Technical Contents

Engineering Guide: Rubber Floor Tiles For Playground

Engineering Insight: Material Selection in Playground Rubber Floor Tiles

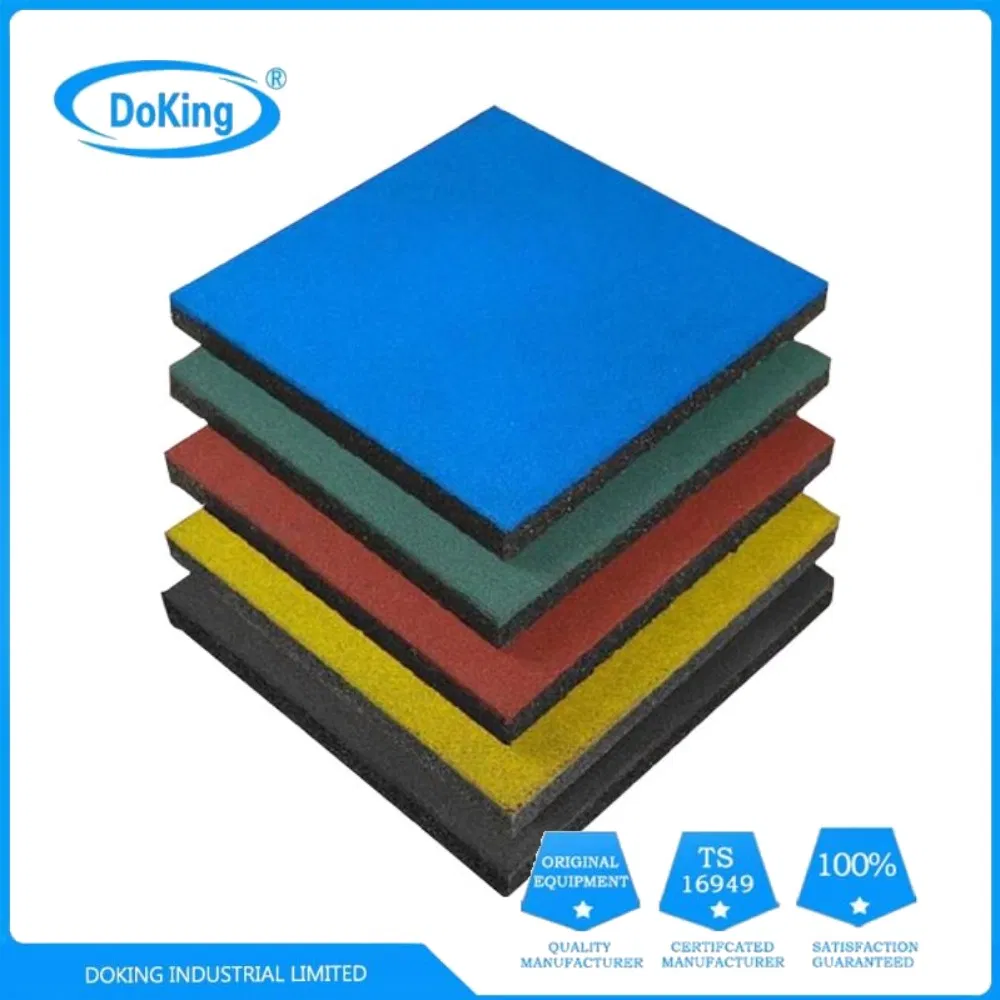

The performance and longevity of rubber floor tiles in playground environments are fundamentally determined by material composition. While many suppliers offer off-the-shelf solutions, these products frequently fail to meet the mechanical, environmental, and safety demands of high-traffic outdoor installations. At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material selection as the cornerstone of durable, compliant, and safe playground surfacing.

