Technical Contents

Engineering Guide: Rubber Decking For Boats

Engineering Insight: Material Selection in Rubber Decking for Boats

The marine environment presents one of the most aggressive service conditions for any deck surfacing material. Constant exposure to saltwater, ultraviolet radiation, thermal cycling, mechanical abrasion, and chemical contaminants demands a highly engineered solution. Off-the-shelf rubber decking products, often designed for recreational or light-duty applications, frequently fail in marine environments due to inadequate material formulation and insufficient performance testing under real-world conditions. This underscores the critical importance of precision material selection in the design of rubber decking systems for boats.

At Suzhou Baoshida Trading Co., Ltd., our approach to rubber decking is rooted in industrial polymer science. We prioritize compound formulations that balance elasticity, tensile strength, and environmental resistance. Standard rubber mats, typically composed of reclaimed rubber or low-grade SBR (styrene-butadiene rubber), lack the molecular stability required for prolonged maritime use. These materials degrade rapidly when exposed to ozone and UV radiation, leading to surface cracking, delamination, and loss of traction—posing serious safety and maintenance risks.

In contrast, our engineered solutions utilize high-purity EPDM (ethylene propylene diene monomer) and specialized nitrile blends. EPDM offers superior resistance to weathering, ozone, and temperature extremes, maintaining integrity from -40°C to +135°C. Nitrile components enhance oil and fuel resistance—critical for engine room decks and areas exposed to hydraulic fluids. The cross-linking density and curing protocols are optimized to ensure long-term resilience against flex fatigue, a common failure mode in deck mats subjected to repeated foot traffic and vessel motion.

Another key differentiator is the reinforcement architecture. Many commercial products rely on textile backings that absorb moisture and promote microbial growth. Our industrial-grade composites integrate closed-cell foam or scrim-reinforced substrates that resist water ingress, reduce weight, and improve acoustic damping. This structural design minimizes deck corrosion underneath the matting—a hidden but costly consequence of poor material choice.

The following table outlines the comparative performance characteristics of standard versus engineered rubber decking materials:

| Property | Standard SBR-Based Mat | Engineered EPDM/Nitrile Composite |

|---|---|---|

| Tensile Strength | 7–10 MPa | 15–18 MPa |

| Elongation at Break | 250–300% | 400–500% |

| Shore A Hardness | 60–70 | 65–75 |

| UV Resistance | Poor (cracking in 6–12 months) | Excellent (10,000+ hrs QUV testing) |

| Ozone Resistance | Low | High (no cracking at 50 pphm, 40°C) |

| Water Absorption (24 hrs) | 3–5% | <0.5% |

| Service Temperature Range | -20°C to +80°C | -40°C to +135°C |

| Slip Resistance (wet) | Moderate (COF ~0.5) | High (COF >0.8) |

Ultimately, the failure of generic rubber decking stems from a fundamental mismatch between material capability and operational demand. True performance is not measured in initial cost, but in lifecycle durability, safety, and total cost of ownership. By applying industrial rubber engineering principles, Suzhou Baoshida delivers solutions that meet the rigorous demands of marine applications—where reliability is non-negotiable.

Material Specifications

Material Specifications for Marine Rubber Decking Solutions

Selecting the optimal elastomer for boat decking requires rigorous evaluation of environmental stressors including UV exposure, hydrocarbon contact, saltwater immersion, and thermal cycling. Suzhou Baoshida Trading Co., Ltd. specializes in engineered rubber compounds that maintain structural integrity and slip resistance under extreme marine conditions. Our formulations prioritize long-term durability while meeting stringent OEM safety standards for commercial and recreational vessels. Three primary elastomer systems dominate this application space, each offering distinct performance profiles tailored to specific operational demands.

Viton fluorocarbon rubber excels in high-exposure zones such as engine compartments or fuel dock areas due to its unparalleled resistance to marine fuels, hydraulic fluids, and ozone degradation. Its thermal stability spans from -20°C to 230°C, making it ideal for vessels operating in tropical or arctic climates. Nitrile butadiene rubber (NBR) provides cost-effective performance for general deck surfaces, with robust resistance to aliphatic hydrocarbons and moderate oil exposure. However, NBR exhibits limited UV stability without supplemental stabilizers, necessitating Suzhou Baoshida’s proprietary antioxidant package for extended marine service life. Silicone rubber delivers exceptional flexibility at cryogenic temperatures down to -60°C and maintains non-slip properties across 200°C ranges, though its susceptibility to hydrocarbon swelling restricts use to non-fuel-contact zones like cabinetry or passenger walkways.

Critical performance metrics must be validated against ISO 188, ASTM D2000, and ISO 1817 standards to ensure compliance with maritime safety regulations. All Suzhou Baoshida compounds undergo accelerated salt-fog testing per ASTM B117 and UV exposure per ISO 4892-3 to quantify degradation rates. Shore A hardness is precision-engineered between 60–75 to balance deck comfort with abrasion resistance, while DIN 51130 ramp testing certifies R10–R13 slip ratings for wet surfaces.

