Technical Contents

Engineering Guide: Ramp Cleats

Engineering Insight: Ramp Cleat Material Selection Imperatives

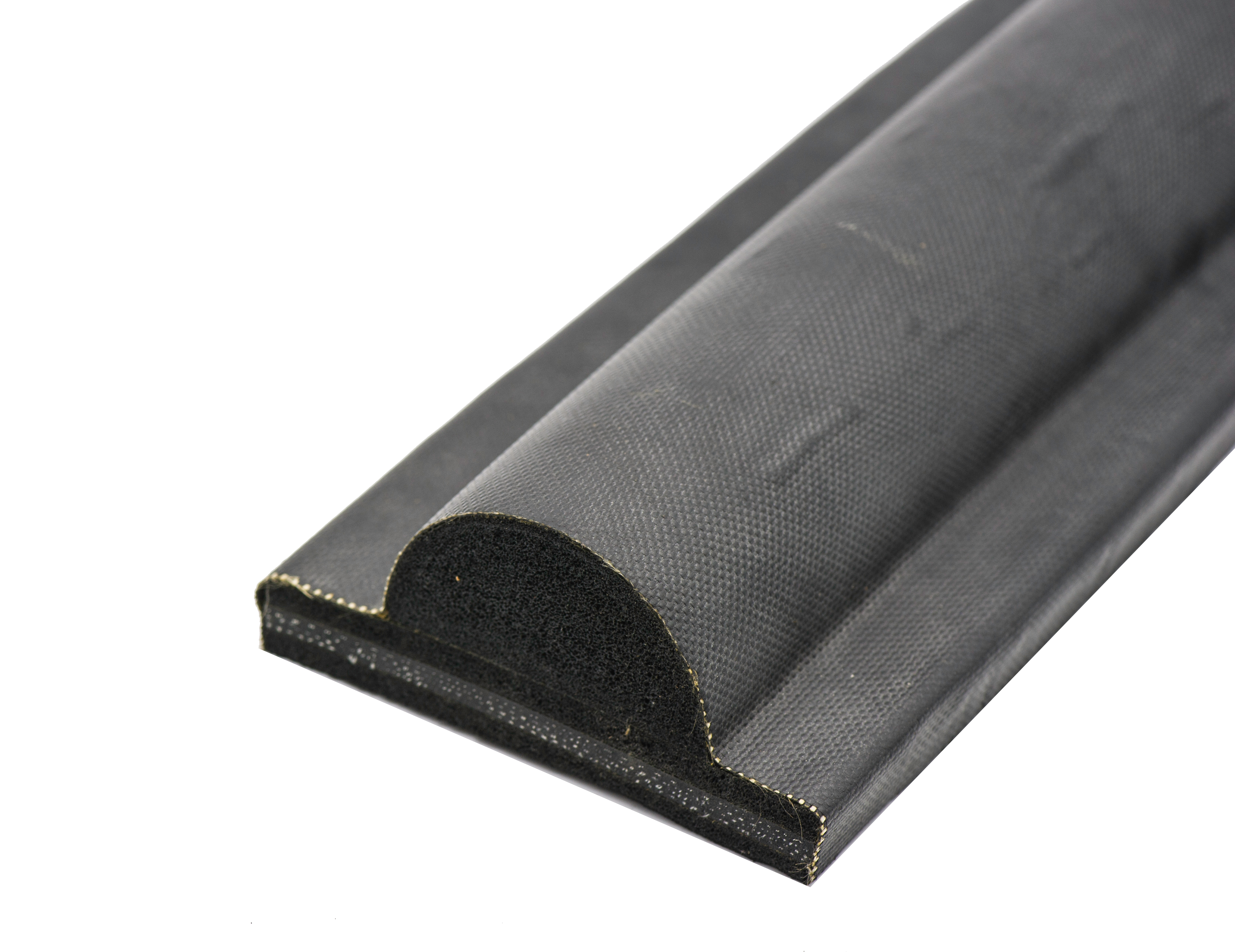

Ramp cleats represent a critical interface between mobile equipment and loading infrastructure, where material science directly dictates operational safety and lifecycle cost. Generic off-the-shelf rubber cleats frequently fail under industrial conditions due to inadequate compound engineering, leading to premature wear, detachment, or catastrophic slip events. The root cause lies in the misalignment between standardized material formulations and the dynamic mechanical, thermal, and chemical stresses encountered in real-world applications.

Off-the-shelf solutions typically utilize generic SBR or low-acrylonitrile NBR compounds optimized for cost, not performance. These materials exhibit insufficient resistance to ozone degradation, petroleum-based fluids, and temperature extremes common in logistics and manufacturing environments. For instance, standard compounds often exceed ±15 Shore A hardness variance at -20°C, causing brittle fracture during cold-weather operations. Simultaneously, they lack the tear strength to withstand repeated impact from forklift tires or heavy pallet jacks, accelerating edge delamination. Crucially, inadequate filler dispersion in mass-produced batches creates weak points prone to chunking under shear forces, compromising traction integrity within months of installation.

