Technical Contents

Engineering Guide: Quick Shut Off Valve

Engineering Insight: Material Selection in Quick Shut Off Valves

In industrial fluid control systems, the quick shut off valve serves as a critical safety and operational component, designed to halt media flow rapidly in response to process deviations or emergency conditions. While mechanical design and actuation response times are frequently emphasized, material selection is equally pivotal—yet often underestimated in standard off-the-shelf valve offerings. At Suzhou Baoshida Trading Co., Ltd., our focus on precision rubber engineering underscores that material compatibility directly determines valve longevity, sealing integrity, and system reliability.

Standard commercial valves typically utilize generic elastomers such as NBR (nitrile butadiene rubber) or EPDM, selected for cost efficiency rather than performance under demanding conditions. These materials may suffice in benign environments with stable temperatures and non-aggressive media. However, in applications involving hydrocarbons, ozone, steam, or extreme pH levels, such elastomers degrade rapidly, leading to seal extrusion, cracking, or loss of compression set. For instance, NBR exhibits poor resistance to polar solvents and oxidizing agents, while EPDM performs inadequately in oil-rich environments. The result is premature valve failure, unplanned downtime, and potential safety hazards.

In contrast, engineered elastomers such as FKM (fluoroelastomer), FFKM (perfluoroelastomer), or HNBR (hydrogenated nitrile) offer superior chemical and thermal stability. FKM, for example, maintains performance up to 200°C and resists a broad spectrum of industrial fluids, including fuels, hydraulic oils, and many acids. FFKM extends this capability further, with resistance to aggressive chemicals such as ketones and amines, making it suitable for semiconductor and pharmaceutical applications. HNBR combines the oil resistance of NBR with enhanced thermal stability, ideal for dynamic sealing in high-cycle pneumatic systems.

Material selection must also consider mechanical stressors. Quick shut off valves undergo repeated compression and rapid actuation, necessitating elastomers with high tensile strength, excellent resilience, and low compression set. A material that deforms permanently after repeated cycles will compromise the seal, allowing leakage paths even when the valve is nominally closed.

The failure of off-the-shelf valves often stems from a one-size-fits-all approach to material specification. Without application-specific analysis, standard valves cannot meet the combined demands of chemical exposure, temperature fluctuation, and mechanical fatigue inherent in industrial processes.

To ensure optimal performance, we recommend a systematic evaluation of operating parameters before finalizing elastomer choice. The following table outlines key material properties relevant to quick shut off valve applications.

| Material | Temperature Range (°C) | Key Chemical Resistances | Typical Applications |

|---|---|---|---|

| NBR | -30 to +100 | Aliphatic hydrocarbons, water, hydraulic fluids | General industrial, low-cost systems |

| EPDM | -50 to +150 | Steam, water, alkalis, oxygenated solvents | HVAC, water treatment |

| FKM | -20 to +200 | Fuels, oils, acids, chlorinated hydrocarbons | Oil & gas, chemical processing |

| FFKM | -15 to +300 | Ketones, amines, strong acids, plasma | Semiconductor, aerospace, high-purity |

| HNBR | -40 to +150 | Oils, ozone, hot water, some acids | Automotive, pneumatic systems |

At Suzhou Baoshida Trading Co., Ltd., we prioritize material science as the foundation of reliable valve performance. Custom elastomer formulation and OEM collaboration ensure that quick shut off valves meet exact process requirements—delivering safety, durability, and operational continuity.

