Technical Contents

Engineering Guide: Pvc Garage Floor

Engineering Insight: PVC Garage Floor Material Selection Criticality

The performance longevity of PVC garage flooring systems hinges on precise polymer formulation and industrial-grade material selection. Generic retail solutions frequently fail due to inadequate consideration of dynamic garage environments, where exposure to automotive fluids, thermal cycling, and mechanical abrasion demands engineered resilience. Off-the-shelf products often utilize low-cost plasticizers and excessive filler content, accelerating degradation through plasticizer migration and embrittlement. This results in premature cracking, delamination, and loss of structural integrity under real-world conditions.

Industrial applications require PVC compounds with optimized polymer chain stability and cross-linking density. Standard consumer-grade PVC typically employs ortho-phthalate plasticizers, which volatilize when exposed to engine oils or temperature fluctuations exceeding 40°C. This causes surface hardening and microfracturing, compromising slip resistance and dimensional stability. Conversely, engineered solutions incorporate high-molecular-weight non-phthalate plasticizers (e.g., DINCH or polymerics) with superior retention properties, maintaining flexibility across -30°C to 80°C operational ranges. Fillers must be minimized to ≤15% by weight and strictly controlled for particle size distribution; excessive calcium carbonate or chalk content in retail products reduces tensile strength by up to 40% and promotes moisture wicking at substrate interfaces.

Chemical resistance is another critical differentiator. Garage floors face routine exposure to hydrocarbons, brake fluids, and battery acids. Retail PVC often lacks sufficient barrier properties, leading to swelling and adhesion failure. Industrial formulations integrate co-polymer modifiers and UV stabilizers to resist common automotive contaminants without compromising mechanical properties.

The following table contrasts key specifications between standard retail PVC flooring and engineered industrial solutions:

| Parameter | Standard Retail PVC | Industrial-Grade PVC (Suzhou Baoshida Specification) |

|---|---|---|

| Shore A Hardness | 60–70 | 85–90 |

| Tensile Strength (MPa) | 8–12 | ≥18 |

| Elongation at Break (%) | 150–250 | ≥350 |

| Plasticizer Retention (70°C/168h) | ≤60% loss | ≤8% loss |

| Hydrocarbon Resistance | Swelling >15% | Swelling <3% |

Failure analysis of retail PVC installations consistently reveals three root causes: insufficient thermal stability leading to curling at seams, inadequate filler dispersion causing localized stress fractures, and poor adhesion promoter integration resulting in debonding under cyclic loading. These defects manifest within 12–18 months in commercial settings, incurring replacement costs exceeding initial material investment by 300%.

Suzhou Baoshida’s OEM-grade PVC flooring leverages proprietary polymer blending and extrusion protocols to achieve consistent density (1.35–1.40 g/cm³) and homogeneous additive distribution. This ensures dimensional stability under 50,000+ abrasion cycles (DIN 53333) and sustained chemical resistance per ISO 175 standards. Material selection is not a cost variable but a performance determinant—where precision engineering directly correlates with operational uptime and lifecycle value in demanding industrial environments.

