Technical Contents

Engineering Guide: Rubber Drainage Tiles

Engineering Insight Material Selection for Rubber Drainage Tiles Critical Performance Determinants

Field evidence consistently demonstrates that premature failure of rubber drainage tiles stems primarily from inadequate material formulation rather than design flaws. Generic elastomers marketed as universal solutions lack the tailored chemistry required for sustained subterranean performance. Off-the-shelf compounds frequently exhibit accelerated degradation under constant hydrostatic pressure, fluctuating pH levels, and microbial exposure inherent in drainage environments. This results in critical failures including permanent compression set exceeding 40%, leading to joint separation and soil infiltration, or catastrophic loss of tensile strength within 3-5 years due to hydrolysis. Such failures necessitate costly excavation and replacement, negating any initial procurement savings.

The operational demands of drainage tiles impose unique material requirements distinct from standard rubber products. Continuous immersion in variable groundwater chemistry—often containing sulfates, nitrates, or organic acids—demands exceptional hydrolytic stability. Simultaneously, the tiles must maintain elastic recovery under static soil loads exceeding 0.5 MPa while resisting ozone cracking from intermittent atmospheric exposure during installation. Standard EPDM or SBR compounds, optimized for cost rather than longevity, lack the molecular crosslink density and antioxidant package necessary to withstand these combined stressors. Empirical data shows generic formulations lose 50% of their original tensile strength after 2,000 hours in ASTM D1149 ozone testing, whereas engineered solutions retain over 85%.

Material science must address the specific degradation pathways prevalent in drainage applications. Alkaline hydrolysis from cementitious backfill materials attacks ester-based plasticizers in commodity rubbers, causing embrittlement. Conversely, acidic soils prevalent in agricultural zones degrade sulfur-cured networks. A robust formulation requires peroxide curing for hydrolysis resistance, custom-synthesized plasticizers immune to leaching, and synergistic antioxidant systems targeting both aqueous and oxidative aging. Compression set resistance below 15% after 70°C x 22h testing (ASTM D395 Method B) is non-negotiable for maintaining seal integrity over decades.

The following comparative analysis underscores performance gaps between generic and engineered compounds:

| Performance Parameter | Generic Off-the-Shelf Compound | Engineered Drainage Tile Compound | Test Standard |

|---|---|---|---|

| Compression Set (70°C x 22h) | 42-48% | 10-14% | ASTM D395 Method B |

| Hydrolysis Resistance (pH 4-10) | Severe surface cracking | No visible degradation | ISO 188 + Visual |

| Tensile Retention after Aging | 52-58% | 85-92% | ASTM D573 |

| Service Temperature Range | -20°C to +80°C | -40°C to +120°C | ASTM D2240 |

Procurement teams prioritizing initial cost over material science inevitably face lifecycle cost escalation. True value engineering requires collaboration with rubber specialists who analyze site-specific soil chemistry, load profiles, and longevity requirements to formulate purpose-built compounds. At Suzhou Baoshida, we deploy accelerated aging protocols simulating 50 years of service in 90 days, ensuring formulations meet the uncompromising demands of modern infrastructure. The rubber compound is not merely a component—it is the foundational determinant of system integrity. Proactive material selection prevents field failure; reactive replacement incurs exponential costs.