Material Specifications

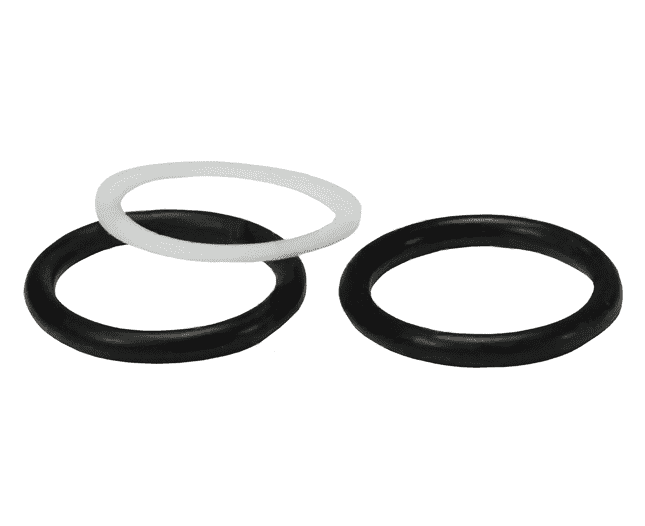

Material Specifications for Quick Shut-Off Valve Sealing Elements

Material selection is a critical engineering determinant for quick shut-off valve performance, directly influencing service life, chemical compatibility, and operational reliability in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., our OEM partnerships leverage deep expertise in elastomer science to match sealing materials precisely to fluid media, temperature profiles, and pressure conditions. Suboptimal material choice leads to premature seal failure through swelling, hardening, or cracking, resulting in costly downtime and safety hazards. We rigorously evaluate Viton (FKM), Nitrile (NBR), and Silicone (VMQ) based on quantifiable physical and chemical properties to ensure optimal valve function across diverse applications. Each polymer offers distinct advantages and limitations that must align with the specific process parameters of the end-use application.

Viton fluorocarbon rubber provides exceptional resistance to high temperatures, aggressive chemicals, oils, and fuels. Its robust molecular structure maintains integrity between -20°C and +230°C continuous service, making it ideal for petrochemical, aerospace, and high-temperature hydraulic systems where exposure to aromatic hydrocarbons, acids, or steam is common. While exhibiting superior fluid resistance, Viton demonstrates lower flexibility at sub-zero temperatures compared to alternatives and carries a higher material cost. Nitrile butadiene rubber offers an excellent balance of cost-effectiveness and performance for general industrial applications. Operating effectively from -40°C to +120°C, NBR provides strong resistance to petroleum-based oils, greases, and water, making it the standard choice for hydraulic valves, compressors, and standard pneumatic systems. Its limitations include poor resistance to ozone, weathering, and polar solvents like ketones or chlorinated hydrocarbons, necessitating careful media compatibility assessment. Silicone rubber excels in extreme temperature flexibility, functioning reliably from -60°C to +200°C, and offers outstanding resistance to oxidation, ozone, and steam. Its biocompatibility and low toxicity also make it suitable for food, beverage, and pharmaceutical applications requiring USP Class VI or FDA compliance. However, Silicone exhibits poor resistance to petroleum oils, fuels, and concentrated acids, limiting its use in hydrocarbon-rich environments.

The comparative analysis below details essential specifications for informed material selection in quick shut-off valve design and manufacturing. These values represent typical commercial grades under standard test conditions per ASTM D2000; actual performance requires validation against specific application parameters.

| Material | Temperature Range (°C) | Key Properties | Fluid Resistance | Primary Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to +230 | High chemical/heat resistance, Low gas permeability, Good mechanical strength | Excellent: Mineral oils, fuels, acids, aromatics. Poor: Ketones, esters, amines, hot hydrofluoric acid | Petrochemical processing, Aerospace hydraulics, High-temperature steam service |

| Nitrile (NBR) | -40 to +120 | Good abrasion resistance, Cost-effective, High tensile strength | Excellent: Water, aliphatic hydrocarbons, hydraulic fluids. Poor: Ozone, weathering, polar solvents, fuels | General industrial hydraulics, Pneumatic systems, Water/gas distribution |

| Silicone (VMQ) | -60 to +200 | Extreme low/high temp flexibility, Biocompatible, High electrical insulation | Excellent: Steam, water, alcohols, ozone. Poor: Petroleum oils, fuels, concentrated acids, solvents | Food & beverage processing, Pharmaceutical equipment, Medical devices, Extreme temp air systems |

Suzhou Baoshida Trading Co., Ltd. provides comprehensive material validation testing and formulation customization to meet exact OEM valve specifications. Partnering with our engineering team ensures the selected elastomer not only meets baseline requirements but also delivers extended service life under the unique stresses of your operational environment, minimizing total cost of ownership through enhanced reliability.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Quick Shut Off Valve Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in deep technical expertise and a systematic approach to industrial rubber formulation and mold design. With a dedicated team comprising five experienced mold engineers and two specialized rubber formula engineers, we deliver engineered solutions tailored specifically for high-performance applications such as quick shut off valves. Our integrated engineering workflow ensures that both material science and mechanical design are optimized in parallel, resulting in durable, reliable, and functionally precise rubber components.

