Technical Contents

Engineering Guide: Recessed Light Gasket

Engineering Insight: Material Selection Criticality in Recessed Light Gasket Performance

Recessed light gaskets represent a deceptively complex engineering challenge within architectural lighting systems. Their primary function—maintaining a hermetic seal against moisture, dust, and environmental contaminants while enduring significant thermal cycling—is frequently underestimated. Off-the-shelf gasket solutions, often fabricated from generic elastomers like standard EPDM or SBR, consistently fail in demanding recessed applications due to fundamental material incompatibility with the operational environment. The core issue lies in the synergistic stressors: sustained exposure to elevated temperatures from high-output LEDs (typically 80-100°C at the housing interface), intermittent UV radiation penetrating fixture optics, cyclic compression during installation/maintenance, and long-term exposure to outdoor elements. Standard materials rapidly degrade under this combination, leading to catastrophic compression set, loss of sealing force, and ultimately, water ingress causing electrical hazards or fixture failure.

Material selection is not merely a cost-driven decision but a critical engineering parameter dictating product lifecycle and reliability. Generic compounds lack the tailored polymer architecture and additive packages necessary for this niche application. For instance, standard EPDM exhibits poor resistance to the specific thermal-oxidative degradation encountered near high-lumen LEDs, while its inherent ozone resistance becomes irrelevant when overwhelmed by heat-induced chain scission. Similarly, SBR lacks the necessary thermal stability and UV resistance, embrittling prematurely. The consequence is a gasket that loses 30-50% of its original sealing force within 12-18 months, rendering the fixture non-compliant with IP65/67 ratings long before the LED module’s rated lifespan.

Precision-engineered silicone formulations, specifically designed for lighting applications, provide the necessary performance envelope. Key differentiators include custom platinum-cure systems for superior high-temperature resilience, specialized UV stabilizers integrated into the polymer matrix (not surface coatings), and optimized filler packages to balance compression set resistance with low-temperature flexibility. The table below contrasts critical performance metrics between generic and engineered solutions:

| Property | Standard EPDM (Off-the-Shelf) | Precision Silicone (Engineered) | Test Standard |

|---|---|---|---|

| Compression Set (100°C, 22h) | 35-45% | 10-15% | ASTM D395 Method B |

| Tensile Strength (MPa) | 8-10 | 9-11 | ASTM D412 |

| Elongation at Break (%) | 250-350 | 400-550 | ASTM D412 |

| UV Resistance (500h QUV) | Severe Cracking/Chalking | Minimal Change | ASTM G154 |

| Shore A Hardness (Post-Age) | Increase >15 points | Stable ±3 points | ASTM D2240 |

Suzhou Baoshida Trading Co., Ltd. engineers gaskets using proprietary silicone compounds validated through accelerated aging protocols simulating 10+ years of real-world exposure. We reject the “one-size-fits-all” approach, recognizing that recessed lighting demands materials engineered at the molecular level. Our OEM partnerships begin with rigorous environmental profiling of the fixture design, enabling us to formulate gaskets that maintain sealing integrity across the fixture’s entire operational lifecycle. Specifying an engineered solution is not a cost premium; it is a strategic investment in eliminating field failures, reducing warranty liabilities, and ensuring end-user safety—proving that in precision sealing, the material is the product.

