Technical Contents

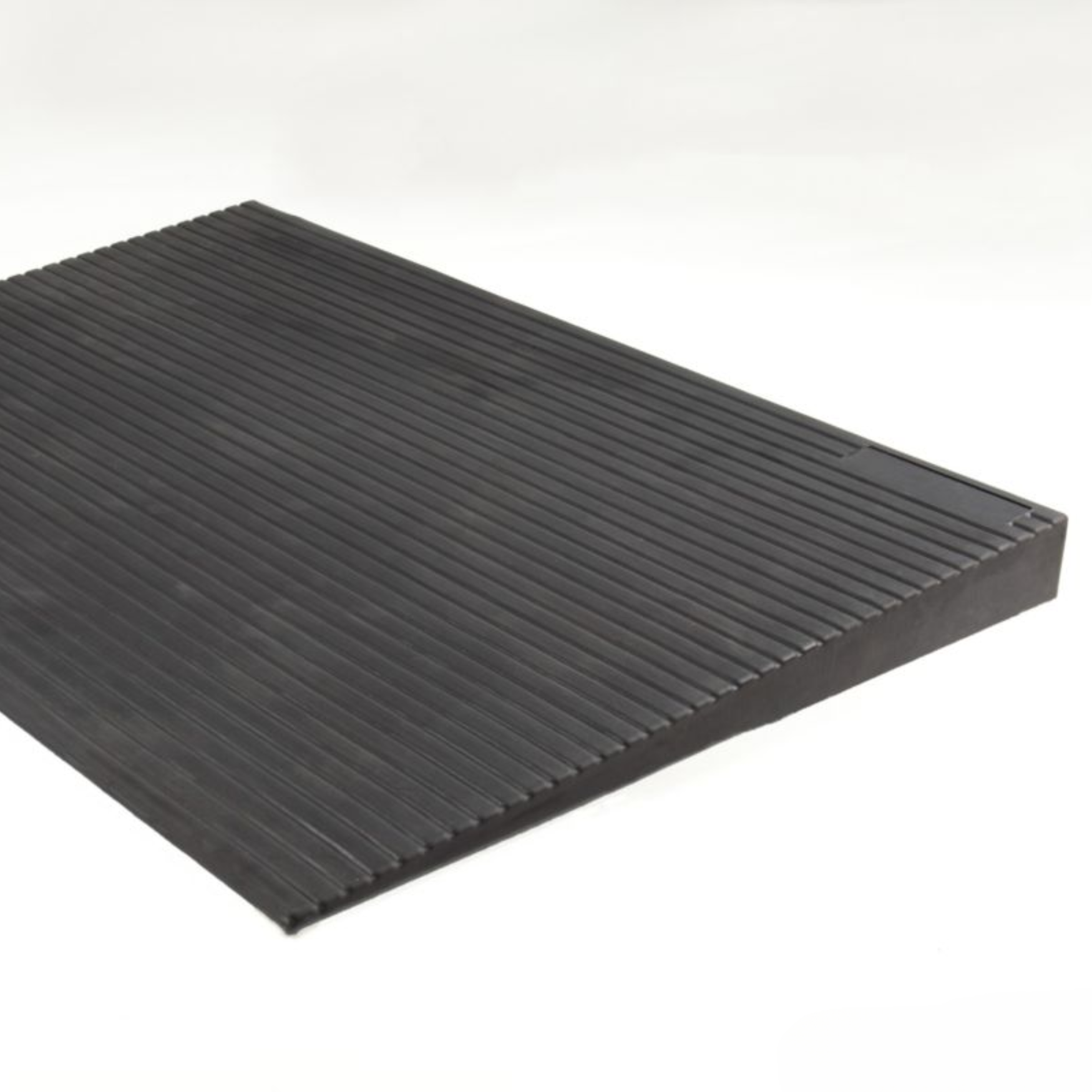

Engineering Guide: Rubber Doorway Ramp

Engineering Insight: The Critical Role of Material Selection in Rubber Doorway Ramps

In industrial and commercial environments, doorway ramps serve a critical functional role—bridging transitions between flooring surfaces while maintaining accessibility, safety, and durability. Despite their seemingly simple design, rubber doorway ramps are subject to complex mechanical and environmental stresses. A common misconception is that any rubber ramp will suffice for entryway applications. However, off-the-shelf solutions frequently fail due to inappropriate material selection, leading to premature degradation, safety hazards, and increased lifecycle costs.

