Technical Contents

Engineering Guide: Ring Lubrication

Engineering Insight: The Critical Role of Material Selection in Ring Lubrication

In precision rubber seal applications, ring lubrication is not merely a maintenance step—it is an integrated component of system performance and longevity. The interaction between elastomeric materials and lubricants directly influences seal integrity, friction behavior, and operational lifespan. Off-the-shelf lubricants and generic seal materials often fail in demanding industrial environments because they are not engineered for specific chemical, thermal, or mechanical conditions. Material compatibility is paramount, and overlooking this leads to premature degradation, leakage, and system failure.

The foundation of effective ring lubrication lies in selecting an elastomer that not only withstands operating temperatures and pressures but also resists chemical attack from the lubricant itself. Common base materials such as Nitrile (NBR), Ethylene Propylene Diene Monomer (EPDM), and Fluoroelastomer (FKM) each exhibit distinct compatibility profiles. For example, NBR offers excellent resistance to mineral oils and aliphatic hydrocarbons but performs poorly against polar solvents and phosphate ester-based lubricants. In contrast, FKM demonstrates superior resistance to high temperatures and aggressive fluids, including synthetic esters and aromatic hydrocarbons, making it ideal for aerospace and high-performance automotive systems.

However, even the most chemically resistant elastomer can fail if paired with an incompatible lubricant. Many standard lubricants contain additives—such as anti-wear agents, detergents, or extreme pressure modifiers—that can extract plasticizers from rubber, leading to embrittlement, volume swell, or compression set. This degradation is often accelerated under dynamic conditions where repeated mechanical stress compounds chemical attack.

Furthermore, the viscosity and consistency of the lubricant must align with the application’s shear rate and temperature range. A lubricant that is too thick may increase friction and energy loss, while one that is too thin may migrate away from the sealing interface, leaving the rubber exposed to dry running conditions.

Suzhou Baoshida Trading Co., Ltd. emphasizes engineered solutions over generic replacements. Our precision rubber seals are developed in tandem with lubrication requirements, ensuring optimal performance under real-world conditions. We conduct comprehensive compatibility testing, including immersion studies, compression stress relaxation, and dynamic sealing trials, to validate material-lubricant pairings before deployment.

The following table outlines key elastomer-lubricant compatibility metrics for common industrial scenarios:

| Elastomer | Temperature Range (°C) | Compatible Lubricants | Incompatible Lubricants | Key Limitations |

|---|---|---|---|---|

| NBR | -30 to +100 | Mineral oils, greases, HFA/HFB hydraulic fluids | Phosphate esters, ketones, brake fluids | Poor ozone and UV resistance |

| EPDM | -50 to +150 | Water-glycol fluids (HFC), silicone oils, alcohols | Mineral oils, hydrocarbon greases | Swells in hydrocarbons |

| FKM | -20 to +200 | Synthetic esters, aromatic fluids, silicone lubricants | Ketones, ethers, low molecular weight acids | High cost, limited low-temp flexibility |

| Silicone (VMQ) | -60 to +180 | Silicone greases, water, some alcohols | Mineral oils, fuels, hydrocarbon solvents | Low tensile strength, poor wear resistance |

Selecting the correct material-lubricant combination is not a secondary consideration—it is central to the design of reliable sealing systems. At Suzhou Baoshida, we engineer for precision, durability, and compatibility, ensuring that every seal performs as intended across its service life.

Material Specifications

Material Science Fundamentals for Ring Lubrication Compatibility

Selecting the optimal elastomer for precision rubber seals in ring lubrication systems demands rigorous analysis of polymer chemistry and operational environment. At Suzhou Baoshida Trading Co., Ltd., we prioritize material integrity under dynamic sealing conditions where lubricant interaction directly impacts seal longevity, friction coefficients, and compression set resistance. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent industry-standard solutions, yet their performance diverges significantly when exposed to lubricants, temperature extremes, and mechanical stress. Misalignment between seal material and lubricant chemistry induces swelling, hardening, or extraction of plasticizers, leading to premature failure. Our OEM validation protocols mandate compatibility testing per ASTM D2000 and ISO 3601 standards to mitigate field risks.

