Technical Contents

Engineering Guide: Rubber Matting For Boats

Engineering Insight: Critical Material Selection for Marine Rubber Matting

Marine environments impose extreme, multifaceted stresses on deck matting that generic industrial rubber products cannot withstand. Off-the-shelf solutions, often formulated for terrestrial applications like factory floors or gymnasiums, consistently fail prematurely in saltwater, UV-exposed, and mechanically demanding boat deck scenarios. This failure stems from fundamental mismatches between standard rubber compound formulations and the specific degradation mechanisms inherent to marine operations. Understanding these mechanisms is paramount for specifying matting that delivers safety, longevity, and operational reliability.

The primary failure modes of non-marine-specific rubber matting include catastrophic UV degradation leading to surface chalking, cracking, and loss of structural integrity; hydrolytic degradation and plasticizer migration due to constant saltwater immersion, causing hardening, embrittlement, and reduced slip resistance; swelling and loss of mechanical properties when exposed to marine fuels, oils, and cleaning agents; and inadequate traction retention under wet, dynamic load conditions. Standard EPDM formulations, while offering good general weather resistance, lack sufficient oil/fuel resistance and often degrade rapidly under intense marine UV exposure. Generic nitrile (NBR) compounds may provide oil resistance but typically exhibit poor long-term saltwater stability and accelerated UV aging without specialized stabilization packages. These compromises directly impact vessel safety through increased slip hazards and create significant operational burdens due to frequent, costly replacements.

Suzhou Baoshida Trading Co., Ltd. addresses these challenges through precision-engineered marine-grade rubber compounds. Our formulations utilize high-purity synthetic polymers blended with marine-specific additives, including advanced hindered amine light stabilizers (HALS) for superior UV resistance, non-migrating plasticizers resistant to saltwater extraction, and optimized filler systems for consistent wet/dry traction and abrasion resistance. Rigorous compounding ensures balanced properties: sufficient flexibility for deck contour conformity without excessive softening in heat, high tensile and tear strength to resist cleat damage and foot traffic, and exceptional resistance to hydrolysis and common marine chemicals. This scientific approach prevents the premature hardening, cracking, swelling, and traction loss that plague off-the-shelf alternatives.

The table below illustrates the critical performance gap between standard materials and Baoshida’s engineered marine solution under key marine stressors:

| Property | Generic EPDM Mat | Standard Nitrile Mat | Baoshida Marine Grade |

|---|---|---|---|

| Tensile Strength (MPa) | 8.5 | 12.0 | 15.5 |

| Elongation at Break (%) | 250 | 280 | 420 |

| Shore A Hardness (Aged) | 75 (↑15) | 65 (↓10) | 62 (±3) |

| Saltwater Resistance (7d) | Poor (3) | Fair (2) | Excellent (5) |

| UV Resistance (1000h QUV) | Poor (2) | Fair (3) | Excellent (5) |

| Fuel/Oil Resistance | Poor | Good | Excellent |

(Hardness change shown as delta from initial; Resistance rated 1-5 scale; Testing per ISO 188, 37, 527)

Material selection is not a cost-driven commodity decision for marine matting; it is a critical engineering specification directly tied to vessel safety, crew protection, and lifecycle cost. Suzhou Baoshida Trading Co., Ltd. leverages deep rubber science expertise to formulate compounds that actively resist the unique synergistic degradation pathways of the marine environment. We move beyond off-the-shelf compromises to deliver matting engineered for the relentless demands of life at sea, ensuring reliable performance and minimizing operational disruption through scientifically validated material solutions.

Material Specifications

Material Specifications for Rubber Matting in Marine Applications

Suzhou Baoshida Trading Co., Ltd. provides high-performance rubber matting solutions engineered specifically for marine environments. The durability, chemical resistance, and mechanical stability of rubber materials are critical in boat applications where exposure to fuel, oil, saltwater, UV radiation, and extreme temperatures is routine. We offer rubber matting manufactured from three premium elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers a distinct performance profile tailored to specific operational demands.