The foundational performance of a rubber doorway ramp is dictated by the elastomer compound used in its construction. Generic or recycled rubber blends, often found in mass-market ramps, lack the tensile strength, abrasion resistance, and UV stability required for sustained performance. These materials tend to crack under thermal cycling, degrade when exposed to oils or cleaning agents, and deform under repeated load impacts—particularly in high-traffic zones such as warehouses, loading docks, and manufacturing facilities.

At Suzhou Baoshida Trading Co., Ltd., we prioritize engineered rubber formulations tailored to operational demands. For instance, EPDM (ethylene propylene diene monomer) is selected for outdoor installations due to its superior resistance to ozone, UV radiation, and extreme temperatures ranging from -40°C to +130°C. In contrast, nitrile rubber (NBR) is preferred in environments exposed to hydraulic fluids, greases, or solvents, offering exceptional oil resistance without compromising structural integrity. For high-impact zones, a hybrid SBR (styrene-butadiene rubber) compound provides optimal rebound resilience and wear resistance, extending service life significantly compared to standard recycled rubber alternatives.

Another critical factor is durometer hardness. A ramp that is too soft will deform under forklift or pallet jack wheels, creating tripping hazards and alignment issues. Conversely, excessive hardness reduces grip and increases vibration transmission. Our engineered solutions maintain a balanced Shore A hardness of 65–75, ensuring both load-bearing stability and slip resistance under dynamic conditions.

Below is a comparison of common rubber materials used in doorway ramp manufacturing, highlighting key performance characteristics.

| Material | Temperature Range (°C) | Hardness (Shore A) | Abrasion Resistance | Oil/Chemical Resistance | UV/Ozone Resistance | Recommended Use |

|---|---|---|---|---|---|---|

| Recycled Rubber | -20 to +80 | 50–60 | Low | Poor | Poor | Low-traffic indoor |

| SBR (Styrene-Butadiene) | -30 to +100 | 65–75 | High | Moderate | Moderate | High-traffic industrial |

| NBR (Nitrile) | -30 to +120 | 60–70 | High | Excellent | Poor | Oil-exposed environments |

| EPDM | -40 to +130 | 65–75 | Moderate | Poor | Excellent | Outdoor/extreme weather |

Off-the-shelf ramps often utilize lower-grade compounds to minimize production costs, sacrificing long-term reliability. In contrast, precision-engineered rubber solutions from Suzhou Baoshida are formulated for mission-critical performance, ensuring compliance with industrial safety standards and reducing total cost of ownership through extended service life and minimal maintenance. Material selection is not a detail—it is the core determinant of functional success in rubber doorway ramp applications.

