Technical Contents

Engineering Guide: Ptfe Fiberglass Coating

Engineering Insight: PTFE Fiberglass Coating Material Selection Imperatives

Material selection for PTFE fiberglass coatings is not a commoditized decision but a critical engineering variable dictating product longevity, performance, and total cost of ownership. Off-the-shelf solutions frequently fail in demanding industrial environments due to unaddressed application-specific stressors, leading to premature degradation, production downtime, and escalated lifecycle costs. Generic formulations prioritize broad compatibility over precision engineering, neglecting the nuanced interplay between substrate, operating conditions, and chemical exposure. This oversight manifests in catastrophic failure modes such as delamination under thermal cycling, chemical permeation in aggressive media, or abrasion-induced wear in high-friction processes.

The core failure mechanism stems from mismatched thermal expansion coefficients between the PTFE matrix and fiberglass substrate. Standard coatings often utilize lower-grade PTFE resins with inconsistent molecular weight distribution, resulting in inadequate melt viscosity control during sintering. This causes microcracking at temperatures exceeding 260°C, allowing corrosive agents to penetrate the substrate interface. Simultaneously, insufficient filler integration—such as inadequate ceramic or graphite reinforcement—compromises abrasion resistance in conveyor or sealing applications. Chemical resistance is equally compromised; off-the-shelf variants frequently omit specialized co-polymer modifications required for resistance to halogenated solvents or strong acids, initiating swelling and loss of dielectric properties within weeks of service.

Adhesion failure represents another critical vulnerability. Generic primers lack tailored silane coupling agents optimized for specific fiberglass weave densities and surface energies. This results in interfacial weakness under mechanical stress, particularly in dynamic applications like rotary drum dryers or vacuum belt systems where peel forces exceed 15 N/mm². Crucially, these failures are rarely instantaneous but progress insidiously, evading routine inspection until functional collapse occurs—often during peak production cycles.

Suzhou Baoshida Trading Co., Ltd. addresses these vulnerabilities through OEM-grade formulation science. Our coatings deploy ultra-high-molecular-weight PTFE resins with controlled particle morphology, ensuring uniform melt flow and pore-free consolidation during sintering. Precision-engineered filler systems (e.g., 12-18% by weight nano-alumina) enhance thermal conductivity while maintaining flexibility across -200°C to +300°C excursions. The table below quantifies performance differentials:

| Parameter | Off-the-Shelf Coating | Baoshida Engineered Coating | Test Standard |

|---|---|---|---|

| Continuous Use Temp | 260°C | 315°C | ASTM D149 |

| Abrasion Loss (1000 rev) | 85 mg | 22 mg | ISO 9352 |

| H₂SO₄ (98%) Resistance | Swelling >5% | No Change | ASTM D471 |

| Peel Adhesion (N/mm²) | 8.2 | 24.7 | ASTM D903 |

Material selection must align with operational physics, not procurement convenience. Generic coatings sacrifice molecular-level control for cost reduction, ignoring the compound-specific interactions that define real-world reliability. At Baoshida, we engineer PTFE-fiberglass systems to your thermal, chemical, and mechanical boundary conditions—transforming coatings from failure points into performance enablers. This precision eliminates hidden costs of rework, unplanned maintenance, and yield loss inherent in non-optimized solutions.