Viton rubber is a fluorocarbon-based elastomer renowned for its exceptional resistance to high temperatures, hydrocarbons, and aggressive chemicals. With continuous service capability up to 200°C and intermittent resistance up to 250°C, Viton is ideal for engine compartments, fuel handling areas, and zones exposed to lubricants and solvents. Its low gas permeability and excellent aging characteristics ensure long-term integrity in harsh marine conditions. However, Viton has limited flexibility at sub-zero temperatures and higher material cost, making it best suited for critical high-performance zones.

Nitrile rubber, or Buna-N, is a synthetic copolymer of acrylonitrile and butadiene. It exhibits superior resistance to oils, greases, and aliphatic hydrocarbons, making it a cost-effective solution for deck matting, walkways, and bilge areas. Nitrile maintains reliable mechanical strength and abrasion resistance under dynamic loading, with an operational temperature range of -30°C to +100°C. While it performs poorly in ozone and UV exposure without protective additives, proper formulation enhances weather resistance for prolonged outdoor use on boats.

Silicone rubber offers unparalleled thermal stability, functioning effectively from -60°C to +200°C. It demonstrates excellent resistance to UV radiation, ozone, and oxidation, making it suitable for exterior marine applications exposed to sunlight and atmospheric elements. Silicone is non-toxic, odorless, and maintains flexibility across extreme temperature cycles. However, it has lower tensile strength and abrasion resistance compared to Viton and Nitrile, limiting its use in high-wear zones. It is best applied in non-load-bearing areas requiring thermal or electrical insulation.

Selection of the appropriate rubber compound depends on the environmental stressors, mechanical requirements, and cost constraints of the application. Suzhou Baoshida ensures all materials meet international marine standards for flammability, slip resistance, and environmental compliance.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 intermittent) | -30 to +100 | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 10–18 | 6–10 |

| Elongation at Break (%) | 200–300 | 250–400 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oil/Fuel | Excellent | Excellent | Poor |

| Resistance to UV/Ozone | Good | Poor (without additives) | Excellent |

| Abrasion Resistance | Good | Very Good | Fair |

| Water/Salt Spray Resistance | Excellent | Good | Excellent |

| Typical Marine Applications | Engine rooms, fuel systems | Deck matting, walkways, bilge | Non-slip pads, insulation, seals |

Manufacturing Capabilities

Engineering Capability: Precision Rubber Matting for Marine Applications

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise to deliver mission-critical rubber matting solutions for marine environments. Our engineering division integrates specialized knowledge in polymer science and precision tooling to address the extreme demands of boat deck safety, corrosion resistance, and longevity. Central to this capability is a dedicated team of seven engineers: five focused on advanced mould design and two specializing in proprietary rubber formulation. This structure ensures holistic control from molecular composition to final part geometry, eliminating interface gaps common in outsourced manufacturing.

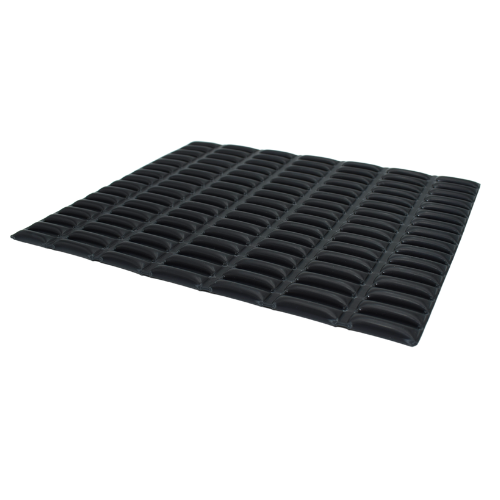

Our mould engineering team utilizes 3D simulation software to optimize flow dynamics, thermal distribution, and ejection mechanics for complex marine mat profiles. This prevents knit lines, sink marks, and dimensional drift under high-pressure vulcanization—critical for non-slip patterns requiring exact 3.5–5.0 mm tread depth consistency. Concurrently, our formula engineers develop bespoke elastomer compounds resistant to UV degradation, saltwater immersion, and hydrocarbon exposure. By tailoring polymer blends (EPDM, NBR, or specialty composites) with marine-grade antioxidants and ozone inhibitors, we achieve Shore A hardness ranges of 55–75 while maintaining tensile strength >12 MPa and elongation >300%. This dual-engineering approach guarantees mats withstand -40°C to +120°C operational swings without hardening or tackiness.