Material Specifications

Material Specifications for Industrial Rubber Doorway Ramps

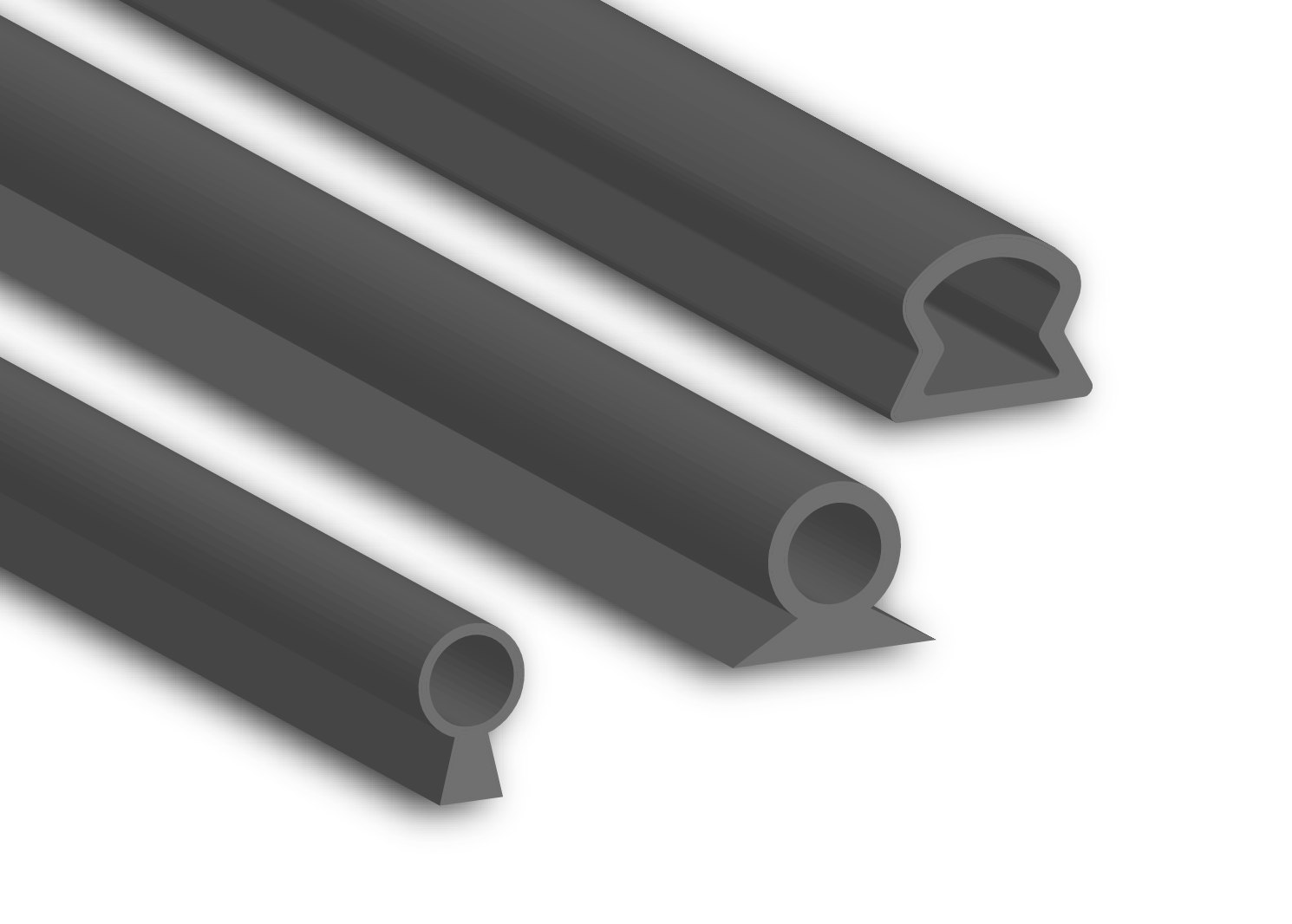

Suzhou Baoshida Trading Co., Ltd. prioritizes material science rigor in designing rubber doorway ramps for demanding industrial environments. These ramps endure continuous mechanical stress, chemical exposure, and thermal cycling, necessitating elastomers with precisely engineered properties. We specify three primary compounds—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—each selected for distinct operational profiles. Viton excels in extreme chemical and thermal resistance, making it indispensable for ramps in petrochemical or semiconductor facilities where exposure to aggressive solvents, acids, or high-temperature hydraulic fluids occurs. Its fluorocarbon backbone provides exceptional stability up to 250°C but commands higher material costs. Nitrile remains the optimal balance for general industrial use, offering robust resistance to oils, greases, and aliphatic hydrocarbons at temperatures spanning -40°C to 120°C. Its cost efficiency and reliable abrasion resistance suit logistics hubs, warehouses, and automotive plants. Silicone delivers critical performance in wide-temperature applications (-60°C to 230°C) and environments requiring UV/ozone stability, such as outdoor ramps in solar farms or coastal facilities. However, its lower tensile strength necessitates reinforcement for high-traffic zones.

All compounds undergo stringent quality control per ASTM D2000 standards, with Shore A hardness calibrated between 60–75 for optimal traction and load distribution. Compression set resistance is non-negotiable; ramps must maintain dimensional integrity after 24 hours at 100°C to prevent permanent deformation under static loads. Fluid immersion testing per ISO 1817 validates performance against ISO Group 1 (water), Group 2 (brake fluids), and Group 3 (mineral oils) contaminants. Reinforcement with aramid fibers or steel cords is integrated where tensile strength >15 MPa is required for heavy-equipment transitions.

The comparative analysis below details critical specifications for informed OEM selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -40 to +120 | -60 to +230 |

| Shore A Hardness Range | 65–80 | 60–75 | 50–70 |

| Tensile Strength (MPa) | 12–18 | 15–25 | 6–12 |

| Fluid Resistance | Excellent (acids, fuels, steam) | Good (oils, water) | Fair (water, steam) |

| Compression Set (%) | ≤20 (24h @ 150°C) | ≤25 (24h @ 100°C) | ≤20 (24h @ 150°C) |

| Abrasion Loss (mm³) | 80–120 | 60–100 | 150–250 |

| OEM Application Focus | Chemical plants, refineries | Warehouses, manufacturing | Outdoor facilities, cleanrooms |

