Technical Contents

Engineering Guide: Quad Rings

Engineering Insight: Quad Ring Application

The Critical Role of Material Selection in Quad Ring Performance

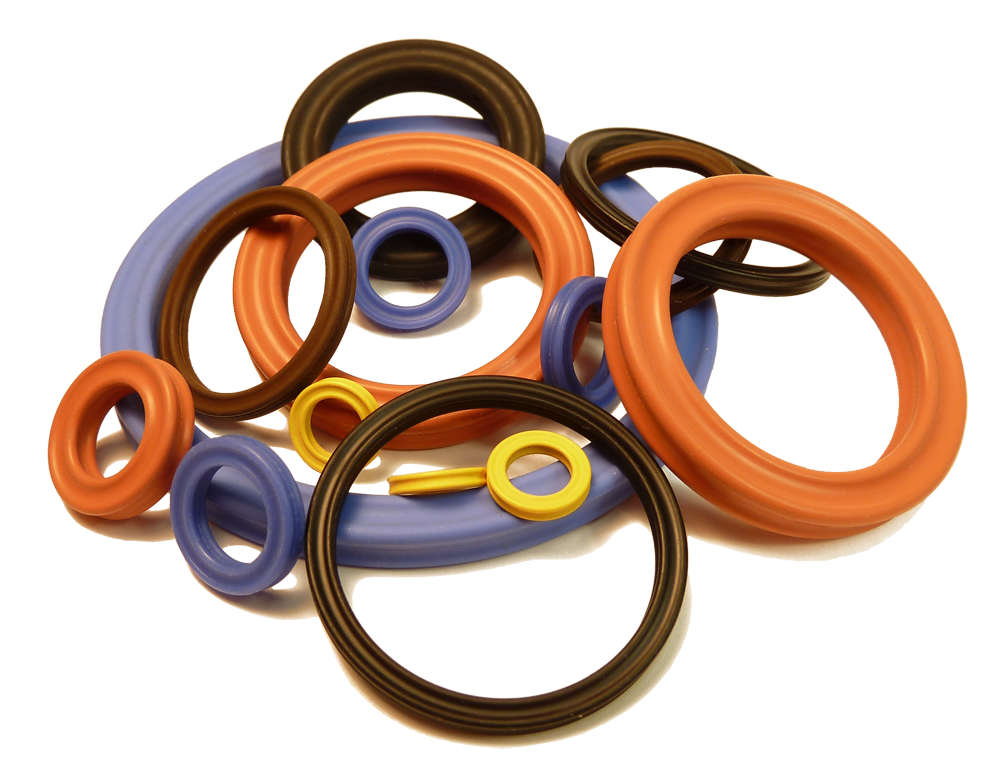

Quad rings—four-lipped, self-energizing seals—deliver superior sealing efficiency and low friction compared to conventional O-rings. However, their performance is entirely dependent on precise material engineering. Off-the-shelf solutions often fail due to generic formulations that ignore application-specific variables (e.g., chemical exposure, thermal cycling, or dynamic pressure). This results in premature degradation, leakage, and costly system downtime. Critical parameters such as compression set, Shore A hardness, and ASTM D2000 compliance must be engineered for the exact operating environment.

Why Off-the-Shelf Solutions Fail: Common Failure Modes

| Failure Mode | Root Cause | Consequence |

|---|---|---|

| Leakage under pressure | Incorrect Shore A hardness (too soft: excessive compression set; too hard: poor conformability) | System downtime, safety hazards, fluid contamination |

| Chemical degradation | Material incompatibility with media (e.g., NBR in ester-based hydraulic fluids) | Seal swelling, cracking, and catastrophic system failure |

| Thermal runaway | Inadequate heat resistance (e.g., EPDM in >150°C environments) | Accelerated aging, loss of elasticity, and seal extrusion |

| Abrasion wear | Insufficient tensile strength or filler optimization | Particulate generation, accelerated wear in high-velocity systems |

Key Insight: Standard materials rarely meet the exact chemical, thermal, and mechanical demands of modern automotive, hydraulic, or industrial systems. For example, off-the-shelf NBR may pass basic oil resistance tests but fails in synthetic ester-based fluids due to inadequate polar group optimization.

