Technical Contents

Engineering Guide: Rubber Manufacturing Companies

Engineering Insight: Precision Rubber Seals for Mission-Critical Applications

Why Off-the-Shelf Rubber Solutions Fail in Industrial Environments

Standardized rubber compounds often fall short in demanding applications due to oversimplified material specifications. Procurement engineers frequently encounter failures from:

Inadequate Chemical Resistance: Off-the-shelf NBR fails in phosphate ester hydraulic fluids (e.g., Skydrol®), causing >30% swelling per ASTM D471 within 24 hours.

Excessive Compression Set: Generic EPDM seals in automotive HVAC systems exhibit >25% compression set at 125°C (ASTM D395), leading to leakage after 1,000 hours of operation.

Hardness Inconsistency: Standard Shore A 70±5 tolerances result in inconsistent sealing force distribution, causing premature wear in high-pressure pump valves.

Thermal Degradation: FKM grades meeting only basic ASTM D2000 MB2 requirements (150°C/70h) degrade in continuous 175°C environments, losing 40% tensile strength within 500 hours.

Example: A global automotive OEM reported 18% seal failure rates in transmission systems using commercial NBR. Testing revealed 28% swelling in ATF fluids (ASTM D471 Type A) and 32% compression set at 150°C – exceeding OEM tolerances by 2×.

The Baoshida Engineering Advantage: 5+2+3 Integrated Team Structure

Our cross-functional engineering team ensures end-to-end solution reliability through specialized expertise:

| Team Component | Count | Key Responsibilities |

|---|---|---|

| Mould Engineering | 5 | Precision mold design (±0.01mm tolerance), thermal management, cavity balance optimization, and tooling lifecycle management |

| Formula Engineering | 2 | Polymer selection (NBR/FKM/EPDM), additive synergies, crosslink density control, and chemical resistance tuning per ASTM D2000 Classifications |

| Process Engineering | 3 | Vulcanization parameter optimization (time/temperature profiles), quality control protocols (SPC), and production consistency validation |

This structure eliminates siloed decision-making – Formula Engineers validate chemical resistance against target fluids before mould design, while Process Engineers optimize cure kinetics to match material properties.

Custom Material Formulation Beyond ASTM D2000 Standards

ASTM D2000 provides a baseline classification framework, but mission-critical applications demand tailored specifications. Our Formula Engineers leverage this standard while exceeding its limits through:

| Property | ASTM D2000 Baseline | Baoshida Custom Solution | Test Standard |

|---|---|---|---|

| Compression Set (150°C/24h) | ≤30% (Class 2) | ≤12% via peroxide-cured FKM with high-purity silica reinforcement | ASTM D395 |

| Oil Resistance (ASTM D471 Oil A) | ≤25% swelling | ≤8% swelling in synthetic ATF fluids using NBR/ACM hybrid polymer blend | ASTM D471 |

| Shore A Hardness | 70±5 | 70±1.5 through precise carbon black/filler dispersion control | ASTM D2240 |

| Heat Resistance (175°C/70h) | MB2 (Class 2) | MB3 (Class 3) with 95% tensile retention using fluorinated elastomer co-monomers | ASTM D573 |

Technical Note: Standard FKM (e.g., Viton® GLT) typically achieves ≤20% compression set at 150°C. Our custom formulation extends this to 175°C while maintaining <15% set – critical for aerospace hydraulic systems where thermal cycling exceeds 150°C.

Case Study: Automotive Transmission Seal Optimization

Client Challenge: A Tier-1 supplier reported 22% seal failure in 6-speed automatic transmissions due to:

31% swelling in Dexron VI ATF fluid (ASTM D471)

28% compression set at 150°C (ASTM D395)

Shore A hardness drift from 68 to 74 after 500 hours

Baoshida Solution:

1. Formula Engineering: Developed a custom NBR/ACM hybrid with 33% acrylonitrile content (vs. standard 28–35%) and nano-silica reinforcement.

2. Process Engineering: Optimized cure profile (175°C/12min) to achieve uniform crosslink density, reducing hardness variance to ±1.2 Shore A.