Material Specifications

Material Specifications for PVC Garage Floor Applications

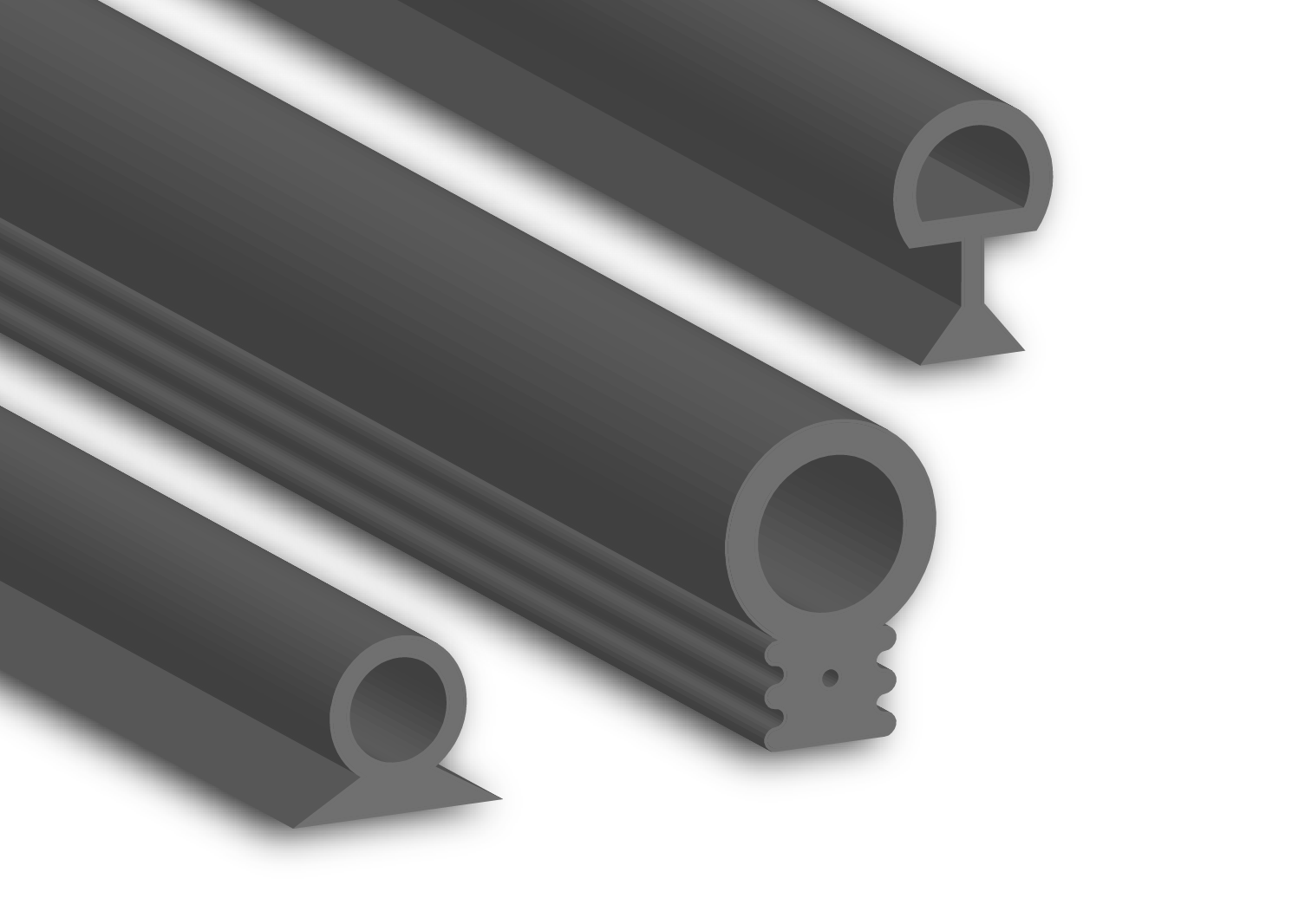

In industrial flooring solutions, particularly within the domain of PVC garage floor systems, selecting the appropriate elastomeric material is critical for ensuring durability, chemical resistance, and long-term performance under variable environmental and mechanical stress. At Suzhou Baoshida Trading Co., Ltd., we specialize in advanced industrial rubber solutions tailored to meet the rigorous demands of commercial and industrial environments. Our expertise includes the integration of high-performance elastomers such as Viton, Nitrile (NBR), and Silicone into flooring applications where resilience and material integrity are paramount.

Viton, a fluorocarbon-based synthetic rubber, offers exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. This makes it ideal for garage environments exposed to automotive fluids, solvents, and elevated thermal conditions. With continuous service capabilities up to 230°C and outstanding aging characteristics, Viton provides long-term stability even in harsh operating conditions. However, its higher cost and reduced flexibility at low temperatures must be considered in cost-sensitive or cold-climate installations.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is widely used due to its excellent resistance to petroleum-based oils, greases, and hydraulic fluids. It offers good mechanical strength and abrasion resistance, making it a practical choice for standard garage flooring subjected to frequent vehicle traffic and fluid exposure. Nitrile performs reliably within a temperature range of -30°C to 105°C, balancing cost and functionality. While less resistant to ozone and UV degradation compared to other elastomers, proper formulation and protective topcoats can mitigate these limitations in indoor applications.