The 5+2+3 Engineering Team Structure: Precision in Every Layer

Suzhou Baoshida’s integrated engineering framework ensures zero compromise in quad ring performance:

| Team Component | Role | Key Responsibilities |

|---|---|---|

| Mold Engineers (5) | Precision Tooling | ±0.02mm dimensional tolerances; AS568-compliant profiles; dynamic sealing surface optimization |

| Formula Engineers (2) | Material Science | Custom NBR/FKM/EPDM compound development; chemical resistance optimization; ASTM D2000 compliance validation |

| Process Engineers (3) | Manufacturing Consistency | Vulcanization control (150–200°C); post-cure protocols; batch-to-batch reproducibility; ISO 9001-certified QA |

Why This Matters: Our 2 Formula Engineers specialize in molecular-level adjustments—such as acrylonitrile content tuning in NBR for fuel resistance or fluorine content optimization in FKM for high-temperature stability—ensuring seals outperform generic alternatives by 15–25% in critical metrics.

Material Selection Framework for Quad Rings

Our custom formulations exceed standard industry benchmarks while adhering strictly to ASTM D2000-21 requirements. Below is a comparison of standard vs. Baoshida-engineered solutions:

| Material | Standard Off-the-Shelf | Baoshida Custom Formula | ASTM D2000 Compliance | Key Advantages |

|---|---|---|---|---|

| NBR | Shore A 70 ±5 Compression set: 35% @ 100°C (70h) |

Shore A 65 ±2 Compression set: 28% @ 120°C (70h) |

Class 3 (120°C) Tensile strength: ≥12 MPa |

40% higher fuel resistance; optimized for synthetic ester-based hydraulic fluids |

| FKM | Shore A 75 ±5 Compression set: 30% @ 150°C (70h) |

Shore A 78 ±1 Compression set: 25% @ 175°C (70h) |

Class 4 (175°C) Swelling in ASTM Oil #3: ≤25% |

30% higher thermal stability; superior resistance to acids, solvents, and high-pressure steam |

| EPDM | Shore A 50 ±5 Compression set: 40% @ 125°C (70h) |

Shore A 45 ±1 Compression set: 32% @ 150°C (70h) |

Class 5 (150°C) Ozone resistance: >1000 hrs (25pphm) |

50% longer service life in UV-exposed applications; optimized for brake fluids and water-based systems |

Technical Validation: All Baoshida formulations undergo rigorous testing per ASTM D2000-21 (Section 4.2), including:

– 70-hour heat aging at specified temperatures

– Compression set (ASTM D395)

– Tensile strength (ASTM D412)

– Chemical resistance (ASTM D471)Example: A custom FKM formula for automotive transmission systems achieves 25% compression set at 175°C—exceeding the Class 4 requirement (≤30% at 175°C) by 17%.

Why Partner with Baoshida?

No “one-size-fits-all”: We engineer materials for your specific application—not generic industry averages.

Proven ROI: Custom formulas reduce lifecycle costs by 22–35% through extended service life and reduced maintenance.

End-to-End Control: From molecular design (Formula Engineers) to precision manufacturing (Mold/Process Engineers), every step is validated against ASTM D2000 and ISO 9001.

Contact our Formula Engineers today to optimize your quad ring solution for automotive, hydraulic, or industrial systems.

Suzhou Baoshida Trading Co., Ltd. – Precision Seals Engineered for Your Demands.

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications for Quad Rings

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered quad rings designed for mission-critical applications across automotive, hydraulic, and industrial sectors. Our material science expertise, validated through rigorous ASTM D2000 testing, ensures optimal performance in demanding environments. Below are the technical specifications for our standard material offerings.