Material selection directly impacts ramp longevity and safety compliance. Viton’s superiority in chemical resistance justifies its use where NBR would swell or degrade, though NBR’s abrasion resistance makes it ideal for forklift traffic. Silicone’s flexibility at cryogenic temperatures suits cold-storage ramps but requires supplemental reinforcement for heavy loads. Suzhou Baoshida collaborates with OEMs to match elastomer properties to site-specific stressors, ensuring ramps meet ISO 9001-certified performance benchmarks. All formulations exclude regulated phthalates and heavy metals, adhering to REACH and RoHS directives for global deployment. Precision compounding—not generic material substitution—defines our engineering approach to industrial mobility solutions.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Solutions for Industrial Doorway Ramps

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the design and production of high-performance rubber doorway ramps. With a dedicated team of five experienced mould engineers and two specialized rubber formulation engineers, we maintain full in-house control over the entire product development lifecycle—from concept and material design to tooling and final production. This integrated approach ensures technical consistency, accelerated development cycles, and superior product reliability tailored to the demanding requirements of industrial environments.

Our mould engineers leverage advanced CAD/CAM software and precision CNC machining to develop robust, long-life moulds optimized for complex geometries and high-volume output. Each doorway ramp mould is engineered with strict attention to dimensional accuracy, surface finish, and demoulding efficiency, ensuring repeatable quality across production batches. Finite element analysis (FEA) is routinely applied to predict structural performance under load, enabling proactive optimization of ramp profiles for durability and load distribution.

Complementing our mould design expertise, our two rubber formulation engineers specialize in custom elastomer development. They formulate proprietary rubber compounds specifically engineered for doorway ramp applications, balancing critical performance attributes such as abrasion resistance, compression set, tear strength, and slip resistance. By tailoring polymer blends—typically based on SBR, NR, or EPDM—and optimizing curatives, fillers, and additives, we achieve materials that perform reliably under dynamic loads, wide temperature ranges, and exposure to oils, UV, and moisture. This formulation control is a key differentiator, allowing us to meet exacting OEM specifications and environmental compliance standards, including RoHS and REACH.

Our OEM capabilities are built on a foundation of technical agility and confidentiality. We work directly with industrial partners to co-develop doorway ramp solutions that integrate seamlessly into their facility infrastructure or equipment systems. Whether modifying dimensions, load ratings, or chemical resistance profiles, we provide full technical documentation, material traceability, and sample validation to support certification and integration.

Below are typical technical specifications for our standard rubber doorway ramp series, illustrating the performance outcomes enabled by our engineering integration:

| Parameter | Specification |

|---|---|

| Material Composition | Custom SBR/NR blend, sulfur-cured |

| Hardness (Shore A) | 60 ± 5 |

| Tensile Strength | ≥12 MPa |

| Elongation at Break | ≥250% |

| Compression Set (22 hrs, 70°C) | ≤25% |

| Operating Temperature Range | -30°C to +80°C |

| Coefficient of Friction (wet/dry) | ≥0.7 |

| Load Capacity (per linear meter) | Up to 5,000 kg |

| Standard Lengths | 1.0 m, 1.5 m, 2.0 m (custom lengths available) |

| Color Options | Black, yellow, gray (custom colors on request) |

Backed by rigorous testing protocols and continuous process refinement, Suzhou Baoshida delivers engineered rubber doorway ramps that meet the highest industrial standards. Our technical team stands ready to support OEM partners with scalable, durable, and precisely engineered solutions.

Customization Process

Customization Process for Industrial Rubber Doorway Ramps

Suzhou Baoshida Trading Co., Ltd. executes a rigorous four-phase customization workflow to deliver engineered rubber doorway ramps meeting precise industrial specifications. This process ensures optimal performance in high-traffic commercial and industrial environments where safety, durability, and dimensional accuracy are non-negotiable.

Phase 1: Drawing Analysis and Application Assessment

Engineering review begins with comprehensive analysis of client-provided CAD drawings and environmental requirements. We evaluate critical factors including load capacity (static/dynamic), substrate compatibility, thermal exposure range, and slip-resistance mandates per ISO 13287 standards. Tolerance verification against ISO 2768-mK standards is performed, with particular attention to threshold height transitions and bevel angles to prevent tripping hazards. Material thickness is cross-referenced with expected footfall frequency to prevent premature deformation.

Phase 2: Polymer Formulation Engineering

Based on application analysis, our rubber compounding team develops a proprietary SBR/NBR hybrid formulation. Key adjustments target Shore A hardness (typically 65–75), compression set resistance (<20% per ASTM D395), and elongation at break (>300%). Anti-oxidant and anti-ozonant packages are calibrated for UV exposure in outdoor installations, while silica reinforcement optimizes wet-surface traction. All formulations undergo predictive aging simulations via Arrhenius modeling to validate 5+ year service life under specified conditions.

