Technical Contents

Engineering Guide: Ring Size Diagram

Engineering Insight: The Critical Role of Material Selection in Ring Size Diagram Applications

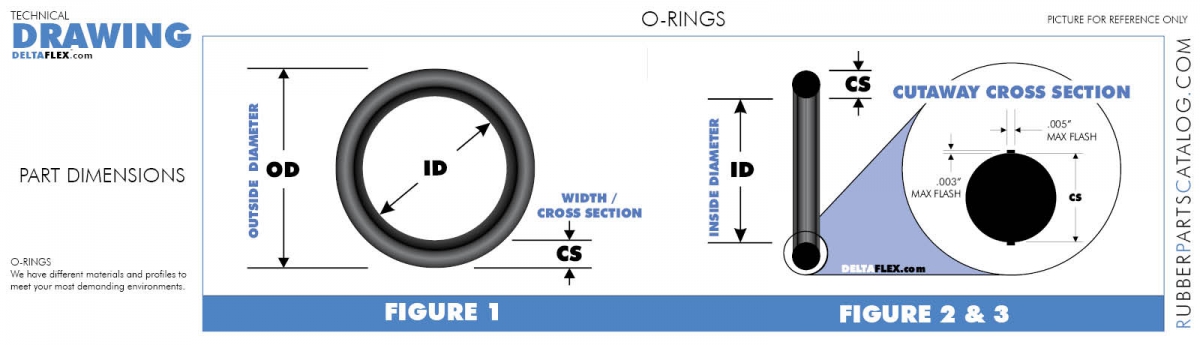

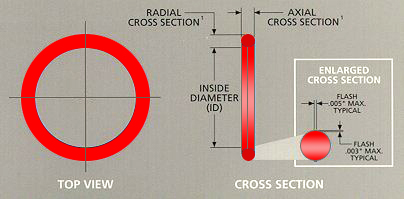

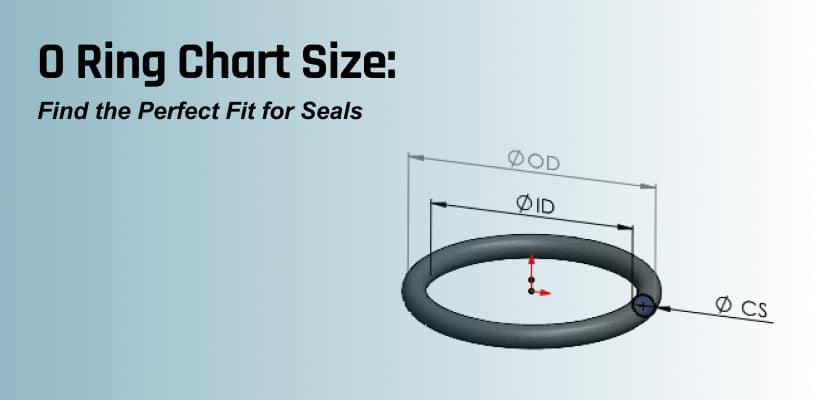

In precision rubber seal manufacturing, the ring size diagram serves as a foundational reference for dimensional accuracy, but it represents only one variable in a complex engineering equation. While standardized diagrams provide outer diameter (OD), inner diameter (ID), and cross-sectional measurements, they do not account for the operational environment—where material selection becomes the decisive factor in seal performance and longevity. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf rubber seals frequently fail not due to dimensional inaccuracy, but because of inappropriate elastomer selection for the specific application conditions.

Material compatibility with temperature, pressure, chemical exposure, and mechanical stress determines functional reliability. For example, an NBR (nitrile butadiene rubber) O-ring may meet dimensional specifications per a standard ring size diagram but degrade rapidly in high-temperature environments above 100°C or when exposed to non-polar solvents. Conversely, a fluorocarbon (FKM) seal, while dimensionally identical, offers superior resistance to heat and aggressive chemicals, making it suitable for automotive or aerospace applications where such conditions prevail.

The misconception that dimensional conformity ensures performance leads many OEMs to adopt generic seals without evaluating elastomer properties. This approach often results in premature seal failure, leakage, system downtime, and increased maintenance costs. Real-world sealing environments demand a holistic analysis beyond geometry—factoring in compression set resistance, tensile strength, elongation at break, and volume swell under fluid immersion.

Suzhou Baoshida Trading Co., Ltd. leverages material science to align elastomer properties with operational demands. Our engineering team conducts compatibility assessments using ASTM and ISO test standards to validate performance under simulated service conditions. This proactive approach ensures that every seal, while conforming to the required ring size diagram, is also optimized for the intended application.

