Technical Contents

Engineering Guide: Rubber Patio Tile

Engineering Insight: Material Selection in Rubber Patio Tile Manufacturing

The performance and longevity of rubber patio tiles are fundamentally determined by material selection—a factor often underestimated in off-the-shelf consumer products. At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered rubber formulations tailored to environmental exposure, mechanical stress, and lifecycle demands. Standard patio tiles, typically produced with recycled rubber and generic binders, frequently exhibit premature degradation due to inadequate resistance to UV radiation, thermal cycling, and moisture ingress. These failures manifest as surface cracking, color fading, delamination, and loss of structural integrity within 12 to 24 months of installation.

Industrial-grade rubber patio tiles require a deliberate balance of elastomer composition, cross-link density, and additive integration. Natural rubber (NR) and styrene-butadiene rubber (SBR) are commonly used, but their susceptibility to ozone and UV degradation necessitates modification. Our formulations incorporate EPDM (ethylene propylene diene monomer) as a primary base polymer due to its superior weather resistance and thermal stability. EPDM maintains elasticity across a broad temperature range (–45°C to +135°C) and resists oxidation, making it ideal for outdoor applications subject to seasonal variation.

Additionally, the choice of curing system impacts long-term resilience. Conventional sulfur-cured systems may lead to reversion under sustained heat, whereas peroxide curing provides higher cross-link stability and improved compression set resistance. This technical distinction is rarely found in mass-market tiles but is critical for commercial or high-traffic installations.

Fillers and reinforcing agents also play a decisive role. While calcium carbonate and reclaimed carbon black are cost-effective, they reduce tensile strength and abrasion resistance. Our engineered compounds utilize high-structure carbon black (N330 grade) and silica co-filler systems to enhance wear performance and dynamic load support. UV stabilizers such as HALS (hindered amine light stabilizers) and antioxidant packages (e.g., TMQ and 6PPD) are integrated at precise concentrations to delay polymer chain scission.

Adhesion between recycled rubber granules and the matrix binder is another failure point in generic tiles. Poor interfacial bonding leads to granule loss and surface pitting. We address this through silane coupling agents and reactive polyurethane binders, ensuring cohesive strength and dimensional stability.

The table below outlines key material specifications differentiating industrial-grade rubber patio tiles from standard commercial variants.

| Property | Industrial-Grade Tile (Baoshida) | Standard Off-the-Shelf Tile |

|---|---|---|

| Base Polymer | EPDM/SBR Blend | Recycled SBR Only |

| Curing System | Peroxide-Cured | Sulfur-Cured |

| UV Stabilizers | HALS + UV-531 (2%) | None or Minimal |

| Reinforcing Filler | N330 Carbon Black + Silica | Calcium Carbonate |

| Binder Type | Reactive Polyurethane | Styrene-Based Adhesive |

| Temperature Range (°C) | –45 to +135 | –20 to +80 |

| Abrasion Loss (DIN 53516, mm³) | ≤ 90 | ≥ 180 |

| Tensile Strength (MPa) | ≥ 9.5 | ≤ 5.0 |

Material selection is not a cost-driven compromise—it is an engineering imperative. Off-the-shelf solutions fail because they prioritize short-term economics over material science. Our approach ensures durability, safety, and lifecycle value for industrial and commercial environments.

Material Specifications

Material Specifications for Industrial Rubber Patio Tiles

The selection of elastomer composition directly determines the performance lifecycle and environmental resilience of rubber patio tiles in commercial applications. At Suzhou Baoshida Trading Co., Ltd., we engineer formulations to withstand dynamic outdoor stressors including UV exposure, thermal cycling, chemical contact, and mechanical abrasion. Viton, Nitrile, and Silicone represent three critical material pathways, each engineered for specific operational parameters. Viton (FKM) leverages fluorine-carbon backbone stability for exceptional resistance to ozone, fuels, and high-temperature degradation, making it optimal for industrial zones with chemical exposure risks. Nitrile (NBR) balances cost efficiency with superior oil and grease resistance due to its acrylonitrile content, though its lower ozone tolerance necessitates protective additives for extended outdoor service. Silicone (VMQ) provides unmatched flexibility across extreme temperatures and inherent UV stability through its siloxane polymer structure, yet requires reinforcement for high-compression-load scenarios.