Material Specifications

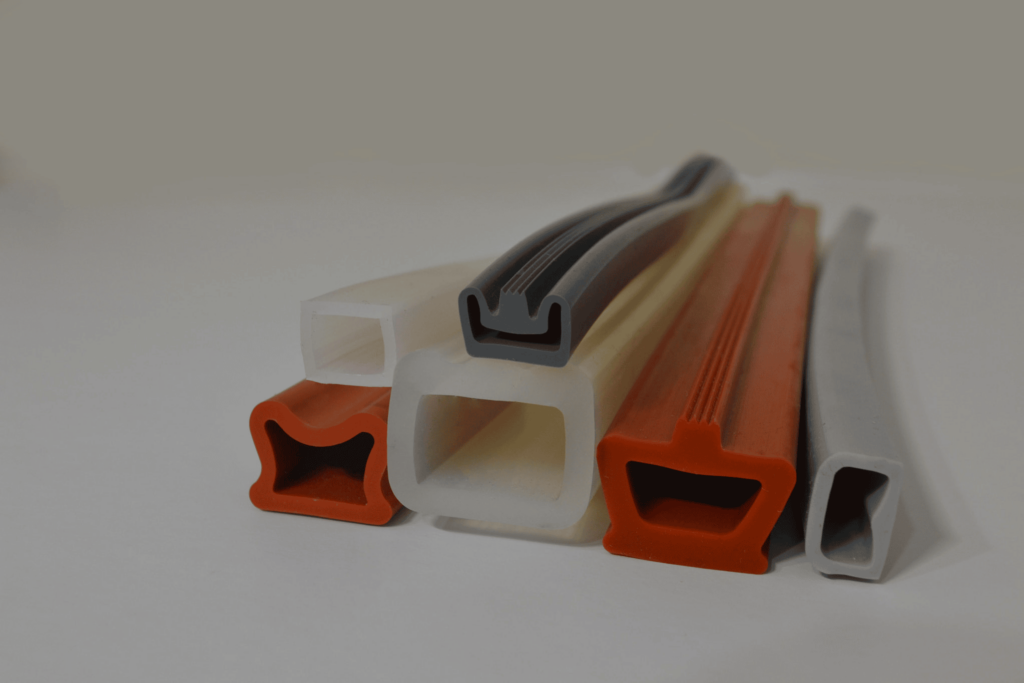

Material selection for recessed light gaskets is critical to ensuring long-term performance under diverse environmental and operational conditions. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered to meet stringent industrial requirements. Our recessed light gaskets are manufactured using three primary elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct advantages depending on temperature range, chemical exposure, mechanical stress, and regulatory compliance needs.

Viton is a fluorocarbon-based rubber renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad spectrum of aggressive chemicals. With continuous service capabilities up to 230°C and intermittent peaks exceeding 260°C, Viton is ideal for recessed lighting installations in industrial kitchens, commercial ovens, and outdoor enclosures exposed to harsh weathering and UV radiation. Its low gas permeability and excellent aging characteristics further enhance reliability in sealed optical systems where outgassing must be minimized.

Nitrile rubber, or Buna-N, is a cost-effective solution for applications involving exposure to petroleum-based oils, greases, and hydraulic fluids. It performs reliably within a temperature range of -30°C to 120°C, making it suitable for indoor and mild outdoor lighting fixtures in automotive, manufacturing, and utility environments. Nitrile exhibits strong abrasion resistance and tensile strength, ensuring durable sealing performance under mechanical compression. However, it has limited resistance to ozone, UV light, and polar solvents, which may restrict its use in certain exterior or chemically aggressive settings.

Silicone rubber provides outstanding thermal stability from -60°C to 200°C, with some formulations capable of withstanding brief excursions to 230°C. It is highly resistant to UV radiation, ozone, and oxidation, making it an optimal choice for outdoor recessed lighting exposed to direct sunlight and fluctuating climates. Silicone also meets stringent flammability and smoke toxicity standards (e.g., UL 94 V-0), which is essential in commercial buildings, transportation, and public infrastructure. While its mechanical strength is lower than Nitrile or Viton, its flexibility at low temperatures and biocompatibility support use in cleanroom and architectural lighting applications.

The following table summarizes key physical and chemical properties of these materials for comparative evaluation:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 12–20 | 10–25 | 5–10 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set (%, 70h at 150°C) | ≤25 | ≤30 | ≤20 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to UV/Ozone | Excellent | Fair | Excellent |

| Electrical Insulation | Good | Good | Excellent |

| FDA/USP Class VI Compliance | Yes (specific grades) | Limited | Yes (specific grades) |

Selection of the appropriate material must balance performance demands with cost efficiency and regulatory requirements. Our engineering team at Suzhou Baoshida supports OEMs with material validation, custom compounding, and accelerated aging testing to ensure optimal gasket performance across the product lifecycle.

Manufacturing Capabilities

Engineering Excellence in Recessed Light Gasket Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages deep material science and precision manufacturing expertise to deliver recessed light gaskets meeting the most stringent OEM requirements. Our core strength resides in the integrated capabilities of our dedicated engineering team: five specialized Mould Engineers and two certified Rubber Formula Engineers. This dual-discipline structure ensures seamless translation of complex lighting application demands into optimal sealing solutions, from molecular formulation through to final production tooling.