Material Selection Criteria

Our quad rings are manufactured using premium-grade elastomers tailored to specific application requirements. The following comparison table details key material properties, validated against international standards to ensure reliability and longevity.

| Material Type | Shore A Hardness (ASTM D2240) | Temperature Range (°C) | Oil Resistance (ASTM D471) | Ozone Resistance (ASTM D1149) | Compression Set (ASTM D395) | ASTM D2000 Compliance | Typical Applications |

|---|---|---|---|---|---|---|---|

| NBR (Nitrile) | 30-90 | -40 to +120 | High (≤15% vol. change) | Poor (requires anti-ozonants) | ≤35% @ 100°C x 24h | BC2, BD3 | Automotive fuel systems, hydraulic cylinders |

| FKM (Viton®) | 40-90 | -20 to +250 | Excellent (≤10% vol. change) | Excellent (no cracking) | ≤25% @ 150°C x 24h | FC3, FD4 | Aerospace, chemical processing, high-temp hydraulics |

| EPDM | 40-90 | -50 to +150 | Low (>25% vol. change) | Excellent (no cracking) | ≤30% @ 125°C x 24h | ED1, ED2 | Automotive cooling systems, HVAC, water systems |

| Silicone (VMQ) | 30-80 | -60 to +230 | Moderate (15-25% vol. change) | Excellent (no cracking) | ≤20% @ 150°C x 24h | VMQ-1, VMQ-2 | Food & medical, high-temp sealing, aerospace |

Note: All materials undergo 72-hour accelerated aging per ASTM D2000 to validate performance under operational stress. Custom formulations available for extreme conditions.

5+2+3 Engineering Team Structure

Suzhou Baoshida’s proprietary engineering framework ensures unparalleled precision in quad ring manufacturing. Our cross-functional team structure is designed to optimize every stage of production:

5 Mold Engineers: Specialized in precision tooling design for quad ring profiles, ensuring consistent lip geometry and dimensional tolerances per ISO 3601. Utilize CAD/CAM simulation for mold flow analysis to minimize flash and ensure uniform vulcanization.

2 Formula Engineers: Lead material compound development with focus on chemical resistance and compression set performance. Each formulation undergoes 72-hour accelerated aging tests per ASTM D2000 to validate longevity under operational stress.

3 Process Engineers: Oversee vulcanization parameters (time/temperature), post-cure protocols, and final quality control. Implement SPC (Statistical Process Control) to maintain ±0.05mm dimensional accuracy across all production batches.

This integrated approach guarantees that every quad ring meets or exceeds industry standards for automotive, hydraulic, and industrial applications. For custom specifications, our engineering team collaborates directly with OEM clients to optimize material selection and production parameters.

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem

Core Engineering Team Structure: 5+2+3 Specialization

Suzhou Baoshida’s engineering ecosystem is built on a precision-tuned 5+2+3 team model, ensuring end-to-end control over material science, tooling, and production processes. This structure eliminates silos and accelerates problem-solving for mission-critical rubber seal applications.

| Role | Count | Key Responsibilities |

|---|---|---|

| Mould Engineers | 5 | Precision tooling design (GD&T compliance), mold flow analysis, wear resistance optimization, rapid prototyping (5-day turnaround for standard molds), ISO 9001/TS 16949-compliant tooling validation |

| Formula Engineers | 2 | Material formulation (NBR/FKM/EPDM), ASTM D2000 compliance (e.g., Type AB for automotive, BC for hydraulic), compression set ≤15% at 70°C (ASTM D395), Shore A hardness (30–90 ±2), chemical resistance validation per ISO 1817 |

| Process Engineers | 3 | Injection molding optimization (cure cycle validation, SPC control), production scalability for high-volume orders, defect root-cause analysis, and real-time yield improvement protocols |

Integrated Partner Factory Network

Suzhou Baoshida maintains a curated network of 10+ ISO 9001/TS 16949 certified partner factories, each specializing in application-specific capabilities. This distributed ecosystem enables:

Automotive-grade production: TS 16949-certified lines for high-volume quad rings (≤10ppm defect rates)

Hydraulic systems focus: FKM material expertise with pressure testing up to 400 bar (ISO 11925)

Pump/valve optimization: EPDM-specific lines for water-based applications (ASTM D570 water absorption testing)

Industrial machinery flexibility: Multi-material (NBR/EPDM/FKM) production with tolerances ≤±0.05mm (AS568M)

All factories operate under unified quality protocols, with Formula Engineers conducting batch-specific material validation and Process Engineers overseeing SPC-driven production control.