Critical performance metrics must be evaluated against project requirements. The following table details comparative specifications for standard formulations used in our patio tile production. All values reflect ASTM D2000-21 compliance with Grade M2BK610 per SAE J200 standards, validated through accelerated aging tests per ISO 188.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Shore A Hardness Range | 60–80 | 50–75 | 40–65 |

| Continuous Temp Range (°C) | -20 to +250 | -30 to +120 | -60 to +230 |

| Tensile Strength (MPa) | 12–18 | 15–22 | 6–10 |

| Elongation at Break (%) | 150–250 | 200–400 | 300–600 |

| Compression Set (70h/100°C) | ≤25% | ≤35% | ≤20% |

| Key Resistance Strengths | Fuels, acids, ozone | Oils, greases | UV, ozone, steam |

| Primary Limitation | Cost, low-temp flexibility | Poor ozone resistance | Low tear strength |

Material selection must align with site-specific environmental and mechanical demands. Viton is recommended for petrochemical facilities or airport tarmacs where hydrocarbon exposure occurs, despite its premium cost. Nitrile delivers optimal value for standard commercial patios with incidental oil contact, such as automotive showrooms or fleet parking areas, provided supplemental anti-ozonants are incorporated. Silicone is indispensable for regions with severe thermal fluctuations (e.g., alpine or arid climates) due to its consistent low-temperature flexibility and non-yellowing properties, though tile thickness must be increased to compensate for lower tensile strength.

Suzhou Baoshida Trading Co., Ltd. rigorously validates all formulations through real-world exposure trials at our Suzhou R&D facility. We emphasize that actual performance depends on compound formulation—including filler type, crosslink density, and additive packages—not merely base polymer selection. Clients should consult our engineering team for application-specific validation data, as patio tile failure often originates from misaligned material chemistry rather than manufacturing defects. This precision-driven approach ensures our rubber solutions meet the exacting durability standards demanded by industrial infrastructure projects.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber solutions, delivering engineered performance to global markets through precision formulation and advanced mold design. Our Engineering Capability division forms the technical backbone of our rubber patio tile manufacturing, integrating material science with mechanical design to produce durable, application-specific products that meet stringent OEM requirements.

At the core of our engineering strength are five dedicated mold engineers and two specialized rubber formula engineers. This technical team operates under a unified development framework, ensuring seamless integration between material composition and mold functionality. Our mold engineers possess extensive experience in designing complex, high-cycle steel and aluminum molds optimized for compression and injection molding processes. These designs emphasize dimensional accuracy, surface texture replication, and long-term durability under industrial production loads. Each mold is subjected to rigorous simulation and stress testing to ensure consistent tile formation, minimal flash, and optimal ejection performance.

Complementing this mechanical expertise, our two in-house rubber formula engineers specialize in elastomer chemistry, focusing on custom compound development for outdoor applications. They formulate rubber blends using SBR, EPDM, and recycled tire granulate, balancing hardness, UV resistance, compression set, and slip resistance. These formulations are tailored not only to meet ASTM and ISO performance benchmarks but also to align with specific client needs such as color stability, noise reduction, or frost resistance in extreme climates. Our lab conducts accelerated aging, tensile strength, and abrasion resistance tests to validate every compound before full-scale production.

Our OEM capabilities are built on this dual-engineering foundation. We support clients from concept to commercialization, offering full technical collaboration in both material selection and mold architecture. Whether scaling an existing design or developing a proprietary tile pattern with unique load-bearing or drainage characteristics, our team ensures technical feasibility, cost efficiency, and regulatory compliance. We maintain full documentation for all formulations and molds, enabling traceability and consistent replication across production batches.

