environmental exposure. That is why Suzhou Baoshida offers fully customizable configurations, including material grading, connection types, and actuation mechanisms. Whether you require ATEX certification for explosive environments or FDA-compliant wetted parts for sanitary processes, our technical team ensures compliance with international standards and OEM specifications.

To support seamless integration into your production systems, we provide comprehensive technical documentation, performance validation reports, and lifecycle testing data. Our quality management system adheres to ISO 9001 standards, with in-house testing facilities for burst pressure, cycle endurance, and chemical compatibility. This commitment to precision engineering and quality control makes us a preferred supplier for global industrial equipment manufacturers.

Below are representative technical specifications for our standard PTFE diaphragm pump series. Custom configurations are available upon request.

| Parameter | Specification |

|---|---|

| Diaphragm Material | PTFE (Teflon™), reinforced with EPDM or FKM backing |

| Maximum Discharge Pressure | 12 bar (174 psi) |

| Flow Rate Range | 0.5 – 60 L/min |

| Operating Temperature | -10°C to +150°C (-14°F to +302°F) |

| Fluid Compatibility | Acids, bases, solvents, halogens, oxidizers |

| Port Connections | 1/4″ to 2″ NPT, Tri-Clamp, or flanged |

| Actuation Type | Compressed air (1–8 bar), double-acting |

| Cycle Life | > 20 million cycles (tested) |

| Certifications | CE, RoHS, optional FDA, ATEX |

For technical consultation, sample requests, or OEM collaboration, contact Mr. Boyce at Suzhou Baoshida Trading Co., Ltd. Direct your inquiries to [email protected] with detailed application requirements, including media type, operating conditions, and performance targets. Our engineering team responds within 24 hours to provide material recommendations, CAD support, and prototyping timelines. Partner with us to integrate next-generation PTFE diaphragm technology into your industrial systems—engineered for performance, built for longevity.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).