Material selection must address three non-negotiable parameters: dynamic coefficient of friction stability across temperature ranges, abrasion resistance under cyclic loading, and adhesion durability to steel substrates. Suzhou Baoshida’s engineered cleats utilize peroxide-cured high-acrylonitrile NBR compounds with reinforced carbon black matrices, ensuring hardness stability within ±5 Shore A from -40°C to +120°C. This precision prevents the “hardening-softening” cycle that degrades generic alternatives, maintaining consistent grip on wet or oily surfaces.

The following table contrasts critical performance metrics between standard and engineered ramp cleat compounds:

| Property | Standard Off-the-Shelf Compound | Baoshida Engineered Compound | Test Standard |

|---|---|---|---|

| Hardness Range (Shore A) | 60–85 (at -20°C) | 68–72 (at -40°C to +120°C) | ASTM D2240 |

| Abrasion Loss (mm³) | 185 | 92 | ASTM D5963 |

| Tear Strength (kN/m) | 28 | 54 | ASTM D624 Type C |

| Ozone Resistance (25pphm) | Cracking at 20% strain | Zero cracking at 30% strain | ASTM D1149 |

| Adhesion to Steel (kN/m) | 4.2 | 8.7 | ASTM D429 Method B |

These specifications translate to measurable operational outcomes. Generic cleats often require replacement every 6–12 months due to surface glazing and adhesive failure, incurring downtime costs exceeding 300% of the initial purchase price. Conversely, engineered compounds sustain COF >0.8 on steel ramps for 3+ years under equivalent loads, eliminating slip-related liability risks. Material selection is not a cost variable but a precision engineering requirement—where molecular stability dictates macroscopic safety. OEMs demanding zero-failure performance must mandate compound validation beyond basic ASTM compliance, focusing on real-world stress simulation. At Suzhou Baoshida, every cleat formulation undergoes 500+ hours of accelerated aging and dynamic load testing, ensuring the rubber performs as predictably as the steel it protects.

Material Specifications

Ramp cleats are critical components in industrial and commercial applications where traction, durability, and resistance to environmental stressors are paramount. At Suzhou Baoshida Trading Co., Ltd., our expertise in industrial rubber solutions enables us to engineer ramp cleats using high-performance elastomers tailored to operational demands. The selection of base material directly influences performance characteristics such as wear resistance, temperature tolerance, chemical compatibility, and mechanical strength. For ramp cleat manufacturing, we specialize in three primary rubber compounds: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers a distinct balance of properties suited to specific service environments.

Viton is a fluorocarbon-based synthetic rubber renowned for exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With continuous service capabilities up to 250°C and short-term exposure tolerance beyond 300°C, Viton is ideal for cleats used in extreme industrial settings such as automotive manufacturing, oil and gas facilities, and chemical processing plants. Its low compression set and excellent aging resistance ensure long-term structural integrity under sustained load and thermal cycling. However, Viton exhibits lower flexibility at sub-ambient temperatures and higher material cost compared to alternatives.

Nitrile rubber, or Buna-N, is a copolymer of butadiene and acrylonitrile, widely used for its outstanding resistance to petroleum-based oils, greases, and hydraulic fluids. It offers good abrasion resistance and mechanical strength, making it a cost-effective choice for ramp cleats in logistics, transportation, and machinery platforms exposed to lubricants and fuel. Nitrile performs reliably in temperature ranges from -30°C to 120°C, though it degrades under prolonged UV or ozone exposure unless specially compounded. Its balance of resilience and affordability makes it a preferred option for general industrial applications.

Silicone rubber excels in extreme temperature environments, with serviceability from -60°C to 230°C, and maintains flexibility across this range. It demonstrates excellent resistance to ozone and UV radiation, making it suitable for outdoor ramp installations. While silicone has relatively lower tensile strength and abrasion resistance compared to Nitrile or Viton, it is non-toxic, odorless, and compliant with stringent hygiene standards, which benefits use in cleanroom or food-handling facilities. Additionally, its electrical insulation properties allow deployment in sensitive electronic environments.

The following table summarizes key performance characteristics of each material for informed selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 150–250 | 200–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Oil & Fuel Resistance | Excellent | Excellent | Poor |

| Ozone & UV Resistance | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Abrasion Resistance | Good | Very Good | Fair |

| Typical Applications | Chemical, aerospace | Automotive, logistics | Outdoor, medical, food |

Material selection must consider the operational environment, mechanical loading, and exposure to fluids or weathering. Suzhou Baoshida Trading Co., Ltd. provides customized formulation and testing support to ensure optimal cleat performance.