The following comparative analysis details core specifications for marine decking applications

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -40 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–18 | 6–10 |

| Shore A Hardness | 65–75 | 60–70 | 55–70 |

| Fuel Resistance | Excellent | Good | Poor |

| Saltwater Resistance | Excellent | Excellent | Excellent |

| UV/Ozone Resistance | Excellent | Fair* | Good |

| Slip Resistance (Wet) | R12–R13 | R10–R12 | R11–R13 |

*Requires Suzhou Baoshida’s marine-grade antioxidant package for >5-year service life

Suzhou Baoshida’s OEM engineering team customizes polymer blends to address client-specific challenges, such as enhancing NBR’s ozone resistance through saturated backbone modification or incorporating ceramic microspheres into silicone for abrasion resistance. All compounds are manufactured under ISO 9001-certified processes with traceable lot numbering for full regulatory compliance. Material selection must align with vessel operational profiles—Viton for offshore workboats, NBR for coastal cruisers, and silicone for luxury yachts requiring premium aesthetics. Partner with our technical team to validate material suitability through application-specific accelerated aging protocols prior to full-scale production.

Manufacturing Capabilities

Engineering Excellence in Marine Rubber Decking Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the specialized domain of rubber decking for boats. With a dedicated team of five certified mould engineers and two advanced formula engineers, we maintain full in-house control over the design, development, and production of high-performance marine-grade rubber decking. This integrated technical team enables us to deliver precision-engineered products tailored to the demanding environmental and mechanical conditions encountered in marine applications.

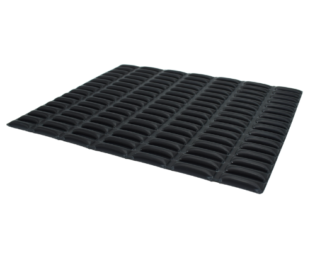

Our mould engineers specialize in the creation of complex compression and transfer moulds used in the fabrication of non-slip, impact-resistant rubber deck surfaces. Utilizing 3D CAD/CAM software and CNC machining, they ensure tight tolerances, consistent texture replication, and seamless integration with marine deck contours. Each mould is designed for durability, ease of maintenance, and optimal material flow, minimizing flash and ensuring uniform curing during vulcanization.

Complementing this expertise, our two formula engineers focus on compound development, formulating rubber blends that meet rigorous marine standards. Using EPDM, SBR, and specialized nitrile-based polymers, they engineer compounds resistant to UV degradation, saltwater corrosion, oil exposure, and extreme temperature fluctuations. Custom additives are incorporated to enhance anti-slip properties, abrasion resistance, and color stability, ensuring long-term performance and aesthetic consistency across diverse maritime environments.

This synergy between mould design and material science empowers our OEM capabilities, allowing us to develop fully customized rubber decking solutions from concept to mass production. We support clients through every phase—prototyping, material testing, tooling validation, and batch production—ensuring compliance with international marine safety and durability standards such as ISO 22094 and IMO FTP Code.

Our OEM service model is built on flexibility and technical transparency. Whether adapting existing patterns or engineering new textures and profiles, we provide full documentation, material certifications, and performance data to support client approvals and classification society submissions.

Below is a summary of key technical specifications for our standard marine rubber decking formulation:

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Tear Resistance | ASTM D624 | ≥40 kN/m |

| Specific Gravity | ASTM D297 | 1.35–1.45 |

| Heat Aging (70°C × 72h) | ASTM D573 | Max 15% change in properties |

| Oil Resistance (IRM 903) | ASTM D471 | Max 20% volume swell |

| Water Absorption (24h) | ASTM D570 | <1.0% |

| Slip Resistance (R10–R13) | DIN 51130 | Confirmed |

This rigorous engineering framework ensures that every rubber deck panel we produce delivers optimal safety, longevity, and performance under real-world marine conditions.

Customization Process

Rubber Decking Customization Process for Marine Applications

Suzhou Baoshida Trading Co., Ltd. executes a rigorous, science-driven customization protocol for rubber decking solutions tailored to demanding marine environments. Our process ensures optimal performance, safety, and longevity while aligning with client-specific vessel design and operational requirements. The methodology progresses through four critical phases, each governed by stringent industrial standards and material science principles.

Initial engagement commences with Drawing Analysis, where our engineering team dissects client-provided naval architectural schematics and performance specifications. We evaluate load distribution patterns, curvature tolerances, non-slip zone requirements, and integration points with underlying deck structures. Critical parameters such as coefficient of friction under wet conditions, thermal expansion coefficients relative to substrate materials, and resistance to marine growth adhesion are quantified. This phase identifies potential stress concentrations and environmental exposure variables, forming the technical foundation for subsequent material development.