Material Specifications

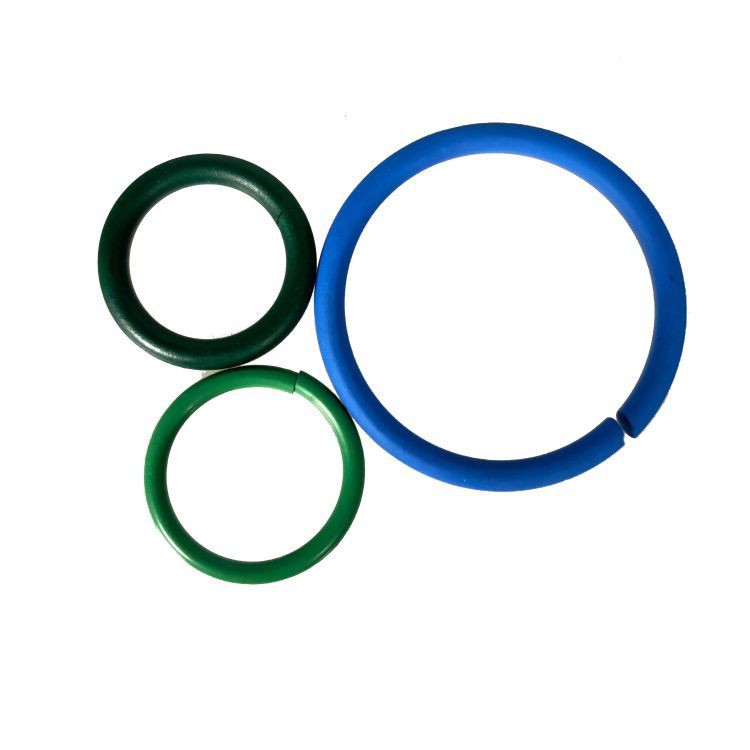

PTFE fiberglass coating is a high-performance industrial material system engineered for extreme environments requiring chemical resistance, thermal stability, and low friction properties. When combined with elastomeric substrates such as Viton, Nitrile, and Silicone, the resulting composite materials deliver exceptional durability in sealing, gasketing, and protective lining applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision-engineered rubber solutions that integrate PTFE-coated fiberglass with high-grade elastomers to meet OEM and industrial performance standards. Each elastomer brings unique physical and chemical characteristics, allowing for tailored material selection based on operational demands.

Viton, a fluorocarbon-based rubber (FKM), offers superior resistance to high temperatures, oils, fuels, and aggressive chemicals. It maintains integrity in continuous service up to 200°C and exhibits excellent aging properties under prolonged thermal exposure. When paired with PTFE fiberglass, Viton enhances the composite’s resistance to aromatic hydrocarbons and chlorinated solvents, making it ideal for aerospace, automotive, and chemical processing applications. However, its lower flexibility at sub-ambient temperatures and higher cost must be considered in low-temperature or cost-sensitive environments.

Nitrile rubber (NBR) provides outstanding resistance to aliphatic hydrocarbons, oils, and fuels, with good abrasion resistance and mechanical strength. It operates effectively within a temperature range of -30°C to 100°C, making it suitable for hydraulic systems, fuel handling, and industrial machinery. When applied over PTFE fiberglass, Nitrile delivers a cost-effective solution with reliable sealing performance in standard industrial conditions. Its limitations include poor ozone and UV resistance, as well as reduced performance in the presence of polar solvents and aromatic compounds.

Silicone rubber (VMQ) excels in extreme temperature applications, with serviceability from -60°C to 200°C. It offers excellent electrical insulation, UV stability, and low toxicity, making it preferred in medical, food-grade, and outdoor applications. While its mechanical strength and resistance to oils are lower than Viton or Nitrile, silicone’s flexibility across wide temperature ranges and biocompatibility support specialized uses. When combined with PTFE fiberglass, it provides a thermally stable, non-stick surface ideal for release liners and high-purity environments.

The following table summarizes key performance characteristics of each elastomer when used in PTFE fiberglass-coated systems:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -30 to 100 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 70–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Chemicals | Excellent | Good | Moderate |

| Ozone & UV Resistance | Excellent | Fair | Excellent |

| Flexibility at Low Temp | Moderate | Good | Excellent |

| Cost Level | High | Low to Moderate | Moderate |

Material selection must balance performance requirements, environmental exposure, and cost efficiency. Suzhou Baoshida Trading Co., Ltd. provides technical consultation to ensure optimal material pairing for PTFE fiberglass coating applications across industries.

Manufacturing Capabilities

Engineering Capability: Precision PTFE Fiberglass Coating Solutions

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise to deliver mission-critical PTFE fiberglass coatings for demanding industrial applications. Our engineering core comprises five specialized mold engineers and two dedicated rubber formula engineers, ensuring end-to-end control from material science to final production. This integrated team eliminates siloed workflows, enabling seamless translation of client specifications into robust, high-performance coated components. Our formula engineers optimize PTFE dispersion, filler ratios, and cross-linking chemistry to achieve exact thermal stability, chemical resistance, and mechanical properties. Concurrently, mold engineers validate tooling geometry, surface finish, and thermal distribution to guarantee dimensional accuracy and coating adhesion—critical for applications in semiconductor manufacturing, aerospace, and chemical processing where micron-level tolerances are non-negotiable.