Silicone rubber is distinguished by its thermal stability across extreme temperatures, ranging from -60°C to 200°C, and excellent resistance to UV radiation and ozone. It maintains flexibility and structural integrity under thermal cycling, making it suitable for environments with fluctuating temperatures. However, silicone exhibits lower tensile strength and abrasion resistance compared to Viton and Nitrile, and it is less resistant to hydrocarbon oils. Its primary advantage lies in non-marking properties and electrical insulation, beneficial in specialized garage or service bay applications.

The following table provides a comparative overview of key material properties to guide selection for PVC garage floor systems:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 105 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor to Fair |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Abrasion Resistance | Good | Very Good | Moderate |

| Chemical Resistance | Outstanding | Good | Moderate |

| Cost Level | High | Moderate | High |

Selection of the optimal elastomer must align with operational demands, environmental exposure, lifecycle expectations, and budgetary constraints. At Suzhou Baoshida Trading Co., Ltd., we support OEMs and industrial clients with precision-engineered rubber solutions, ensuring compatibility and performance in every PVC garage floor application.

Manufacturing Capabilities

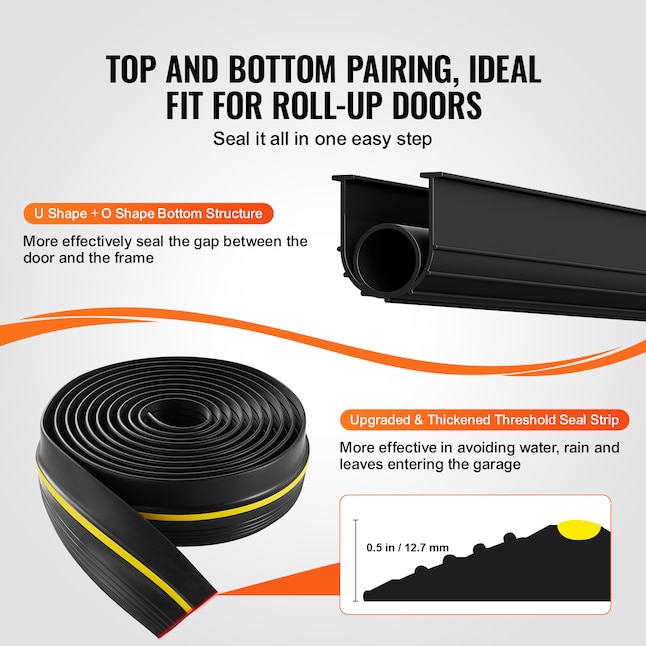

Engineering Capability: Precision-Driven PVC Garage Floor Solutions

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise to deliver engineered PVC garage floor solutions meeting stringent industrial demands. Our core strength lies in a dedicated engineering team comprising five specialized mold designers and two advanced formula chemists. This integrated structure ensures end-to-end control from material science to production tooling, eliminating external dependencies and accelerating time-to-market for OEM partners.

Our mold engineering team utilizes 3D simulation software to optimize cavity design, thermal distribution, and ejection mechanics. This precision minimizes flash, reduces cycle times by up to 18%, and guarantees dimensional stability across complex geometries. Critical for garage flooring, this approach ensures seamless interlocking patterns and consistent thickness tolerances of ±0.15mm, preventing warpage under thermal cycling. Concurrently, our formula engineers focus on polymer matrix modification. Through rigorous compounding of PVC resins, plasticizers, and performance additives, we achieve tailored material properties including enhanced UV resistance, non-slip surface textures, and chemical resilience against automotive fluids. Each formulation undergoes accelerated aging tests to validate 15+ year service life in harsh environments.

OEM collaboration is central to our methodology. We provide full turnkey support: from initial concept validation and prototyping to mass production and quality assurance. Clients retain full intellectual property rights, while our facility handles tooling fabrication, material sourcing, and ISO 9001-certified production. This eliminates capital expenditure for partners and ensures consistent batch-to-batch repeatability. Our engineers work directly with client R&D teams to adjust formulations for regional climate requirements or specific load-bearing needs, such as increased puncture resistance for commercial fleet facilities.