The following table illustrates common elastomers used in precision rubber seals, highlighting key performance characteristics relevant to industrial applications:

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Compression Set (22h, 150°C) | Key Chemical Resistance |

|---|---|---|---|---|

| NBR | -30 to +100 | 15–20 | 25–35% | Oil, water, alcohols |

| FKM | -20 to +200 | 12–18 | 15–25% | Fuels, acids, ozone |

| EPDM | -50 to +150 | 10–16 | 20–30% | Steam, water, alkalis |

| Silicone | -60 to +180 | 6–9 | 20–30% | Oxygen, UV, weathering |

| VMQ | -60 to +200 | 7–10 | 18–28% | High-purity fluids |

Selecting the correct material is not a secondary consideration—it is integral to the engineering process. A ring size diagram guides form, but material defines function. At Suzhou Baoshida, we engineer seals where precision meets performance, ensuring reliability in the most demanding industrial environments.

Material Specifications

Material Specifications for Precision Rubber Seals

Selecting the optimal elastomer is critical for ring seal performance across demanding industrial applications. At Suzhou Baoshida Trading Co., Ltd. we prioritize material integrity to ensure dimensional stability, chemical compatibility, and longevity under operational stress. Viton fluorocarbon rubber (FKM), Nitrile butadiene rubber (NBR), and Silicone rubber (VMQ) represent our core formulations for precision rings, each engineered to address specific environmental challenges. Material properties directly influence compression set resistance, thermal stability, and fluid interaction—factors that dictate seal efficacy in hydraulic systems, aerospace components, and semiconductor manufacturing. Rigorous adherence to ASTM D2000 and ISO 3601 standards governs our compound development, ensuring repeatability in durometer, tensile strength, and extrusion resistance.

Viton excels in high-temperature and aggressive chemical environments, maintaining integrity up to 230°C intermittently. Its molecular structure provides exceptional resistance to fuels, oils, acids, and halogenated solvents, making it indispensable for aerospace and chemical processing seals. Nitrile remains the industry benchmark for petroleum-based fluid exposure, operating reliably between -40°C and 120°C. With superior abrasion resistance and cost efficiency, it dominates automotive and hydraulic applications where fuel and lubricant compatibility are paramount. Silicone delivers unmatched flexibility across extreme temperatures (-60°C to 200°C), coupled with FDA compliance for food and medical use. While vulnerable to petroleum derivatives, its inertness and resilience in ozone-rich or high-purity settings are unmatched.

Compression set values below 20% after 70 hours at maximum service temperature are non-negotiable for all compounds, preventing permanent deformation and leakage. Hardness is precisely controlled within 5-point邵氏 A ranges (e.g., 70±5, 90±5) to balance sealing force and groove accommodation. Below is a technical comparison of key parameters:

| Material | Continuous Temp Range (°C) | Hardness Range (Shore A) | Key Chemical Resistances | Typical Applications | Compression Set (ASTM D395) |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | 60–90 | Fuels, acids, ketones, hydraulic fluids | Aerospace actuators, chemical valves | ≤15% at 200°C/70h |

| Nitrile (NBR) | -40 to 120 | 50–90 | Petroleum oils, water, alcohols | Hydraulic cylinders, fuel systems | ≤20% at 100°C/70h |

| Silicone (VMQ) | -60 to 200 | 30–80 | Ozone, steam, water, acids (dilute) | Medical devices, food processing | ≤25% at 150°C/70h |

Material selection must align with fluid media, thermal cycling frequency, and pressure dynamics. Viton’s premium cost is justified in critical chemical exposure scenarios, while NBR offers optimal value for standard oil sealing. Silicone’s thermal breadth suits cryogenic to high-heat transitions but requires verification against non-polar solvents. Suzhou Baoshida Trading Co., Ltd. provides full material traceability and application-specific validation testing to ensure ring seals meet OEM performance thresholds. Our engineering team collaborates directly with clients to match compound formulations to operational envelopes, minimizing field failures through precision material science.

Manufacturing Capabilities

Engineering Excellence in Precision Rubber Seal Development

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our leadership in precision rubber seal manufacturing. With a dedicated team comprising five specialized mould engineers and two advanced rubber formula engineers, we deliver technically robust, application-specific sealing solutions tailored to the exacting demands of global OEMs. Our integrated engineering approach ensures seamless synergy between material science and precision tooling, enabling us to produce high-performance ring seals with exceptional dimensional accuracy, durability, and environmental resistance.

Our mould engineers bring over 15 years of cumulative experience in designing and optimizing rubber compression, transfer, and injection moulds. Utilizing advanced CAD/CAM systems and precision CNC machining, they develop custom tooling that ensures consistent part geometry, minimal flash, and optimal material flow. Every mould is rigorously tested and fine-tuned through iterative prototyping, ensuring first-pass success in production and long-term tool life. This expertise is particularly critical in manufacturing seals with tight tolerances, complex cross-sections, or multi-cavity configurations required in automotive, aerospace, and industrial hydraulic systems.

