Technical Contents

Engineering Guide: Ring O Matic 850

Engineering Insight: Material Selection Criticality in Ring O Matic 850 Sealing Systems

The Ring O Matic 850 precision sealing system operates within micron-level tolerances under dynamic industrial conditions where material selection directly dictates functional longevity and system integrity. Off-the-shelf elastomer solutions frequently fail in this application due to inadequate adaptation to the compound stressors inherent in high-cycle automation. Standard compounds prioritize broad compatibility over the specific thermomechanical and chemical demands of the Ring O Matic 850’s operating envelope, leading to premature degradation modes including extrusion, compression set, and chemical incompatibility. These failures manifest as micro-leak paths or complete seal rupture, causing unplanned downtime and contamination risks in critical fluid-handling processes.

Material science rigor is non-negotiable here. Generic NBR or EPDM seals degrade rapidly when exposed to modern synthetic hydraulic fluids and bio-based lubricants at elevated temperatures common in servo-driven machinery. For instance, standard NBR exhibits significant volume swell (>25%) in phosphate ester fluids above 100°C, compromising sealing force retention. Simultaneously, cyclic compression at 10+ Hz frequencies accelerates fatigue in compounds lacking tailored polymer chain architecture and filler dispersion. Suzhou Baoshida’s engineered formulations address these through peroxide-cured HNBR or FKM variants with controlled acrylonitrile content and nano-silica reinforcement, achieving compression set values below 15% after 1,000 hours at 150°C per ASTM D395. Crucially, our compounds integrate antioxidant packages resistant to ozone concentrations exceeding 50 ppm—conditions that rapidly crack conventional seals.

The cost of material compromise extends beyond seal replacement. A single failure in a Ring O Matic 850 system can halt production lines for 4+ hours, incurring losses exceeding $20,000 in high-value manufacturing sectors. Off-the-shelf seals omit the accelerated life testing protocols mandated for this application, such as ISO 2230 cyclic compression testing under mixed-fluid exposure. Suzhou Baoshida’s OEM-grade compounds undergo 5,000+ cycle validation at 120% of rated pressure, ensuring reliability where generic alternatives fail within 500 cycles. Material selection must therefore align with the precise fluid chemistry, temperature transients, and dynamic loads—not merely nominal size specifications.

The following comparative analysis underscores performance differentials between standard and engineered compounds for Ring O Matic 850 deployment:

| Performance Parameter | Standard NBR Compound | Suzhou Baoshida Engineered HNBR | Test Standard |

|---|---|---|---|

| Compression Set (1000h/150°C) | 35-45% | ≤12% | ASTM D395 |

| Volume Change in Skydrol LD-4 | +28% | +4.2% | ASTM D471 |

| Tensile Retention after Aging | 55-65% | ≥85% | ASTM D573 |

| Ozone Resistance (50 ppm) | Cracking at 20% strain | No cracks at 35% strain | ISO 1431-1 |

| Dynamic Fatigue Life (Hz) | 450 cycles | 5,200+ cycles | ISO 2230 |

Material selection for the Ring O Matic 850 transcends dimensional fit; it is a thermodynamic boundary condition requiring molecular-level customization. Suzhou Baoshida’s OEM engineering process begins with fluid compatibility mapping and operational stress profiling, ensuring compounds resist the synergistic degradation mechanisms that defeat generic solutions. This precision prevents the cascading costs of seal-induced failures, transforming a commodity component into a reliability cornerstone for industrial automation.