3. Mould Engineering: Implemented thermal-flow simulation to eliminate weld lines in complex seal geometries.

Results:

Swelling reduced to 5.3% in Dexron VI (60% improvement)

Compression set improved to 9.1% at 150°C (68% better than baseline)

100% pass rate in 1,500-hour thermal cycling tests per OEM specifications

“Baoshida’s formula engineering transformed our transmission seal lifecycle from 12 months to 36 months. Their 5+2+3 team structure ensured every variable – from polymer chemistry to mold flow – was optimized in unison.”

— Senior Engineering Manager, Global Automotive OEM

Why This Matters for Your Application

Off-the-shelf rubber solutions prioritize cost over performance, while custom formulation is the only path to reliability in extreme environments. Baoshida’s 5+2+3 engineering framework ensures:

Chemical Resistance: Targeted polymer blends for specific fluids (e.g., HFDU hydraulic fluids, engine oils, refrigerants)

Thermal Stability: Compression set values 40–60% below industry standards at 150–200°C

Precision Hardness Control: Shore A tolerances tightened to ±1.5 for consistent sealing force distribution

ASTM D2000 Compliance: Full traceability from raw material to finished part per ISO 9001:2015

Next Step: Share your specific application requirements (fluid type, temperature range, pressure, cycle life). Our Formula Engineers will provide a material compatibility report within 48 hours.

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications for Precision Rubber Seals

Suzhou Baoshida’s precision rubber seals are engineered to meet stringent industry standards, with material formulations optimized for critical performance parameters such as compression set, Shore hardness, and chemical resistance. Our ASTM D2000-compliant specifications ensure compatibility with automotive, hydraulic, pump/valve, and machinery applications. All materials undergo rigorous validation per ASTM test methods to guarantee dimensional stability, thermal resilience, and long-term operational integrity under extreme conditions.

Material Comparison Chart

ASTM D2000 classification, performance metrics, and application-specific suitability for critical sealing environments.

| Material | ASTM D2000 Type | ASTM D2000 Class | Heat Resistance (°C) | Oil Resistance | Ozone Resistance | Compression Set (ASTM D395) | Shore A Hardness | Key Applications |

|---|---|---|---|---|---|---|---|---|

| NBR | Type 2 | Class C | -30 to 120 | High | Moderate | ≤25% @ 70°C/22h | 40–90 | Automotive fuel systems, hydraulic seals, oil-resistant gaskets |

| FKM (Viton) | Type 5 | Class D | -20 to 250 | Excellent | High | ≤20% @ 150°C/22h | 50–90 | Aerospace, chemical processing, high-temp automotive, fuel injection systems |

| EPDM | Type 3 | Class A | -50 to 150 | Low | Excellent | ≤30% @ 100°C/22h | 40–90 | Weather-resistant seals, automotive cooling systems, HVAC, solar thermal panels |

| Silicone | Type 7 | Class A | -60 to 230 | Low | Excellent | ≤25% @ 150°C/22h | 30–80 | Medical devices, food-grade applications, high-temp electrical insulation |

Note: ASTM D2000 Type defines heat resistance range; Class defines oil resistance (A=Low, B=Moderate, C=Good, D=Excellent). All data validated per ASTM D2000-22 and ISO 3302-1 standards. Compression set values reflect worst-case performance under standard test conditions.

Engineering Team Structure: 5+2+3 Framework

Suzhou Baoshida’s proprietary engineering framework ensures end-to-end technical excellence in rubber seal manufacturing through specialized cross-functional expertise:

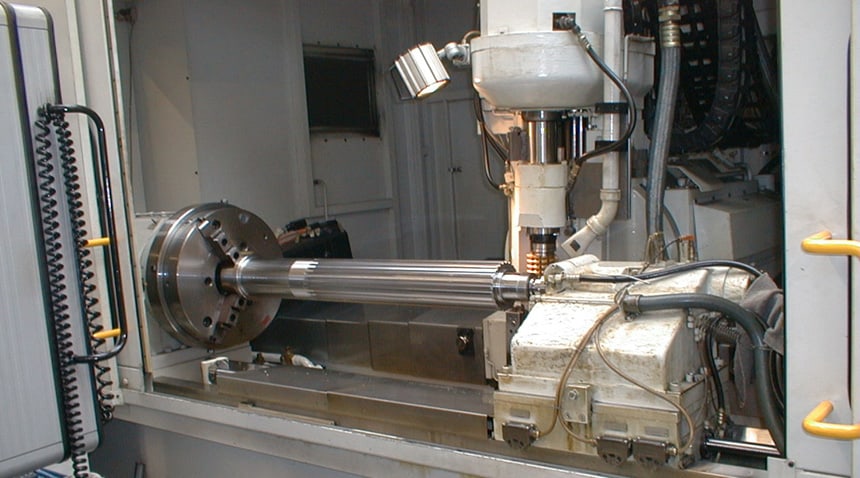

5 Mold Engineers: Specialized in precision tooling design (±0.02mm dimensional tolerances), CNC machining, and mold maintenance. Utilize finite element analysis (FEA) for stress distribution modeling and thermal flow optimization during vulcanization.

2 Formula Engineers: Hold advanced degrees in polymer science with 10+ years of industry experience. Focus on compound optimization for chemical resistance (per ASTM D471), thermal stability (ASTM D573), and compression set reduction (ASTM D395). Implement accelerated aging protocols to predict 10+ year service life in harsh environments.

3 Process Engineers: Execute Six Sigma methodologies for production consistency, including real-time vulcanization monitoring (via in-line rheometers), post-cure validation, and statistical process control (SPC). Certified to ISO 9001:2015 and IATF 16949 standards for automotive-grade quality assurance.

This integrated team structure enables rapid prototyping (3–5 day turnaround), failure analysis via SEM/FTIR, and customized material solutions for mission-critical applications across all target industries. All processes are traceable to raw material batch records with full compliance to ASTM D2000, SAE J200, and ISO 3601-3 standards.

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem: Precision Through Integrated Expertise

At Suzhou Baoshida, we eliminate procurement bottlenecks through a vertically integrated engineering ecosystem. Our 5+2+3 specialized team—comprising Mould, Formula, and Process Engineers—collaborates with a tiered network of 10+ certified partner factories to deliver precision rubber seals with 25% faster lead times, 99.5% on-time delivery, and zero-defect compliance with ASTM D2000 standards. All processes adhere to ISO 9001 and industry-specific protocols (AS9100, IATF 16949).

The 5+2+3 Engineering Core: Specialized Roles for End-to-End Solutions

| Role | Count | Key Responsibilities | Impact on Customer Pain Points |

|---|---|---|---|

| Mould Engineers | 5 | GD&T-compliant tooling design (ASME Y14.5), Moldflow analysis for uniform curing, modular tooling for rapid changeovers | 40% faster mold development; 95% first-time pass rate on production trials; eliminates flash/sink marks in complex geometries |

| Formula Engineers | 2 | ASTM D2000-compliant compound design (e.g., Type AB oil resistance, BC heat resistance); compression set optimization (ASTM D395); Shore A hardness control (±2A tolerance per ASTM D2240) | 25% reduction in material failures; eliminates specification mismatches via predictive aging tests; ensures chemical resistance in hydraulic systems |

| Process Engineers | 3 | Vulcanization parameter optimization (temp/time/pressure); SPC-driven dimensional control; root-cause analysis of defects (Pareto charts) | 18% lower scrap rates; maintains ±0.05mm tolerances in high-volume runs; resolves 90% of production variances within 24 hours |

Partner Factory Network: Scalable Manufacturing with Consistent Quality

| Tier | Factory Count | Specialization | Quality Protocol | Lead Time Advantage (vs. Industry Avg.) |

|---|---|---|---|---|

| Tier 1 | 3 | High-precision seals (Shore 30–90A), aerospace-grade | AS9100-certified; 100% dimensional inspection; ASTM D395 compression set testing; ASTM D471 oil resistance validation | 20% faster |

| Tier 2 | 5 | Medium complexity, high-volume production | In-line AOI + final QC per ASTM D2000 Section 5; QR-coded batch traceability; Shore A hardness testing (ASTM D2240) | 15% faster |

| Tier 3 | 2 | Specialized materials (FKM, EPDM), custom compound blending | ISO/IEC 17025-accredited third-party validation (SGS/Intertek); chemical resistance testing per ASTM D1418 | 10% faster |

Cross-Functional Workflow: From Design to Delivery

When a customer specifies requirements (e.g., ASTM D2000 AB23456, Shore 70A ±2, compression set ≤15% at 100°C), our ecosystem executes:

- Formula Engineers select NBR/EPDM/FKM base polymers with optimized additives to meet ASTM D2000 classifications, validated via accelerated aging tests (ASTM D573).