The Formulation stage leverages Suzhou Baoshida’s proprietary polymer science expertise. Based on the drawing analysis, our rubber chemists select base polymers—typically EPDM or specialized nitrile blends—for optimal UV resistance, saltwater stability, and ozone durability. Reinforcing agents, plasticizers, and vulcanizing systems are precisely dosed to achieve target Shore A hardness (typically 60–85), tensile strength, and elongation at break. Additives for flame retardancy (IMO FTP Code compliant), anti-microbial protection, and enhanced traction are incorporated as required. Every compound undergoes computational modeling to predict aging behavior under accelerated weathering protocols before physical prototyping.

Prototyping validates theoretical formulations against real-world marine conditions. Small-batch samples are molded using production-intent tooling to assess dimensional accuracy, surface texture consistency, and adhesion to common marine substrates (e.g., aluminum, fiberglass). Prototypes undergo exhaustive testing: ISO 10545-17 slip resistance evaluation on wet/oily surfaces, ASTM D2240 hardness profiling, and ISO 188 accelerated aging cycles simulating 5+ years of tropical marine exposure. Client feedback on ergonomics and aesthetic integration is incorporated iteratively until all performance KPIs are met.

Upon prototype approval, Mass Production initiates under Suzhou Baoshida’s ISO 9001-certified manufacturing system. Continuous inline monitoring tracks cure state via dielectric analysis, Shore hardness uniformity, and thickness tolerances (±0.3mm). Statistical process control (SPC) charts ensure batch-to-batch consistency, while every roll undergoes 100% visual inspection for surface defects. Final products are packaged with moisture-barrier wrapping and traceability codes linking to raw material lot numbers and test certificates, enabling full supply chain accountability for OEM integration.

Critical Rubber Decking Material Specifications

| Property | Standard Marine Grade | Custom Formulation Range | Test Standard |

|---|---|---|---|

| Shore A Hardness | 70 ± 5 | 60–85 | ASTM D2240 |

| Tensile Strength (MPa) | ≥12.0 | 10.0–18.0 | ASTM D412 |

| Elongation at Break (%) | ≥300 | 250–450 | ASTM D412 |

| Tear Resistance (kN/m) | ≥30 | 25–45 | ASTM D624 |

| Wet Slip Resistance (DCOF) | ≥0.42 | 0.40–0.65 | ANSI A326.3 |

| Accelerated Weathering (h) | 1000 | 500–2000 | ISO 188 (150°C) |

This systematic approach guarantees that Suzhou Baoshida’s rubber decking solutions exceed maritime safety regulations while delivering seamless integration into diverse vessel manufacturing workflows. Our commitment to material science precision ensures decks maintain structural integrity and safety performance throughout their operational lifecycle.

Contact Engineering Team

For marine-grade rubber decking solutions engineered to meet the rigorous demands of commercial and recreational vessels, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber innovation. As a trusted OEM manager and rubber formula engineer, we specialize in custom-formulated rubber decking materials that deliver superior traction, UV resistance, abrasion performance, and long-term durability in harsh marine environments. Our products are designed for seamless integration across boat decks, swim platforms, gangways, and high-traffic marine zones where safety, longevity, and aesthetic consistency are non-negotiable.

At Suzhou Baoshida, we understand that no two marine applications are identical. That is why our engineering team develops proprietary rubber compounds tailored to specific OEM requirements, including Shore hardness calibration, color stability, mold resistance, and compliance with international marine safety standards. Whether you require non-skid textured surfaces, custom thickness profiles, or integration with existing deck hardware, our manufacturing capabilities support full customization—from prototype to mass production.

Our rubber decking materials are manufactured using advanced vulcanization techniques and high-purity synthetic and natural rubber blends, ensuring dimensional stability and resistance to saltwater, oils, and prolonged sun exposure. Every batch undergoes rigorous quality control, including tensile strength testing, elongation verification, and adhesion performance checks, to guarantee consistent performance across production runs.

To support global partners, we offer comprehensive technical documentation, material test reports, and sample provisioning to facilitate integration into your design and manufacturing workflows. Our team collaborates directly with naval architects, marine fabricators, and OEM procurement departments to ensure alignment with project timelines and performance benchmarks.

Below are representative specifications for our standard marine rubber decking product line. Custom formulations can exceed these parameters based on application needs.

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60–75 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Tear Resistance | ASTM D624 | ≥45 kN/m |

| Specific Gravity | ASTM D297 | 1.25–1.35 |

| Operating Temperature Range | — | -40°C to +80°C |

| Water Absorption (7 days) | ASTM D570 | <1.5% |

| UV Resistance | ASTM G154 | Pass (2000 hrs) |

| Slip Resistance (dry/wet) | ASTM F2913 | >0.70 COF |

Partnering with Suzhou Baoshida means gaining access to precision-engineered rubber solutions backed by deep material science expertise and responsive OEM support. For technical inquiries, sample requests, or project consultations, contact Mr. Boyce, Rubber Formula Engineer and OEM Manager, directly at [email protected]. We respond to all inquiries within 12 business hours and offer virtual technical meetings to review material specifications, compliance requirements, and production timelines. Let us help you elevate your marine deck performance with rubber solutions built for endurance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).