Technical Contents

Engineering Guide: Rubber Floor Matts

Engineering Insight: The Critical Role of Material Selection in Rubber Floor Mats

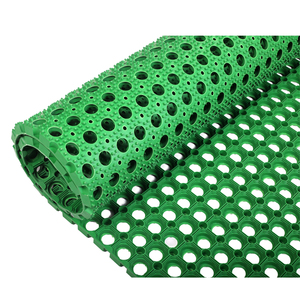

In industrial environments, rubber floor mats are far more than simple comfort aids—they are engineered components designed to withstand mechanical stress, chemical exposure, thermal fluctuations, and prolonged wear. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is the cornerstone of performance, safety, and longevity. Off-the-shelf rubber mats often fail under real-world industrial conditions due to generic material formulations that do not account for operational variables.

Standard commercial mats are typically manufactured from reclaimed rubber or low-grade SBR (styrene-butadiene rubber), chosen primarily for cost efficiency. While adequate for light-duty applications such as gym floors or retail entrances, these materials degrade rapidly when exposed to oils, solvents, ozone, or extreme temperatures. Industrial facilities, including automotive workshops, food processing plants, and chemical handling units, demand materials with specific resistance profiles. Using non-specialized mats results in premature cracking, loss of traction, and increased slip hazards—posing both safety and financial risks.

The engineering solution lies in precise material formulation. Natural rubber (NR) offers excellent resilience and tear strength, making it ideal for high-impact zones. Nitrile rubber (NBR) is preferred in oil- and fuel-rich environments due to its superior resistance to hydrocarbons. For outdoor or UV-exposed areas, EPDM (ethylene propylene diene monomer) provides unmatched weathering and ozone resistance. Each polymer has distinct physical and chemical characteristics that must align with the operational environment.

Beyond base polymers, compounding additives play a crucial role. Antioxidants, plasticizers, and reinforcing fillers such as carbon black or silica are tailored to enhance durability, flexibility, and flame retardancy. For example, incorporating halogen-free flame retardants is essential in electrical substations or public transit facilities where smoke toxicity must be minimized during combustion.

Custom-engineered rubber mats from Suzhou Baoshida are formulated using OEM-grade compounds, ensuring compatibility with specific industrial demands. We conduct rigorous testing for compression set, tensile strength, abrasion resistance, and chemical exposure per ASTM and ISO standards. This precision eliminates the guesswork associated with off-the-shelf products and ensures long-term reliability.

The following table outlines key rubber compounds and their industrial performance characteristics:

| Material | Temperature Range (°C) | Oil Resistance | Abrasion Resistance | Key Applications |

|---|---|---|---|---|

| Natural Rubber (NR) | -40 to +80 | Low | Excellent | Heavy machinery areas, impact zones |

| Nitrile Rubber (NBR) | -30 to +100 | Excellent | Good | Automotive shops, oil handling |

| EPDM | -50 to +150 | Moderate | Fair | Outdoor platforms, HVAC rooms |

| SBR (Reclaimed) | -20 to +70 | Poor | Low | Low-traffic offices, temporary use |

| Neoprene | -40 to +120 | Good | Very Good | Electrical rooms, marine environments |

Material selection is not a one-size-fits-all decision. It is a calculated engineering process that determines safety, efficiency, and lifecycle cost. At Suzhou Baoshida, we partner with OEMs and industrial clients to deliver rubber floor mats that perform—precisely where and how they are needed.

Material Specifications

Material Specifications for Industrial Rubber Floor Mats

Suzhou Baoshida Trading Co., Ltd. provides engineered rubber floor mat solutions tailored to demanding industrial environments. Precise material selection is critical for safety, durability, and operational efficiency. This section details three core elastomers—Viton, Nitrile, and Silicone—optimized for high-stress applications including chemical plants, automotive facilities, and food processing units. Each material undergoes rigorous compounding to meet ISO 2230 and ASTM D2000 standards, ensuring consistent performance under mechanical load, thermal cycling, and chemical exposure.

