Technical Contents

Engineering Guide: Rope Packing For Valves

Engineering Insight: The Critical Role of Material Selection in Rope Packing for Valves

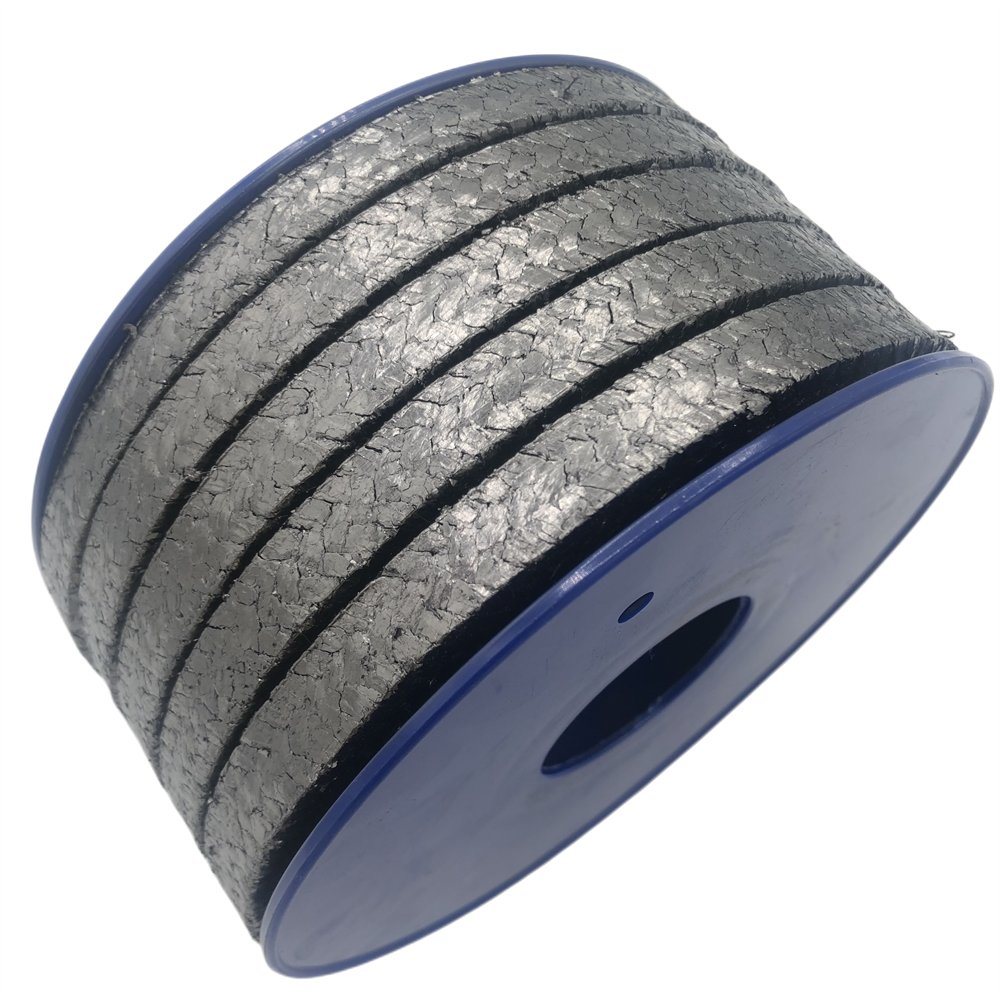

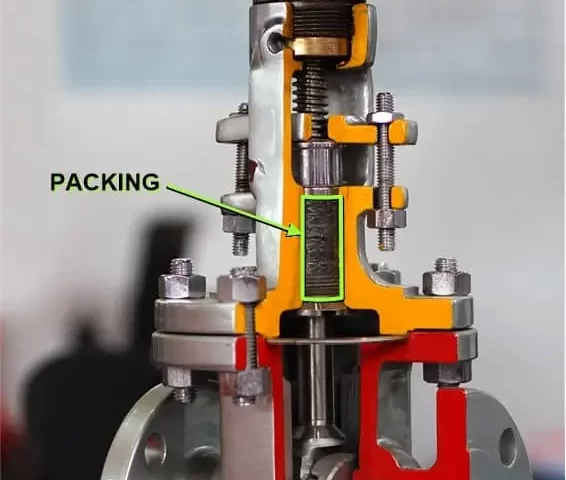

In industrial valve applications, rope packing serves as a primary sealing mechanism to prevent leakage of fluids under pressure and temperature extremes. While often perceived as a commodity item, the performance and reliability of rope packing are profoundly influenced by material selection. Off-the-shelf solutions, though cost-attractive in the short term, frequently fail to meet the specific demands of complex operating environments, leading to unplanned downtime, safety hazards, and increased maintenance costs.