Viton fluorocarbon elastomers deliver exceptional resistance to synthetic ester-based and phosphate-ester lubricants across aerospace and high-performance automotive applications. Their saturated backbone withstands temperatures from -20°C to +230°C continuous service, with short-term peaks at 300°C. Critical for ring lubrication, Viton exhibits minimal swell (<5%) in Skydrol hydraulic fluids and MIL-PRF-23699 oils, though compatibility with silicone greases requires additive verification. Nitrile butadiene rubber remains the cost-effective solution for mineral oil and petroleum-based lubricant environments, particularly in industrial hydraulics and gearboxes. Standard NBR (34% acrylonitrile) tolerates temperatures from -30°C to +100°C, with high-acrylonitrile variants extending to +125°C. Its polarity provides robust resistance to aliphatic hydrocarbons but renders it vulnerable to swelling in phosphate esters or silicone fluids. Silicone elastomers excel in extreme temperature stability (-60°C to +200°C) and inertness toward silicone-based lubricants, making them ideal for food-grade or medical ring lubrication systems. However, their low tensile strength and susceptibility to tearing under high-pressure lubricant injection necessitate careful profile design.

Material selection must account for lubricant base stocks, additives, and operational dynamics. For instance, NBR seals in biodiesel systems require saturated nitrile variants to prevent excessive swell from organic acid esters. Viton’s resistance to aromatic hydrocarbons diminishes above 150°C, mandating peroxide-cured grades for turbocharger applications. Silicone’s poor abrasion resistance often excludes it from high-speed rotary seals despite thermal advantages.

The following comparative analysis distills critical parameters for ring lubrication contexts:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Base Polymer | Fluorocarbon | Acrylonitrile Butadiene | Polydimethylsiloxane |

| Temp Range (°C) | -20 to +230 | -30 to +125 | -60 to +200 |

| Lubricant Compatibility | Synthetic esters, Skydrol, MIL-PRF-23699 | Mineral oils, greases, biodiesel | Silicone greases, water-glycol |

| Fluid Resistance | Excellent | Good (petroleum) | Poor (mineral oils) |

| Compression Set (ASTM D395) | ≤20% (200°C/70h) | ≤30% (100°C/70h) | ≤25% (200°C/70h) |

| Key Limitation | Cost, low-temp flexibility | Poor ozone/weathering | Low tensile strength |

Suzhou Baoshida Trading Co., Ltd. engineers collaborate with OEMs to validate material-lubricant pairings through accelerated aging tests in client-specified media. We provide certified material data sheets with swell ratios at 100°C/72h per ISO 1817, ensuring seal performance aligns with dynamic ring lubrication requirements. Precision in elastomer selection is non-negotiable for zero-leakage reliability in critical assemblies.

Manufacturing Capabilities

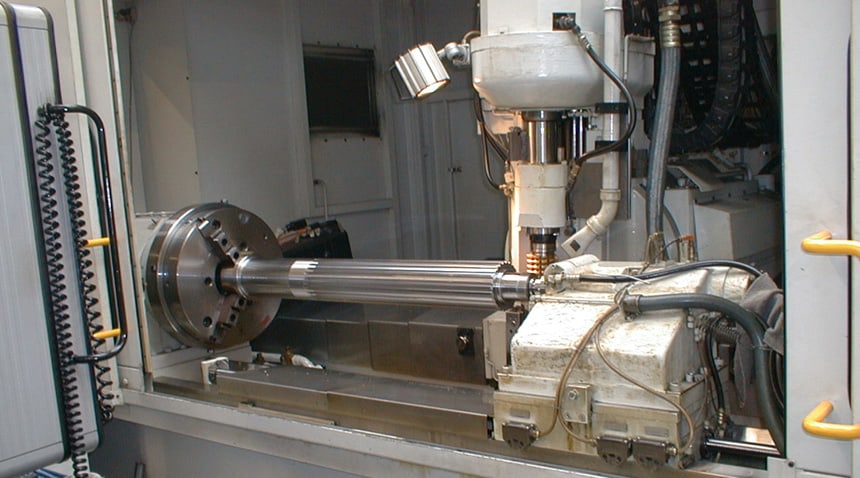

Suzhou Baoshida Trading Co., Ltd. maintains a robust engineering infrastructure dedicated to the development and production of high-performance rubber seals, with a specialized focus on ring lubrication systems. Our engineering team comprises five dedicated mould engineers and two advanced rubber formula engineers, enabling us to deliver precision-engineered solutions tailored to the exacting demands of industrial OEM clients. This integrated technical team ensures seamless development from concept to final product, combining material science with precision tooling expertise.