Viton (FKM) fluoroelastomers deliver exceptional resistance to aggressive chemicals, including hydrocarbons, acids, and jet fuels. With a continuous service temperature range of -20°C to 230°C, Viton mats withstand extreme thermal degradation while maintaining structural integrity. Its low gas permeability and non-flammable properties make it ideal for semiconductor cleanrooms and oil refinery walkways. Compounded hardness typically spans 60–90 Shore A, balancing slip resistance with foot fatigue reduction.

Nitrile (NBR) butadiene rubber offers cost-effective resilience against oils, greases, and aliphatic solvents. Operating effectively from -30°C to 120°C, NBR mats excel in automotive workshops and machinery floors where hydraulic fluid exposure is routine. Standard formulations achieve 50–85 Shore A hardness, with tensile strengths of 15–25 MPa. Enhanced grades incorporate nitrile-polyvinyl chloride (PVC) blends for improved ozone resistance in outdoor industrial settings.

Silicone (VMQ) high-consistency rubber provides unmatched thermal stability from -60°C to 200°C, coupled with FDA compliance for food and pharmaceutical zones. Its inert composition resists microbial growth and withstands repeated steam sterilization. Silicone mats maintain flexibility at cryogenic temperatures, suiting cold-storage facilities, while 40–70 Shore A hardness ensures ergonomic comfort during prolonged standing. Limitations include moderate abrasion resistance and higher cost versus hydrocarbon-based elastomers.

The comparative table below summarizes critical performance metrics for informed material selection.

| Material | Temperature Range (°C) | Chemical Resistance | Hardness Range (Shore A) | Tensile Strength (MPa) | Typical Industrial Applications |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | Excellent (aromatics, acids, fuels) | 60–90 | 10–15 | Chemical processing, aerospace, oil/gas |

| Nitrile (NBR) | -30 to 120 | Good (oils, greases, aliphatics) | 50–85 | 15–25 | Automotive manufacturing, machinery halls |

| Silicone (VMQ) | -60 to 200 | Fair (water, mild acids; poor for hydrocarbons) | 40–70 | 6–12 | Food processing, pharmaceuticals, cryogenics |

Suzhou Baoshida’s OEM team collaborates with clients to refine formulations for site-specific challenges. Custom additives—including anti-static agents, flame retardants (UL 94 V-0), and reinforced fibers—optimize mats for electrical safety, fire codes, or heavy-impact zones. All compounds undergo accelerated aging tests per ASTM D573 and compression set validation at 100°C for 72 hours. Partner with us to translate material science into engineered floor safety solutions that reduce workplace incidents and lifecycle costs. Precision compounding begins with your operational requirements.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered rubber floor mats through a vertically integrated approach that combines advanced material science with robust mold design and manufacturing expertise. At the core of our engineering capability are five dedicated mold engineers and two specialized rubber formulation engineers, enabling full control from concept to production. This integrated team ensures that every rubber floor mat meets exacting performance, durability, and dimensional standards required in industrial, commercial, and transportation environments.

Our mold engineering team utilizes state-of-the-art CAD/CAM software, including SolidWorks and AutoCAD, to design high-precision steel and aluminum molds optimized for long cycle life, consistent part quality, and efficient production. Each mold is engineered with detailed attention to parting lines, venting, gate design, and thermal management to minimize defects and maximize throughput. Prototyping is conducted in-house using CNC machining and EDM processes, allowing rapid validation and iteration before mass production. The team supports both standard and custom mold configurations, ensuring compatibility with hydraulic and pneumatic press systems across global manufacturing facilities.