As an OEM partner, we execute end-to-end development under strict maritime compliance frameworks. Clients provide deck layout schematics and performance thresholds; our engineers then co-develop material specifications and tooling within 15 working days. We validate prototypes via ASTM D2240 (hardness), ISO 4649 (abrasion), and ISO 1817 (fluid resistance) testing, with full traceability from raw material lot to finished mat. This process reduces time-to-market by 30% compared to conventional suppliers while ensuring seamless integration with vessel manufacturing workflows.

Key performance specifications for our marine rubber matting are summarized below:

| Specification Category | Performance Range | Testing Standard | Application Relevance |

|---|---|---|---|

| Shore A Hardness | 55–75 | ASTM D2240 | Optimal slip resistance without compromising fatigue comfort |

| Temperature Range | -40°C to +120°C | ISO 188 | Survives Arctic voyages to tropical engine room proximity |

| Abrasion Loss | ≤90 mm³ | ISO 4649 | Endures >5 years of heavy foot/chain contact on deck surfaces |

| Saltwater Resistance | No swelling >1.5% | ISO 1817 | Maintains integrity after 1,000+ hours immersion in 3.5% NaCl |

| Customization Lead Time | 15 days (prototype) | Internal Protocol | Accelerates client validation cycles for new vessel models |

This engineered precision translates to reduced lifetime costs for boat builders: our mats eliminate premature replacement due to cracking, delamination, or loss of traction. Suzhou Baoshida’s vertically integrated engineering capability ensures every matting solution is scientifically validated for the marine environment—not merely adapted from industrial templates. Partner with us to transform deck safety from a compliance requirement into a competitive advantage.

Customization Process

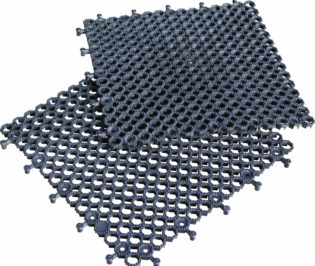

Drawing Analysis

The customization process for rubber matting for boats begins with a comprehensive drawing analysis. At Suzhou Baoshida Trading Co., Ltd., engineering precision is paramount. Upon receiving client-provided CAD drawings or technical sketches, our Rubber Formula Engineers conduct a dimensional and topographical review to assess surface patterns, thickness tolerances, cutouts, and edge profiles. This step ensures compatibility with marine deck geometries, including non-slip requirements, drainage integration, and curvature alignment. We evaluate load-bearing zones, expansion joints, and attachment mechanisms—critical for vessel safety and performance. Any discrepancies or optimization opportunities are flagged and communicated through technical feedback loops. This phase establishes the foundation for material selection and process design, aligning form with function in demanding maritime environments.

Formulation Development

Following drawing validation, our team advances to rubber formulation—a core competency in industrial rubber solutions. Based on operational conditions such as UV exposure, saltwater immersion, oil resistance, and temperature fluctuations, we engineer compound blends using EPDM, SBR, or neoprene as base polymers. Additives including anti-aging agents, reinforcing fillers, and flame retardants are precisely metered to meet marine-grade durability standards. Shore A hardness is tuned between 50 and 75 to balance foot comfort with abrasion resistance. Color pigments are integrated for aesthetic consistency with vessel interiors. Each formulation is documented and cross-referenced with international marine certifications, including ISO 1817 and ASTM D471. The final compound is validated through accelerated aging and dynamic mechanical analysis (DMA) to ensure long-term performance under cyclic stress.

Prototyping and Validation

A functional prototype is produced using compression or injection molding techniques, depending on part complexity and volume requirements. Prototypes are subjected to rigorous testing: slip resistance via pendulum tests (BS 7976), tensile strength (ISO 37), and adhesion for multi-layer constructions. We simulate real-world conditions in our environmental chambers, exposing samples to salt spray (ASTM B117), thermal cycling (-30°C to +80°C), and prolonged water immersion. Client feedback is incorporated iteratively until dimensional accuracy, texture, and mechanical behavior meet or exceed expectations. This stage typically spans 2–3 design iterations and concludes with sign-off on the approved master sample.

