Technical Contents

Engineering Guide: Rubber And Foam Supplies

Engineering Insight: Material Selection in Rubber and Foam Components – Why Off-the-Shelf Solutions Fail

Field failures in rubber and foam components rarely stem from manufacturing defects alone. They predominantly originate from inadequate material selection for the specific operational environment. Off-the-shelf compounds offer superficial cost savings but introduce critical vulnerabilities when deployed in demanding industrial applications. Generic formulations lack the tailored polymer architecture, filler systems, and additive packages necessary to withstand the confluence of mechanical stress, chemical exposure, thermal cycling, and aging factors inherent in real-world use.

The core deficiency lies in the oversimplification of application requirements. A standard nitrile rubber (NBR) gasket may function adequately in static, room-temperature hydraulic systems. However, introduce dynamic vibration, intermittent exposure to biodiesel fuels, and temperature excursions from -30°C to 120°C, and the same compound rapidly degrades through swelling, compression set, and loss of tensile strength. Similarly, a commodity polyurethane foam seal might provide initial compression recovery but catastrophically hardens when exposed to ozone or UV radiation in outdoor enclosures. These failures manifest as leaks, binding, loss of sealing force, or premature component disintegration – directly impacting equipment uptime, safety, and total cost of ownership.

Material performance is not defined by a single property but by the synergistic balance across multiple critical parameters under end-use conditions. Below is a comparative analysis highlighting why engineered solutions outperform generic alternatives in demanding scenarios:

| Critical Parameter | Generic Off-the-Shelf Compound | Engineered Baoshida Solution | Failure Consequence of Generic Material |

|---|---|---|---|

| Compression Set (ASTM D395) | 45% after 70h @ 100°C | 18% after 70h @ 150°C | Seal leakage due to permanent deformation |

| Fluid Resistance (Biodiesel) | Volume Swell: +35% | Volume Swell: +8% | Loss of mechanical integrity, seal extrusion |

| Low-Temperature Flex (ASTM D1329) | -25°C (Brittle Point) | -55°C (Brittle Point) | Seal cracking during cold starts |

| Compression Force Deflection | Inconsistent (±25% variation) | Tight tolerance (±8% variation) | Uneven sealing pressure, assembly issues |

| Ozone Resistance (ASTM D1149) | Severe cracking @ 50pphm | No cracking @ 100pphm | Premature seal failure in outdoor use |

The data underscores a fundamental principle: the cost of field failure exponentially exceeds the modest premium for a correctly engineered material. Generic compounds fail because they optimize for broad market appeal, not your specific duty cycle. At Suzhou Baoshida Trading Co., Ltd., we reject the one-size-fits-all approach. Our engineering process begins with rigorous application analysis – mapping fluid types, temperature profiles, dynamic loads, and regulatory constraints. We then formulate proprietary compounds using advanced elastomers (HNBR, FKM, ACM) or engineered foams (EPDM, silicone, specialized PU), validated through accelerated aging and application-specific testing protocols.

Material selection is an engineering discipline, not a procurement exercise. Partnering with a specialist who understands the interplay between polymer chemistry and real-world physics transforms rubber and foam from a potential failure point into a reliable, long-life component. This precision engineering approach is the only viable path to eliminating preventable downtime and ensuring operational integrity in critical industrial systems.

Material Specifications

Suzhou Baoshida Trading Co., Ltd. provides high-performance industrial rubber solutions tailored for demanding manufacturing environments. Our expertise in elastomer materials ensures clients receive optimal sealing, durability, and chemical resistance across diverse applications. This section outlines the technical specifications of three core materials: Viton (FKM), Nitrile (NBR), and Silicone (VMQ), enabling informed selection based on operational requirements.

Viton, a fluorocarbon-based rubber, is engineered for extreme environments involving high temperatures and aggressive chemicals. It demonstrates exceptional resistance to oils, fuels, acids, and ozone, making it ideal for aerospace, automotive, and chemical processing industries. Operating effectively from -20°C to +230°C, Viton maintains integrity under prolonged thermal stress. Its low gas permeability and excellent aging characteristics further enhance reliability in critical sealing applications. However, Viton is less flexible at low temperatures and carries a higher material cost compared to alternatives.