Complementing mold design is our advanced rubber compounding capability. Our two formulation engineers specialize in developing proprietary elastomer blends tailored to specific mechanical, thermal, and chemical resistance requirements. Utilizing laboratory-scale mixers, rheometers, tensile testers, and aging chambers, we formulate compounds based on natural rubber (NR), styrene-butadiene rubber (SBR), ethylene propylene diene monomer (EPDM), and nitrile rubber (NBR). These formulations are optimized for critical performance parameters such as abrasion resistance, compression set, slip resistance, and aging stability under extreme temperatures.

We maintain full OEM (Original Equipment Manufacturer) capability, supporting global partners in private-label production and co-development projects. Our engineering team collaborates directly with clients to interpret technical drawings, reverse-engineer legacy parts, and develop new designs that meet exact dimensional and functional specifications. Traceability, batch consistency, and compliance with international standards (including ISO 9001 and RoHS) are embedded into our manufacturing protocols.

The integration of mold and material engineering allows Suzhou Baoshida to deliver rubber floor mats that perform reliably in demanding environments—ranging from heavy-duty industrial flooring to automotive interior applications. By controlling both the physical tooling and chemical composition, we ensure optimal part integrity, service life, and cost-efficiency.

Below is a summary of our core technical specifications and capabilities:

| Parameter | Specification |

|---|---|

| Mold Materials | H13, P20, 718H Steel; 6061, 7075 Aluminum |

| Mold Tolerance | ±0.05 mm |

| Rubber Hardness Range (Shore A) | 40–90 |

| Temperature Resistance | -40°C to +150°C (depending on compound) |

| Production Capacity | Up to 500,000 units/month |

| Standard Compounds | NR, SBR, EPDM, NBR, CR |

| Testing Equipment | Tensile Tester, Hardness Durometer, Aging Oven, Compression Set Apparatus |

Suzhou Baoshida Trading Co., Ltd. stands as a technically advanced partner in industrial rubber solutions, offering engineering depth, material innovation, and scalable OEM manufacturing for global clients.

Customization Process

Customization Process for Industrial Rubber Floor Mats

At Suzhou Baoshida Trading Co., Ltd., our customization process for industrial rubber floor mats integrates material science with precision engineering to deliver solutions meeting exact operational demands. This structured four-phase workflow ensures optimal performance, durability, and compliance with sector-specific standards.

Drawing Analysis

Initial technical drawings undergo rigorous dimensional verification and manufacturability assessment. Our engineering team evaluates critical parameters including load distribution zones, edge sealing requirements, and surface texture specifications against ISO 10289 corrosion resistance classifications and ISO 2230 slip resistance criteria. Tolerance stacks are cross-referenced with polymer flow dynamics to preempt molding defects. This phase includes production scalability assessment, confirming tooling feasibility for volumes exceeding 50,000 units monthly while maintaining ±0.5mm dimensional accuracy.

Formulation Development

Material composition is engineered using proprietary compound databases calibrated for industrial environments. We select base polymers (SBR, EPDM, or nitrile) based on chemical exposure profiles, thermal ranges (-40°C to +150°C), and mechanical stress requirements. Additives such as silica reinforcements or flame retardants (UL 94 V-0 compliant) are precisely dosed to achieve target properties. Key formulation metrics are validated through predictive modeling before prototyping:

| Parameter | Industrial Standard Range | Testing Method |

|---|---|---|

| Hardness (Shore A) | 55–85 | ASTM D2240 |

| Tensile Strength | 8–15 MPa | ASTM D412 |

| Elongation at Break | 200–400% | ASTM D412 |

| Compression Set (70°C) | ≤25% | ASTM D395 |

| Abrasion Resistance | ≤120 mm³ | DIN 53516 |

Prototyping and Validation

Three functional prototypes are produced using client-approved tooling inserts. Each unit undergoes accelerated life testing simulating 5 years of industrial wear: 10,000 cycles of ASTM F1677-05 ramp testing for slip resistance, 500-hour chemical immersion per ISO 1817, and dynamic load testing at 5x operational weight. Surface texture consistency is verified via laser profilometry (Ra ≤ 15μm). Client feedback triggers iterative adjustments within 72 hours, with final sign-off requiring ≥95% conformance to performance KPIs.