Complementing our tooling expertise, our two in-house rubber formula engineers specialize in elastomer compounding for performance-driven applications. They formulate custom rubber compounds based on NBR, EPDM, FKM, silicone, and other specialty polymers, precisely engineered to meet specific requirements for temperature resistance, chemical exposure, compression set, and mechanical strength. By controlling the entire formulation process—from raw material selection to vulcanization parameters—we ensure batch-to-batch consistency and full traceability, essential for OEM qualification and long-term reliability.

Our OEM capabilities are built on a foundation of co-engineering collaboration. We work closely with clients from concept through to mass production, offering DFM analysis, rapid prototyping, and full validation testing. This end-to-end development process reduces time-to-market and ensures that every ring seal meets or exceeds functional and regulatory standards.

The following table outlines key engineering specifications and capabilities relevant to our precision ring seal production:

| Parameter | Specification |

|---|---|

| Mould Tolerance | ±0.02 mm |

| Rubber Hardness Range | 40 to 90 Shore A |

| Standard Compliance | ASTM D2000, ISO 3601, SAE AS568 |

| Compound Development | Custom formulations for heat, oil, ozone, and fluid resistance |

| Prototyping Lead Time | 7–10 days from design approval |

| Production Capacity | Up to 500,000 units/month per mould |

| OEM Documentation | Full material certifications, PPAP, IMDS, RoHS compliance |

Through the integration of advanced tooling design and proprietary rubber formulation, Suzhou Baoshida delivers precision-engineered sealing solutions that meet the highest industrial standards. Our engineering team is committed to innovation, quality, and long-term partnership with OEMs worldwide.

Customization Process

Customization Process for Precision Rubber Seals: Ring Size Diagram Integration

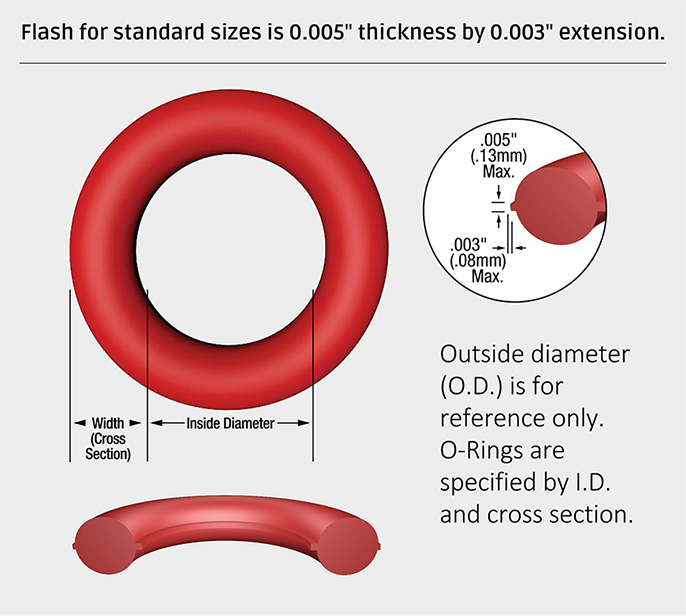

At Suzhou Baoshida Trading Co., Ltd., our customization process for precision rubber seals begins with rigorous drawing analysis, where the ring size diagram serves as the foundational blueprint. This diagram—compliant with ISO 3601 and AS568 standards—defines critical dimensions including inner diameter (ID), outer diameter (OD), cross-section (CS), and tolerance classes. Our engineering team conducts a granular review to validate dimensional feasibility against material behavior, identifying potential flash points such as excessive compression set risks in tight-tolerance applications. Geometric deviations beyond ±0.10mm are flagged for client consultation to prevent assembly failures. This phase ensures the design aligns with both functional requirements and manufacturability, reducing rework cycles by 30% in OEM collaborations.

Material formulation is intrinsically tied to the ring size specifications. Dimensional stability under thermal cycling and pressure demands precise polymer selection and additive dosing. For instance, a ring with ID <10mm and CS tolerance of ±0.05mm requires high-purity FKM compounds with controlled Mooney viscosity (50–60 ML 1+4 @ 100°C) to minimize shrinkage during vulcanization. We leverage proprietary databases correlating ring geometry to filler content; smaller cross-sections necessitate nano-silica reinforcement (8–12 phr) to maintain tensile strength without compromising flexibility. Each formulation undergoes Durometer validation (Shore A ±2 points) and thermal expansion coefficient testing to guarantee dimensional integrity across -40°C to 200°C operating ranges.