Standard commercial rubber tiles often utilize recycled rubber granules bound with low-grade polyurethane or styrene-butadiene (SBR) adhesives. These materials may reduce upfront costs but compromise critical performance metrics. For instance, SBR-based tiles exhibit poor UV resistance, leading to rapid surface degradation, color fading, and embrittlement under prolonged solar exposure. Additionally, inconsistent granule size and inadequate binder ratios result in delamination, cracking, and reduced impact absorption over time—directly undermining fall protection compliance.

In contrast, engineered playground tiles require a precise balance of virgin and post-consumer rubber, reinforced with high-performance thermoplastic polyurethane (TPU) or vulcanized EPDM (ethylene propylene diene monomer) compounds. These materials offer superior elasticity, tensile strength, and resistance to thermal cycling. EPDM, in particular, provides exceptional color retention and ozone resistance, essential for maintaining both aesthetics and safety ratings across seasons.

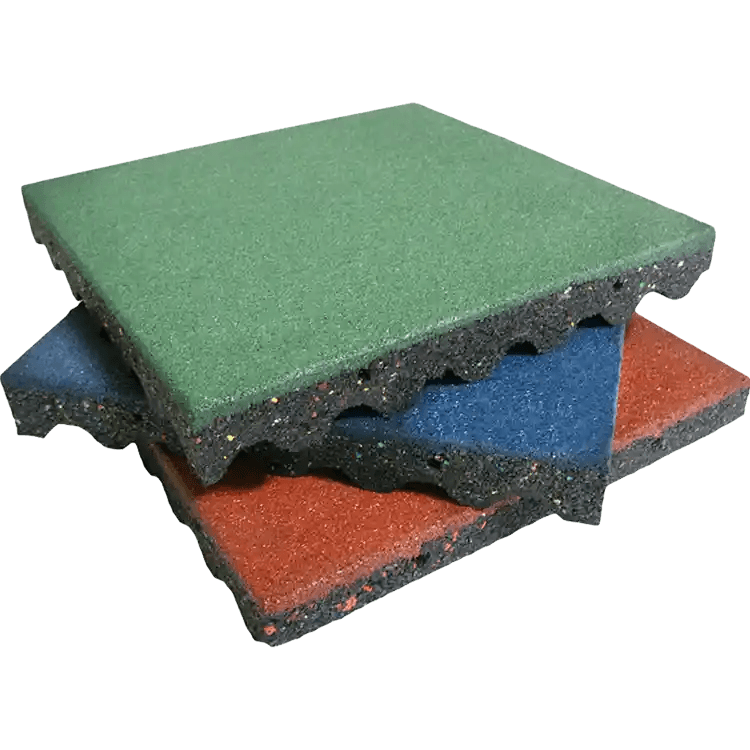

Another critical factor is the cellular structure of the rubber compound. Closed-cell formulations prevent water absorption, minimizing freeze-thaw damage in colder climates. Open-cell designs, while offering higher impact attenuation, are prone to water retention and microbial growth if not properly sealed. Our proprietary compounding process ensures optimal cell density and cross-linking, achieving a balance between shock absorption (critical for fall heights up to 3 meters) and dimensional stability.

Off-the-shelf tiles often fail to meet ASTM F1292 (impact attenuation) and ASTM F1951 (accessibility) standards under real-world conditions due to inconsistent material quality. Batch variability in recycled feedstock leads to non-uniform compression set and rebound resilience, increasing the risk of injury and non-compliance during safety audits.

At Baoshida, we apply industrial rubber formulation principles to playground applications, treating each installation as a site-specific engineering challenge. This includes adjusting Shore A hardness, optimizing binder-to-filler ratios, and incorporating UV stabilizers and anti-fungal agents tailored to regional climate profiles.