Our mould engineers possess extensive experience in designing multi-cavity, high-tolerance tooling for elastomeric components used in dynamic sealing applications. With advanced proficiency in CAD/CAM software and finite element analysis (FEA), they optimize gate placement, flow balance, and cooling channels to ensure uniform curing and minimal flash. This precision directly enhances the performance of lubrication rings by maintaining consistent cross-sectional geometry and dimensional stability under thermal cycling and mechanical compression.

Complementing this capability are our two in-house rubber formula engineers, who specialize in custom elastomer development for demanding environments. They formulate compounds that exhibit optimal tribological properties, low compression set, and resistance to oils, greases, and temperature extremes—critical for effective ring lubrication. By tailoring polymer base selection (NBR, FKM, ACM, or HNBR), crosslinking systems, and additive packages (including solid lubricants such as PTFE or MoS₂), we achieve controlled friction coefficients and extended service life in lubricated systems.

Our OEM capabilities are built on a foundation of collaborative engineering. We work directly with client design teams to co-develop sealing solutions that integrate seamlessly into lubrication mechanisms, whether in automotive transmissions, industrial gearboxes, or hydraulic actuators. This includes iterative prototyping, material validation under real-world conditions, and full traceability of formulations and tooling revisions. All compounds are developed and tested in accordance with ASTM, ISO, and customer-specific standards.

The following table outlines key technical specifications achievable through our integrated engineering approach:

| Parameter | Capability | Test Standard |

|---|---|---|

| Hardness Range | 40–90 Shore A | ASTM D2240 |

| Tensile Strength | Up to 22 MPa | ASTM D412 |

| Elongation at Break | Up to 550% | ASTM D412 |

| Compression Set (70 hrs, 100°C) | ≤20% | ASTM D395B |

| Operating Temperature Range | -40°C to +250°C (depending on compound) | ISO 1817 |

| Friction Coefficient (vs. steel, lubricated) | 0.08–0.15 | ASTM D1894 |

| Volume Swell in Synthetic Oil (70 hrs, 150°C) | ≤15% | ASTM D471 |

This synergy between material formulation and precision tooling allows Suzhou Baoshida to deliver lubrication rings with superior sealing integrity, reduced wear, and consistent performance under continuous operation. Our engineering model is designed for scalability, supporting low-volume prototyping through to high-volume OEM production with zero compromise on quality.

Customization Process

Precision Ring Lubrication Customization Process for Industrial Seals

At Suzhou Baoshida Trading Co., Ltd., our ring lubrication customization for precision rubber seals follows a rigorously controlled engineering pathway. This ensures optimal friction reduction, wear resistance, and compatibility with demanding industrial environments. The process eliminates guesswork through systematic validation at each phase, directly addressing client-specific operational challenges such as extreme temperatures, chemical exposure, or dynamic motion requirements.

Drawing Analysis

Initial assessment begins with comprehensive review of client-provided technical drawings and application parameters. We scrutinize seal geometry, surface finish tolerances, mating component materials, and dynamic load conditions. Critical factors like compression set limits, extrusion gaps, and potential lubricant migration pathways are evaluated against ISO 3601 standards. This phase identifies non-negotiable constraints and defines the lubrication performance envelope, forming the foundation for material and formulation decisions.

Formulation Development

Based on drawing analysis, our rubber compounding team designs bespoke lubricant-infused elastomer formulations. Standard polymers like FKM, EPDM, or HNBR undergo targeted modifications: polymer backbone adjustments, crosslink density optimization, and strategic incorporation of proprietary solid lubricants (e.g., PTFE, MoS₂) or liquid lubricant reservoirs (e.g., PFPE, silicone oils). The table below illustrates key specification differentiators between standard and custom formulations:

| Parameter | Standard Spec | Custom Spec (Baoshida) | Testing Method |

|---|---|---|---|

| Viscosity Range | 100-500 cSt @ 40°C | 50-2000 cSt @ 25-150°C | ASTM D445 |

| Temp. Resistance | -30°C to +150°C | -60°C to +250°C | ASTM D2240 |

| Chemical Resistance | General oils | Custom solvent blends | ISO 1817 |

| Friction Coefficient | 0.25-0.35 (dry) | 0.08-0.15 (lubricated) | ASTM D1894 |

| Compression Set | ≤30% @ 70°C/22h | ≤15% @ 125°C/70h | ASTM D395 |

Prototyping and Validation

Precision-molded prototypes undergo accelerated life testing in simulated operational conditions. We measure lubricant retention via gravimetric analysis, evaluate friction coefficients using tribometers per DIN 53505, and conduct dynamic seal testing on custom jigs replicating stroke speed, pressure cycles, and media exposure. Iterative adjustments to lubricant concentration and distribution are made until all performance targets are consistently achieved. Client validation data, including Stribeck curve analysis, is provided for sign-off.