Our Rubber Formula Engineers possess advanced proficiency in elastomer chemistry, focusing exclusively on compounds for demanding optical and thermal environments. We develop proprietary silicone and EPDM formulations engineered for critical recessed light performance factors: exceptional resistance to thermal cycling (-40°C to +150°C continuous), long-term UV stability preventing yellowing or embrittlement, and minimal compression set to maintain seal integrity over 10,000+ hours. Precise control over cure kinetics using peroxide or platinum systems ensures consistent physical properties and eliminates outgassing risks that could cloud lenses. Every compound undergoes rigorous validation against ASTM D2000 and specific OEM material specifications before release.

Complementing this material mastery, our five Mould Engineers execute precision tooling strategies for complex gasket geometries. Utilizing advanced CAD/CAM (SolidWorks, Moldflow) and ISO 9001-certified processes, we achieve tight tolerances (±0.05mm on critical sealing surfaces) essential for consistent light cutoff and ingress protection (IP65/IP67). Our expertise spans multi-cavity hot runner systems for high-volume efficiency and intricate insert molding for integrated mounting features. Finite Element Analysis (FEA) predicts and mitigates potential flash, weld lines, or dimensional drift during production, ensuring first-article approval rates exceed 95%.

This integrated engineering approach directly enables our robust OEM partnership model. We collaborate from the initial concept stage, providing material selection guidance, DFM feedback, and rapid prototyping (3-5 days for functional samples). Our facility supports low-volume pilot runs through to high-volume production (500k+ units/month), with full traceability via batch-controlled raw materials and in-process SPC. Tooling ownership remains with the client, and our engineers provide continuous process optimization support to enhance yield and reduce total cost of ownership.

Critical Recessed Light Gasket Performance Specifications

| Parameter | Typical Value (Silicone) | Typical Value (EPDM) | Test Standard | Significance for Recessed Lighting |

|---|---|---|---|---|

| Hardness (Shore A) | 45 ± 5 | 55 ± 5 | ASTM D2240 | Ensures proper compression force without lens stress |

| Tensile Strength (MPa) | ≥ 6.0 | ≥ 7.0 | ASTM D412 | Resists tearing during installation/service |

| Elongation at Break (%) | ≥ 300 | ≥ 250 | ASTM D412 | Accommodates housing tolerances & thermal movement |

| Compression Set (%) | ≤ 20 (22h @ 150°C) | ≤ 30 (22h @ 125°C) | ASTM D395 Method B | Maintains sealing force after prolonged heat exposure |

| Temp. Range (°C) | -55 to +200 | -45 to +135 | ASTM D2240 | Survives thermal shock from LED operation & outdoor exposure |

| Volume Resistivity (Ω·cm) | ≥ 1.0 x 10¹² | ≥ 1.0 x 10¹⁰ | ASTM D257 | Prevents electrical leakage paths |

| Accelerated Weathering | Pass 3000h QUV-A | Pass 2000h QUV-A | ASTM G154 | Guarantees long-term appearance & function outdoors |

Suzhou Baoshida’s engineering-centric methodology guarantees recessed light gaskets that deliver absolute sealing reliability, optical clarity preservation, and extended service life under real-world operational stresses, forming a critical foundation for our OEM partners’ lighting system performance and brand reputation.

Customization Process

Customization Process for Recessed Light Gaskets at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our approach to producing high-performance recessed light gaskets is rooted in precision engineering and material science. As a trusted OEM partner in the precision rubber seals industry, we follow a structured four-phase customization process: Drawing Analysis, Formulation Development, Prototyping, and Mass Production. This ensures that every gasket meets exact functional, environmental, and dimensional requirements.

The process begins with Drawing Analysis, where our technical team reviews customer-provided CAD drawings, 2D technical prints, or physical samples. We assess critical parameters such as cross-sectional diameter, inner and outer dimensions, groove fit, compression set requirements, and installation environment. Special attention is given to sealing interface geometry and potential stress points. Tolerance analysis is performed per ISO 3302 and ISO 2768 standards to ensure compatibility with automated assembly lines and long-term sealing integrity.

Following dimensional validation, we proceed to Formulation Development. Based on the operating conditions—such as temperature range, exposure to UV, moisture, or chemical agents—we select the optimal elastomer compound. Our standard formulations include silicone (VMQ), EPDM, and fluorosilicone (FVMQ), each offering distinct advantages in thermal stability, weather resistance, and compression recovery. Hardness is typically tuned between 40 to 70 Shore A, depending on compression load requirements. All compounds are REACH and RoHS compliant, and we maintain full traceability of raw materials.