The following table outlines key material specifications that differentiate engineered rubber tiles from generic alternatives:

| Property | Generic Recycled Rubber Tile | Engineered EPDM/TPU Tile (Baoshida Standard) |

|---|---|---|

| Shore A Hardness | 55–70 (variable) | 65–70 (consistent) |

| Tensile Strength | 0.8–1.2 MPa | ≥1.8 MPa |

| Elongation at Break | 100–150% | ≥250% |

| UV Resistance | Poor (fading in 6–12 months) | Excellent (color retention >5 years) |

| Water Absorption (24h) | 8–12% | ≤2% |

| Compression Set (22h, 70°C) | 30–40% | ≤15% |

| Fall Height Compliance | Up to 1.5 m (degrades rapidly) | Up to 3.0 m (stable over 8+ years) |

Material selection is not a cost-driven compromise—it is a performance imperative. By leveraging industrial-grade rubber formulations, Suzhou Baoshida ensures playground tiles that endure environmental stress, maintain safety standards, and deliver lifecycle value.

Material Specifications

Material Specifications for Playground Rubber Floor Tiles

Selecting the optimal elastomer for playground rubber floor tiles requires rigorous evaluation of mechanical properties, environmental resistance, and safety compliance. At Suzhou Baoshida Trading Co., Ltd., we engineer formulations to meet ASTM F1292 impact attenuation standards while ensuring longevity under UV exposure, temperature extremes, and mechanical stress. Viton, Nitrile, and Silicone each offer distinct performance profiles critical for playground safety surfaces.

Viton fluoroelastomers provide exceptional resistance to ozone, UV radiation, and high temperatures, making them ideal for regions with intense sunlight and thermal cycling. Their chemical inertness ensures no leaching of hazardous compounds, complying with EN 71-3 toy safety standards. Viton tiles maintain structural integrity between -20°C and +230°C, with Shore A hardness typically stabilized at 60–70 for optimal shock absorption. However, higher material costs necessitate strategic application in high-exposure zones.

Nitrile rubber (NBR) balances cost efficiency with robust mechanical performance. Its acrylonitrile content (33–36%) delivers superior abrasion resistance and tensile strength (15–20 MPa), critical for high-traffic playground areas. NBR formulations achieve Shore A 55–65 hardness, meeting ASTM F1292 fall height requirements up to 2.5 meters. While NBR exhibits moderate UV resistance, our proprietary antioxidant packages extend service life in temperate climates. It remains the most economical solution for general-use tiles where extreme thermal stability is non-critical.

Silicone rubber excels in ultra-broad temperature resilience (-60°C to +200°C) and unparalleled UV/ozone stability. Its hydrophobic nature prevents moisture-induced degradation, ensuring consistent impact absorption in humid environments. Silicone tiles achieve Shore A 45–55, optimizing cushioning for critical fall heights per EN 1177. Though higher in cost than NBR, silicone’s non-toxic decomposition and compliance with FDA 21 CFR §177.2600 make it preferred for infant/toddler zones. Cure system compatibility with standard compression molding processes ensures manufacturability.

The comparative analysis below details key specifications for informed material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Shore A Hardness | 60–70 | 55–65 | 45–55 |

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 12–18 | 15–20 | 6–10 |

| Elongation at Break (%) | 200–300 | 300–450 | 400–600 |

| UV/Ozone Resistance | Excellent | Moderate* | Excellent |

| Primary Playground Use | High-sun exposure zones | General traffic areas | Sensitive age zones |

*Enhanced via Suzhou Baoshida’s antioxidant masterbatches.

Material selection directly dictates tile performance lifecycle and regulatory adherence. Viton is recommended for equatorial installations requiring thermal stability, NBR for cost-sensitive municipal projects in moderate climates, and Silicone for premium installations prioritizing child safety and extreme weather resilience. All formulations undergo third-party validation for heavy metals (ASTM F963), phthalates (REACH), and slip resistance (ASTM E303). Suzhou Baoshida’s OEM partnerships ensure precise compounding to your regional safety standards and aesthetic requirements, with batch traceability from raw material to finished tile.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, ensuring precision, durability, and compliance in every rubber floor tile designed for playground applications. Our team comprises five dedicated mould engineers and two specialized rubber formula engineers, each with extensive experience in material science, polymer chemistry, and precision tooling. This integrated technical team enables us to deliver fully customized OEM solutions that meet the exact performance, safety, and aesthetic requirements of global playground flooring standards.