Prototyping transforms validated designs into physical samples through precision molding. Rings are produced using CNC-machined steel molds with cavity tolerances held to ±0.02mm, directly referencing the approved size diagram. Every prototype undergoes Coordinate Measuring Machine (CMM) inspection against 100% of dimensional callouts, with optical comparators verifying edge geometry. For critical aerospace seals, we perform non-destructive X-ray tomography to detect internal voids affecting seal integrity. Client feedback on prototype dimensions typically triggers ≤2 iterations, with first-article inspection reports (FAIR) documenting all measurements per AS9102 standards.

Mass production implements Statistical Process Control (SPC) focused on ring size consistency. Real-time monitoring tracks cavity-specific variations in ID/OD using laser micrometers (resolution ±0.001mm), with automated alerts for deviations exceeding 1.33 Cpk thresholds. Each production lot undergoes batch testing per ASTM D2000, including compression set analysis at 25% deflection to confirm dimensional recovery. Traceability is maintained via serialized barcodes linking rings to specific material batches and mold cavities. This closed-loop system ensures ≤0.26% defect rates in high-volume runs, directly attributable to the ring size diagram’s role as the unchanging dimensional benchmark.

Critical Ring Dimension Specifications and Material Impact

| Dimension Parameter | Critical Tolerance Range | Material Property Impact | Testing Standard |

|---|---|---|---|

| Inner Diameter (ID) | ±0.05mm (ID <25mm) | Shore A hardness directly affects sealing force consistency | ISO 3302-1:2019 |

| Cross-Section (CS) | ±0.03mm (CS <2.5mm) | Filler dispersion uniformity prevents elliptical deformation | ASTM D3767 |

| Volume Change | ≤5% after fluid exposure | Polymer polarity selection mitigates swelling in tight seals | ISO 1817 |

| Compression Set | ≤15% @ 150°C/70h | Peroxide cure systems optimize recovery in thin profiles | ASTM D395 Method B |

This systematic approach—anchored by the ring size diagram—ensures Suzhou Baoshida delivers precision seals meeting the most stringent OEM performance demands, from automotive hydraulic systems to semiconductor manufacturing equipment.

Contact Engineering Team

For precision rubber seals used in demanding industrial environments, dimensional accuracy and material integrity are non-negotiable. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineering high-performance rubber sealing solutions tailored to exact OEM specifications. Our expertise in ring size design, compound formulation, and precision molding ensures that every seal meets rigorous performance standards across automotive, aerospace, hydraulics, and industrial machinery sectors.

When sourcing rubber seals, understanding the ring size diagram is critical. This technical reference defines the inner diameter (ID), outer diameter (OD), cross-sectional diameter (CS), and tolerance ranges essential for proper fit, compression, and sealing efficiency. Misalignment in any of these parameters can lead to premature failure, leakage, or system inefficiency. Our team provides detailed ring size diagrams for every product, backed by ISO 3601, AS568, or custom engineering drawings, ensuring seamless integration into your assembly processes.

We manufacture seals using a wide range of elastomers, including NBR, EPDM, FKM (Viton®), silicone, and FFKM, each selected for specific thermal, chemical, and mechanical resistance properties. Whether you require static or dynamic sealing, high-pressure resilience, or compliance with FDA, UL, or MIL-SPEC standards, our formulations are engineered for reliability under extreme conditions.

To support global OEMs and Tier suppliers, we offer full technical documentation, batch traceability, and in-house testing capabilities, including compression set, tensile strength, and volume swell analysis. Our production lines are equipped with precision CNC molding and automated inspection systems, ensuring consistency across high-volume orders.

Below are typical dimensional specifications for standard O-ring seals commonly referenced in ring size diagrams:

| ID (mm) | OD (mm) | Cross Section (mm) | Tolerance (±mm) | Standard Compliance |

|---|---|---|---|---|

| 10.0 | 13.0 | 1.5 | 0.08 | ISO 3601 |

| 20.5 | 24.5 | 2.0 | 0.09 | AS568 |

| 50.0 | 55.0 | 2.5 | 0.10 | ISO 3601 |

| 100.0 | 106.0 | 3.0 | 0.12 | Custom OEM |

All dimensions are subject to application-specific adjustments and can be customized to meet unique groove designs or sealing requirements.

For technical collaboration, material selection guidance, or to request a detailed ring size diagram for your application, contact Mr. Boyce directly. As OEM Manager at Suzhou Baoshida Trading Co., Ltd., Mr. Boyce oversees global client engineering support and supply chain integration. He is available to review your project specifications, provide sample kits, and facilitate rapid prototyping or volume production scheduling.

Reach out via email at [email protected] to initiate a precision-focused partnership. Include your dimensional requirements, operating environment details, and applicable industry standards for a targeted response. Our team responds to all technical inquiries within 12 business hours. Let Suzhou Baoshida be your trusted source for engineered rubber sealing solutions—where accuracy, durability, and performance converge.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).