Technical Contents

Engineering Guide: Pvc Clear Sheeting

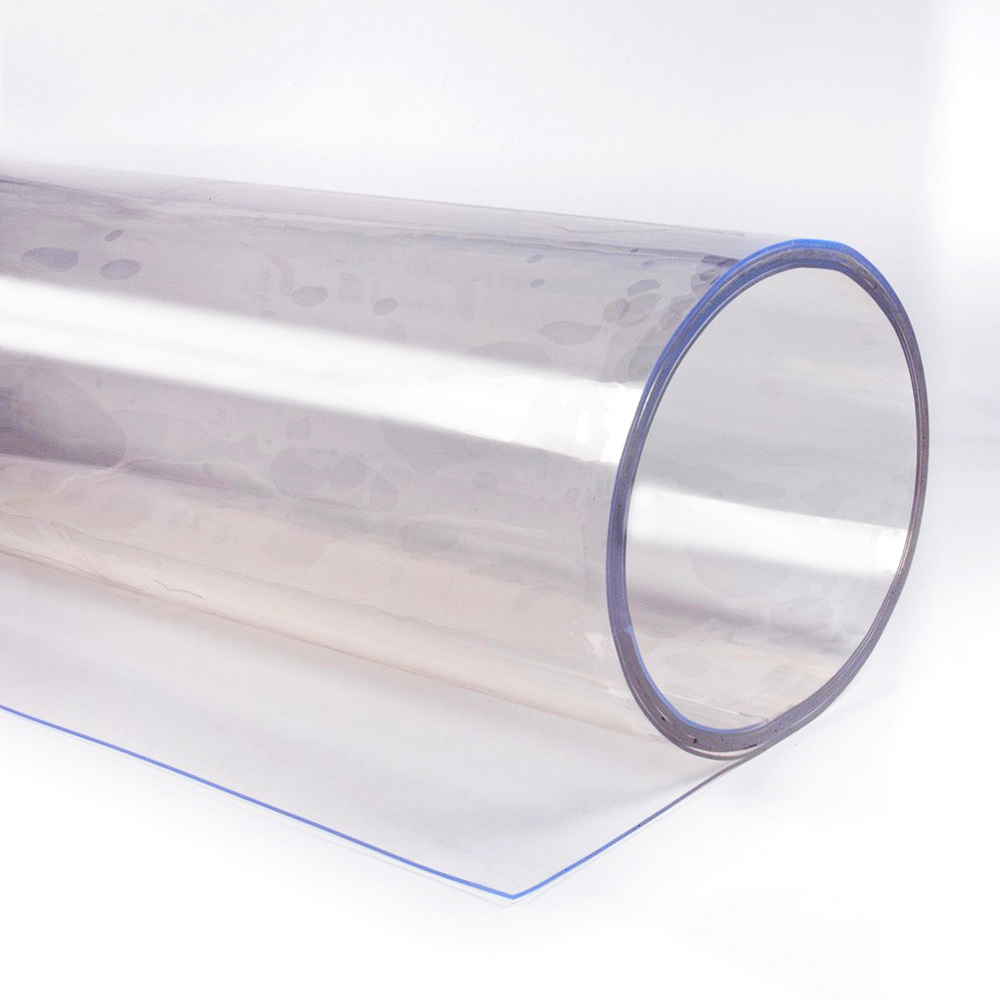

Engineering Insight: PVC Clear Sheeting – The Critical Role of Material Selection

In industrial environments where performance, durability, and regulatory compliance are non-negotiable, the selection of PVC clear sheeting cannot be treated as a commodity decision. Off-the-shelf formulations frequently fail under real-world operational demands due to oversimplified design assumptions and inadequate material engineering. At Suzhou Baoshida Trading Co., Ltd., we emphasize that precision in polymer formulation, plasticizer selection, and additive integration directly determines functional lifespan and system integrity.

Standard PVC sheeting, often marketed as “general purpose,” typically employs low-cost plasticizers such as DEHP or DBP. These compounds exhibit poor migration resistance and thermal stability, leading to embrittlement, clouding, and loss of flexibility within months of service. In dynamic sealing or high-flex applications, this degradation accelerates, resulting in premature failure. Moreover, such formulations may not meet evolving environmental and safety standards, particularly in food-contact, medical, or cleanroom settings governed by FDA, REACH, or RoHS regulations.