The failure of generic rope packing typically stems from a mismatch between material properties and service conditions. Common failure modes include extrusion, thermal degradation, chemical attack, and loss of resilience. For example, standard PTFE-based packings may perform well in low-temperature, non-oxidizing environments but degrade rapidly when exposed to high heat or UV radiation. Similarly, aramid fiber packings, while strong and abrasion-resistant, can suffer from hydrolysis in steam applications or chemical breakdown in strong alkalis.

Material selection must consider multiple engineering parameters: fluid compatibility, operating temperature and pressure, shaft or stem velocity, and cyclic service conditions. A precision-engineered rope packing integrates fibers, lubricants, and impregnation agents tailored to the application. For instance, expanded graphite is preferred in high-temperature steam valves due to its inertness and thermal stability, while PTFE-impregnated aramid is selected for corrosive chemical services requiring low friction.

Equally important is the braid structure. Different braid patterns—such as square, diamond, or interlock—affect conformability, resilience, and load distribution. A poorly structured braid, even with high-grade materials, can lead to uneven wear and premature leakage.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific engineering over one-size-fits-all solutions. Our industrial rubber solutions are developed with OEM-level precision, ensuring compatibility with international standards and client-specific operating profiles.

The table below outlines key material types used in high-performance rope packing and their typical service limits:

| Material Type | Max Temperature (°C) | Pressure Limit (bar) | Chemical Resistance | Common Applications |

|---|---|---|---|---|

| Expanded Graphite | 650 (inert atm) | 300 | Excellent | Steam, high-temp valves |

| PTFE-Impregnated Aramid | 260 | 200 | Very Good | Chemical processing, pumps |

| Carbon Fiber | 350 (oxidizing) | 250 | Good | High-pressure valves, cryogenics |

| Pure PTFE | 260 | 100 | Excellent | Low-load, corrosive media |

| Ceramic Fiber | 1260 | 70 | Moderate | Extreme heat, furnace applications |

Selecting the appropriate rope packing is not a generic procurement decision—it is an engineering imperative. By integrating material science with operational data, Suzhou Baoshida ensures sealing solutions that enhance safety, efficiency, and longevity in critical valve systems.

Material Specifications

Material Specifications for Valve Rope Packing

Valve rope packing performance hinges on precise elastomer selection aligned with operational parameters. At Suzhou Baoshida Trading Co., Ltd., we engineer rope packing solutions using Viton, Nitrile, and Silicone compounds, each formulated for distinct chemical, thermal, and mechanical environments. Material choice directly impacts sealing longevity, fugitive emission control, and maintenance intervals in critical industrial valves. Understanding the intrinsic properties of these polymers ensures optimal compatibility with media, temperature excursions, and pressure differentials.

Viton (FKM) rope packing delivers exceptional resistance to aggressive chemicals, including hydrocarbons, acids, and halogenated solvents. Its fluorocarbon backbone sustains continuous service from -20°C to +230°C, with short-term peaks up to 300°C. Viton maintains sealing integrity under high pressures exceeding 250 bar in refinery, petrochemical, and aerospace applications where hydrocarbon exposure is prevalent. Compression set values remain below 25% after 70 hours at 200°C per ASTM D395, ensuring reliable reseating.

Nitrile (NBR) rope packing provides cost-effective resilience against petroleum-based oils, water, and aliphatic hydrocarbons. Operating effectively between -30°C and +120°C, it excels in hydraulic systems, water treatment, and general industrial valves. NBR formulations achieve tensile strengths of 15-25 MPa and elongation at break exceeding 300%, balancing flexibility with abrasion resistance. Its limitation lies in poor ozone and ketone resistance, restricting use in aromatic solvent environments.

Silicone (VMQ) rope packing dominates extreme temperature scenarios, functioning from -60°C to +200°C continuously. While offering excellent resistance to water, steam, and oxygen, it exhibits lower mechanical strength and permeability to gases compared to Viton or NBR. Silicone is ideal for food-grade, pharmaceutical, and cryogenic applications where inertness and wide thermal stability are paramount, but it is unsuitable for prolonged exposure to concentrated acids or hydrocarbons.