Our mould engineers utilize advanced CAD/CAM software and CNC machining techniques to develop high-tolerance steel and aluminum moulds capable of producing complex tile geometries with consistent dimensional accuracy. Each mould is rigorously tested for cycle life, wear resistance, and thermal stability to ensure long-term production reliability. The integration of finite element analysis (FEA) in the design phase allows for predictive modeling of material flow and stress distribution, minimizing defects and optimizing production efficiency.

Complementing this capability are our two in-house rubber formula engineers, who specialize in thermoplastic elastomers (TPE), ethylene propylene diene monomer (EPDM), and styrene-butadiene rubber (SBR) formulations. These engineers develop proprietary rubber blends tailored to specific impact absorption, UV resistance, colorfastness, and slip-resistant properties required in playground environments. By controlling the formulation process internally, we ensure batch-to-batch consistency, compliance with international safety standards (such as ASTM F1292 and EN 1177), and the ability to rapidly iterate formulations based on client feedback or regulatory updates.

Our OEM capabilities extend beyond manufacturing to full product development cycles, including concept design, material selection, prototype testing, and scalable production. Clients benefit from our end-to-end control over both formulation and tooling, enabling rapid turnaround times and seamless transition from prototype to mass production. Whether developing custom tile thicknesses, unique surface textures, or region-specific color palettes, our engineering team ensures every product meets functional and aesthetic demands.

We support low minimum order quantities (MOQs) without compromising on quality, making our solutions accessible to distributors, municipal suppliers, and private developers alike. All rubber floor tiles are manufactured under ISO 9001-certified processes, with full traceability from raw material sourcing to final inspection.

The table below outlines key technical specifications of our standard playground rubber floor tiles, engineered for optimal performance and safety.

| Specification | Value |

|---|---|

| Material Composition | EPDM + SBR Recycled Granules (Bound with Polyurethane) |

| Thickness Options | 20 mm, 25 mm, 30 mm, 40 mm |

| Impact Attenuation (HIC) | ≤ 1000 (ASTM F1292 Compliant) |

| Critical Fall Height | Up to 3.0 meters |

| Shore A Hardness | 45–65 |

| Temperature Range | -40°C to +80°C |

| UV Resistance | > 5 years (Color Retention) |

| Slip Resistance (Wet) | ≥ 0.6 CoF (ASTM E303) |

| Fire Rating | Class B (ASTM E648) |

| Installation Method | Loose-lay or Adhesive Bonded |

Through deep technical expertise and vertical integration of formulation and mould engineering, Suzhou Baoshida delivers engineered rubber flooring solutions that combine safety, longevity, and design flexibility for playground environments worldwide.

Customization Process

Customization Process for Playground Rubber Floor Tiles

At Suzhou Baoshida Trading Co., Ltd., our customization process for playground rubber floor tiles begins with rigorous drawing analysis. Engineering teams dissect client-provided CAD files to validate critical dimensions, interlocking geometries, and safety-critical features such as impact attenuation zones. We cross-reference specifications against ASTM F1292 and EN 1177 standards, ensuring fall-height compliance and dimensional tolerances within ±0.5mm. Any deviations in slope gradients or drainage channel designs are flagged for collaborative redesign, prioritizing both safety and manufacturability.

Formulation development follows, leveraging our proprietary rubber compounding expertise. We select base polymers—typically SBR or EPDM—based on required abrasion resistance, UV stability, and color retention. Additives like silica for tear strength, UV inhibitors for outdoor durability, and non-toxic colorants are precisely dosed. Each formulation undergoes computational modeling to predict curing kinetics and compression set behavior, ensuring the final product maintains Shore A 65–75 hardness under playground thermal cycling. Critical performance parameters are quantified in the table below.