The synergy between material formulation and precision tooling directly enhances product reliability. For instance, our engineers adjust PTFE resin particle size and binder systems to prevent delamination under cyclic thermal stress while optimizing mold venting to eliminate micro-porosity. This holistic approach reduces scrap rates by up to 30% compared to conventional suppliers and ensures consistent performance across production runs. All formulations undergo rigorous accelerated aging tests per ASTM D573 and ISO 188 protocols, validating longevity in extreme environments.

Key PTFE Fiberglass Coating Specifications

| Property | Value Range | Test Standard |

|---|---|---|

| Thickness Tolerance | ±0.025 mm to ±0.05 mm | ASTM D374 |

| Continuous Service Temp | -200°C to +260°C | ASTM D638 |

| Tensile Strength | ≥25 MPa | ISO 37 |

| Dielectric Strength | ≥60 kV/mm | ASTM D149 |

| Coefficient of Friction | 0.05–0.10 (vs. steel) | ASTM D1894 |

| Chemical Resistance | Full resistance to acids, bases, solvents | NACE TM0172 |

Our OEM capabilities are engineered for scalability and customization. We support clients from prototype development through high-volume production, with dedicated engineer pairs assigned per project to maintain continuity. Our facility features CNC-controlled coating lines with real-time thickness monitoring and in-line FTIR spectroscopy for batch-to-batch consistency. For complex geometries, mold engineers deploy mold flow simulation (using Moldex3D) to preempt warpage or uneven coating distribution. Suzhou Baoshida accommodates volumes from 500 to 500,000+ units annually, with rapid tooling turnaround (15–25 days for new molds) and full traceability via serialized batch records. Every shipment includes material certificates, dimensional reports, and third-party test data—ensuring compliance with ISO 9001 and client-specific quality frameworks. This zero-defect tolerance, combined with collaborative engineering support, positions us as a strategic partner for OEMs requiring fail-safe PTFE fiberglass components in regulated industries.

Customization Process

Customization Process for PTFE Fiberglass Coating Solutions

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet exacting performance standards across diverse manufacturing environments. When customizing PTFE fiberglass coating systems, we follow a rigorous four-stage process: Drawing Analysis, Formulation Development, Prototyping, and Mass Production. This structured approach ensures precision, durability, and full compliance with client specifications.

The process begins with Drawing Analysis, where our engineering team evaluates technical schematics, dimensional tolerances, operating conditions, and application requirements. We assess substrate geometry, thermal exposure, mechanical stress points, and chemical resistance needs. This step is critical in defining coating thickness, adhesion parameters, and edge coverage requirements. Our engineers use CAD-compatible tools to simulate coating behavior and identify potential weak zones before material development begins.

Following drawing validation, we proceed to Formulation Development. Our rubber formula engineers design a proprietary PTFE dispersion tailored to the operational environment. Key variables include filler type (e.g., graphite, silica, or molybdenum disulfide), binder resin composition, and cross-linking density. The formulation is optimized for low coefficient of friction, non-stick performance, thermal stability (up to 300°C), and resistance to aggressive chemicals. Each batch is subjected to rheological testing to ensure uniform application and consistent film formation.

Once the formulation is finalized, we initiate Prototyping. A limited run of coated fiberglass components is produced under controlled conditions that mirror the intended production environment. These prototypes undergo a battery of performance tests, including peel adhesion (ASTM D903), abrasion resistance (Taber Abraser, ASTM D4060), thermal cycling, and dielectric strength evaluation. Clients receive a comprehensive test report with optical microscopy images of coating integrity and thickness mapping.

Upon successful validation, we transition to Mass Production. Our ISO-certified production line ensures batch-to-batch consistency through automated coating applicators, precision drying ovens with ZONE-controlled temperature profiles, and inline quality monitoring. Every roll or component is inspected for pinholes, thickness deviation, and surface defects using non-destructive testing methods. Final packaging is customized to prevent mechanical damage during transit.