Material Specifications

Material Specifications for Precision Rubber Seals – Ring O Matic 850

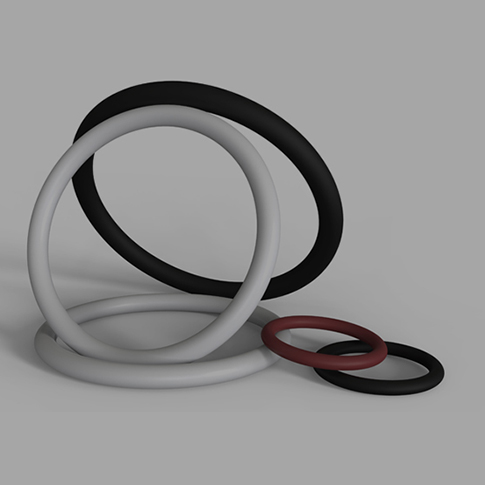

Suzhou Baoshida Trading Co., Ltd. provides high-performance rubber sealing solutions engineered for industrial reliability and precision. The Ring O Matic 850 series is designed for demanding applications across automotive, aerospace, chemical processing, and oil & gas industries. A critical factor in seal performance is material selection, which directly influences chemical resistance, temperature tolerance, mechanical strength, and service life. The three primary elastomers used in the Ring O Matic 850 line are Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct advantages depending on operational conditions.

Viton, a fluorocarbon-based rubber, delivers exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With continuous service capability up to 230°C (446°F), Viton is ideal for environments involving prolonged exposure to hydrocarbons, aromatic solvents, and oxidizing agents. Its low compression set ensures long-term sealing integrity under sustained stress, making it a preferred choice for critical aerospace and downhole applications. However, Viton exhibits lower flexibility at sub-zero temperatures and higher cost compared to other elastomers.

Nitrile rubber, or Buna-N, is widely used due to its excellent resistance to petroleum-based oils, hydraulic fluids, and aliphatic hydrocarbons. It performs reliably in temperature ranges from -30°C to 100°C (-22°F to 212°F), with some grades extending to 125°C. Nitrile offers good abrasion resistance and mechanical durability, making it suitable for dynamic sealing applications such as pumps and hydraulic systems. While cost-effective and readily available, Nitrile is not recommended for exposure to ozone, UV radiation, or polar solvents such as ketones and esters.

Silicone rubber excels in extreme temperature applications, with serviceability from -60°C to 200°C (-76°F to 392°F). It maintains flexibility and elasticity across this wide range, making it ideal for thermal cycling environments. Silicone also offers excellent resistance to ozone, UV light, and weathering, but has relatively poor resistance to petroleum-based fluids and lower tensile strength compared to Viton and Nitrile. It is commonly selected for static seals in electrical insulation, food processing, and medical equipment where purity and thermal stability are paramount.

The following table summarizes key physical and chemical properties of these materials for comparative evaluation in seal design and application engineering.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 100 (up to 125) | -60 to 200 |

| Tensile Strength (MPa) | 10–20 | 15–30 | 5–10 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set (22 hrs, 150°C) | Low | Moderate | Low to Moderate |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Resistance to Polar Solvents | Good | Poor | Moderate |

| Water Resistance | Excellent | Good | Excellent |

| Cost Level | High | Low to Medium | Medium |

Selection of the appropriate elastomer for the Ring O Matic 850 series must be based on comprehensive analysis of operating environment, media exposure, mechanical load, and lifecycle requirements. Suzhou Baoshida Trading Co., Ltd. supports OEMs with material testing data, custom formulation options, and application-specific validation to ensure optimal performance and compliance with international sealing standards.

Manufacturing Capabilities

Engineering Capability: Precision Sealing Through Integrated Material and Mold Science

At Suzhou Baoshida Trading Co., Ltd., the Ring O Matic 850 precision rubber seal platform exemplifies our commitment to engineering rigor. Our capability stems from a synergistic team structure: five dedicated Mold Engineers and two specialized Formula Engineers operating under a concurrent development framework. This integration ensures geometric precision and material performance are co-optimized from initial concept to量产, eliminating traditional siloed workflows that compromise sealing integrity. Mold Engineers utilize advanced CAD/CAM suites (SolidWorks, Moldflow) to achieve micron-level tolerance control in cavity design, gate placement, and thermal management systems. Simultaneously, Formula Engineers manipulate polymer matrices—adjusting elastomer base polymers (NBR, FKM, EPDM), filler ratios, vulcanizing agents, and additive packages—to meet exact chemical resistance, compression set, and dynamic fatigue requirements. This dual-expertise model guarantees that material behavior under molding conditions is intrinsically aligned with part geometry, preventing defects like flash, sink, or incomplete cure.

