Technical Contents

Engineering Guide: Ptfe Pans

Engineering Insight: PTFE Pans – The Critical Role of Material Selection in Industrial Applications

In industrial environments where precision, durability, and chemical resistance are paramount, PTFE (polytetrafluoroethylene) pans serve as essential components in processes ranging from semiconductor manufacturing to pharmaceutical drying. However, despite the widespread availability of off-the-shelf PTFE pans, many end users encounter premature failure, contamination risks, and operational inefficiencies. These issues are not inherent to PTFE as a material but stem from inadequate material selection and a lack of application-specific engineering.

PTFE is renowned for its non-stick properties, thermal stability (up to 260°C continuously), and resistance to nearly all industrial chemicals. Yet, not all PTFE formulations are equivalent. Virgin PTFE, while chemically inert and pure, lacks mechanical strength under repeated thermal cycling or mechanical loading. In dynamic environments involving frequent handling or vibration, virgin PTFE pans may crack or deform. Conversely, filled PTFE compounds—reinforced with glass, carbon, or graphite—offer improved wear resistance and dimensional stability but may introduce extractables that compromise purity-critical processes.

Off-the-shelf PTFE pans are typically manufactured using standardized molds and generic material grades optimized for cost, not performance. These products often fail to account for application-specific variables such as thermal gradients, load distribution, exposure to aggressive solvents, or cleanroom compatibility. For example, a standard pan used in a high-vacuum deposition process may outgas fluoropolymers or absorb moisture, leading to particle contamination and yield loss. Similarly, in high-humidity environments, improperly sintered PTFE can exhibit micro-porosity, accelerating chemical ingress and structural degradation.

At Suzhou Baoshida Trading Co., Ltd., we approach PTFE pan fabrication as a systems engineering challenge. Each component is evaluated against the operational profile of the intended process. Material selection is guided by chemical exposure logs, thermal mapping data, and mechanical stress analysis. Our engineered solutions utilize high-molecular-weight PTFE resins with controlled sintering profiles to ensure homogeneity and minimize internal stresses. We also offer customization in wall thickness, radii, and surface finish to mitigate stress concentrations and improve process compatibility.

The following table outlines key PTFE material variants and their performance characteristics for industrial pan applications:

| Material Type | Max Continuous Temp | Chemical Resistance | Mechanical Strength | Outgassing Level | Recommended Use Case |

|---|---|---|---|---|---|

| Virgin PTFE | 260°C | Excellent | Low | Very Low | High-purity labs, food-grade processes |

| Glass-Filled PTFE | 280°C | Very Good | High | Low | High-load drying trays, automation lines |

| Carbon-Graphite PTFE | 300°C | Good | Very High | Moderate | High-wear transfer systems |