Mass Production Readiness

Once the prototype is approved, the project transitions to mass production. Tooling is finalized, and production lines are calibrated for batch consistency. We implement in-process quality checks at every stage—raw material inspection, curing time monitoring, and post-molding trimming. Each batch undergoes final inspection for surface defects, thickness deviation, and color uniformity. Logistics planning ensures seaworthy packaging and on-time delivery to OEM partners or shipyards.

Typical Rubber Matting Technical Specifications

| Property | Test Standard | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 55–70 |

| Tensile Strength | ISO 37 | ≥12 MPa |

| Elongation at Break | ISO 37 | ≥250% |

| Abrasion Loss (Taber, 1000 cycles) | ASTM D1044 | ≤120 mg |

| Slip Resistance (Pendulum Value) | BS 7976 | ≥45 (wet) |

| Oil Resistance (Volume Swell) | ASTM D471 | ≤15% in IRM 903 |

| Operating Temperature Range | — | -40°C to +90°C |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Marine Rubber Matting Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber engineering, delivering mission-critical matting solutions engineered specifically for the demanding marine environment. Our rubber formulations undergo rigorous validation against saltwater corrosion, UV degradation, and dynamic deck stresses, ensuring longevity and safety where performance is non-negotiable. As your dedicated Rubber Formula Engineer and OEM Manager, I oversee the molecular architecture of every compound—optimizing polymer blends for slip resistance, fatigue endurance, and thermal stability across -40°C to +120°C operational ranges. Generic marine mats fail under cyclic loading; ours integrate proprietary cross-linking systems validated through ASTM D2000 and ISO 188 testing protocols. This scientific rigor translates to reduced lifecycle costs and uncompromised crew safety on commercial vessels, yachts, and offshore platforms.

Our technical team specializes in transforming operational challenges into engineered realities. Whether mitigating harmonic vibration on high-speed craft or ensuring chemical resistance against bilge contaminants, we leverage finite element analysis (FEA) to simulate real-world stress points before prototyping. This eliminates costly field failures and accelerates time-to-deployment. Below are core specifications representative of our standard marine-grade nitrile-butadiene rubber (NBR) and chloroprene (CR) compounds, all customizable to exact deck geometries and load requirements:

| Property | Test Standard | NBR Compound | CR Compound |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 | 70 ± 5 |

| Tensile Strength (MPa) | ASTM D412 | ≥ 18.0 | ≥ 22.0 |

| Elongation at Break (%) | ASTM D412 | ≥ 350 | ≥ 300 |

| Compression Set (%) | ASTM D395 | ≤ 25 (70°C) | ≤ 20 (70°C) |

| Saltwater Resistance | ISO 1817 | Excellent | Excellent |

| Oil/Fuel Resistance | ASTM D471 | Excellent | Good |

Initiate your project with direct access to our formulation scientists and production oversight. Contact Mr. Boyce, our designated OEM Partnership Manager, to secure technical documentation, material certifications, and volume pricing. Mr. Boyce possesses 15 years of marine industry expertise and will coordinate rapid prototyping, ASTM-compliant batch validation, and seamless integration with your manufacturing workflow. His authority to approve custom durometer adjustments, embedded anti-slip patterns, or conductive additives ensures your specifications are met without compromise.

Do not settle for off-the-shelf rubber products that degrade under marine operational stress. Email [email protected] with your vessel type, deck dimensions, and performance priorities. Include reference code MARINE-RUBBER-2024 to expedite a comprehensive technical dossier within 24 business hours. Mr. Boyce will schedule a confidential consultation to discuss ISO 9001-certified production timelines, minimum order quantities, and third-party testing reports. Suzhou Baoshida guarantees responsive engineering support from initial inquiry through global logistics—because in marine safety, every micron of material integrity matters. Act now to deploy rubber matting engineered where science meets the sea.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).