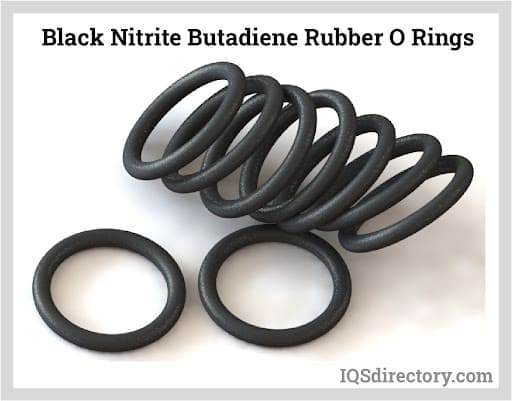

Nitrile rubber, also known as Buna-N or NBR, is a cost-effective solution widely used in hydraulic and fuel systems. It offers strong resistance to aliphatic hydrocarbons, mineral oils, and water, with good abrasion resistance and mechanical strength. Nitrile operates efficiently within a temperature range of -30°C to +100°C, extendable to +120°C for short durations. Its performance diminishes in the presence of aromatic hydrocarbons, chlorinated solvents, and ozone. Nitrile is commonly selected for O-rings, gaskets, and seals in industrial and automotive sectors due to its balance of performance and affordability.

Silicone rubber (VMQ) is distinguished by its outstanding thermal stability and biocompatibility. It functions reliably from -60°C to +200°C, with some formulations tolerating brief excursions up to +230°C. Silicone exhibits excellent resistance to UV radiation, ozone, and weathering, making it suitable for outdoor and medical applications. It is inherently low in toxicity and meets regulatory standards for food and pharmaceutical contact. While silicone performs well in extreme temperatures and maintains flexibility in cryogenic conditions, it has lower tensile strength and abrasion resistance compared to Viton and Nitrile. It is not recommended for dynamic sealing under high mechanical stress.

The following table summarizes key physical and chemical properties for comparative analysis.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +100 (+120 short) | -60 to +200 |

| Tensile Strength (MPa) | 15–25 | 10–30 | 5–10 |

| Elongation at Break (%) | 200–300 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set Resistance | Excellent | Good | Good to Excellent |

| Resistance to Oils/Fuels | Excellent | Good to Excellent | Poor |

| Resistance to Ozone | Excellent | Poor | Excellent |

| Resistance to Water | Good | Good | Excellent |

| Common Applications | Aerospace seals, chemical gaskets | Hydraulic seals, fuel systems | Medical devices, food-grade seals, outdoor insulation |

Selecting the appropriate elastomer requires a precise understanding of service conditions, including media exposure, thermal load, and mechanical stress. Suzhou Baoshida Trading Co., Ltd. supports OEMs and industrial partners with material data sheets, application engineering, and customized rubber formulations to ensure optimal performance and longevity.

Manufacturing Capabilities

Engineering Capabilities: Precision Rubber Solutions for Demanding Applications

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise to deliver engineered rubber and foam solutions that meet exacting industrial standards. Our core strength lies in the integration of advanced material science and precision manufacturing, driven by a dedicated team of seven specialized engineers: five mould engineers and two formula engineers. This structure ensures seamless collaboration from compound development through to final production, eliminating silos that compromise performance in complex applications.

Our formula engineering team applies rigorous polymer science to develop custom elastomer compounds addressing specific operational challenges. Through controlled manipulation of cross-link density, filler dispersion, and additive packages, we achieve targeted properties such as extreme temperature resilience, chemical resistance, or low compression set. Every formulation undergoes accelerated aging tests, dynamic mechanical analysis (DMA), and real-world simulation to validate performance under stress. This scientific approach prevents field failures caused by inadequate material selection, a common pain point for OEMs in automotive, aerospace, and industrial equipment sectors.