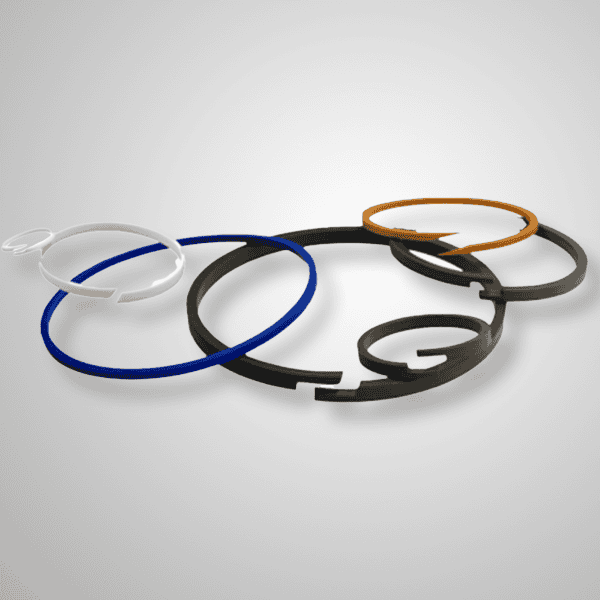

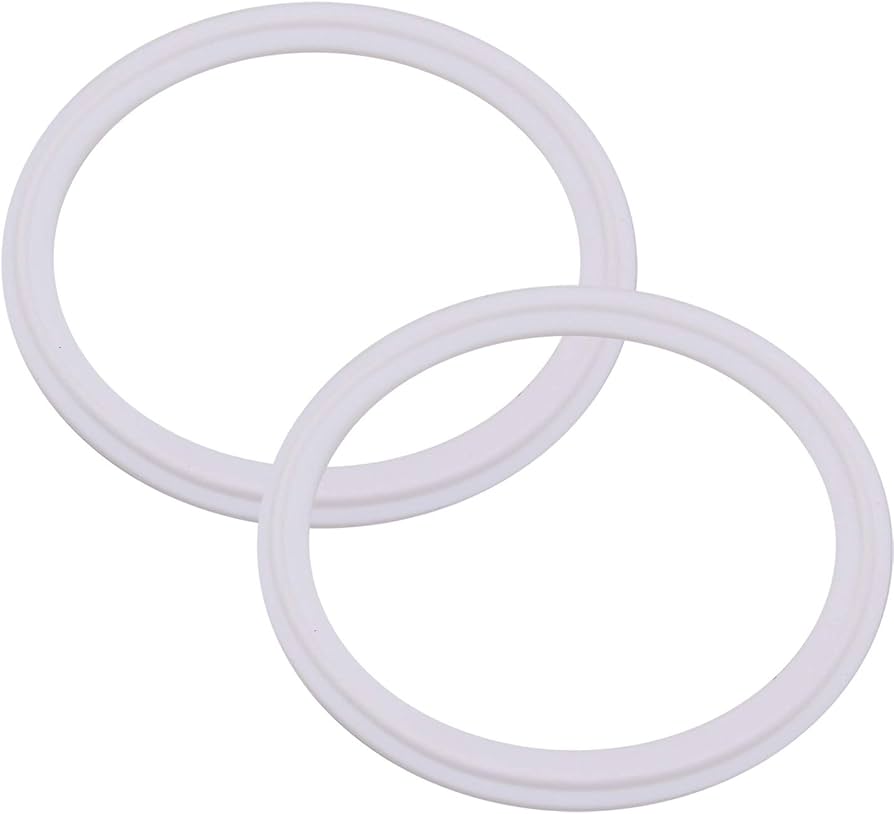

| Expanded PTFE (ePTFE) | 260°C | Excellent | Low (flexible) | Very Low | Sealing gaskets, low-pressure forms |

Material selection is not a commodity decision—it is a precision engineering imperative. Standardized PTFE pans may appear functionally identical, but their performance diverges significantly under real-world conditions. By prioritizing application-specific material engineering, Suzhou Baoshida ensures reliability, longevity, and compliance in the most demanding industrial settings.

Material Specifications

Material Specifications for Industrial Rubber Components

Suzhou Baoshida Trading Co., Ltd. clarifies a critical industry distinction: PTFE (polytetrafluoroethylene) is a fluoropolymer, not a rubber compound. Our expertise lies in elastomeric solutions for industrial sealing, gasketing, and fluid-handling applications where Viton, Nitrile, and Silicone rubber formulations deliver optimal performance. These materials are engineered to withstand extreme operational demands in automotive, aerospace, chemical processing, and semiconductor manufacturing. Precision in material selection directly impacts component longevity, safety, and system efficiency. Below we detail the scientific specifications governing each elastomer’s suitability for mission-critical applications.

Viton (FKM) fluorocarbon rubber excels in high-temperature and aggressive chemical environments. Its molecular structure provides exceptional resistance to oils, acids, and aromatic hydrocarbons up to 250°C continuous service. Standard formulations achieve 15–20 MPa tensile strength and 200–300% elongation, with hardness typically ranging 60–90 Shore A. Viton’s low gas permeability makes it indispensable for fuel systems and semiconductor tool seals where purity is non-negotiable. Nitrile (NBR) butadiene rubber offers cost-effective resilience against petroleum-based fluids and hydraulic oils. Operating effectively from -40°C to 120°C, it delivers 10–25 MPa tensile strength and 250–500% elongation at 50–90 Shore A hardness. Its superior abrasion resistance suits it for O-rings in hydraulic cylinders and low-pressure fuel lines, though ozone and ketone exposure must be mitigated. Silicone (VMQ) rubber provides unmatched thermal stability across -60°C to 230°C, with electrical insulation properties critical for aerospace and medical devices. While tensile strength is moderate (5–12 MPa), its 400–700% elongation and 30–80 Shore A hardness enable flexibility in dynamic seals. Silicone’s biocompatibility and resistance to UV/weathering support outdoor and life-science applications, though mechanical strength in high-stress scenarios requires reinforcement.

Material selection must align with fluid compatibility, thermal profiles, and mechanical stress. Suzhou Baoshida’s OEM engineering team validates formulations against ASTM D2000 standards, customizing compounds for compression set resistance, low-temperature flexibility, or plasma etch durability per client specifications. Our ISO 9001-certified production ensures batch-to-batch consistency for high-reliability components.