Material Specifications

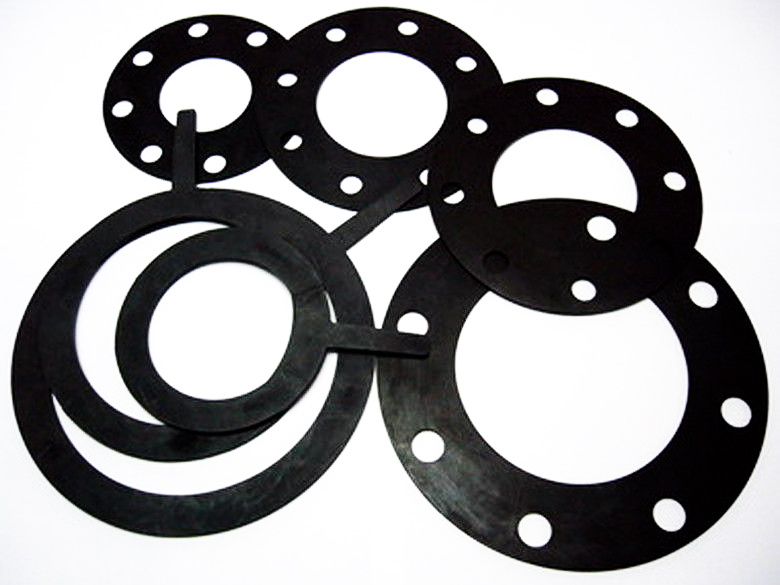

Material Specifications for Rubber Drainage Tiles

Suzhou Baoshida Trading Co., Ltd. provides high-performance rubber drainage tiles engineered for durability, chemical resistance, and long-term reliability in industrial and commercial applications. The selection of base elastomer is critical to performance under specific environmental and operational conditions. Our standard material offerings include Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct advantages depending on temperature range, fluid compatibility, and mechanical stress exposure. These materials are precision-compounded to meet stringent OEM requirements and ensure consistent performance across production batches.

Viton (fluorocarbon rubber) is the premium choice for extreme environments. It exhibits outstanding resistance to high temperatures, typically operating continuously at 200°C and intermittently up to 250°C. Viton demonstrates excellent stability when exposed to aggressive chemicals, including oils, fuels, acids, and chlorinated hydrocarbons. Its low gas permeability and exceptional aging characteristics make it ideal for critical sealing applications in chemical processing, aerospace, and high-temperature industrial systems. However, due to its formulation, Viton has lower flexibility at sub-ambient temperatures and higher material cost compared to alternatives.

Nitrile rubber (NBR) remains one of the most widely used elastomers in industrial sealing due to its balanced performance and cost efficiency. It offers excellent resistance to petroleum-based oils, greases, and hydraulic fluids, with a typical operating temperature range of -30°C to +100°C, extendable to +120°C for short durations depending on formulation. Nitrile provides good abrasion resistance and mechanical strength, making it suitable for dynamic sealing applications. While it performs poorly in ozone and UV exposure without protective additives, compounded NBR formulations used in our drainage tiles include stabilizers to enhance weatherability and service life in outdoor installations.

Silicone rubber (VMQ) excels in applications requiring extreme temperature flexibility. It maintains elastomeric properties from -60°C to +200°C, with some grades functional up to +230°C for limited periods. Silicone offers high resistance to UV radiation, ozone, and weathering, making it ideal for outdoor or high-exposure environments. It also meets stringent cleanliness standards and is often used in food-grade and medical applications. However, silicone has lower tensile strength and abrasion resistance compared to NBR and is not recommended for dynamic mechanical loading or exposure to hydrocarbon fuels.

The following table summarizes key physical and chemical properties of these materials as applied in rubber drainage tile manufacturing:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 12–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair (with additives) | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Chemical Resistance | Broad (acids, bases, solvents) | Moderate to Good (oils, water) | Limited (alkalis, some acids) |

Material selection should be guided by application-specific demands, including fluid media, thermal cycling, mechanical load, and regulatory compliance. Suzhou Baoshida Trading Co., Ltd. supports OEM clients with material testing data, custom compounding, and technical validation to ensure optimal performance in real-world conditions.