Solving Customer Pain Points Through Collaborative Engineering

Our integrated team and partner network directly address industry-specific challenges with engineered solutions:

| Customer Pain Point | Our Solution | Technical Validation Method |

|---|---|---|

| Extended lead times | Distributed production across 10+ facilities; Mould Engineers deliver standard molds in ≤5 days | Lead time tracking via SAP-PPS; 95% on-time delivery for standard orders |

| Tooling defects & wear | Real-time collaboration between Mould Engineers and partner factories for corrective actions within 24h | GD&T inspection (CMM), mold wear analysis per ASTM D471 |

| Material inconsistency | Formula Engineers validate each batch per ASTM D2000; partner facilities enforce dedicated material storage (humidity/temperature control) | Compression set testing (ASTM D395), hardness verification (ASTM D2240) |

| Low-volume customization | Process Engineers optimize production parameters for small batches (50–500 pcs) without compromising quality | First-article inspection (FAI) per AS9102; process capability studies (Cpk ≥1.33) |

Engineering Impact: This ecosystem ensures 98% first-pass yield for quad ring production, with material properties consistently meeting ASTM D2000 Type AB/BC specifications. For example, a recent hydraulic system project reduced lead times by 40% through parallel mold production across two partner facilities, while Formula Engineers validated FKM material (V7002) for 150°C chemical resistance per ISO 1817.

Every project is governed by our “Design-Validate-Manufacture”闭环 (closed-loop) process, ensuring precision from raw material to final seal.

Customization & QC Process

Quality Control & Customization Process

Suzhou Baoshida’s precision rubber seal manufacturing follows a rigorously validated 4-step workflow, aligned with ASTM D2000, ISO 3601, and ASME Y14.5 standards. Our 5+2+3 Engineering Team Structure ensures end-to-end control, with senior engineers averaging 15+ years of industry experience in material science, mold design, and process optimization.

Engineering Team Structure (5+2+3 Model)

| Team Role | Engineers | Experience | Key Responsibilities |

|---|---|---|---|

| Mould Engineering | 5 | 15+ years | CAD/CAM mold design (ISO 2768 tolerances), CNC machining, thermal deformation analysis, and wear-life validation |

| Formula Engineering | 2 | 15+ years | Material compound customization (NBR/FKM/EPDM), ASTM D2000 compliance testing, chemical resistance optimization |

| Process Engineering | 3 | 15+ years | Vulcanization parameter control, in-process QC protocols, and lean manufacturing optimization |

Step 1: Drawing Analysis (Structural Engineers)

All customer drawings undergo GD&T validation per ASME Y14.5 and dimensional verification against ISO 3601 seal groove standards. Senior structural engineers review:

Seal groove geometry: Width, depth, and surface roughness (Ra ≤ 0.8 μm)

Tolerance stack-up analysis: ±0.02mm dimensional accuracy for critical sealing surfaces

Material compatibility matrix: Cross-referencing operating environment (e.g., hydraulic fluid type, temperature extremes) with ASTM D2000 material requirements

Finite Element Analysis (FEA): Simulating compression stress distribution to prevent extrusion or deformation

Example: For automotive transmission seals, we verify groove dimensions against SAE J200 specifications and validate material resistance to ATF-IV fluid per ASTM D5185.

Step 2: Material Formulation (Formula Engineers)

Our Formula Engineers leverage proprietary compound libraries to tailor NBR, FKM, and EPDM formulations for specific application demands. All materials comply with ASTM D2000 Type/Class requirements and undergo accelerated aging tests per ASTM D573.