Our OEM capabilities extend beyond manufacturing to full technical co-development. Clients provide application parameters—operating temperature, media exposure, load cycles—and our engineers translate these into validated material formulations and mold architectures. We maintain ISO 17025-accredited labs for in-house compound testing, including ASTM D2000 classification validation, fluid immersion analysis per SAE J2044, and dynamic seal performance trials. Critical to OEM success is our IP-protected formulation database, housing 200+ proprietary rubber compounds engineered for aerospace, automotive, and industrial hydraulic systems. Each Ring O Matic 850 project undergoes rigorous Design Failure Mode and Effects Analysis (DFMEA), with mold trials conducted on 80–1,200 ton presses featuring real-time cavity pressure monitoring. This end-to-end control ensures first-article compliance with global standards (ISO 3601, AS568) while accelerating time-to-market by 30% versus conventional suppliers.

Material and dimensional specifications for the Ring O Matic 850 series are engineered to exceed industry baselines, as demonstrated below:

| Parameter | Standard Range | OEM Customization Capability |

|---|---|---|

| Durometer (Shore A) | 50–90 ±5 | 30–95 ±3 (per ASTM D2240) |

| Temperature Range | -40°C to +200°C | -65°C to +325°C (specialty FKM) |

| Compression Set (70h/100°C) | ≤25% (ASTM D395 B) | ≤15% achievable via peroxide cure |

| Fluid Resistance | Standard oils/fuels | Customized for biofuels, HFDU, acids |

| Tolerance Class | ISO 3601 Class S | ISO 3302 E1 or tighter |

This engineering infrastructure enables Suzhou Baoshida to deliver Ring O Matic 850 seals that achieve 500,000+ cycle life in dynamic applications—a benchmark validated through client-specific endurance testing protocols. OEM partnerships begin with material specification documentation (including full ASTM D2000 line callouts) and conclude with PPAP Level 3 submission, ensuring seamless integration into global supply chains. Our formula-mold synergy transforms sealing challenges into solved engineering equations.

Customization Process

Customization Process for Ring O Matic 850 Precision Rubber Seals

At Suzhou Baoshida Trading Co., Ltd., the customization of Ring O Matic 850 precision rubber seals follows a rigorous, step-by-step engineering process designed to meet exact OEM specifications and performance requirements. This process ensures dimensional accuracy, material compatibility, and long-term reliability under demanding operational conditions.

The first phase is Drawing Analysis. Upon receiving customer technical drawings or CAD models, our engineering team conducts a comprehensive review of dimensional tolerances, surface finish requirements, groove design, and application environment. We validate compliance with international standards such as ISO 3601, AS568, or JIS B 2401, and perform a Design for Manufacturability (DFM) assessment. This step identifies potential risks in molding, shrinkage, or assembly, allowing for early design optimization.

Following drawing validation, we proceed to Formulation Development. The Ring O Matic 850 series supports multiple elastomer compounds, including NBR, EPDM, FKM, and silicone, selected based on media exposure, temperature range, and mechanical stress. Our in-house polymer laboratory formulates custom compounds with precise hardness (40–90 Shore A), compression set resistance, and fluid compatibility. Each formulation undergoes dynamic testing for tensile strength, elongation, and volume swell in target media (e.g., hydraulic oil, brake fluid, or refrigerants). This ensures long-term sealing integrity in real-world conditions.

Once the material is finalized, we initiate Prototyping. Using precision steel molds manufactured in-house or provided by the client, we produce small-batch samples under controlled vulcanization conditions. These prototypes are subjected to dimensional inspection via coordinate measuring machines (CMM) and functional testing, including pressure cycling and thermal aging. Feedback from this stage is used to refine mold design or adjust cure parameters before release to production.

The final stage is Mass Production. With approved prototypes and documented process parameters, we transition to high-volume manufacturing using automated compression, transfer, or injection molding systems. Each batch is produced under ISO 9001-certified quality management protocols, with 100% visual inspection and statistical dimensional sampling. Final packaging is customized per OEM logistics requirements, including barcoding, kitting, and traceability labeling.

