Technical Contents

Engineering Guide: Rubber & Gasket Company Of America

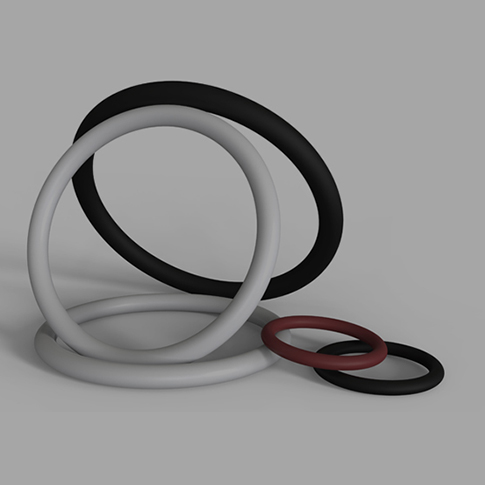

Engineering Insight: The Critical Role of Material Selection in Precision Rubber Seals

In the field of industrial sealing solutions, material selection is not merely a design consideration—it is the foundation upon which performance, longevity, and system reliability are built. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf rubber seals, while economically appealing, often fail to meet the rigorous demands of dynamic operating environments. These pre-manufactured components are typically formulated for generalized applications and lack the tailored properties required to withstand specific combinations of temperature, pressure, chemical exposure, and mechanical stress.

The failure of standard seals frequently manifests in premature degradation, compression set, extrusion, or chemical swelling. Such failures compromise system integrity, increase maintenance cycles, and can lead to costly downtime. For example, an NBR (nitrile butadiene rubber) seal may perform adequately in low-temperature hydraulic systems but will rapidly deteriorate when exposed to ozone or high-temperature environments exceeding 120°C. Similarly, EPDM seals, while excellent for steam and hot water applications, are incompatible with most hydrocarbon-based oils and fuels.

Precision rubber seals must be engineered in alignment with the application’s environmental and mechanical parameters. Material selection directly influences critical performance metrics such as tensile strength, elongation at break, compression set resistance, and fluid compatibility. At Suzhou Baoshida, we work closely with OEMs to analyze operating conditions and recommend optimized elastomers based on comprehensive testing and real-world validation.

The following table outlines key elastomer types and their functional limits, illustrating why generalized solutions fall short in precision applications:

| Material | Temperature Range (°C) | Key Strengths | Common Limitations | Typical Applications |

|---|---|---|---|---|

| NBR (Nitrile) | -30 to +120 | High resistance to oils, fuels, and hydraulic fluids | Poor ozone and UV resistance; limited high-temp performance | Automotive seals, hydraulic systems |

| EPDM | -50 to +150 | Excellent steam, water, and ozone resistance | Swells in hydrocarbons; poor oil resistance | HVAC systems, steam valves |

| FKM (Viton®) | -20 to +230 | Superior chemical and heat resistance | High cost; lower flexibility at low temperatures | Aerospace, chemical processing |

| Silicone (VMQ) | -60 to +200 | Excellent thermal stability and flexibility | Low tensile strength; poor abrasion resistance | Medical devices, food processing |

| HNBR | -40 to +150 | Enhanced mechanical strength and oil resistance vs. NBR | Limited low-temperature elasticity | Off-road vehicle engines, industrial rollers |

Material selection must also account for regulatory compliance, such as FDA, NSF, or UL certifications, particularly in food-grade or safety-critical applications. A one-size-fits-all approach ignores these nuances, leading to suboptimal performance.

At Suzhou Baoshida, we advocate for engineered-to-order solutions. By prioritizing material science and application-specific design, we ensure that every precision rubber seal delivers consistent, reliable performance under real-world conditions—proving that in sealing technology, the right material isn’t just an option—it’s the standard.

Material Specifications

Material Specifications for Precision Rubber Seals

Selecting the optimal elastomer for precision sealing applications requires rigorous analysis of operational parameters including temperature extremes, chemical exposure, pressure differentials, and regulatory compliance. At Suzhou Baoshida Trading Co., Ltd., we engineer compounds to meet exacting OEM specifications, prioritizing long-term sealing integrity under dynamic service conditions. Below we detail three critical materials—Viton®, Nitrile (NBR), and Silicone—focusing on quantifiable performance metrics essential for industrial validation.