True engineering-grade PVC clear sheeting requires a systems approach. Plasticizers must be selected for compatibility with operating temperatures and mechanical stress profiles. For instance, polymeric plasticizers like DINCH or TOTM offer superior extraction resistance and long-term flexibility compared to phthalate-based alternatives. UV stabilizers, thermal inhibitors, and anti-fog additives must be compounded at optimal concentrations to preserve optical clarity and mechanical performance under prolonged exposure.

Equally critical is the control of manufacturing variables—melt homogeneity, cooling rate, and calendering precision—which influence tensile strength, haze, and dimensional stability. Sheet thickness tolerance, often overlooked in generic products, becomes paramount in automated assembly lines where ±0.05 mm deviation can disrupt sealing consistency.

We illustrate key differentiators between standard and engineered PVC clear sheeting in the comparative specification table below.

| Property | Standard PVC Sheeting | Engineered PVC Sheeting (Baoshida) |

|---|---|---|

| Thickness Range | 0.3 – 2.0 mm | 0.15 – 3.0 mm (±0.05 mm tolerance) |

| Plasticizer Type | DEHP, DBP | DINCH, TOTM (non-phthalate) |

| Tensile Strength (MPa) | 18 – 22 | 28 – 32 |

| Elongation at Break (%) | 200 – 280 | 350 – 420 |

| Operating Temperature Range | -10°C to 60°C | -30°C to 80°C |

| Optical Clarity (Haze, %) | ≤ 12% | ≤ 5% |

| Regulatory Compliance | Limited (REACH SVHC) | FDA, RoHS, REACH fully compliant |

| Flex Durability (Gelbo Flex, 10k cycles) | Cracking observed | No cracking, minimal haze increase |

The data underscores a fundamental principle: performance is engineered, not assumed. At Suzhou Baoshida Trading Co., Ltd., our formulations are validated through accelerated aging, dynamic flex testing, and real-environment simulation. We collaborate with OEMs to align material properties with application-specific stressors—ensuring that PVC clear sheeting performs not just on day one, but throughout its intended lifecycle.

Material Specifications

Material Specifications: PVC Clear Sheeting in Industrial Rubber Component Manufacturing

Suzhou Baoshida Trading Co., Ltd. provides critical material specifications for PVC clear sheeting used as a processing aid in industrial rubber component production. While PVC clear sheeting itself is a thermoplastic film, its role in rubber manufacturing—particularly as release liners, protective barriers, or calibration layers during vulcanization—demands precise technical alignment with elastomeric compounds. This sheeting must exhibit optical clarity for visual process control, consistent thickness tolerance (±0.02mm), and thermal stability up to 180°C to withstand curing cycles without deformation or residue transfer. Key properties include Shore A hardness of 85–95, tensile strength ≥25 MPa (ASTM D638), and exceptional release characteristics against uncured rubber compounds like Viton, Nitrile, and Silicone. Crucially, PVC sheeting must resist plasticizer migration that could contaminate sensitive rubber formulations, ensuring final product integrity.

The performance of end-use rubber components hinges on selecting the correct elastomer. Below is a comparative analysis of three primary materials processed with PVC sheeting in OEM manufacturing environments. Specifications reflect standard industrial grades compliant with ASTM D2000 and ISO 37.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -30 to +120 | -60 to +230 |

| Tensile Strength (MPa) | 15–25 | 10–20 | 6–12 |

| Elongation at Break (%) | 150–300 | 200–400 | 200–800 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Key Chemical Resistance | Fuels, oils, acids | Aliphatic hydrocarbons | Ozone, UV, water |

| Critical Limitation | Poor steam resistance | Limited high-temp stability | Low tear strength |

Viton excels in aerospace and chemical sealing where extreme heat and aggressive fluids are present but requires precise mold temperature control (160–180°C) during curing. Nitrile remains the cost-effective solution for automotive fuel and oil systems, though its narrower thermal window necessitates strict process monitoring to avoid reversion. Silicone dominates medical and high-purity applications due to biocompatibility and wide thermal resilience, yet its low tear strength demands careful handling during demolding—where PVC sheeting’s non-stick surface prevents surface damage.