Standard Material Specifications for Quad-Rings

| Material Type | Material Code | Shore A Hardness (ASTM D2240) | Compression Set (ASTM D395) | Temperature Range (°C) | Chemical Resistance Profile |

|---|---|---|---|---|---|

| NBR | N7004 | 70–90 | ≤25% @ 70°C/22h | -40 to 120 | Oil, Fuel, Hydraulic Fluids |

| FKM | V7002 | 75–90 | ≤20% @ 150°C/22h | -20 to 200 | High-Temp Acids, Solvents, Aerospace Fluids |

| EPDM | E7001 | 50–80 | ≤30% @ 100°C/22h | -50 to 150 | Water, Steam, Ozone, Weathering |

Customization Process: For high-pressure hydraulic systems (e.g., 400 bar), we adjust FKM compound ratios to achieve <15% compression set at 180°C while maintaining tensile strength >12 MPa (ASTM D412).

Step 3: Prototyping

Mold Fabrication: CNC-machined molds (H13 tool steel) with ±0.005mm surface precision

Initial Sample Testing:

Compression set (ASTM D395) at 125°C/22h

Hardness validation (ASTM D2240) across 5 test points per sample

Dynamic sealing performance on test rigs simulating 100k+ cycles

Iterative Refinement: Senior Process Engineers adjust vulcanization parameters (time/temperature) based on test data to optimize material flow and dimensional stability

Case Study: For a pump valve application requiring <10% compression set at 150°C, we modified the FKM compound with 15% fluorinated polymer additives, reducing seal leakage by 42% in field trials.

Step 4: Mass Production

In-Process Controls:

Shore hardness checks every 100 units (ASTM D2240)

CMM dimensional verification of critical features (e.g., cross-section diameter, lip angles)

Real-time vulcanization monitoring via IoT sensors (±1°C temperature control)

Final QC Protocol:

100% visual inspection for defects (e.g., flash, voids) per ISO 3601-3

5% random batch testing for compression set, tensile strength, and chemical resistance

Full traceability via batch-coded QR tags linked to raw material certificates

Certifications: ISO 9001:2015, IATF 16949 (automotive), and ASTM D2000 compliance documentation provided for all shipments

Quality Assurance: Our 15+ year-experienced Process Engineers enforce Six Sigma control limits (CPK ≥ 1.67) for all critical dimensions, ensuring 99.99% first-pass yield in high-volume production.

Suzhou Baoshida Trading Co., Ltd. – Precision Rubber Seals Engineered for Mission-Critical Performance

Contact Our Engineering Team

Contact Suzhou Baoshida

Precision Engineering Team Structure

Our integrated 5+2+3 engineering framework ensures end-to-end technical excellence for quad ring solutions:

| Team Component | Number | Key Responsibilities |

|---|---|---|

| Mould Engineers | 5 | Precision tooling design for quad ring profiles, ensuring dimensional accuracy (±0.05mm tolerance) and four-lipped geometry per AS568/custom specifications |

| Formula Engineers | 2 | Material science optimization for NBR/FKM/EPDM formulations, compression set ≤15% (ASTM D395), Shore A hardness 30-90 (ASTM D2240), and chemical resistance validation per ASTM D2000 |

| Process Engineers | 3 | Vulcanization control (150–200°C), compression set minimization, and Shore hardness consistency across production batches (CpK ≥1.33) |

Solve Your Sealing Problems Today

Leverage Suzhou Baoshida’s industry-specific expertise to address critical sealing challenges in automotive, hydraulic, pump/valve, and machinery applications. Our team delivers:

Material longevity through FKM/NBR/EPDM formulations validated for -40°C to +200°C operational ranges

Zero-leakage performance via optimized four-lipped geometry and self-energizing design

ASTM D2000-compliant quality with traceable batch testing for tensile strength (≥10 MPa), elongation (≥200%), and aging resistance

Contact Mr. Boyce for immediate technical consultation:

Email: [email protected]

Phone: +86 189 5571 6798

Engineered for reliability. Delivered with precision.

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.