Viton® (FKM) fluorocarbon rubber delivers exceptional resistance to aggressive chemicals, fuels, and high temperatures. Formulated to ASTM D2000 classification AA, its molecular structure provides minimal swell in aromatic hydrocarbons, acids, and chlorinated solvents. Continuous service is validated from -20°C to 230°C, with short-term excursions up to 300°C. Critical applications include aerospace fuel systems and semiconductor manufacturing where outgassing must remain below 0.1% per ASTM E595. Compression set values consistently achieve ≤15% after 70 hours at 200°C (ASTM D395 Method B), ensuring reliable seal force retention.

Nitrile rubber (NBR) remains the industry standard for cost-effective resistance to petroleum-based fluids and hydraulic oils. Our precision compounds adhere to ASTM D2000 BA/B4/B14/B32 specifications, with acrylonitrile content tailored between 34%–45% to balance fuel resistance and low-temperature flexibility. Operational limits span -40°C to 120°C, with specialized grades extending to 150°C. NBR exhibits ≤35% volume swell in ASTM No. 3 oil (ASTM D471) and tensile strength of 20–30 MPa (ISO 37). Its dominance in automotive transmission seals stems from predictable wear characteristics and compatibility with automatic transmission fluids.

Silicone (VMQ) excels in applications demanding wide-temperature resilience and biocompatibility. Our medical-grade and food-safe formulations comply with USP Class VI, ISO 10993, and FDA 21 CFR 177.2600. Serviceable from -60°C to 200°C, silicone maintains elasticity where other elastomers harden or degrade. Critical for pharmaceutical and food processing seals, it achieves ≤20% compression set at 150°C (70 hours) and exhibits negligible extractables. While vulnerable to concentrated acids and steam sterilization cycles exceeding 135°C, its electrical insulation properties (≥10¹⁴ Ω·cm volume resistivity) make it indispensable for medical device housings.

Material selection must align with fluid compatibility charts and dynamic stress modeling. The following comparative table summarizes key specifications for engineering validation:

| Property | Viton® (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| ASTM D2000 Reference | AA | BA/B4/B14/B32 | AA |

| Hardness Range (Shore A) | 60–90 | 50–90 | 30–80 |

| Temp Range (°C) | -20 to 230 | -40 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 10–20 | 20–30 | 5–10 |

| Compression Set (70h) | ≤15% @ 200°C | ≤25% @ 100°C | ≤20% @ 150°C |

| Key Resistance | Acids, fuels, ozone | Petroleum oils, water | Extreme temps, steam |

| Critical Limitation | Poor ketone resistance | Limited heat resistance | Low tear strength |

Material performance is non-negotiable in critical sealing systems. Suzhou Baoshida Trading Co., Ltd. provides certified test data per ISO 188, ASTM D2000, and OEM-specific protocols to validate compound suitability. Engage our engineering team early in the design phase to optimize material selection against your operational envelope—preventing field failures through precision formulation.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering foundation is built on deep technical expertise in rubber formulation and precision mold design, enabling us to deliver high-performance sealing solutions tailored to the demanding requirements of industrial and automotive OEMs. Our core team comprises five dedicated mold engineers and two specialized rubber formula engineers, working in tandem to ensure every component meets exacting performance, durability, and dimensional accuracy standards. This integrated approach allows us to control the entire development cycle—from material selection and compound optimization to mold design and final prototyping—ensuring seamless scalability into high-volume production.

Our mold engineers utilize advanced CAD/CAM systems, including SolidWorks, AutoCAD, and UG NX, to develop precision tooling for complex rubber seals. Each mold is designed with strict attention to parting lines, gate placement, venting, and shrinkage compensation, critical for achieving consistent repeatability and zero-defect manufacturing. Finite element analysis (FEA) is routinely applied to simulate mold flow and curing behavior, reducing trial iterations and accelerating time-to-market. With experience across multi-cavity, family, and insert molds, we support low-volume custom runs as well as large-scale OEM production programs.