Comparative Material Specifications

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -40 to +120 | -60 to +230 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–12 |

| Elongation at Break (%) | 200–300 | 250–500 | 400–700 |

| Hardness Range (Shore A) | 60–90 | 50–90 | 30–80 |

| Key Chemical Resistance | Fuels, Acids, Ozone | Petroleum Oils, Water | Steam, Oxygen, UV |

| Primary Industrial Use | Semiconductor seals, Jet engine gaskets | Hydraulic seals, Fuel hoses | Medical tubing, Aerospace insulation |

Suzhou Baoshida Trading Co., Ltd. leverages decades of rubber compounding expertise to transform these material properties into engineered solutions. We rigorously test all formulations for compression set, fluid immersion, and dynamic performance to exceed OEM requirements. Contact our technical team for application-specific validation data and accelerated lifecycle testing protocols.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber solutions, delivering precision-engineered components tailored to the demanding requirements of modern manufacturing. Central to our technical capability is a dedicated team of five certified mould engineers and two specialized rubber formula engineers, enabling end-to-end control over product development, material optimization, and production scalability. This integrated engineering framework ensures that every PTFE pan and related component meets exacting performance standards across thermal stability, chemical resistance, and mechanical durability.

Our mould engineering team employs advanced CAD/CAM and finite element analysis (FEA) tools to design high-precision moulds optimized for PTFE and fluoropolymer processing. With over 60 combined years of experience in compression, transfer, and isostatic moulding techniques, the team ensures minimal material waste, consistent dimensional accuracy, and extended tool life. Each mould is rigorously tested under simulated production conditions to validate flow dynamics, pressure distribution, and cycle efficiency, resulting in reliable, repeatable output suitable for high-volume OEM manufacturing.

Complementing this capability is our in-house rubber formulation expertise. Our two formula engineers specialize in modifying elastomeric compounds to meet specific application demands, including enhanced thermal resilience, low outgassing, and compatibility with aggressive chemical environments. While PTFE itself is a high-performance fluoropolymer, our formulation team ensures that any composite or hybrid components—such as seals, gaskets, or backing layers—utilize optimized rubber blends that maintain integrity under continuous exposure to temperatures up to 260°C and corrosive agents like strong acids or solvents.

OEM collaboration is a cornerstone of our service model. We support clients from concept validation through prototyping, design for manufacturability (DFM) analysis, and full-scale production. Our engineers work directly with client specifications to develop customized PTFE pans with defined wall thickness, surface finish, dimensional tolerances, and performance benchmarks. With ISO 9001-certified processes and traceable material documentation, we ensure compliance with international quality standards across aerospace, semiconductor, chemical processing, and pharmaceutical industries.

The following table summarizes key technical capabilities and material performance metrics relevant to our PTFE-based manufacturing solutions:

| Parameter | Specification |

|---|---|

| Mould Design Capacity | Up to 1,200 mm diameter components |

| Dimensional Tolerance | ±0.1 mm (standard), ±0.05 mm (precision grade) |

| Operating Temperature Range | -200°C to +260°C |

| Chemical Resistance | Excellent against acids, bases, solvents |

| Tensile Strength (PTFE) | ≥25 MPa (ASTM D4894) |

| Elongation at Break (PTFE) | ≥300% |

| Surface Finish (Ra) | 0.8–3.2 μm (customizable) |

| OEM Lead Time (Prototype) | 15–25 days |

| Production Scale | Batch to high-volume serial production |

Through the synergy of advanced mould engineering and precise rubber formulation, Suzhou Baoshida delivers technically robust, application-specific PTFE solutions. Our OEM-ready infrastructure ensures rapid turnaround, consistent quality, and full compliance with industrial performance requirements.

Customization Process

Customization Process for Industrial PTFE Pans: Precision Engineering from Concept to Volume

At Suzhou Baoshida Trading Co., Ltd., our customization process for industrial PTFE pans integrates rigorous material science with OEM manufacturing excellence. This structured workflow ensures dimensional accuracy, chemical resilience, and thermal stability for demanding applications, from semiconductor processing to chemical handling. We begin with Drawing Analysis, where our engineering team scrutinizes client CAD files against ISO 2768 medium tolerances. Critical parameters—such as wall thickness uniformity, flange geometry, and surface roughness (Ra ≤ 0.8 µm)—are validated using GD&T protocols. Any deviations from manufacturable standards trigger collaborative redesigns, ensuring feasibility before material commitment.

The Formulation phase leverages our proprietary fluoropolymer compounding expertise. Unlike generic PTFE, our custom blends incorporate fillers like glass fiber or carbon to enhance wear resistance or thermal conductivity. Each formulation is modeled using rheological simulations to predict flow behavior during sintering, targeting optimal density (2.15–2.20 g/cm³) and minimizing void formation. Material batches undergo FTIR spectroscopy to confirm molecular integrity, with additives precisely metered to ±0.5% tolerance. This stage defines the pan’s core performance envelope, balancing non-stick properties against mechanical load requirements.