Manufacturing Capabilities

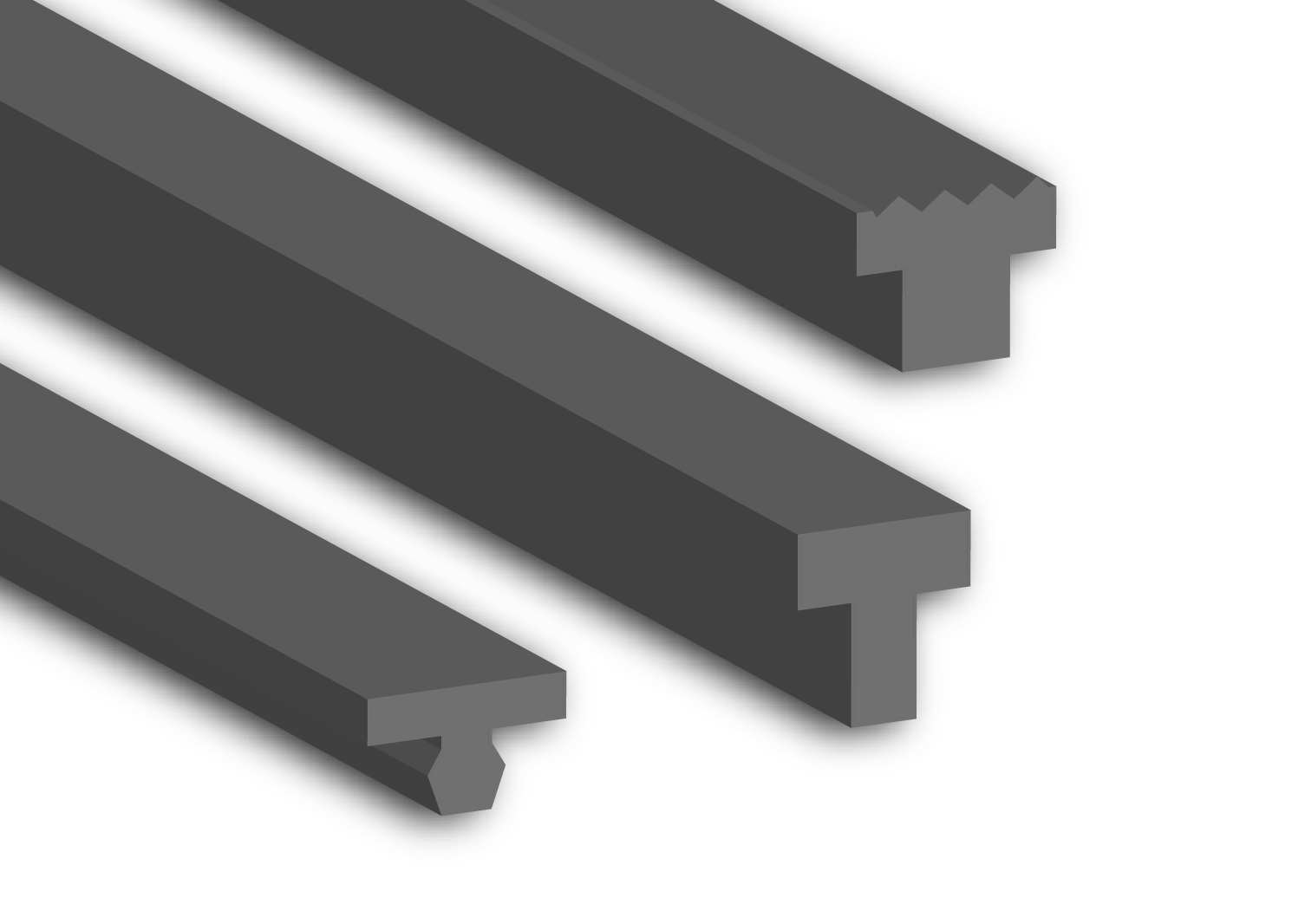

Engineering Capability: Precision Rubber Drainage Tile Development

At Suzhou Baoshida Trading Co., Ltd., our engineering framework for rubber drainage tiles integrates advanced material science with industrial-scale manufacturability. We deploy a dedicated team of five mould engineers and two rubber formula specialists to ensure every product meets stringent performance criteria for soil stability, hydraulic efficiency, and long-term environmental resistance. This dual-discipline approach eliminates siloed development, enabling seamless translation of client specifications into production-ready solutions.

Our formula engineers optimize elastomer compounds using ASTM D2000 and ISO 37 standards as baselines, but we exceed these through proprietary additive systems. Key innovations include dynamic vulcanization for enhanced ozone resistance and tailored polymer blends that maintain flexibility at -40°C while resisting hydrolysis in acidic/alkaline soils. Each formulation undergoes accelerated aging tests simulating 20+ years of subterranean exposure, with compression set values rigorously controlled below 15% after 70 hours at 70°C. This precision ensures tiles retain structural integrity under sustained load, preventing channel collapse in critical drainage applications.

The mould engineering team leverages 3D flow analysis and finite element simulation to design cavities that eliminate weld lines and minimize material waste. With expertise in multi-cavity hot-runner systems, we achieve ±0.15 mm dimensional tolerances across complex geometries—critical for interlocking tile assemblies requiring exact hydraulic continuity. Our in-house tooling facility supports rapid prototyping, reducing time-to-trial from concept to physical sample by 35% versus industry averages.

OEM collaboration is engineered into our workflow. Clients provide performance targets or CAD models; we respond with material certification dossiers, mould flow reports, and validation protocols within 10 business days. Our closed-loop process includes: initial compound screening, pre-production mould trials with SPC-monitored cavity balance analysis, and final validation against ISO 1133 (melt flow) and ASTM D2240 (hardness) benchmarks. Full traceability—from raw material batch codes to cure press parameters—is documented per ISO 9001 requirements.