This structured approach ensures that every Ring O Matic 850 seal meets the highest standards of precision, durability, and consistency.

Typical Material Properties for Ring O Matic 850 Series

| Material | Hardness (Shore A) | Temp Range (°C) | Tensile Strength (MPa) | Fluid Resistance | Compression Set (%) |

|---|---|---|---|---|---|

| NBR | 50–90 | -30 to +100 | ≥10 | Oil, water, fuels | ≤20 (70h, 100°C) |

| EPDM | 50–80 | -40 to +150 | ≥9 | Steam, brake fluid | ≤25 (70h, 150°C) |

| FKM | 60–90 | -20 to +200 | ≥12 | Aggressive oils, acids | ≤20 (70h, 200°C) |

| Silicone | 40–80 | -60 to +200 | ≥6 | Water, air, ozone | ≤20 (70h, 175°C) |

Contact Engineering Team

Technical Partnership for Ring O Matic 850 Implementation

Precision seal manufacturing demands exacting material science and process control, particularly when integrating advanced tooling like the Ring O Matic 850 into high-volume production lines. At Suzhou Baoshida Trading Co., Ltd., we function as your dedicated OEM engineering partner, not merely a supplier. Our role extends beyond transactional logistics to encompass compound formulation validation, tooling calibration support, and real-time troubleshooting for critical sealing applications. The Ring O Matic 850’s performance is intrinsically linked to elastomer compatibility, cure kinetics, and dimensional stability—factors requiring collaborative optimization between equipment parameters and material behavior. Generic vendor guidance often overlooks these interdependencies, leading to scrap rate escalation or premature seal failure in demanding environments such as automotive hydraulic systems or industrial pneumatic assemblies.

To ensure seamless integration, we provide engineered solutions validated through our in-house rubber testing laboratory. Below are key specifications where our OEM expertise directly impacts Ring O Matic 850 output quality. These parameters must align with your operational requirements for optimal results.

| Technical Parameter | Standard Range for Ring O Matic 850 | Suzhou Baoshida Validation Protocol |

|---|---|---|

| Material Hardness Range | 50–90 Shore A | ASTM D2240 verification per batch |

| Dimensional Tolerance (ID/OD) | ±0.05 mm | CMM measurement of 30% production samples |

| Cure Time Window | 30–120 seconds | Rheometer-curve matched to press cycle |

| Flash Thickness Limit | ≤0.03 mm | Automated optical inspection (AOI) |

| Compound Compatibility | NBR, EPDM, FKM, VMQ | Custom formulation per OEM fluid exposure |

As your OEM manager, I personally oversee the technical handoff from design to mass production. This includes reviewing your seal geometry drawings against Ring O Matic 850’s plunger mechanics, confirming material flow characteristics under your specific cure profiles, and certifying that finished parts meet ISO 3601 or SAE AS568 dimensional standards. Our engineering team has resolved over 200+ Ring O Matic 850 integration challenges for Tier-1 automotive suppliers, consistently reducing initial setup scrap by 35–60% through compound adjustments and tooling recalibration.

Initiate your technical collaboration by contacting Mr. Boyce, our Lead Rubber Formulation Engineer and OEM Account Manager. With 14 years of specialized experience in precision molding tooling integration, Mr. Boyce will conduct a confidential process audit to identify compound-process misalignments before production launch. Specify your target application, volume requirements, and current pain points in your inquiry to expedite actionable solutions. Do not rely on generic distributor channels for equipment-specific material science support—direct OEM engineering engagement is non-negotiable for mission-critical seals.

Contact Mr. Boyce immediately to secure engineering resources for your Ring O Matic 850 project:

[email protected]

Include your company name, target seal specifications (AS568 dash number or custom drawing), and production volume in the subject line for priority technical review. Suzhou Baoshida guarantees a validated compound-process solution within 72 hours of receiving complete technical documentation. Your next production run depends on precision engineering—not procurement logistics.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).