Mass Production Assurance

Upon prototype approval, dedicated production lines initiate full-scale manufacturing under ISO 9001-certified protocols. In-process controls monitor lubricant dispersion homogeneity via FTIR spectroscopy and cure characteristics via moving die rheometry. Every production batch undergoes 100% dimensional inspection and抽样 testing for critical lubrication metrics. Traceability is maintained from raw material lot to finished seal, ensuring consistent performance that meets the exact specifications defined during the initial drawing analysis phase. This end-to-end control guarantees rings deliver extended service life and reduced maintenance costs in the client’s application.

Contact Engineering Team

For precision-critical applications in automotive, aerospace, industrial hydraulics, and medical device manufacturing, ring lubrication is not merely a maintenance step—it is a foundational element in ensuring long-term seal integrity, minimizing frictional wear, and preventing premature system failure. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber seals and advanced lubrication solutions tailored to the exacting demands of OEMs and Tier-1 suppliers worldwide. Our expertise extends beyond product supply; we provide technical integration support, material compatibility analysis, and custom formulation services to ensure optimal performance under extreme thermal, chemical, and mechanical conditions.

Ring lubrication plays a pivotal role in dynamic sealing environments where elastomeric components interact with moving shafts, pistons, or rotating elements. The correct lubricant reduces the coefficient of friction, prevents extrusion and spiral failure, and enhances sealing efficiency by promoting even contact stress distribution. However, improper lubrication—or using off-the-shelf greases without considering base polymer compatibility—can lead to swelling, hardening, or degradation of the seal material. This is particularly critical when working with specialty elastomers such as FKM, FFKM, EPDM, NBR, or silicone, each of which exhibits unique chemical resistance profiles and temperature tolerances.

At Suzhou Baoshida, we collaborate directly with design engineers and production managers to select or develop lubricants that are chemically matched to the seal compound and operational environment. Our technical team conducts rigorous testing for parameters such as NLGI grade, base oil viscosity, drop point, oxidation stability, and elastomer interaction per ASTM D471 and ISO 1817 standards. Whether your application involves high-vacuum environments, exposure to aggressive media like biodiesel or halogenated solvents, or cryogenic service conditions, we ensure compatibility and long-term reliability.

Below is a representative specification profile of a high-performance perfluoroelastomer (FFKM) ring lubricant formulation developed for extreme-condition sealing:

| Property | Test Method | Typical Value |

|---|---|---|

| Base Oil Type | Internal Analysis | Perfluoropolyether (PFPE) |

| Thickener | Internal Analysis | PTFE-based |

| Consistency (NLGI Grade) | ASTM D217 | 2 |

| Dropping Point | ASTM D2265 | >250°C |

| Operating Temperature Range | Engineering Evaluation | -40°C to +300°C |

| Density (g/cm³) | ASTM D1480 | 1.85 |

| Elastomer Compatibility (FKM, FFKM) | ASTM D471 | No cracking, <10% volume change |

| Vacuum Outgassing (TML) | ASTM E595 | <0.5% |

To initiate a technical consultation or request a custom formulation dossier, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce brings over 15 years of experience in rubber material science and industrial sealing systems, supporting global clients in optimizing seal-lubricant pairings for mission-critical applications. He is available to review your engineering specifications, conduct failure mode assessments, and recommend validated lubrication protocols that extend service life and reduce total cost of ownership.

Reach Mr. Boyce directly via email at [email protected]. Include your application parameters, seal material type, operating environment, and performance expectations to receive a targeted technical response within 24 business hours. For urgent project support, please indicate “Priority Engineering Review” in the subject line. Suzhou Baoshida is committed to precision, reliability, and partnership-driven innovation in every sealing solution we deliver.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).