Complementing this, our mould engineering division excels in translating compound behavior into flawless part geometry. Utilizing 3D flow simulation and finite element analysis (FEA), we optimize tool design for consistent curing, minimal flash, and dimensional stability across high-volume production runs. Expertise spans intricate multi-cavity tools, insert moulding, and micro-moulding for components requiring tolerances down to ±0.05 mm. Proactive cavity pressure monitoring and thermal mapping ensure process robustness, directly reducing scrap rates and accelerating time-to-market for client programs.

Material performance is non-negotiable in critical sealing and damping applications. The table below illustrates how our engineered compounds outperform generic alternatives across key parameters:

| Material Type | Hardness Range (Shore A) | Temp Range (°C) | Tensile Strength (MPa) | Key Application Focus | Customizable |

|---|---|---|---|---|---|

| High-Purity EPDM | 40–90 | -55 to +150 | 12–22 | Automotive coolant systems, medical fluid handling | Chemical resistance profiles |

| Oil-Resistant NBR | 50–95 | -30 to +120 | 15–25 | Hydraulic seals, fuel system components | Swell control in aggressive media |

| High-Temp Silicone | 30–80 | -60 to +230 | 6–10 | Aerospace gaskets, semiconductor handling | Low outgassing, ultra-pure grades |

OEM partnership is central to our operational model. We provide full technical stewardship from prototype to量产, including IP-protected compound development, tooling validation, and production line integration support. Our closed-loop feedback system synchronizes factory data with engineering teams, enabling rapid iteration for continuous improvement. Clients benefit from reduced R&D burden, assured supply chain continuity, and solutions certified to ISO 9001 and IATF 16949 standards.

With Suzhou Baoshida, engineering capability translates directly into product reliability. We transform material constraints into competitive advantages through disciplined science and manufacturing excellence, ensuring your rubber components perform flawlessly in the most demanding environments. Partner with us for precision-engineered solutions where failure is not an option.

Customization Process

Drawing Analysis: Precision as the Foundation

The customization process for industrial rubber and foam components begins with rigorous drawing analysis. At Suzhou Baoshida Trading Co., Ltd., we treat technical drawings as the blueprint for performance, durability, and compatibility. Each submitted design undergoes dimensional verification, tolerance assessment, and material suitability evaluation. Our engineering team cross-references ISO, ASTM, and customer-specific standards to ensure compliance. Critical parameters such as wall thickness, sealing surfaces, and mating interfaces are scrutinized to identify potential manufacturing challenges early. This phase also includes a Design for Manufacturability (DFM) review, where we propose geometric optimizations to enhance mold flow, reduce flash, and improve demolding efficiency—without compromising functional integrity.

Formulation: Tailoring Material Chemistry to Application Demands

Once the drawing is validated, we transition to rubber and foam formulation—a phase where material science defines performance. Our in-house laboratory leverages a comprehensive database of elastomers and polymer foams, including NBR, EPDM, silicone, neoprene, and polyurethane. The selection is driven by application conditions such as temperature range, chemical exposure, compression set resistance, and mechanical stress. For instance, a gasket exposed to automotive engine oils will require a nitrile-based compound with high oil resistance, while a weather seal demands EPDM for superior UV and ozone stability. Custom additives—reinforcing fillers, plasticizers, antioxidants, and flame retardants—are precisely compounded to meet target hardness (Shore A), tensile strength, elongation, and aging characteristics. Every formulation is documented and archived for full traceability.

Prototyping: Bridging Design and Production

Prototyping transforms chemistry and geometry into physical samples for validation. We employ precision compression, transfer, or injection molding techniques based on part complexity and volume projections. Rapid tooling using aluminum or prototype steel enables delivery of functional samples within 7–14 days. Each prototype is subjected to dimensional inspection via CMM (Coordinate Measuring Machine) and performance testing, including compression deflection, sealing efficacy, and environmental exposure. Feedback from customer trials is integrated into iterative refinements, ensuring the final design meets all operational requirements. This phase mitigates risk and accelerates time-to-market by uncovering functional gaps before tooling finalization.