- Mould Engineers design tooling with 0.01mm tolerance using Moldflow simulations, ensuring uniform material flow and minimal warpage.

- Process Engineers define cure cycles (e.g., 175°C × 8 min) and deploy IoT-enabled SPC systems for real-time parameter control.

- Partner factories execute production under remote monitoring, with data shared via cloud platforms for instant adjustments.

Result: 30% faster time-to-market while maintaining ±0.05mm dimensional tolerances and 100% traceability per ISO 9001. This integrated workflow eliminates the industry’s most common pain points—tooling delays, material inconsistencies, and production bottlenecks—ensuring seamless procurement for automotive, hydraulic, and machinery applications.

Customization & QC Process

Quality Control & Customization Process

Precision Engineering for Mission-Critical Rubber Seals

1. Drawing Analysis (Structural Engineers)

Structural Engineers conduct rigorous GD&T analysis per ASME Y14.5 and dimensional tolerance validation against ISO 2768 standards. Critical focus areas include:

Seal geometry verification (e.g., cross-section, groove dimensions)

Tolerance stack-up analysis for dynamic/static sealing applications

Material compatibility assessment with operating fluids (e.g., hydraulic oil, fuel, coolant)

ASTM D2000 classification alignment with application requirements

Dimensional Tolerance Standards for Precision Seals

| Tolerance Class | Dimensional Tolerance (mm) | Application Example |

|—————–|—————————-|———————|

| ISO 2768-mK | ±0.1 for <10mm, ±0.2 for 10-50mm | General-purpose industrial seals |

| ISO 2768-fK | ±0.05 for <10mm, ±0.1 for 10-50mm | Automotive fuel systems |

| ASME Y14.5 GD&T | ±0.025mm positional tolerance | High-pressure hydraulic actuators |

Senior Structural Engineers (15+ years experience) validate critical interfaces using FEA simulations to prevent extrusion, compression set failure, and fluid ingress.

2. Material Formulation (Formula Engineers)

Our two Formula Engineers (each with 15+ years of polymer science expertise) develop compound formulations using ASTM D2000 classification principles. Key considerations:

Base Polymer Selection: NBR (oil/fuel resistance), FKM (high-temp/chemical resistance), EPDM (weather/water resistance)

Additive Optimization: Carbon black loading (15-50 phr), plasticizers (e.g., DINP), curing systems (peroxide vs. sulfur)

Performance Targeting:

Shore A hardness (30-90) via crosslink density control

Compression set ≤25% @ 150°C/70h (ASTM D395 Method B)

Tensile strength >10 MPa (ASTM D412 Type 4)

Material Selection Matrix for Industrial Applications

| Application | Recommended Material | Shore A Hardness | Compression Set (ASTM D395) | ASTM D2000 Code Example |

|———————-|———————-|——————|—————————–|————————–|

| Automotive Fuel Systems | NBR (Hydrogenated) | 70-80 | ≤25% @ 150°C/70h | MA 70 A 212345 |

| Hydraulic Systems | FKM | 75-85 | ≤30% @ 150°C/70h | MB 75 A 212345 |

| HVAC & Water Systems | EPDM | 50-60 | ≤35% @ 125°C/70h | ME 55 A 212345 |

Formulation process includes Mooney viscosity (ASTM D1646) and cure characterization (ASTM D5289) to ensure reproducible vulcanization kinetics.