Our mold engineers bring extensive experience in designing complex, high-precision molds for dynamic sealing applications. Each design undergoes rigorous simulation and tolerance analysis to ensure dimensional stability, consistent part quality, and long mold life under high-cycle production environments. Utilizing advanced CAD/CAM software and collaborating closely with our formula engineers, the team ensures that mold geometry supports optimal material flow and curing behavior—critical factors in achieving defect-free production of elastomeric valve seals and diaphragms.

Complementing this structural expertise, our two in-house rubber formula engineers specialize in developing custom elastomer compounds that meet the demanding operational conditions of quick shut off valves. These include resistance to high pressure, thermal cycling, and exposure to aggressive media such as steam, oils, and industrial chemicals. By formulating proprietary blends based on NBR, EPDM, FKM, and silicone, we achieve precise balance between compression set resistance, tensile strength, and dynamic resilience. This scientific approach allows us to tailor material performance to specific OEM requirements, ensuring extended service life and minimal maintenance in critical fluid control systems.

Our OEM capabilities are built on a foundation of technical collaboration and process transparency. We work directly with original equipment manufacturers to co-develop components that integrate seamlessly into their valve assemblies. From initial concept and material selection to prototype validation and serial production, we maintain full traceability and documentation in accordance with ISO 9001 standards. This enables rapid iteration, regulatory compliance, and scalability across diverse industrial sectors including automotive, HVAC, and process automation.

The synergy between our mold design proficiency and advanced rubber formulation expertise positions Suzhou Baoshida as a trusted engineering partner for technically demanding quick shut off valve applications. We do not merely manufacture parts—we engineer performance.

Typical Material Properties for Quick Shut Off Valve Applications

| Material | Hardness (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) | Temperature Range (°C) | Media Resistance |

|---|---|---|---|---|---|

| NBR | 60–90 | 15–22 | 250–400 | -30 to +120 | Oil, water, aliphatic hydrocarbons |

| EPDM | 50–80 | 12–18 | 300–450 | -50 to +150 | Steam, hot water, polar solvents |

| FKM | 65–80 | 16–20 | 200–300 | -20 to +220 | Oils, fuels, acids, aromatic hydrocarbons |

| Silicone | 40–80 | 6–10 | 200–600 | -60 to +200 | Ozone, UV, hot air, some chemicals |

Customization Process

Customization Process for Quick Shut-Off Valve Rubber Components

Precision engineering of quick shut-off valve seals demands a systematic customization approach to ensure operational reliability under extreme industrial conditions. At Suzhou Baoshida Trading Co., Ltd., our process integrates material science with stringent manufacturing controls, beginning with comprehensive drawing analysis. We dissect OEM technical specifications to verify dimensional tolerances per ISO 3302, assess fluid compatibility requirements, and identify critical sealing surfaces. This phase includes GD&T validation to prevent assembly interference and finite element analysis (FEA) simulation of compression stress distribution, ensuring optimal sealing force without extrusion risk in high-pressure cycles.

Material formulation follows rigorous polymer selection based on介质 exposure, temperature range, and dynamic motion profiles. Our engineers prioritize elastomers meeting ASTM D2000 classification standards, adjusting sulfur vulcanization systems for accelerated aging resistance. Critical parameters include optimizing Shore A hardness (60–80 range) for resilience against chatter, minimizing compression set (<20% per ASTM D395), and enhancing ozone resistance for outdoor applications. Each compound undergoes iterative lab testing for tensile strength, elongation at break, and fluid immersion stability per ISO 1817 before prototyping.

Prototyping utilizes CNC-machined molds to produce functional samples within ±0.05mm tolerance. We conduct multi-stage validation: bench testing for leak rates at 1.5x rated pressure, thermal cycling from -40°C to 150°C, and 50,000+ cycle durability trials replicating real-world actuation. Failure mode analysis identifies micro-leak paths or compression set deviations, triggering formulation refinements. Client feedback on fitment and functional performance is integrated before final sign-off.