Mass Production: Scalable Quality with Consistent Control

Upon prototype approval, we initiate mass production using hardened steel molds built for longevity and repeatability. Our production lines operate under strict ISO 9001 protocols, with real-time process monitoring for temperature, cure time, and pressure. Each batch undergoes incoming and outgoing quality checks, including hardness testing, visual inspection, and batch-to-batch consistency validation. We support production runs from 1,000 to over 1 million units annually, with JIT delivery options for OEM supply chains.

Typical Material Properties Achieved in Custom Compounds

| Property | Test Method | Typical Range |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 40–90 |

| Tensile Strength | ASTM D412 | 8–20 MPa |

| Elongation at Break | ASTM D412 | 200–600% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% |

| Temperature Range | — | -40°C to +150°C (up to +300°C for silicone) |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Industrial Rubber Solutions

As the OEM Manager and Lead Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd., I emphasize that material selection and supply chain reliability directly impact your production efficiency and product longevity. Industrial rubber and foam components must withstand extreme variables—thermal cycling, chemical exposure, compression set, and dynamic stress—without compromise. Generic suppliers often lack the formulation expertise to address these challenges, leading to premature part failure, costly downtime, or non-compliance with sector-specific standards. At Suzhou Baoshida, we bridge this gap through scientifically validated compound development and rigorous quality control, ensuring every seal, gasket, or damping component performs to exacting OEM specifications.

Our technical team specializes in tailoring solutions for automotive, aerospace, energy, and medical device manufacturing. We do not merely supply materials; we engineer them. Utilizing advanced polymer science and accelerated aging protocols, we optimize compounds for critical parameters such as tensile strength retention after fluid immersion, low-temperature flexibility, and compression force deflection consistency. This precision minimizes scrap rates and extends service life in demanding operational environments. Below is a representative snapshot of our core material capabilities, validated per ASTM D2000 and ISO 37 standards:

| Material Type | Tensile Strength (MPa) | Temperature Range (°C) | Durometer Range (Shore A) | Key Applications |

|---|---|---|---|---|

| Hydrogenated Nitrile (HNBR) | 25–32 | -40 to +150 | 50–90 | Fuel systems, oil seals |

| Perfluoroelastomer (FFKM) | 10–18 | -20 to +327 | 60–90 | Semiconductor, chemical pumps |

| Silicone (VMQ) | 6–12 | -60 to +230 | 30–80 | Medical tubing, LED lighting |

| Ethylene Acrylic (AEM) | 15–22 | -40 to +175 | 55–85 | Turbocharger hoses, coolant seals |

All formulations undergo batch-specific certification, including FTIR spectroscopy for polymer identification and MDR rheometry for cure kinetics validation. Our ISO 9001:2015-certified supply chain guarantees traceability from raw material sourcing to final shipment, with durometer tolerances held to ±0.5 Shore A and dimensional accuracy within ±0.1 mm for critical features.

For immediate technical collaboration, contact Mr. Boyce, our Senior Technical Account Manager, who holds 15 years of experience in rubber compounding for Tier-1 automotive and industrial OEMs. Mr. Boyce will coordinate material failure analysis, prototype validation, and rapid-response supply chain solutions tailored to your production schedule. Provide your compound specifications, performance requirements, or failure mode data, and our engineering team will deliver a customized formulation proposal within 72 hours. Do not settle for off-the-shelf materials that risk system integrity. Email Mr. Boyce directly at [email protected] with subject line “Technical Inquiry: [Your Project Code]” to initiate a precision-engineered supply partnership. Include your ASTM/SAE grade requirements, annual volume, and critical performance thresholds for expedited review. Suzhou Baoshida operates under strict confidentiality agreements—your intellectual property and supply chain security are non-negotiable priorities. Let us transform your material challenges into engineered reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).