Complementing our mold expertise, our two in-house rubber formula engineers bring over 15 years of combined experience in polymer chemistry and elastomer compounding. They specialize in developing custom formulations for extreme environments—resisting high temperatures, aggressive fluids, compression set, and dynamic stress. We routinely formulate and validate compounds in NR, NBR, EPDM, FKM, VMQ, ACM, and specialty blends, ensuring optimal balance between mechanical properties, processability, and cost efficiency. All formulations are tested in our on-site lab using ASTM and ISO-compliant methods for tensile strength, elongation, hardness, compression set, and fluid resistance.

We operate as a full-service OEM partner, providing end-to-end engineering support from initial concept to serial supply. Our customers benefit from design for manufacturability (DFM) reviews, rapid prototyping, PPAP documentation, and full traceability through ERP-integrated production tracking. This capability is reinforced by our ISO 9001-certified quality management system and ongoing collaboration with material suppliers and end-users to stay ahead of industry trends.

The table below outlines key technical parameters supported by our engineering team:

| Parameter | Capability |

|---|---|

| Mold Design Software | SolidWorks, AutoCAD, UG NX, Moldflow |

| Rubber Compounding Range | Shore A 30 to 90 hardness |

| Standard Elastomers | NBR, EPDM, FKM, NR, VMQ, ACM, CR, IIR |

| Custom Formulations | Oil-resistant, heat-resistant, low-temperature, flame-retardant, conductive |

| Tooling Lead Time | 15–25 days (depending on complexity) |

| Prototype Turnaround | 7–10 days after mold completion |

| OEM Documentation Support | Full PPAP, IMDS, RoHS, REACH compliance |

| Production Scaling | Pilot runs to annual volumes exceeding 1 million units |

By combining advanced tooling engineering with deep materials science, Suzhou Baoshida delivers technically robust, application-specific rubber seals that meet the highest standards of performance and reliability.

Customization Process

Precision Rubber Seal Customization Process: From Concept to Volume Production

At Suzhou Baoshida Trading Co., Ltd., our customization process for precision rubber seals integrates scientific rigor with industrial scalability to meet the exacting demands of OEMs like Rubber & Gasket Company of America. This structured workflow ensures dimensional accuracy, material compatibility, and functional reliability across aerospace, automotive, and industrial applications.

Drawing Analysis

The process initiates with comprehensive drawing validation. Our engineering team scrutinizes CAD files or technical sketches per ASME Y14.5 standards, verifying critical dimensions, geometric tolerances, and surface finish requirements. We cross-reference material specifications against environmental factors such as fluid exposure, temperature extremes, and compression set limits. Any ambiguities in callouts—like undefined draft angles or undercuts—are resolved collaboratively with the client to prevent tooling deviations. This phase establishes the foundation for manufacturability and compliance with ISO 3601 or SAE AS568 standards.

Formulation Development

Based on the validated drawing, our rubber chemists engineer bespoke elastomer compounds. We select base polymers (e.g., FKM, EPDM, or HNBR) and optimize filler systems, curatives, and additives to achieve target properties. Key considerations include resistance to specific chemicals (e.g., jet fuel or hydraulic fluid), operating temperature ranges, and dynamic sealing forces. Each formulation undergoes predictive modeling for cure kinetics and compression set using Mooney Viscometry and RPA data, ensuring the compound meets ASTM D2000 classification codes without over-engineering cost.

Prototyping and Validation

Rapid prototyping follows via precision CNC-machined molds or 3D-printed tooling, producing 5–10 samples for rigorous testing. Samples undergo dimensional inspection via CMM, followed by functional validation:

Fluid immersion per ASTM D471

Compression set testing at elevated temperatures (ASTM D395)

Dynamic seal performance in simulated operational cycles

Client feedback on prototype performance triggers iterative refinements until all KPIs are satisfied. This phase typically reduces time-to-qualification by 30% compared to conventional approaches.