For OEMs, material selection directly impacts yield rates and lifecycle performance. Viton molds require extended cure times (15–20 min) to minimize compression set (<20%), while NBR’s faster cure (8–12 min) suits high-volume production but risks under-cure if process parameters deviate. Silicone’s peroxide curing demands immaculate mold release—PVC sheeting here prevents adhesion to tooling without silicone-specific release agents. At Suzhou Baoshida, we validate all PVC sheeting against these elastomer-specific requirements, ensuring dimensional stability during press cycles and zero interaction with accelerators or fillers. Our technical team collaborates with OEMs to match sheeting thickness (0.1–0.5mm) and surface energy to compound tackiness, eliminating production defects like air entrapment or surface pitting. This precision guarantees seamless integration into automated rubber manufacturing lines while maintaining the stringent quality standards demanded by global industrial sectors.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for PVC Clear Sheeting

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance PVC clear sheeting. With a dedicated team comprising five experienced mould engineers and two specialized rubber formula engineers, we integrate material science with precision manufacturing to deliver tailored, OEM-grade products that meet exacting industrial standards.

Our formula engineers focus on the molecular architecture of PVC compounds, optimizing plasticizer selection, thermal stabilizers, UV resistance, and clarity retention. This scientific approach ensures that our clear sheeting maintains optical transparency, mechanical resilience, and long-term durability under diverse environmental conditions. By adjusting the polymer matrix formulation, we achieve precise control over hardness (ranging from 50 to 90 Shore A), tensile strength, elongation at break, and low-temperature flexibility—critical parameters for applications in protective covers, industrial glazing, and transparent enclosures.

Complementing this material expertise, our five mould engineers specialize in tooling design, dimensional accuracy, and process optimization for continuous sheet extrusion. They employ advanced CAD/CAM systems and finite element analysis (FEA) to simulate flow dynamics and cooling profiles, minimizing defects such as warpage, surface haze, or thickness variation. Their deep understanding of extrusion die geometry and temperature zoning enables consistent production of sheets with tight tolerances and superior surface finish.

This synergy between material formulation and mould engineering allows us to offer full OEM services—from concept validation and prototype development to mass production and quality assurance. Clients benefit from rapid turnaround times, regulatory compliance (REACH, RoHS), and batch-to-batch consistency. Whether the requirement is anti-static, flame-retardant, or food-contact compliant sheeting, our team delivers engineered solutions aligned with functional and regulatory demands.

We maintain strict process controls across all production stages, supported by in-house testing laboratories that verify physical, thermal, and optical properties. Our facility is equipped for wide-format extrusion, enabling sheet widths up to 1,500 mm and thicknesses from 0.15 mm to 3.0 mm, with options for co-extrusion and surface treatments.

The following table outlines key technical specifications achievable with our engineered PVC clear sheeting:

| Property | Standard Range | Test Method |

|---|---|---|

| Hardness (Shore A) | 50–90 | ASTM D2240 |

| Tensile Strength | 12–25 MPa | ASTM D412 |

| Elongation at Break | 200–400% | ASTM D412 |

| Thickness Tolerance | ±0.05 mm (for 1.0 mm sheet) | ISO 2768 |

| Light Transmission | ≥85% (at 1 mm thickness) | ASTM D1003 |

| Operating Temperature | -10°C to +60°C | Internal |

| Width Capability | Up to 1,500 mm | Custom |

| Regulatory Compliance | REACH, RoHS, FDA (upon request) | — |

Through integrated engineering expertise and a commitment to innovation, Suzhou Baoshida Trading Co., Ltd. ensures that every meter of PVC clear sheeting produced meets the highest benchmarks in performance, clarity, and reliability.

Customization Process

PVC Clear Sheeting Customization Process: Precision Engineering Pathway

Suzhou Baoshida Trading Co., Ltd. executes a rigorous, science-driven customization protocol for industrial PVC clear sheeting, ensuring OEM-grade consistency from concept to volume output. This structured methodology minimizes iteration risk and guarantees final product alignment with demanding application requirements. The process initiates with comprehensive Drawing Analysis. Our engineering team conducts meticulous dimensional verification against client-provided CAD files or technical drawings, focusing on critical features such as thickness gradients, tolerance zones per ISO 2768-mK, edge geometry, and surface finish specifications. We identify potential manufacturability conflicts early, particularly regarding complex contours or ultra-tight optical clarity zones, providing actionable feedback before material commitment. This phase leverages GD&T principles to prevent downstream production deviations.