Prototyping transforms validated designs into testable units under controlled ISO Class 8 cleanroom conditions. We produce 3–5 pre-series units using CNC-machined molds, followed by sintering in nitrogen-purged ovens (375°C ±5°C ramp profile). Each prototype undergoes destructive and non-destructive testing: helium leak checks for porosity, ASTM D1457 friction coefficient validation (µ ≤ 0.10), and thermal cycling from -200°C to 260°C. Client feedback on dimensional reports and chemical exposure trials (e.g., 72-hour HNO₃ immersion) informs final adjustments.

Mass Production commences only after prototype sign-off, with full traceability via serialized batch records. Our Suzhou facility employs automated molding presses with real-time pressure monitoring (±0.3 MPa accuracy) and in-line vision systems for 100% geometric inspection. Every pan is serialized, with material certificates (including ASTM F739 permeation data) and sintering logs archived for 10 years. Production lots undergo AQL 1.0 sampling, with critical dimensions verified via CMM. This closed-loop system achieves >99.2% first-pass yield at volumes up to 50,000 units monthly.

Key PTFE formulation properties for industrial pans are standardized below:

| Property | Test Standard | Target Value | Significance |

|---|---|---|---|

| Continuous Use Temp | ASTM D1457 | -200°C to 260°C | Thermal stability in cryogenic/high-heat processes |

| Coefficient of Friction | ASTM D1894 | ≤ 0.10 | Non-stick performance under load |

| Tensile Strength | ASTM D1457 | ≥ 24 MPa | Structural integrity during handling |

| Dielectric Strength | ASTM D149 | ≥ 60 kV/mm | Electrical insulation for semiconductor tools |

| Chemical Resistance | ISO 175 | Pass (all acids/bases) | Compatibility with aggressive media |

This end-to-end customization framework ensures Suzhou Baoshida delivers PTFE pans that meet exact operational demands, reducing client downtime through scientifically validated manufacturing rigor. Partner with us to transform specifications into reliable industrial assets.

Contact Engineering Team

For industrial manufacturers seeking high-performance rubber solutions tailored to demanding applications, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in advanced material engineering. Specializing in precision rubber components and industrial tooling systems, we extend our expertise beyond conventional offerings to support specialized manufacturing environments—such as those utilizing PTFE-coated pans in high-temperature, low-friction processing operations. While PTFE pans themselves are not rubber products, their integration into industrial systems often requires complementary elastomeric seals, gaskets, and thermal management components, where our engineering insight becomes critical. Our team ensures seamless compatibility between rubber materials and adjacent systems, including those involving fluoropolymer surfaces.

At Suzhou Baoshida, we combine deep formulation knowledge with OEM-level production capabilities to deliver custom-engineered rubber solutions. Whether you are managing heat press lines, composite curing systems, or industrial molding equipment that incorporates PTFE-coated tooling, our engineers can assist in selecting and fabricating rubber components that maintain integrity under continuous thermal cycling, chemical exposure, and mechanical stress. Our formulations are optimized for long service life, dimensional stability, and resistance to degradation when operating in proximity to non-stick surfaces and elevated temperatures.

To ensure optimal performance, we recommend evaluating the full operational environment—including temperature profiles, compression loads, and media exposure—when specifying rubber parts for use alongside PTFE systems. Our technical team conducts comprehensive material analysis to match elastomer properties with your process requirements, supporting applications in aerospace, automotive, electronics, and advanced manufacturing sectors.

For immediate technical consultation or custom quotation, contact Mr. Boyce, Rubber Formula Engineer and OEM Manager at Suzhou Baoshida Trading Co., Ltd. He leads material development and client engineering support, ensuring that every solution is grounded in scientific rigor and industrial practicality. Reach Mr. Boyce directly via email at [email protected] to discuss your specifications, review material compatibility, or initiate a collaborative development project.

Below is a representative specification table for commonly requested rubber materials used in high-temperature industrial environments, such as those involving PTFE-coated equipment:

| Material | Temperature Range (°C) | Hardness (Shore A) | Tensile Strength (MPa) | Key Resistance Properties |

|---|---|---|---|---|

| Silicone Rubber (VMQ) | -60 to +230 | 40–80 | 6–9 | Heat, UV, Ozone |

| Fluorocarbon Rubber (FKM) | -20 to +220 | 60–90 | 12–18 | Oil, Chemicals, Heat |

| EPDM Rubber | -50 to +150 | 50–80 | 8–15 | Steam, Water, Weathering |

| PTFE-Composite Gasket | -200 to +260 | 55–75 (filled) | 10–14 | Non-stick, Chemical Inertness |

All materials can be customized in formulation, shape, and size to meet OEM drawings or functional requirements. Partner with Suzhou Baoshida for technically driven rubber solutions backed by precision engineering and responsive service. Contact Mr. Boyce today to advance your manufacturing performance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).