Phase 3: Prototyping and Validation Testing

CNC-machined molds produce functional prototypes for client validation. Each prototype undergoes accelerated lifecycle testing: 50,000+ cycles of simulated foot traffic via DIN 51130 ramp testing, thermal cycling between -40°C to +80°C, and chemical resistance checks against common industrial cleaners. Dimensional conformity is verified using CMM metrology to ±0.2mm tolerance. Client feedback on ergonomics and integration is incorporated before final sign-off.

Phase 4: Precision Mass Production

Approved designs transition to ISO 9001-certified production lines. Continuous vulcanization presses maintain ±1.5°C temperature control, with real-time rheometer monitoring of cure kinetics. Every batch undergoes inline quality checks: durometer verification, visual inspection for surface defects, and adhesion testing for embedded reinforcement grids. Final products are serialized for traceability and packaged with material certificates.

Critical Performance Specifications for Rubber Doorway Ramps

| Parameter | Test Standard | Minimum Requirement | Typical Value |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 65 | 70 ± 3 |

| Tensile Strength | ASTM D412 | 12 MPa | 15 MPa |

| Elongation at Break | ASTM D412 | 300% | 350% |

| Compression Set (22h/70°C) | ASTM D395 | – | <18% |

| Slip Resistance (wet) | ISO 13287 | R11 | R12 |

| Temperature Range | Custom | -40°C to +80°C | -50°C to +90°C |

This systematic approach eliminates guesswork in rubber product development, ensuring doorway ramps withstand demanding industrial use while complying with global safety regulations. Suzhou Baoshida’s integration of materials science and precision manufacturing delivers solutions that reduce long-term replacement costs and enhance facility safety compliance.

Contact Engineering Team

For industrial-grade rubber doorway ramps that meet the highest standards in durability, safety, and performance, Suzhou Baoshida Trading Co., Ltd. stands as a trusted leader in the field of engineered rubber solutions. With years of specialized expertise in custom-formulated rubber products, we deliver doorway ramps designed for long-term functionality across warehouses, factories, loading docks, and commercial facilities. Our commitment to precision manufacturing ensures that every product adheres to strict quality benchmarks while meeting the unique operational demands of our global clientele.

At Suzhou Baoshida, we understand that a reliable doorway ramp is more than just a transition piece—it is a critical component in maintaining workflow efficiency, ensuring personnel safety, and protecting material handling equipment. Our rubber doorway ramps are formulated using high-resilience synthetic and natural rubber compounds, offering superior resistance to abrasion, impact, UV exposure, and temperature extremes. Whether your environment requires oil-resistant formulations, anti-slip surface textures, or custom dimensions for non-standard doorways, our engineering team works closely with OEM partners and industrial buyers to deliver tailored solutions.

We invite technical buyers, procurement managers, and engineering teams to contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer, for direct technical consultation and product support. Mr. Boyce brings over a decade of experience in rubber compounding and industrial application design, ensuring that every doorway ramp solution is optimized for mechanical performance, environmental compatibility, and cost-efficiency. From initial concept and material selection to prototyping and volume production, our team provides end-to-end support with full traceability and documentation.

To request a technical datasheet, sample evaluation, or customized quote, please reach out to Mr. Boyce via email at [email protected]. We respond to all inquiries within 24 business hours and offer multilingual support for international clients. Our production facility in Suzhou is equipped with advanced molding and curing systems, enabling tight tolerance control and rapid turnaround for both standard and custom orders. With ISO-certified quality management practices and a focus on sustainable rubber sourcing, Suzhou Baoshida ensures every product meets global regulatory requirements.

Below are the standard technical specifications for our most widely deployed rubber doorway ramp model. Custom variants are available upon request.

| Property | Specification |

|---|---|

| Material Composition | NR/SBR Blend (Custom Compounds Available) |

| Hardness (Shore A) | 60 ± 5 |

| Tensile Strength | ≥12 MPa |

| Elongation at Break | ≥250% |

| Operating Temperature Range | -30°C to +80°C |

| Surface Finish | Diamond Tread / Smooth (Custom Options) |

| Standard Lengths | 600 mm, 900 mm, 1200 mm |

| Standard Widths | 600 mm, 800 mm, 1000 mm |

| Height Profile | 25 mm (Gradual Slope Design) |

| Color | Black (Custom Colors on Request) |

| Compliance | RoHS, REACH, ISO 9001:2015 |

Partner with Suzhou Baoshida Trading Co., Ltd. to integrate high-performance rubber doorway ramps into your facility infrastructure. Contact Mr. Boyce today at [email protected] to initiate a technical discussion and discover how our industrial rubber solutions can enhance safety, reduce maintenance costs, and improve operational continuity.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).