| Parameter | Target Value | Tolerance | Test Method |

|---|---|---|---|

| Thickness | 25–50 mm | ±1.0 mm | ASTM D2240 |

| Durometer Hardness | 65–75 Shore A | ±3 | ASTM D2240 |

| Tensile Strength | ≥7.0 MPa | ±0.5 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ±20% | ASTM D412 |

| Critical Fall Height | 1.5–3.0 m | Zero deviation | ASTM F1292 |

Prototyping employs CNC-machined molds to produce 1m² test tiles for client validation. We conduct accelerated weathering (QUV aging per ASTM G154), slip resistance testing (ASTM E303), and impact attenuation trials. Iterations address micro-cracking or color fading, with formulation adjustments documented in our traceability system. Client feedback on texture, joint integrity, and aesthetic alignment is integrated within 72 hours.

Mass production initiates only after formal sign-off. We deploy closed-mixing systems for batch consistency, with real-time rheometry monitoring during extrusion calendering. Each tile undergoes inline laser scanning for dimensional conformity and automated vision inspection for surface defects. Lot traceability links raw material batches to final products via QR codes, ensuring full accountability. Our production lines maintain ±0.3mm thickness uniformity at volumes exceeding 10,000 m² monthly, supported by ISO 9001-certified process controls. This structured workflow guarantees playground tiles that merge safety, longevity, and design precision for global OEM partners.

Contact Engineering Team

For industrial manufacturers and procurement managers sourcing high-performance rubber floor tiles for playground applications, Suzhou Baoshida Trading Co., Ltd. stands as a trusted OEM partner in the field of engineered rubber solutions. Our expertise lies in delivering durable, impact-absorbing, and weather-resistant rubber flooring systems that meet international safety standards for child play environments. With precision manufacturing processes and rigorous quality control, we ensure every tile batch aligns with technical specifications required for commercial, municipal, and educational installations.

Our rubber floor tiles are formulated using high-grade recycled rubber granules and virgin EPDM (Ethylene Propylene Diene Monomer) binding agents, providing optimal shock absorption, slip resistance, and long-term resilience under UV exposure and temperature fluctuations. Each product is tested for compliance with ASTM F1292 (impact attenuation), EN 1177 (safety requirements), and CE marking protocols, ensuring suitability for global distribution. Whether you require custom thickness, color combinations, or interlocking patterns, our engineering team supports tailored development to meet project-specific demands.

To initiate a technical consultation or request sample validation, contact Mr. Boyce, OEM Project Manager at Suzhou Baoshida Trading Co., Ltd. With over 12 years of experience in rubber compounding and export logistics, Mr. Boyce specializes in aligning material performance with client regulatory and dimensional requirements. He serves as the primary technical liaison between international buyers and our production units, ensuring seamless communication from prototype to bulk delivery.

Below are key technical specifications for our standard playground rubber tile series:

| Parameter | Specification |

|---|---|

| Material Composition | 80% recycled SBR + 20% virgin EPDM binder |

| Thickness Options | 25 mm, 30 mm, 40 mm, 50 mm |

| Standard Tile Size | 500 mm × 500 mm (custom sizes available) |

| Impact Attenuation (HIC) | ≤ 200 (ASTM F1292 compliant at 25 mm+) |

| Compression Deflection | 18–25% at 10 kN |

| Shore A Hardness | 45–55 |

| UV Resistance | > 2,000 hours (QUV accelerated testing) |

| Temperature Range | -40°C to +80°C |

| Fire Rating | Class B (DIN 4102) |

| Installation Method | Interlocking or adhesive-bonded |

| Service Life | Minimum 8–10 years (outdoor exposure) |

All products undergo batch testing for density, tensile strength, and colorfastness, with full traceability from raw material sourcing to final packaging. We support MOQs starting at 500 m², with container load optimization for FCL and LCL shipping from Shanghai Port.

For technical data sheets, 3D CAD models, or sample requests, contact Mr. Boyce directly at [email protected]. Include project scope, target market, and performance criteria to receive a tailored proposal with material certifications and lead time estimates. Suzhou Baoshida is committed to engineering excellence in industrial rubber applications—partner with us to deliver safer, smarter playground surfaces worldwide.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).