Mass Production Execution

Upon prototype approval, production commences under ISO 9001-certified protocols. Each batch undergoes real-time quality monitoring: 100% visual inspection for surface defects, statistical hardness/tensile sampling (AQL 1.0), and batch traceability via laser-etched lot codes. Automated mixing systems ensure ±0.3% formulation accuracy, while vulcanization profiles are dynamically adjusted using in-mold pressure sensors. Finished mats are palletized with anti-static wrapping and shipped with material test reports (MTRs) documenting full compliance with EN 14041 acoustic and safety standards.

This end-to-end process reduces time-to-market by 30% versus industry averages while guaranteeing mats withstand extreme industrial conditions. Suzhou Baoshida’s integration of formula engineering and lean manufacturing delivers zero-defect solutions scalable from 1,000 to 500,000 units monthly.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Industrial Rubber Floor Mats

When it comes to high-performance rubber floor mats for industrial, commercial, and specialized applications, Suzhou Baoshida Trading Co., Ltd. stands as a trusted leader in the field of engineered rubber solutions. With years of technical expertise, precision manufacturing capabilities, and a deep understanding of material science, we deliver durable, reliable, and customized rubber matting products that meet the rigorous demands of modern facilities. Whether you require anti-fatigue matting for production lines, slip-resistant flooring for wet environments, or heavy-duty protection for machinery zones, our team ensures every product is formulated for optimal performance, longevity, and safety.

Our rubber floor mats are manufactured using premium-grade compounds, including natural rubber, SBR, EPDM, and NBR, each selected based on application-specific requirements such as temperature resistance, oil resistance, compression set, and abrasion performance. Through advanced vulcanization techniques and strict quality control protocols, we ensure consistent physical properties and dimensional accuracy across all production batches. Every mat is designed to withstand extreme operational conditions while maintaining structural integrity and functional reliability.

We specialize in both standard and custom configurations, offering tailored dimensions, surface textures, color coding, and embedded features such as grounding elements or identification markings. Our engineering team works closely with OEMs, facility managers, and procurement officers to develop solutions that align precisely with operational needs and regulatory standards.

Below is a representative specification table for our most commonly requested industrial rubber floor mat series:

| Property | Standard Industrial Mat | Heavy-Duty Mat | Anti-Fatigue Mat | Oil-Resistant Mat |

|---|---|---|---|---|

| Material | SBR + Natural Rubber | Reinforced EPDM | Closed-Cell NBR | Nitrile Rubber (NBR) |

| Thickness Range | 6–12 mm | 10–20 mm | 8–15 mm | 6–15 mm |

| Hardness (Shore A) | 65 ± 5 | 70 ± 5 | 55 ± 5 | 68 ± 5 |

| Temperature Range | -30°C to +80°C | -40°C to +100°C | -20°C to +70°C | -25°C to +90°C |

| Tensile Strength | ≥12 MPa | ≥15 MPa | ≥10 MPa | ≥14 MPa |

| Elongation at Break | ≥250% | ≥280% | ≥300% | ≥260% |

| Slip Resistance (DIN 51130) | R10 | R11 | R10 | R11 |

| Oil Resistance | Moderate | Good | Limited | Excellent |

All products comply with international standards including ISO 9001, REACH, and RoHS, ensuring environmental safety and operational compliance.

To discuss your specific application requirements or request a technical datasheet, please contact Mr. Boyce, our dedicated OEM and Engineering Manager. With a background in polymer engineering and over a decade of experience in industrial rubber manufacturing, Mr. Boyce provides expert guidance on material selection, performance optimization, and cost-effective sourcing strategies. He is available to support technical evaluations, sample coordination, and volume production planning.

Reach out today via email at [email protected] to initiate a consultation. Let Suzhou Baoshida be your strategic partner in delivering high-integrity rubber floor mat solutions engineered for performance and built to last.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).