Material Comparison for Valve Rope Packing

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Chemical Resistance | Excellent: Hydrocarbons, acids, solvents | Good: Oils, water; Poor: Ozone, ketones | Good: Water, steam; Poor: Acids, hydrocarbons |

| Pressure Limit (bar) | >250 | 150-200 | 100-150 |

| Tensile Strength (MPa) | 10-15 | 15-25 | 5-10 |

| Compression Set (ASTM D395) | ≤25% @ 200°C/70h | ≤30% @ 100°C/70h | ≤20% @ 150°C/70h |

| Key Applications | Refineries, chemical processing, aerospace | Hydraulics, water systems, general industry | Food/pharma, cryogenics, high-purity steam |

Selection requires rigorous validation against fluid composition, cyclic temperature profiles, and dynamic valve stem movement. Suzhou Baoshida Trading Co., Ltd. provides customized compound formulations within these material families to address specific OEM valve design requirements, ensuring compliance with ISO 2230 and API 641 standards for emission control. Consult our engineering team for media compatibility testing and accelerated life cycle analysis.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in industrial rubber solutions is anchored in a specialized team of technical experts and a disciplined approach to material science and product development. We employ five dedicated mould engineers and two advanced formula engineers who work in close synergy to deliver high-performance rope packing for valves tailored to demanding industrial environments. This integrated team structure allows us to control both the physical design and chemical composition of our products, ensuring optimal functionality, durability, and compatibility across diverse operational conditions.

Our mould engineers bring extensive experience in precision tooling design and manufacturing process optimization. They utilize advanced CAD/CAM software and finite element analysis (FEA) to simulate stress distribution, thermal behavior, and compression characteristics of rope packing under real-world valve service conditions. This enables us to produce consistent cross-sectional geometries and dimensional accuracy, critical for achieving reliable sealing performance in high-pressure and high-temperature applications. Each mould design undergoes rigorous validation testing to ensure cycle durability and dimensional stability over extended production runs.

Complementing this capability are our two in-house rubber formulation engineers, who specialize in polymer chemistry and compound development for sealing applications. They formulate custom elastomeric blends using nitrile (NBR), ethylene propylene diene monomer (EPDM), fluorocarbon (FKM), and other specialty rubbers, adjusting filler systems, plasticizers, and vulcanization agents to meet specific customer requirements for temperature resistance, chemical compatibility, compression set, and abrasion resistance. All formulations are developed and tested in our on-site laboratory, where we conduct aging tests, fluid immersion analysis, and dynamic sealing evaluations to validate long-term performance.

Our OEM manufacturing capability is built on this strong engineering foundation. We support original equipment manufacturers with full design-for-manufacturability reviews, rapid prototyping, and scalable production runs. Whether adapting existing designs or developing new cross-sections and braiding patterns for rope packing, we ensure seamless integration with customer valve systems. Our traceability systems and process documentation meet international quality standards, supporting certification requirements in sectors such as oil & gas, chemical processing, and power generation.

The following table outlines key technical specifications achievable through our engineering and production capabilities:

| Parameter | Standard Range | Custom Capability | Test Method |

|---|---|---|---|

| Temperature Resistance | -30°C to +200°C | Up to +300°C (FKM-based) | ASTM D573 |

| Pressure Rating | Up to 25 bar | Up to 40 bar (reinforced braid) | ISO 15848-1 |

| Media Resistance | Water, oil, steam, mild acids/alkalis | Custom compounds for aggressive chemicals | ASTM D471 |

| Hardness (Shore A) | 60–90 | Adjustable within 50–95 | ASTM D2240 |

| Elongation at Break | ≥200% | Up to 500% (EPDM/NBR blends) | ASTM D412 |

This combination of skilled personnel, advanced materials science, and precision engineering positions Suzhou Baoshida as a trusted partner for technically demanding rope packing solutions in critical valve applications.

Customization Process

Customization Process for High-Performance Valve Rope Packing

At Suzhou Baoshida Trading Co., Ltd., our OEM customization process for industrial valve rope packing is engineered for precision, reliability, and seamless integration into demanding fluid control systems. We execute a rigorous four-phase methodology to transform client specifications into certified sealing solutions, minimizing risk and maximizing service life under extreme conditions.

Step 1: Drawing Analysis & Requirement Validation

Initial engagement commences with meticulous technical drawing review against ASME B16.20, ISO 9001:2015, and client-specific GD&T standards. Our engineering team cross-references valve stem diameter, groove dimensions, operating pressure differentials, and media compatibility requirements. Critical parameters including maximum cyclic frequency, thermal cycling range, and fugitive emission targets are quantified. This phase concludes with a formal Technical Feasibility Report, identifying potential tolerance conflicts or material limitations before formulation begins.

Step 2: Precision Rubber Formulation Development

Leveraging 18 years of compound database analytics, our formula engineers design bespoke elastomer matrices targeting the validated operational envelope. Base polymers (FKM, EPDM, PTFE composites) are selected based on chemical resistance profiles. Critical additives—reinforcing silica for extrusion stability, specialized anti-extrusion agents for high-pressure differentials, and low-friction modifiers—are dosed at ±0.25 phr accuracy. Each formulation undergoes virtual simulation for compression set prediction at 200°C/72h prior to lab mixing. Material Safety Data Sheets (MSDS) and FDA/EC1935 compliance documentation are generated concurrently.

