Technical Contents

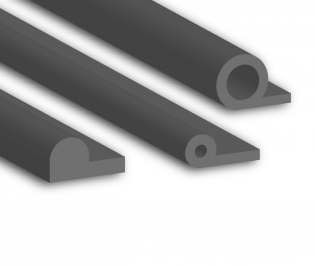

Engineering Guide: Rubber Beading

Engineering Insight: Material Selection in Rubber Beading – Why Off-the-Shelf Solutions Fail

In industrial sealing and edge protection applications, rubber beading performs a critical function in ensuring durability, environmental resistance, and long-term performance. While off-the-shelf rubber beading may appear to offer a cost-effective and readily available solution, its frequent failure in demanding environments underscores a fundamental oversight: improper material selection. At Suzhou Baoshida Trading Co., Ltd., we emphasize that successful rubber beading design begins not with shape or size, but with a precise understanding of operational conditions and material compatibility.

Rubber is not a monolithic material. Its performance is dictated by polymer chemistry, compounding additives, and curing processes. Standard rubber profiles are typically formulated for general-purpose use, often based on natural rubber (NR) or styrene-butadiene rubber (SBR), which lack resistance to ozone, UV exposure, oils, and extreme temperatures. When deployed in industrial environments—such as automotive assembly lines, marine enclosures, or chemical processing units—these generic materials degrade rapidly, leading to cracking, hardening, compression set, and ultimately seal failure.

The consequences of such failure extend beyond replacement costs. Downtime, safety risks, and compromised product integrity are common outcomes when non-optimized rubber beading is used. For example, a beading installed in an outdoor enclosure exposed to sunlight and rain may appear functional initially but will degrade within months if made from non-ozone-resistant SBR. Similarly, rubber exposed to hydraulic fluids or solvents without proper chemical resistance will swell, lose elasticity, and fail to maintain a seal.

Custom-engineered rubber beading, in contrast, begins with a detailed analysis of service conditions. Key parameters include temperature range, fluid exposure, mechanical stress, compression requirements, and regulatory compliance (e.g., FDA, RoHS). Based on this data, appropriate elastomers such as EPDM, silicone (VMQ), nitrile (NBR), or fluorocarbon (FKM) are selected. Each offers distinct advantages tailored to specific environments.

Below is a comparative overview of common elastomers used in industrial rubber beading applications:

| Elastomer | Temperature Range (°C) | Key Strengths | Common Applications |

|---|---|---|---|

| EPDM | -50 to +150 | Excellent ozone and UV resistance, good weatherability | Outdoor enclosures, automotive weatherstripping |

| NBR | -30 to +100 | High resistance to oils, fuels, and aliphatic hydrocarbons | Machinery seals, hydraulic systems |

| Silicone (VMQ) | -60 to +200 | Exceptional thermal stability, FDA-compliant grades available | Food processing, high-temperature enclosures |

| FKM | -20 to +250 | Superior chemical and heat resistance | Aerospace, chemical processing |

| SBR | -40 to +100 | Low cost, good abrasion resistance | General-purpose, indoor applications |

Material selection is not a one-size-fits-all proposition. At Suzhou Baoshida, we work closely with OEMs and industrial clients to develop application-specific rubber beading solutions that ensure reliability, longevity, and cost efficiency over the product lifecycle. Relying on off-the-shelf profiles may reduce initial procurement costs, but it invariably increases total cost of ownership through premature failure and maintenance. Precision engineering begins with the right compound—every time.

Material Specifications

Material Specifications for Industrial Rubber Beading

Selecting the optimal elastomer for rubber beading applications requires rigorous evaluation of chemical exposure, thermal demands, and mechanical stress. At Suzhou Baoshida Trading Co., Ltd., we prioritize material science precision to ensure sealing integrity and longevity in demanding industrial environments. Our engineered solutions for Viton, Nitrile, and Silicone beading undergo stringent ASTM D2000 and ISO 37 testing protocols to validate performance under real-world conditions. Material choice directly impacts compression set resistance, fluid compatibility, and operational lifespan, necessitating data-driven selection aligned with OEM specifications.

Viton fluoroelastomer beading excels in extreme chemical and thermal scenarios. It maintains structural integrity from -20°C to 230°C continuous service, with brief excursions to 300°C. Its exceptional resistance to aggressive media—including jet fuels, aromatic hydrocarbons, and concentrated acids—makes it indispensable for aerospace and chemical processing seals. Viton’s tensile strength typically ranges 12–18 MPa (ASTM D412), with hardness options between 60–90 Shore A. Critical for high-value OEM assemblies, its low gas permeability prevents leakage in vacuum systems, though higher material costs necessitate justified application requirements.