Subsequent Formulation development is rooted in polymer science. Based on the validated drawing requirements and application environment (e.g., UV exposure, chemical contact, temperature range), our rubber formula engineers select base PVC resins and curate proprietary additive packages. Key considerations include optimizing plasticizer systems for permanent clarity and low migration, incorporating UV stabilizers compliant with ASTM D4329, and integrating thermal stabilizers meeting strict RoHS/REACH standards. All formulations are designed phthalate-free where mandated, utilizing alternatives like DINCH or DOTP. Computational modeling predicts compound behavior during extrusion, ensuring target mechanical properties and optical performance are achievable.

Prototyping follows formulation finalization using dedicated pilot lines. Short-run sheets are produced under controlled conditions mirroring mass production parameters. Each prototype undergoes stringent in-house validation against the agreed specification sheet. Critical tests include haze measurement per ASTM D1003, tensile strength per ASTM D638, Shore A hardness, and accelerated aging for yellowing resistance. Dimensional accuracy is verified using calibrated CMM equipment. Client feedback on physical samples is integrated iteratively; only upon formal sign-off does the process advance.

Mass Production deployment utilizes Baoshida’s fully automated extrusion lines with integrated SPC systems. Real-time monitoring of melt temperature, line speed, and cooling rates ensures batch-to-batch repeatability. Every production meter is subject to inline optical inspection for defects and periodic batch testing against the core specification parameters. Rigorous traceability links each roll to its specific formulation batch and process log, enabling full quality auditability. This closed-loop system guarantees that the final PVC clear sheeting consistently meets the exact performance profile validated during prototyping.

Core PVC Clear Sheeting Specification Parameters

| Parameter | Target Specification | Test Method |

|---|---|---|

| Thickness Tolerance | ±0.05 mm (for 0.5mm) | ASTM D5947 |

| Clarity (Haze) | ≤ 1.5% | ASTM D1003 |

| Shore A Hardness | 70 ± 5 | ASTM D2240 |

| Thermal Stability | No yellowing @ 100°C/72h | ISO 188 |

Contact Engineering Team

For industrial manufacturers seeking high-performance PVC clear sheeting solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the global supply chain. Specializing in precision-engineered rubber and polymer materials, our company delivers consistent quality, technical reliability, and scalable production capabilities tailored to the rigorous demands of industrial applications. Our PVC clear sheeting is manufactured under strict quality control protocols, ensuring optical clarity, mechanical durability, and resistance to environmental stressors such as UV exposure, moisture, and chemical agents.

We serve a diverse range of industries including automotive, construction, electronics, and medical device manufacturing, where transparency, dimensional stability, and long-term performance are non-negotiable. Whether you require custom thicknesses, specific plasticizer formulations, or anti-static properties, our technical team collaborates directly with clients to engineer solutions that meet exact functional and regulatory requirements.

To ensure compatibility with your application, we provide comprehensive material data sheets, batch traceability, and third-party test certifications upon request. Our production facilities adhere to ISO 9001 standards, and all PVC formulations are REACH and RoHS compliant, supporting sustainable and safe manufacturing practices.

The following table outlines the standard technical specifications for our most commonly requested PVC clear sheeting product line:

| Property | Test Method | Value |

|---|---|---|

| Thickness Range | ASTM D374 | 0.15 mm – 3.0 mm |

| Tensile Strength | ASTM D412 | ≥18 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Hardness (Shore A) | ASTM D2240 | 85 ± 5 |

| Light Transmission | ASTM D1003 | ≥88% (at 1.0 mm thickness) |

| Operating Temperature Range | — | -10°C to +60°C |

| Plasticizer Content | ISO 177 | DINP, 35–40% |

| Flame Resistance | UL94 | HB Rated |

| Specific Gravity | ASTM D792 | 1.28 – 1.32 |

Custom modifications are available for enhanced flame retardancy, UV stabilization, low-temperature flexibility, and anti-fog properties. Minimum order quantities and lead times are optimized for both prototype development and high-volume production runs.

For technical consultation, sample requests, or pricing inquiries, please contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce leads material formulation and client integration projects, ensuring that every product delivered aligns precisely with the engineering and operational needs of our partners.

Reach out directly via email at [email protected] to initiate a technical discussion. Include your application requirements, volume expectations, and any performance criteria to receive a tailored proposal within 24 business hours. Our team supports communication in English, Mandarin, and German, facilitating seamless collaboration across international markets.

Partner with Suzhou Baoshida for PVC clear sheeting that combines scientific precision with industrial resilience. Your next-generation manufacturing solution begins with an engineered conversation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).