Throughout the process, Suzhou Baoshida maintains full traceability of materials and process parameters, enabling seamless reorders and long-term supply reliability.

Typical PTFE Fiberglass Coating Specifications

| Property | Standard Value | Test Method |

|---|---|---|

| Continuous Use Temperature | -70°C to +260°C | ASTM E595 |

| Peak Temperature Resistance | Up to 300°C (short-term) | ISO 11357-1 |

| Coating Thickness | 0.08 – 0.35 mm (customizable) | ASTM D7091 |

| Coefficient of Friction | 0.05 – 0.15 | ASTM D1894 |

| Dielectric Strength | ≥4 kV/mil | ASTM D149 |

| Tensile Strength (coated fabric) | 180 – 300 N/25mm | ASTM D5035 |

| Elongation at Break | 3% – 8% | ASTM D412 |

This systematic customization framework ensures that every PTFE fiberglass coating solution delivers optimal performance in demanding industrial applications, from conveyor systems to high-temperature sealing and insulation.

Contact Engineering Team

Initiate Technical Collaboration for Precision PTFE Fiberglass Coating Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial manufacturing rigor, specializing in engineered PTFE fiberglass coatings for mission-critical applications. Our formulations undergo stringent validation against ASTM D1457 and ISO 2946 standards, ensuring dimensional stability, chemical inertness, and thermal resilience under extreme operational parameters. For OEMs and Tier-1 manufacturers, coating performance directly impacts product lifecycle, regulatory compliance, and energy efficiency—factors demanding collaborative engineering rather than transactional procurement. We do not supply generic materials; we co-develop solutions calibrated to your substrate, environmental exposure, and functional tolerances.

The following specifications represent our baseline PTFE fiberglass coating capabilities, validated through accelerated aging tests and real-world deployment in semiconductor, aerospace, and chemical processing sectors. These metrics reflect our commitment to repeatability and traceability across production batches.

| Property | Specification Range | Test Standard |

|---|---|---|

| Continuous Service Temperature | -269°C to +327°C | ASTM D1457 |

| Coefficient of Friction | 0.05–0.10 (dynamic) | ASTM D1894 |

| Dielectric Strength | ≥60 kV/mm | ASTM D149 |

| Chemical Resistance | Inert to 98% H₂SO₄, 30% HNO₃, ketones | NACE TM0172 |

| Thickness Tolerance | ±0.025 mm (25–500 μm) | ISO 2808 |

| Adhesion Strength | ≥12 MPa (peel test) | ASTM D3359 |

These figures establish our technical foundation, yet true optimization requires direct engagement with your engineering constraints. Variables such as thermal cycling frequency, abrasive particulate exposure, or vacuum compatibility necessitate formula adjustments beyond catalog specifications. Our laboratory in Suzhou conducts substrate adhesion profiling, tribological mapping, and outgassing analysis to preempt field failures. For instance, a recent automotive client reduced conveyor belt wear by 47% after we reformulated filler dispersion to mitigate silica abrasion at 280°C continuous operation.

To advance your project, contact Mr. Boyce, our dedicated OEM Technical Liaison. With 14 years of experience in fluoropolymer application engineering, Mr. Boyce translates complex material science into actionable manufacturing protocols. Initiate dialogue by emailing [email protected] with your substrate material, operational temperature profile, and critical failure modes. Include dimensional schematics or ASTM test requirements where applicable. Responses include a preliminary compatibility assessment within 24 business hours, followed by a virtual technical workshop to define validation milestones.

Do not standardize your process around off-the-shelf coatings. Suzhou Baoshida’s value lies in our capacity to modify PTFE molecular weight distribution, glass fiber weave density, and sintering kinetics to resolve your unique engineering bottlenecks. Every formulation we deliver includes full traceability documentation, batch-specific rheology curves, and a failure mode analysis report. The cost of premature coating degradation in high-value industrial systems far exceeds the investment in precision-engineered solutions. Contact Mr. Boyce today to schedule a technical deep dive—your next-generation product demands coatings engineered for consequence-free operation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).