Material performance is non-negotiable. The table below details our standard PVC garage floor compound specifications, all achievable within our 5,000m² Suzhou facility equipped with 200-ton hydraulic presses and automated mixing lines. Custom parameters are developed within 4–6 weeks through iterative lab testing and pilot runs.

| Property | Test Standard | Value Range |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65–85 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Operating Temperature | ISO 188 | -30°C to +80°C |

| Abrasion Loss (H18) | ISO 4649 | ≤0.15 g |

| Oil Resistance (IRMA) | ASTM D471 | ≤15% volume swell |

This engineering rigor translates to reliable, high-yield manufacturing for global OEMs. By unifying material science with precision tooling expertise, Baoshida delivers PVC garage floors that exceed performance benchmarks while reducing total production costs. We invite partners to collaborate on specifications where technical excellence defines market differentiation.

Customization Process

Customization Process for PVC Garage Floor Solutions

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet precise client specifications, particularly in high-demand applications such as PVC garage flooring. Our structured customization process ensures optimal performance, durability, and chemical resistance tailored to each operational environment. The journey from concept to mass production follows four critical stages: Drawing Analysis, Formulation, Prototyping, and Mass Production.

The process begins with Drawing Analysis, where technical blueprints, dimensional requirements, and performance expectations are thoroughly evaluated. We assess load-bearing needs, surface texture, thickness tolerance, and environmental exposure conditions such as oil, UV, or temperature fluctuations. This phase involves close collaboration with the client’s engineering team to validate design feasibility and identify potential manufacturing constraints early.

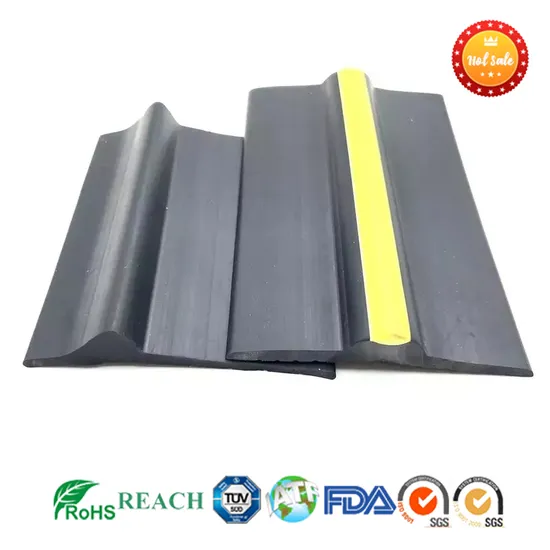

Following approval of technical drawings, we proceed to Formulation. Our rubber formula engineers develop a customized PVC compound that balances hardness, flexibility, abrasion resistance, and anti-slip properties. Additives such as UV stabilizers, plasticizers, and flame retardants are precisely calibrated based on the intended use case. Each formulation is documented under strict quality control protocols to ensure batch-to-batch consistency and compliance with international standards such as ISO 9001 and RoHS.

Once the formulation is finalized, we move to Prototyping. A small-batch production run is executed using the client’s exact specifications. The prototype undergoes rigorous laboratory testing, including tensile strength, compression set, wear resistance, and slip coefficient evaluation. We also perform real-world simulation tests for oil resistance and thermal cycling to validate long-term performance. Client feedback is integrated at this stage, allowing for iterative refinement before full-scale production.

Upon successful prototype validation, the project transitions into Mass Production. Utilizing automated extrusion and calendaring lines, we manufacture the PVC garage flooring at scale with continuous in-line quality monitoring. Each batch is traceable, and final products are inspected for dimensional accuracy, surface finish, and mechanical properties. Logistics and packaging are customized to minimize transit damage and support just-in-time delivery schedules.

Our end-to-end customization process ensures that every PVC garage floor solution is not only fit-for-purpose but also optimized for cost-efficiency and long-term reliability in industrial environments.