Mass Production

Upon prototype approval, we transition to high-volume manufacturing using steel cavity molds with ±0.05 mm tolerances. Production adheres to IATF 16949 protocols, with real-time process monitoring of injection pressure, cure time, and post-cure parameters. Every batch undergoes first-article inspection and statistical process control (SPC), with full traceability from raw material lot to finished part. Final validation includes PPAP Level 3 documentation and accelerated life testing to guarantee 10+ years of service integrity.

Key Elastomer Properties for Seal Applications

| Material | Temperature Range (°C) | Fluid Resistance | Typical Hardness (Shore A) | Primary Applications |

|---|---|---|---|---|

| NBR | -30 to +105 | Oils, fuels | 50–90 | Automotive hydraulic systems |

| FKM | -20 to +230 | Jet fuel, acids | 60–80 | Aerospace fuel seals |

| EPDM | -50 to +150 | Water, steam | 40–90 | HVAC thermal seals |

| HNBR | -40 to +170 | Ozone, coolants | 50–85 | Industrial pump shafts |

This end-to-end process minimizes risk while delivering seals that exceed OEM performance benchmarks. Suzhou Baoshida’s commitment to material science precision and scalable manufacturing ensures Rubber & Gasket Company of America receives defect-free, application-optimized components on schedule.

Contact Engineering Team

For mission-critical sealing applications in aerospace, automotive, industrial machinery, and medical device manufacturing, precision matters. At Suzhou Baoshida Trading Co., Ltd., we specialize in the development and production of high-performance rubber seals and gaskets engineered to meet the most stringent OEM requirements. Our expertise spans material formulation, mold design, compression and injection molding, and rigorous quality control—ensuring every component meets exact dimensional, chemical, and thermal specifications.

Our precision rubber seals are manufactured using advanced elastomeric compounds including NBR, EPDM, FKM (Viton®), silicone, and specialty blends tailored for extreme environments. Whether you require low-temperature flexibility, resistance to aggressive fluids, or long-term compression set performance, our engineering team collaborates directly with clients to select the optimal material and design for your application. With in-house tooling capabilities and ISO 9001-certified processes, we deliver consistent quality across prototyping, low-volume validation, and high-volume production runs.

We understand that reliability in sealing technology directly impacts system safety, efficiency, and longevity. That is why every product leaving our facility undergoes comprehensive testing, including dimensional inspection, hardness verification, tensile strength analysis, and environmental exposure simulation. Our traceability systems ensure full documentation from raw material sourcing to final shipment, supporting compliance with AS9100, IATF 16949, and other industry-specific standards.

To support global partners effectively, Suzhou Baoshida maintains a responsive technical sales and engineering support team. We provide detailed technical data packages, material certifications, and design for manufacturability (DFM) feedback to accelerate your product development cycle. Our logistics network ensures on-time delivery to North America, Europe, and Asia, with flexible packaging and labeling options to meet your supply chain needs.

If your operation demands sealing solutions built with scientific rigor, industrial precision, and unwavering consistency, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. He will connect you with the right engineering resources, provide material samples, and assist in qualifying our seals for integration into your production systems.

Below is a representative specification profile for a commonly requested precision rubber seal:

| Property | Value / Description |

|---|---|

| Material | FKM 70 Durometer |

| Hardness (Shore A) | 70 ± 5 |

| Tensile Strength | ≥15 MPa |

| Elongation at Break | ≥180% |

| Compression Set (70 hrs, 150°C) | ≤20% |

| Operating Temperature Range | -20°C to +200°C (intermittent to 250°C) |

| Fluid Resistance | Excellent against oils, fuels, acids |

| Standards Compliance | ASTM D2000, ISO 3601, FDA (optional) |

| Manufacturing Process | Injection Molding |

| Lead Time (Production) | 15–25 days after sample approval |

To initiate a technical consultation or request a quote, contact Mr. Boyce directly at [email protected]. Include your application requirements, performance environment, and preferred materials for a tailored response. Suzhou Baoshida is committed to being your trusted partner in precision rubber sealing technology.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).