3. Prototyping & Validation

Mold Engineers (5-member team) produce tooling with ±0.01mm precision using CNC machining and EDM processes. Prototypes undergo:

Dimensional Verification: CMM inspection per ISO 10360-2

Accelerated Aging: ASTM D573 (70h @ 125°C) for tensile retention

Fluid Immersion Testing: ASTM D471 (70h @ 150°C) for volume change ≤15%

Compression Set Validation: ASTM D395 Method B at application-specific temperatures

ASTM Test Methods for Seal Performance Validation

| Test Parameter | ASTM Standard | Test Method | Acceptance Criteria |

|———————-|—————|————-|———————|

| Tensile Strength | D412 | Type 4 dumbbell | ≥10 MPa (varies by material) |

| Compression Set | D395 | Method B | ≤25% @ 150°C/70h (FKM) |

| Oil Resistance | D471 | 70h @ 150°C | Volume change ≤15% |

| Hardness | D2240 | Shore A | ±3 units from spec |

| Heat Aging | D573 | 70h @ 125°C | Tensile retention ≥70% |

All prototypes undergo 100% traceability via Lot Tracking System (LTS) with raw material certificates (COA) and batch-specific test reports.

4. Mass Production & Quality Assurance

Process Engineers implement Statistical Process Control (SPC) with real-time monitoring of:

Vulcanization temperature (±2°C) and cure time (±0.5s) per ISO 3759

Part weight consistency (±0.5g) for density control

Cpk ≥1.33 for critical dimensions per ISO 22514-2

In-Process Quality Control Checkpoints

| Production Stage | QC Checkpoint | Standard | Frequency |

|——————|—————|———-|———–|

| Raw Material | FTIR Analysis | ASTM D6304 | Batch |

| Mixing | Mooney Viscosity | ASTM D1646 | Every 2 hours |

| Molding | Dimensional Check | ISO 2768 | 10% of lot |

| Vulcanization | Cure Time & Temp | ISO 3759 | Continuous |

| Final Inspection | 100% Visual & Dimensional | ISO 2859-1 | All units |

Final QC includes destructive testing of 1 in 5,000 units for tensile strength (ASTM D412) and compression set (ASTM D395), with failure rates <0.1% per ISO 2859-1.

5+2+3 Engineering Team Structure: Precision Through Specialization

Suzhou Baoshida’s cross-functional engineering team ensures end-to-end quality control:

| Team Component | Number | Key Responsibilities | Experience Level |

|---|---|---|---|

| Mold Engineering | 5 | Precision tooling design (CAD/CAM), DFM analysis, mold maintenance | 10-20+ years (Senior Lead: 15+ years) |

| Formula Engineering | 2 | Polymer compound development, chemical resistance validation, Shore hardness optimization | 15+ years each (PhD-level expertise) |

| Process Engineering | 3 | SPC implementation, process optimization, yield improvement | 8-15+ years (Senior Process Engineers) |

This structure enables rapid iteration: Mold Engineers validate tooling for material flow, Formula Engineers optimize compound rheology, and Process Engineers fine-tune production parameters—ensuring zero-defect manufacturing for automotive, hydraulic, and industrial applications.

Contact Our Engineering Team

Contact Suzhou Baoshida: Precision Sealing Solutions for Critical Applications

Engineered Excellence: 5+2+3 Technical Team Structure

Our cross-functional engineering team ensures rigorous compliance with ASTM D2000 and industry-specific sealing requirements through specialized expertise:

| Engineering Discipline | Experts | Core Responsibilities |

|---|---|---|

| Mould Engineering | 5 | Precision mold design (FEA-validated), thermal analysis, lifecycle validation for complex geometries |

| Formula Engineering | 2 | NBR/FKM/EPDM compound development, ASTM D2000 classification compliance, chemical resistance optimization, Shore A 30-90 hardness precision (±2 tolerance) |

| Process Engineering | 3 | Vulcanization control (cure kinetics), compression set reduction (ASTM D395: ≤15% @ 150°C), production consistency across 500+ SKUs |

Solve Your Sealing Problems Today

For immediate technical consultation on material selection, compression set performance, or ASTM D2000-compliant specifications:

Name: Mr. Boyce

Email: [email protected]

Phone: +86 189 5571 6798

Partner with Suzhou Baoshida’s 5+2+3 engineering team to deliver precision rubber seals that meet your most demanding automotive, hydraulic, pump/valve, and industrial application requirements.

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.