Typical Technical Specifications for Custom PVC Garage Flooring

| Property | Standard Value | Test Method | Notes |

|---|---|---|---|

| Hardness (Shore A) | 70 – 90 | ASTM D2240 | Customizable per application |

| Tensile Strength | ≥ 10 MPa | ASTM D412 | Enhanced with reinforcing fillers |

| Elongation at Break | ≥ 200% | ASTM D412 | Adjusted via plasticizer level |

| Abrasion Loss (Taber) | ≤ 0.20 g/1000 cycles | ASTM D1044 | Critical for high-traffic areas |

| Oil Resistance (70°C, 7d) | Volume Change ≤ 15% | ASTM D471 | Tested with synthetic motor oil |

| Operating Temperature | -20°C to +80°C | — | Extended range available |

| Thickness Tolerance | ±0.2 mm | ISO 23529 | Based on 3 mm nominal thickness |

Contact Engineering Team

Contact Suzhou Baoshida for Precision PVC Garage Floor Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber formulation and OEM manufacturing, delivering engineered polymer solutions where performance, durability, and chemical resistance are non-negotiable. Our specialization in PVC-based industrial flooring systems, particularly for demanding environments like commercial and high-traffic residential garages, is built upon decades of compound development expertise and rigorous quality control protocols. We understand that a garage floor is not merely a surface but a critical component subjected to extreme mechanical stress, oil and chemical exposure, temperature fluctuations, and continuous abrasion. Generic PVC sheets fail under these conditions; engineered formulations succeed. Our proprietary PVC compounds integrate advanced plasticizers for low-temperature flexibility, UV stabilizers for color retention, and specialized fillers to enhance tensile strength and dimensional stability, ensuring long-term integrity far beyond standard offerings.

The technical superiority of our PVC garage flooring is quantifiable. Below is a direct comparison of key performance metrics between Suzhou Baoshida’s engineered solution and typical industry baselines. This data reflects our commitment to exceeding standard specifications through precise material science.

| Parameter | Suzhou Baoshida Standard | Industry Baseline |

|---|---|---|

| Thickness Tolerance | ±0.1 mm | ±0.3 mm |

| Shore A Hardness | 75 ± 3 | 65 – 85 (Variable) |

| Tensile Strength | ≥ 18 MPa | ≥ 12 MPa |

| Elongation at Break | ≥ 300% | ≥ 200% |

| Tear Resistance (DIN) | ≥ 65 kN/m | ≥ 45 kN/m |

| Oil Resistance (IRHD) | Δ Hardness ≤ +5 | Δ Hardness ≤ +15 |

| Low Temp Flexibility | -35°C (No Cracking) | -20°C |

| VOC Emissions | Compliant with EU REACH | Often Non-Compliant |

This performance differential translates directly into reduced lifecycle costs, minimized maintenance downtime, and enhanced safety for end-users. As your OEM partner, Suzhou Baoshida provides more than just material supply; we offer comprehensive technical collaboration. Our engineering team works directly with your designers to optimize formulations for specific substrate adhesion requirements, customize surface textures for slip resistance, and ensure compatibility with regional environmental regulations. We manage the entire production process under ISO 9001-certified systems, from raw material sourcing through precision calendering and quality validation, guaranteeing batch-to-batch consistency essential for large-scale installations.

Initiate a strategic partnership to elevate your PVC garage floor product line. Contact Mr. Boyce, our dedicated OEM Manager, for a confidential technical consultation. Mr. Boyce possesses in-depth knowledge of global market specifications and the engineering acumen to translate your performance requirements into a manufacturable, high-value solution. He will facilitate immediate access to our compounding laboratory data, arrange sample production runs for validation, and develop a scalable supply chain strategy tailored to your volume needs. Do not compromise on the foundational performance of your flooring system. Reach out directly via email at [email protected] to discuss formulation specifics, request detailed technical dossiers, or schedule an engineer-to-engineer conference call. Suzhou Baoshida responds to all OEM inquiries within 24 business hours. Advance your product development cycle with scientifically validated rubber solutions engineered for real-world industrial demands. Contact Mr. Boyce today to secure your competitive advantage.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).