Once the formulation is finalized, we enter the Prototyping phase. Using precision molding techniques—either compression, transfer, or injection molding—we produce small-batch samples (typically 50–100 units). These prototypes are subjected to rigorous in-house testing, including compression deflection analysis, thermal cycling (-50°C to +200°C), and leak testing under simulated installation conditions. Dimensional inspection is carried out using digital micrometers and optical comparators to ensure conformance within ±0.1 mm tolerance.

Upon customer approval, we transition to Mass Production. Our automated production lines, supported by statistical process control (SPC), ensure consistency across batches up to several hundred thousand units. Each production lot undergoes first-article inspection and periodic quality audits. Packaging is customized to customer logistics needs, including tray stacking, reel feeding, or anti-static boxing.

The table below summarizes typical performance specifications for recessed light gaskets manufactured at our facility.

| Parameter | Standard Range | Test Standard |

|---|---|---|

| Material Options | VMQ, EPDM, FVMQ | ASTM D2000 |

| Hardness (Shore A) | 40–70 | ASTM D2240 |

| Temperature Resistance | -50°C to +200°C (continuous) | ISO 188 |

| Tensile Strength | ≥6.0 MPa | ASTM D412 |

| Elongation at Break | ≥200% | ASTM D412 |

| Compression Set (22h, 150°C) | ≤25% | ASTM D395 |

| Tolerance (Dimensions) | ±0.1 mm (critical), ±0.2 mm (std) | ISO 3302 |

Through this disciplined workflow, Suzhou Baoshida ensures that every recessed light gasket delivers reliable sealing performance, durability, and seamless integration into lighting assemblies.

Contact Engineering Team

Elevate Recessed Lighting Performance Through Precision Sealing Engineering

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced rubber compounding and industrial manufacturing excellence, specializing in mission-critical sealing solutions for the global lighting sector. Our recessed light gaskets are not generic components but engineered systems designed to mitigate thermal stress, prevent moisture ingress, and ensure long-term structural integrity in demanding environments. With decades of formulation expertise and ISO 9001-certified production processes, we transform complex material science into reliable, high-yield components that directly enhance your luminaire’s lifespan and compliance profile. For lighting OEMs facing challenges with condensation-induced failures, UV degradation, or inconsistent compression sealing, our gaskets deliver quantifiable performance gains through rigorously controlled polymer matrices and dimensional tolerances held to ±0.1mm.

Our technical team leverages proprietary silicone and EPDM formulations tailored to specific application stressors, including extreme temperature cycling from -60°C to +200°C and exposure to harsh chemical cleaners. Every gasket undergoes cross-functional validation against IEC 60598 and UL 1598 standards, with batch-specific certification reports provided. Unlike off-the-shelf alternatives, we integrate early in your design phase to optimize material selection, tooling geometry, and assembly compatibility—reducing scrap rates and accelerating time-to-market. As your strategic OEM partner, we manage end-to-end production from raw material sourcing to final packaging, ensuring supply chain resilience for high-volume programs across North America, Europe, and Asia.

Critical performance parameters for our standard recessed light gasket series are validated per international testing protocols:

| Property | Value | Test Standard |

|---|---|---|

| Hardness (Shore A) | 45 ± 5 | ASTM D2240 |

| Tensile Strength | ≥8.5 MPa | ASTM D412 |

| Elongation at Break | ≥300% | ASTM D412 |

| Compression Set (22h/70°C) | ≤20% | ASTM D395 |

| Operating Temperature | -60°C to +200°C | ISO 188 |

| Flame Resistance | UL94 V-0 | UL 94 |

These specifications represent baseline capabilities; our engineering team routinely develops custom formulations exceeding these metrics for specialized applications such as medical-grade luminaires or outdoor-rated fixtures requiring IP68 ingress protection. Material certifications, full traceability documentation, and accelerated life testing data are integral to every project.

Initiate a technical consultation with Mr. Boyce, our dedicated OEM Account Manager and Rubber Formulation Specialist, to resolve your specific sealing challenges. With 15 years of experience in lighting industry material solutions, Mr. Boyce provides direct engineering support for gasket integration, failure analysis, and cost-optimized production scaling. Contact him at [email protected] to submit your technical requirements, request sample kits with full material test reports, or schedule a virtual design review. Suzhou Baoshida operates under strict NDA protocols and responds to all qualified engineering inquiries within 4 business hours. Partner with us to convert sealing vulnerabilities into competitive advantages—where material science precision meets manufacturing certainty. Your production line’s reliability starts with a single engineered component.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).