Step 3: Prototyping & Performance Validation

Prototypes are manufactured using client-specified braiding density (typically 48-96 ends) and preformed cross-sections. Every batch undergoes accelerated life testing per API 641 Annex B: 500 thermal cycles (-40°C to 260°C), 10,000 stem reciprocations at 150 bar, and helium leak testing to 1×10⁻⁶ mbar·L/s. Dimensional conformance is verified via CMM against the original drawing. Performance data is compiled into a Prototype Validation Dossier, including stress-strain curves and friction coefficient analysis. Client approval requires zero leakage events during testing.

Step 4: Controlled Mass Production & Quality Assurance

Approved formulations transition to ISO 13485-certified production lines with real-time rheometer monitoring. Each production lot undergoes stringent in-process checks: Shore A hardness ±2 points, tensile strength ±5%, and braiding pitch consistency. Final inspection includes 100% visual examination for surface defects and batch traceability via laser-etched lot codes. Statistical Process Control (SPC) charts for critical dimensions are provided with shipment. OEM packaging adheres to ESD-safe protocols with humidity indicators for global logistics.

Key Performance Specifications for Custom Rope Packing

| Parameter | Standard Range | Customizable Range | Test Method |

|---|---|---|---|

| Temperature Resistance | -50°C to +260°C | -70°C to +320°C | ASTM D2240 |

| Pressure Rating | Up to 250 bar | Up to 450 bar | API 641 Annex B |

| Chemical Resistance | Water, Oils, Mild Acids | HF, Amines, Superheated Steam | ASTM D471 |

| Compression Set (22h/200°C) | ≤25% | ≤15% | ISO 3384 |

| Friction Coefficient | 0.12-0.18 | 0.08-0.12 | DIN 53505 |

This structured approach ensures every meter of rope packing meets the exacting demands of critical valve applications while maintaining Suzhou Baoshida’s 99.82% on-time delivery record for OEM partners. All custom solutions include comprehensive technical documentation for seamless integration into client quality management systems.

Contact Engineering Team

For industrial operations requiring reliable sealing performance under demanding conditions, rope packing for valves remains a critical component in maintaining system integrity. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance industrial rubber solutions engineered to meet the exacting standards of global OEMs and maintenance teams. Our technical expertise, advanced material formulations, and rigorous quality control ensure that every meter of rope packing delivered meets precise operational requirements—whether in high-temperature steam systems, chemical processing plants, or heavy-duty mechanical applications.

Our rope packing solutions are manufactured using premium-grade fibers impregnated with specialized lubricants and corrosion-resistant compounds. This ensures low friction, extended service life, and minimal maintenance downtime. Materials such as PTFE, aramid, graphite, and cotton are selected based on application-specific demands, including temperature range, media compatibility, shaft speed, and pressure differentials. Each product is designed to deliver consistent sealing force, resist extrusion, and maintain dimensional stability across dynamic operating cycles.

We understand that selecting the correct rope packing involves more than just material choice—it requires a deep understanding of system dynamics and failure modes. That’s why our engineering team provides technical support from specification through installation, ensuring optimal performance and longevity. Our products are compliant with international standards and have been successfully integrated into systems across petrochemical, power generation, pulp and paper, and water treatment industries.

For custom applications or volume procurement, Suzhou Baoshida offers tailored manufacturing programs, technical documentation, and on-site consultation services. We partner with clients to develop sealing solutions that reduce leakage risks, improve energy efficiency, and lower total cost of ownership.

To discuss your specific rope packing requirements or request technical data sheets, please contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer. With over a decade of experience in industrial sealing technology, Mr. Boyce leads material development and client engineering support at Suzhou Baoshida. He is available to assist with product selection, custom formulation, and performance optimization for your valve sealing challenges.

Reach out via email at [email protected] to initiate a technical consultation or request a sample for evaluation. We respond to all inquiries within 24 hours during business days and provide multilingual support for international clients.

Below are representative specifications of our standard rope packing series for reference:

| Material Type | Temperature Range (°C) | Pressure Resistance (bar) | Shaft Speed (m/s) | Media Compatibility |

|---|---|---|---|---|

| PTFE Braided | -200 to +260 | Up to 20 | ≤ 5 | Acids, solvents, water, steam |

| Aramid-PTFE Hybrid | -100 to +250 | Up to 35 | ≤ 8 | Alkalis, oils, moderate chemical exposure |

| Flexible Graphite | -200 to +650 (inert) | Up to 30 | ≤ 3 | Steam, high-temp water, hydrocarbons |

| Cotton-PTFE | -30 to +180 | Up to 15 | ≤ 4 | Water, mild chemicals, food-grade options |

Contact Mr. Boyce today at [email protected] to ensure your valve systems operate with maximum reliability and efficiency.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).