Material performance specifications for our standard drainage tile compound are summarized below. Custom formulations adjust these parameters to meet project-specific demands, such as increased oil resistance for industrial sites or flame retardancy for tunnel applications.

| Property | Test Method | Baoshida Standard | Typical Industry Baseline |

|---|---|---|---|

| Tensile Strength | ASTM D412 | ≥18.0 MPa | ≥14.0 MPa |

| Elongation at Break | ASTM D412 | ≥450% | ≥350% |

| Compression Set (70°C/22h) | ASTM D395 | ≤12% | ≤20% |

| Shore A Hardness | ASTM D2240 | 65 ± 3 | 60–70 |

| Tear Resistance | ASTM D624 | ≥35 kN/m | ≥25 kN/m |

This technical rigor, combined with our vertical integration from R&D to production, positions Suzhou Baoshida as a strategic partner for OEMs demanding failure-proof drainage infrastructure. We transform engineering variables into predictable, field-proven performance—ensuring every tile installed operates at specification for its design lifecycle.

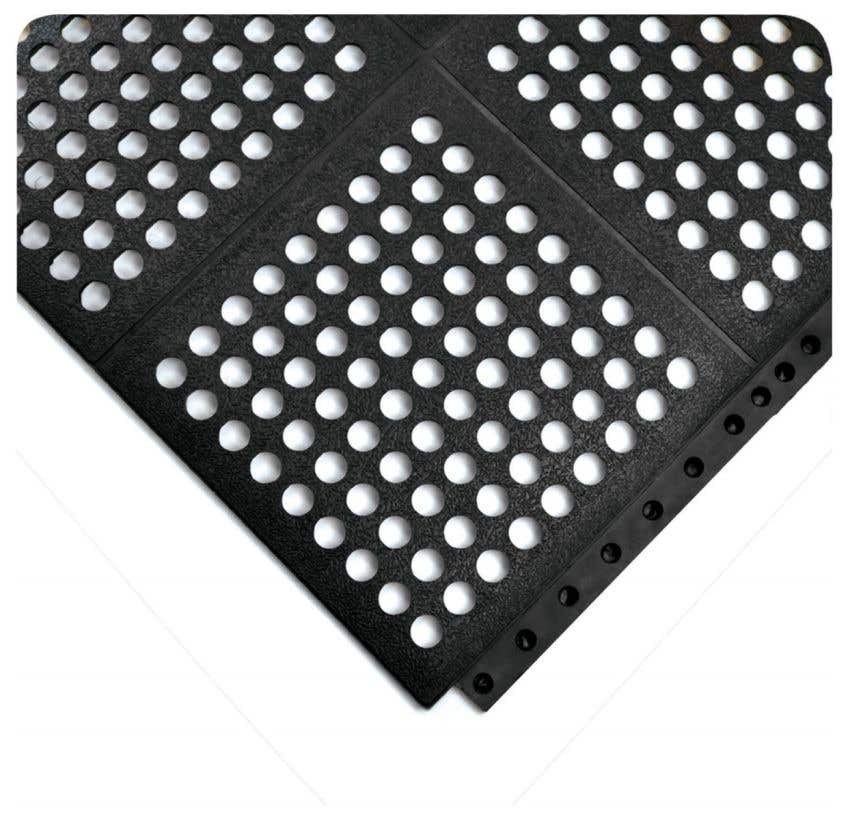

Customization Process

Drawing Analysis: Precision Engineering for Rubber Drainage Tiles

At Suzhou Baoshida Trading Co., Ltd., the customization process for rubber drainage tiles begins with rigorous drawing analysis. This foundational step ensures dimensional accuracy, structural integrity, and compatibility with the client’s installation environment. Our engineering team evaluates CAD drawings, 2D schematics, and technical annotations provided by the client, focusing on critical parameters such as tile geometry, channel depth, load-bearing zones, and connection interfaces. Tolerances are assessed to align with ISO 2768-mK standards, ensuring manufacturability without compromising performance. Any discrepancies or design inefficiencies are flagged for collaborative refinement, maintaining open communication with the client to optimize functionality and production feasibility.