Manufacturing Capabilities

Engineering Capabilities for Precision Ramp Cleat Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise in rubber formulation and precision mold engineering to deliver superior ramp cleats for demanding industrial material handling applications. Our dedicated engineering cohort, comprising five specialized Mold Engineers and two advanced Rubber Formula Engineers, operates at the core of our OEM manufacturing process. This integrated team structure ensures seamless translation of client specifications into high-performance, durable cleat solutions. Our Formula Engineers possess extensive knowledge of polymer chemistry, filler systems, and vulcanization kinetics, enabling precise control over critical material properties such as traction coefficient, abrasion resistance, and low-temperature flexibility. Concurrently, our Mold Engineering team utilizes advanced CAD/CAM software and mold flow analysis to optimize cavity design, gating systems, and cooling channels, guaranteeing dimensional accuracy, consistent part geometry, and minimized cycle times for complex cleat profiles.

This synergistic engineering approach is fundamental to our OEM capability. We do not merely replicate existing designs; we partner with clients to solve specific application challenges. Whether enhancing cleat geometry for superior load stability on inclined conveyor belts, developing compounds resistant to aggressive oils or chemicals encountered in specific facilities, or modifying profiles to meet stringent regulatory standards, our engineers initiate development from first principles. We conduct rigorous application analysis to identify potential failure modes – be it cleat tearing under heavy impact, loss of grip in wet conditions, or premature wear from abrasive materials – and engineer solutions directly addressing these concerns. Prototyping and iterative testing under simulated operational conditions are standard practice, ensuring the final cleat design performs reliably within the client’s unique operational environment before full-scale production commences.

Our commitment to material science excellence allows for extensive customization beyond standard offerings. The table below illustrates key performance parameters achievable through our tailored compound development, demonstrating the range of properties we engineer for specific client requirements.

| Property | Standard Cleat Range | Custom Engineered Range (OEM Capability) | Test Standard |

|---|---|---|---|

| Hardness (Shore A) | 60 – 75 | 45 – 85 | ASTM D2240 |

| Tensile Strength (MPa) | ≥ 10.0 | ≥ 15.0 (High-Tear Compounds) | ASTM D412 |

| Elongation at Break (%) | ≥ 250 | ≥ 400 (Flex-Critical Applications) | ASTM D412 |

| Temp. Range (°C) | -30 to +80 | -50 to +100 (Specialty Polymers) | ISO 188 / ASTM D573 |

| Abrasion Loss (mm³) | ≤ 120 | ≤ 80 (Enhanced Wear Resistance) | ASTM D5963 |

Quality assurance is intrinsically woven into our engineering process. Every cleat batch undergoes stringent in-process and final validation against the engineered specifications, including dimensional checks, physical property verification, and application-specific performance testing. This systematic, engineering-driven methodology ensures Suzhou Baoshida ramp cleats consistently deliver the safety, longevity, and operational efficiency demanded by global industrial partners, minimizing downtime and maximizing return on investment. Our OEM strength lies in transforming client challenges into precisely engineered rubber solutions.

Customization Process

Drawing Analysis: Precision Engineering at the Foundation

The customization process for industrial ramp cleats begins with rigorous drawing analysis, where technical blueprints provided by the client are evaluated for dimensional accuracy, load-bearing requirements, and environmental exposure conditions. At Suzhou Baoshida Trading Co., Ltd., our engineering team conducts a comprehensive review using CAD-based validation tools to ensure compatibility with OEM specifications. Critical parameters such as cleat pitch, height, base width, and mounting configuration are cross-referenced against application demands—whether for material handling conveyors, loading docks, or mobile equipment. This stage also identifies potential design inefficiencies, allowing for early optimization to enhance performance and reduce material waste. Tolerance analysis is performed to guarantee slip resistance and structural integrity under dynamic loads.

Formulation: Tailored Rubber Compounding for Performance

Once the design parameters are confirmed, our rubber formulation engineers develop a compound tailored to the operational environment. The selection of polymer base—typically natural rubber (NR), styrene-butadiene rubber (SBR), or nitrile rubber (NBR)—depends on required abrasion resistance, oil resistance, temperature range, and coefficient of friction. Additives such as carbon black for reinforcement, sulfur for vulcanization, and anti-oxidants for longevity are precisely metered. For ramp cleats exposed to extreme conditions, specialized formulations may include halogenated butyl rubber for ozone resistance or thermoplastic polyurethane (TPU) blends for enhanced wear life. Each formulation is documented and batch-traceable to ensure consistency from prototype to full-scale production.