Nitrile butadiene rubber (NBR) beading delivers cost-effective performance for petroleum-based fluid exposure. Operating effectively between -40°C and 120°C (short-term to 140°C), it demonstrates superior resistance to mineral oils, greases, and aliphatic hydrocarbons. With tensile strength of 10–20 MPa and hardness spanning 50–90 Shore A, NBR balances flexibility and durability for automotive fuel systems and hydraulic seals. However, its vulnerability to ozone, ketones, and phosphate esters requires careful environmental assessment. NBR remains the industry standard for cost-sensitive applications where chemical exposure is non-aggressive.

Silicone rubber beading provides unmatched thermal stability across -60°C to 200°C ranges, with specialty grades enduring 230°C. Its inert composition ensures biocompatibility and resistance to water, steam, and oxygenated solvents, making it ideal for medical device seals and food processing gaskets. Silicone exhibits moderate tensile strength (5–10 MPa) but exceptional elongation (>400%), though lower abrasion resistance necessitates protective housing in high-friction zones. Hardness customization from 30–80 Shore A allows tailored resilience for delicate sealing interfaces.

The comparative analysis below details critical parameters for informed material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range | -20°C to 230°C | -40°C to 120°C | -60°C to 200°C |

| Key Chemical Resistance | Fuels, acids, oils | Mineral oils, fuels | Water, steam, ozone |

| Tensile Strength (MPa) | 12–18 | 10–20 | 5–10 |

| Hardness Range (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set (%) | 10–25 (24h @ 200°C) | 15–35 (24h @ 100°C) | 20–35 (24h @ 200°C) |

| OEM Recommendation | Critical chemical/thermal exposure | Cost-sensitive oil/hydraulic systems | High/low temp biocompatible applications |

Suzhou Baoshida Trading Co., Ltd. validates all material batches against these benchmarks through in-house tensile, durometer, and fluid immersion testing. Partner with our engineering team to specify beading compounds meeting ISO 9001-certified production standards, ensuring zero-defect performance in your final assembly. Material selection is not merely a cost exercise—it is a strategic investment in system reliability.

Manufacturing Capabilities

Engineering Excellence in Rubber Beading Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the precision manufacturing of rubber beading. Our team comprises five dedicated mould engineers and two specialized rubber formula engineers, enabling us to deliver technically robust, application-specific products tailored to diverse OEM requirements. This integrated engineering approach ensures seamless development from concept to final production, with rigorous control over material behavior, dimensional accuracy, and performance under real-world conditions.

Our mould engineers specialize in the design and optimization of high-precision tooling for rubber beading profiles used in automotive sealing, construction glazing, and industrial equipment. Utilizing advanced CAD/CAM software and finite element analysis (FEA), they ensure optimal flow dynamics during vulcanization, minimizing flash and dimensional variance. Each mould is engineered for durability, cycle efficiency, and repeatability, supporting both low-volume prototyping and high-volume continuous production. With in-house CNC machining and EDM capabilities, we maintain tight tolerances down to ±0.1 mm, critical for applications requiring consistent sealing performance.

Complementing our tooling expertise, our two rubber formula engineers bring deep knowledge of polymer chemistry and compounding. They formulate custom elastomer compounds tailored to specific environmental and mechanical demands—such as UV resistance, ozone stability, low-temperature flexibility, and compression set performance. Whether the application requires NR, SBR, EPDM, NBR, or specialty silicones and FKM, our formulations are developed and validated through accelerated aging tests, hardness profiling, and dynamic mechanical analysis (DMA). This ensures that every rubber beading product not only fits perfectly but also performs reliably over its intended service life.

Our OEM capabilities are built on a foundation of collaborative engineering. We work directly with clients to interpret technical drawings, reverse-engineer legacy components, and co-develop new profiles optimized for manufacturability and cost-efficiency. From initial concept sketches to production-ready tooling and compound selection, we manage the entire development cycle in-house, reducing lead times and ensuring intellectual property protection.

The following table outlines key engineering specifications and capabilities relevant to our rubber beading production:

| Parameter | Capability |

|---|---|

| Mould Tolerance | ±0.1 mm |

| Compound Hardness Range (Shore A) | 40–90 |

| Standard Materials | EPDM, NBR, NR, SBR, Silicone, FKM |

| Temperature Resistance Range | -60°C to +250°C (material-dependent) |

| Lead Time (Mould + Sample) | 15–25 days |

| Custom Compound Development | Full in-house R&D with testing validation |

| OEM Design Support | CAD modeling, FEA, GD&T, prototyping |

| Production Scale | 1,000 to 1,000,000+ units per order |

This technical depth, combined with vertical integration and strict quality control, positions Suzhou Baoshida as a trusted engineering partner for industrial rubber beading solutions worldwide.