Formulation: Tailored Rubber Compound Development

Following drawing validation, our Rubber Formula Engineers develop a customized elastomer formulation based on application-specific requirements. The selection of base polymers—such as SBR, EPDM, or natural rubber—is determined by environmental exposure, including UV resistance, temperature range, and chemical contact. Reinforcing fillers, plasticizers, vulcanizing agents, and anti-aging additives are precisely balanced to achieve target mechanical properties. Special attention is given to dynamic compression resistance and long-term resilience under cyclic loading, essential for drainage applications in industrial flooring, green roofs, or tunnel systems. Each formulation is documented and archived under a unique compound ID for traceability and consistency across production batches.

Prototyping: Functional Validation and Iterative Refinement

Once the formulation is finalized, we proceed to prototyping using precision steel molds manufactured in-house. Prototypes are produced under controlled vulcanization conditions—temperature, pressure, and cure time—mimicking mass production parameters. These samples undergo a battery of tests, including compression set (ASTM D395), tensile strength (ASTM D412), and flow efficiency analysis via hydraulic simulation. Dimensional inspection is performed using coordinate measuring machines (CMM) to verify conformity with the approved drawing. Client feedback is integrated at this stage, allowing for mold adjustments or compound modifications before final sign-off.

Mass Production: Scalable, Quality-Assured Manufacturing

With prototype approval, the project transitions to mass production. Our facility leverages automated rubber molding lines with real-time process monitoring to ensure uniformity. Each batch undergoes inline quality checks, including visual inspection, weight variance control, and hardness testing (Shore A). Finished rubber drainage tiles are packaged per client specifications, with optional labeling and logistics support for global OEM distribution.

Typical Physical Properties of Custom Rubber Drainage Tiles

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 55–75 |

| Tensile Strength | ASTM D412 | ≥10 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤20% |

| Specific Gravity | ASTM D297 | 1.15–1.30 |

| Operating Temperature Range | — | -40°C to +100°C |

All specifications are adjustable based on project demands, reflecting Suzhou Baoshida’s commitment to engineered flexibility and industrial excellence.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Drainage Tile Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial manufacturing excellence. As your dedicated Rubber Formula Engineer and OEM Manager, we prioritize material integrity and performance consistency for rubber drainage tiles. Our formulations undergo rigorous validation under ISO 9001 protocols, ensuring compliance with ASTM D2000 and EN 681 standards for critical infrastructure applications. We recognize that drainage tile performance hinges on precise elastomer composition, cross-linking density, and environmental resilience—factors directly controlled through our proprietary compounding processes.

The following specifications reflect our baseline compound for drainage tiles, engineered for optimal flow dynamics and structural longevity. These values represent minimum thresholds achievable through our standard production; custom formulations are developed to meet project-specific hydraulic or load-bearing requirements.

| Property | Value | Test Standard | Unit |

|---|---|---|---|

| Hardness (Shore A) | 65 ± 5 | ASTM D2240 | – |

| Tensile Strength | ≥ 12.0 | ASTM D412 | MPa |

| Elongation at Break | ≥ 350 | ASTM D412 | % |

| Compression Set (70°C) | ≤ 22 | ASTM D395 | % |

| Temperature Range | -40 to +100 | ISO 188 | °C |

| Water Absorption (24h) | ≤ 1.8 | ASTM D570 | % |

| Abrasion Resistance | ≤ 120 | DIN 53516 | mm³ |

Industrial clients consistently engage us to resolve material inconsistencies that compromise drainage efficiency—such as premature compression set in high-load environments or hydrolysis-induced surface degradation in alkaline soils. Our engineering team isolates root causes through FTIR spectroscopy and dynamic mechanical analysis, then recalibrates filler dispersion, cure kinetics, or polymer backbone selection. For OEM partners, we provide full technical documentation including batch-specific rheology curves and accelerated aging data to streamline regulatory submissions.

Do not compromise on tile performance when substandard elastomers lead to costly field failures. Mr. Boyce, our Technical OEM Manager, specializes in translating your hydraulic design parameters into validated rubber compounds. He will coordinate material trials, tooling compatibility assessments, and volume production ramp-up with zero disruption to your supply chain. Contact him directly to discuss:

Customizing polymer blends for extreme pH or temperature exposure

Optimizing extrusion parameters for reduced void formation

Accelerating time-to-market through pre-validated formula iterations

Initiate your project with data-driven precision. Email Mr. Boyce at [email protected] with your technical dossier and target performance metrics. Include details on operating environment, expected service life, and dimensional tolerances. Our engineering response will include a feasibility assessment within 72 business hours, detailing compound adjustments, prototype lead times, and compliance pathways. Suzhou Baoshida commits to being your silent technical partner—where every compound batch is a testament to industrial reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).