Prototyping: Validation Through Real-World Simulation

A functional prototype is manufactured using compression or injection molding, depending on the complexity and volume requirements. Prototypes undergo a series of in-house performance tests, including tensile strength, hardness (Shore A scale), slip resistance on wet and inclined surfaces, and thermal cycling. These tests validate both the mechanical design and material performance. Client feedback is integrated at this stage, with iterative adjustments made to geometry or compound as needed. Finite element analysis (FEA) may be employed to simulate stress distribution under load, ensuring optimal durability before tooling for mass production.

Mass Production: Scalable Manufacturing with Quality Assurance

Upon client approval, ramp cleats enter mass production using high-precision steel molds and automated rubber processing lines. Our facility maintains ISO 9001-certified quality control protocols, with real-time monitoring of cure time, temperature, and pressure. Each batch is subjected to random sampling for dimensional verification and physical property testing. Logistics coordination ensures timely delivery, with packaging optimized for container efficiency and protection during transit.

| Specification | Standard Range | Test Method |

|---|---|---|

| Hardness (Shore A) | 55–75 | ASTM D2240 |

| Tensile Strength | ≥12 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Abrasion Loss (DIN) | ≤120 mm³ | ISO 4649 |

| Operating Temperature | -30°C to +80°C | Internal Protocol |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Ramp Cleat Engineering Solutions

Industrial ramp cleats represent a critical interface point between heavy machinery and operational surfaces, demanding uncompromising performance under extreme mechanical stress, environmental exposure, and dynamic load profiles. Substandard cleat formulations directly impact equipment safety, operational efficiency, and total cost of ownership through premature wear, reduced traction, and unexpected downtime. Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber compound development, specifically engineered to address the multifaceted challenges inherent in demanding ramp applications. Our expertise transcends basic manufacturing; we deliver scientifically validated material science solutions tailored to your unique operational parameters and longevity requirements.

Our ramp cleat compounds are formulated using proprietary polymer blends and reinforcement systems, rigorously tested against industry benchmarks and custom client specifications. We prioritize achieving the optimal balance between critical performance metrics: high abrasion resistance to withstand constant scraping and grinding forces, exceptional tear strength to resist impact damage and cleat deformation, and consistent coefficient of friction across wet, oily, and dry surfaces to ensure reliable traction. Crucially, our formulations maintain structural integrity and performance characteristics across wide operational temperature ranges, from sub-zero logistics environments to high-heat industrial settings, while resisting degradation from common hydraulic fluids, greases, and UV exposure. This scientific approach to material design translates directly into extended service life, reduced maintenance cycles, and enhanced operational safety for your equipment.

The performance differentiation lies in the molecular architecture of our rubber compounds. Standard materials often fail to simultaneously optimize all critical properties, leading to trade-offs that compromise real-world performance. Suzhou Baoshida’s engineered solutions eliminate these compromises. The table below illustrates the measurable performance advantages of our proprietary ramp cleat compound (SD-RampPro™) compared to a typical industry-standard formulation under identical testing protocols.

| Performance Parameter | Industry Standard Compound | Suzhou Baoshida SD-RampPro™ | Test Standard |

|---|---|---|---|

| Abrasion Resistance (Volume Loss) | 185 mm³ | 92 mm³ | ISO 4649 (Abrader) |

| Tensile Strength | 18 MPa | 24 MPa | ISO 37 |

| Tear Strength (Die C) | 45 kN/m | 78 kN/m | ISO 34-1 |

| Shore A Hardness (23°C) | 68 | 72 | ISO 48 |

| Operating Temperature Range | -20°C to +80°C | -40°C to +110°C | ASTM D2240/D573 |

| Coefficient of Friction (Wet Steel) | 0.55 | 0.78 | ASTM F2913 |

These quantifiable results demonstrate our commitment to delivering rubber components that perform reliably under the harshest industrial conditions. We understand that your ramp cleat specifications are not merely dimensional; they are functional requirements demanding precise material behavior. Suzhou Baoshida functions as your dedicated rubber engineering partner, capable of developing custom compounds, validating performance through in-house and third-party testing, and ensuring seamless integration into your manufacturing process with consistent, high-yield production.

Initiate the process of enhancing your equipment’s safety and durability through superior rubber engineering. Contact Mr. Boyce, our dedicated OEM Manager specializing in industrial traction solutions, to discuss your specific ramp cleat application requirements, material performance targets, and volume needs. Mr. Boyce possesses the technical expertise to translate your operational challenges into a precisely engineered rubber compound solution and will coordinate our engineering and production teams to deliver results that meet your exacting standards. Request material certification dossiers, discuss custom formulation possibilities, or arrange a technical consultation. Reach Mr. Boyce directly via email at [email protected] to secure the performance advantage your industrial equipment demands. Allow Suzhou Baoshida to become your strategic partner in engineered rubber performance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).