Customization Process

Rubber Beading Customization Process: Precision Engineering from Concept to Volume Production

At Suzhou Baoshida Trading Co., Ltd., our rubber beading customization process integrates rigorous material science with industrial manufacturing discipline. This structured workflow ensures optimal performance, cost efficiency, and seamless OEM integration. The sequence begins with comprehensive drawing analysis, where our engineering team deconstructs client-provided technical schematics to verify geometric feasibility, tolerance alignment with ISO 3302-1 standards, and material compatibility with operational stressors such as dynamic compression, chemical exposure, or thermal cycling. Critical dimensions, surface finish requirements, and assembly interfaces are cross-referenced against polymer behavior models to preempt molding defects like flash or shrinkage.

Subsequent formulation development leverages our proprietary compound database and accelerated aging protocols. Material scientists select base polymers—EPDM for ozone resistance, NBR for fuel compatibility, or silicone for extreme temperatures—then calibrate filler ratios, vulcanizing agents, and additive packages to meet exact Shore A hardness, tensile strength, and elongation targets. Each formulation undergoes predictive simulation for compression set per ASTM D395 and fluid resistance per ASTM D471, ensuring the compound will sustain performance over 10,000+ cycles in the client’s specific environment.

Prototyping employs CNC-machined aluminum molds for rapid iteration, producing functional samples within 15 business days. These prototypes undergo dimensional validation via CMM inspection against GD&T callouts and application-specific functional testing, including pressure decay checks for sealing integrity and adhesion trials for bonded assemblies. Client feedback is systematically incorporated, with reformulation cycles limited to ≤2 iterations through our DOE-optimized adjustment protocol.

Mass production transitions occur only after formal OEM sign-off on First Article Inspection reports. We implement statistical process control (SPC) with real-time monitoring of cure time, temperature profiles, and weight consistency. Every production lot includes traceable material certificates and undergoes 100% visual inspection plus batch-level physical testing per the agreed AQL 1.0 standard. This closed-loop system reduces scrap rates to <0.5% while maintaining ±0.10 mm dimensional repeatability.

Key technical parameters for standard rubber beading are summarized below:

| Parameter | Standard Range | Tolerance Class | Material Options |

|---|---|---|---|

| Shore A Hardness | 30–90 | ±5 | EPDM, NBR, VMQ, CR, FKM |

| Cross-Section | 1.5–15.0 mm | ±0.10 mm | Solid, Hollow, Multi-rib |

| Linear Tolerance | Up to 3000 mm length | ±0.15 mm | Custom profiles per drawing |

| Temp. Resistance | -50°C to +250°C | Class-specific | Material-dependent validation |

This end-to-end methodology minimizes time-to-market while guaranteeing that every beading component meets the uncompromising functional demands of automotive, aerospace, and industrial sealing applications. Suzhou Baoshida’s engineering oversight ensures zero compromise between design intent and manufactured reality.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Beading Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance industrial rubber solutions, with a focused expertise in rubber beading for sealing, insulation, and protective applications across automotive, construction, electronics, and manufacturing sectors. Our engineered rubber profiles are designed to meet exacting OEM specifications, ensuring durability, compression resistance, and environmental resilience. Whether you require custom cross-sectional profiles, specific durometer ratings, or specialized elastomer compounds such as EPDM, silicone, nitrile, or neoprene, our team delivers precision-engineered beading that performs under real-world operational demands.

We understand that reliability in sealing and edge protection begins with material integrity and dimensional accuracy. That’s why our rubber beading is manufactured under strict quality controls, utilizing advanced extrusion, splicing, and curing techniques to ensure consistent performance. Our in-house R&D capabilities allow us to develop tailored solutions for complex sealing challenges, including UV resistance, ozone stability, flame retardancy, and low-temperature flexibility.

To support global OEMs and Tier suppliers, we offer scalable production with rapid prototyping, comprehensive testing, and full documentation including material certifications and dimensional reports. Our logistics network ensures timely delivery to North America, Europe, and Asia, backed by responsive technical support throughout the product lifecycle.

Below are key technical specifications commonly associated with our standard and custom rubber beading offerings:

| Property | Typical Range | Test Method |

|---|---|---|

| Hardness (Shore A) | 40–90 | ASTM D2240 |

| Tensile Strength | 8–18 MPa | ASTM D412 |

| Elongation at Break | 200–600% | ASTM D412 |

| Operating Temperature | -40°C to +150°C (varies by compound) | — |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395 |

| Splice Type | V-notch, butt, or molded | — |

| Standard Lengths | 1m, 2m, 5m, or continuous rolls | — |

| Customization | Cross-section, color, hardness, packaging | — |

All formulations and dimensions are adjustable based on client requirements. We work closely with engineering teams to reverse-engineer legacy parts, validate material compatibility, and optimize cost-performance ratios without compromising quality.

For technical inquiries, sample requests, or project collaboration, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. Direct your specifications, drawings, or application details to [email protected]. Our team responds within 24 business hours to provide material recommendations, quotations, and development timelines. Partner with us to ensure your rubber beading components meet the highest standards in performance, consistency, and industrial reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).