Mass production implements statistical process control (SPC) with real-time monitoring of cure time, temperature, and clamp pressure. Every batch undergoes 100% visual inspection per ASME B46.1 surface finish standards and抽样 testing for hardness consistency (±3 Shore A). Traceability is maintained via laser-etched lot codes linked to raw material certificates and process logs, ensuring compliance with ISO 13000 automotive and ISO 22301 industrial safety frameworks. This closed-loop system guarantees ≤50 PPM defect rates in volume output.

Key Material Specifications for Valve Seals

| Material Type | Key Properties | Application Fit |

|---|---|---|

| EPDM 70 Shore A | Temp Range: -50°C to +150°C; Compression Set: ≤18%; Water/Glycol Resistant | Cooling systems, low-pressure hydraulic valves |

| FKM 75 Shore A | Temp Range: -20°C to +230°C; Compression Set: ≤22%; Fuel/Oil Resistant | High-temp fuel lines, chemical processing valves |

| VMQ 65 Shore A | Temp Range: -60°C to +180°C; Compression Set: ≤25%; Steam Resistant | Steam autoclaves, food-grade sanitary valves |

This structured workflow—from dimensional validation to SPC-controlled production—ensures Suzhou Baoshida delivers quick shut-off valve components with zero field failure risk, directly supporting OEM uptime and safety mandates. All formulations remain adaptable to client-specific fluid compatibility matrices and regulatory certifications.

Contact Engineering Team

For industrial manufacturers seeking reliable, high-performance quick shut off valves tailored to demanding operational environments, Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered rubber solutions that meet exacting global standards. As a trusted OEM partner in the industrial rubber sector, we specialize in the design, formulation, and production of elastomeric components that ensure rapid response, leak-free sealing, and extended service life under extreme pressure and temperature conditions. Our quick shut off valves are developed using advanced rubber compounding techniques, integrating materials such as Nitrile (NBR), EPDM, Fluorocarbon (FKM), and Silicone to match specific media compatibility, hardness, and durability requirements.

Each valve is manufactured under strict quality control protocols, ensuring dimensional accuracy, consistent actuation performance, and resistance to wear, compression set, and chemical degradation. We serve clients across hydraulics, petrochemical processing, food and beverage, and semiconductor manufacturing—industries where safety, reliability, and regulatory compliance are non-negotiable. Our engineering team collaborates directly with OEMs to customize valve geometry, sealing interfaces, and material formulations for optimal integration into existing systems.

To support seamless adoption and long-term performance, Suzhou Baoshida provides full technical documentation, including material certifications (e.g., FDA, NSF, RoHS), compression set data, and thermal stability profiles. We also offer accelerated life cycle testing and on-site technical consultation to validate performance under real-world conditions.

For immediate technical support or to initiate a custom development project, contact Mr. Boyce, OEM Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce brings over 12 years of experience in industrial rubber applications and leads our client engineering integration team. He is available to discuss your specific valve requirements, material challenges, or system integration needs with a focus on reducing downtime, improving safety margins, and lowering total cost of ownership.

Reach out via email at [email protected] to request samples, technical datasheets, or a formal quotation. Our team responds to all inquiries within 12 business hours and can provide prototype delivery within 10–15 working days for qualified projects. For time-sensitive applications, expedited development and testing pathways are available upon request.

Below are key technical specifications representative of our standard quick shut off valve offerings. All parameters can be modified to meet client-specific performance criteria.

| Parameter | Standard Value | Customization Range |

|---|---|---|

| Operating Pressure | Up to 40 bar | 10–60 bar |

| Temperature Range | -30°C to +150°C (material dependent) | -50°C to +200°C |

| Response Time | ≤ 0.2 seconds | ≤ 0.1 seconds (high-speed option) |

| Seal Material Options | NBR, EPDM, FKM, Silicone | Specialty compounds available |

| Hardness (Shore A) | 70 ± 5 | 50–90 |

| Media Compatibility | Water, oil, air, mild chemicals | Aggressive solvents, steam, food-grade fluids |

| Connection Type | Threaded (NPT, BSP), Flanged | Custom porting and mounting |

| Certifications | RoHS, CE, FDA (upon request) | Full compliance documentation |

Partner with Suzhou Baoshida to engineer quick shut off valves that perform under pressure—every time. Contact Mr. Boyce today at [email protected] to begin your next industrial rubber solution.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).