The following table outlines key technical specifications achievable through our engineering integration:

| Parameter | Standard Range | Custom Capability |

|---|---|---|

| Shore A Hardness | 50–85 | Up to 95 with reinforced blends |

| Tensile Strength | ≥7 MPa | ≥12 MPa with high-strength EPDM |

| Elongation at Break | 200–400% | Up to 500% with modified SBR |

| Compression Set (70°C, 22h) | ≤25% | ≤15% with premium cross-linking |

| UV Resistance (ASTM G154) | Pass (1000h) | Pass (2000h) with stabilizer packs |

| Tile Dimension Tolerance | ±0.5 mm | ±0.3 mm with precision tooling |

| Mold Cycle Life | 100,000+ cycles | 500,000+ cycles with hardened steel |

This level of engineering control enables Suzhou Baoshida to deliver rubber patio tiles that are not only functionally robust but also fully aligned with OEM branding, performance targets, and environmental conditions. Our integrated approach ensures faster time-to-market, reduced development risk, and long-term product reliability.

Customization Process

Customization Process for Industrial Rubber Patio Tiles

At Suzhou Baoshida Trading Co., Ltd., our OEM customization process for rubber patio tiles integrates engineering precision with industrial scalability. We transform client specifications into high-performance products through a rigorously controlled four-phase workflow, ensuring compliance with ASTM D2632 and ISO 18868 standards.

Drawing Analysis

Initial engagement begins with comprehensive CAD drawing assessment. Our engineering team scrutinizes dimensional tolerances, load-bearing requirements, drainage patterns, and interlocking geometries. Critical parameters include surface texture depth (±0.2 mm), tile thickness variance (max ±1.5%), and edge chamfer angles. We identify potential manufacturing constraints early, such as undercuts affecting mold release or draft angles below 1.5° that risk part deformation. This phase culminates in a feasibility report with proposed adjustments to optimize producibility without compromising functional intent.

Formulation Development

Based on the validated design, our rubber chemists engineer a bespoke compound. We prioritize abrasion resistance for high-traffic zones and UV stability for outdoor exposure, selecting between SBR, EPDM, or recycled rubber blends per client durability and sustainability targets. Key variables adjusted include: filler ratio (silica vs. carbon black), vulcanization accelerators for cure kinetics, and plasticizers for low-temperature flexibility. The table below illustrates standard versus custom formulation benchmarks.

| Property | Standard Compound | Custom High-Traffic Compound | Test Method |

|---|---|---|---|

| Shore A Hardness | 65 ± 3 | 72 ± 2 | ASTM D2240 |

| Tensile Strength (MPa) | 8.5 | 12.0 | ASTM D412 |

| Abrasion Loss (mm³) | 120 | 75 | ASTM D5963 |

| Compression Set (%) | 25 | 18 | ASTM D395 |

| UV Resistance (ΔE after 500h) | 3.5 | 1.8 | ISO 4892-2 |

Prototyping & Validation

Precision molds are machined from H13 tool steel to produce 3–5 prototype tiles per design iteration. Each unit undergoes accelerated lifecycle testing: 50,000 cycles of simulated foot traffic, freeze-thaw exposure (-40°C to 70°C), and chemical resistance checks against common oils and de-icing salts. We measure deflection under 1,500 kg/m² loads and validate slip coefficients per DIN 51130. Client feedback on prototypes triggers micro-adjustments to compound viscosity or mold venting before final sign-off.

Mass Production Execution

Approved designs transition to our 10,000 m² facility with automated hydraulic presses (500–2,000 tons clamping force). Real-time monitoring tracks cure temperature (±2°C accuracy) and pressure profiles. Every production batch undergoes inline spectrometry for compound consistency and post-cure dimensional checks via CMM. We implement AQL 1.0 sampling for surface defects and maintain traceability through laser-etched batch codes. Typical lead time from prototype approval to 20,000-unit shipment is 22 working days, supported by our ERP-driven inventory of pre-compounded rubber stocks.

This end-to-end methodology ensures Suzhou Baoshida delivers patio tiles that meet exact mechanical and environmental demands while minimizing time-to-market for industrial clients. Our process reduces client rework risk by 70% through embedded engineering validation at each phase.

Contact Engineering Team

For industrial buyers seeking high-performance rubber patio tiles engineered for durability, safety, and long-term value, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in advanced rubber material solutions. As a specialized OEM manager and rubber formula engineer, we design and manufacture rubber patio tiles that meet rigorous industrial standards while delivering aesthetic versatility for commercial, municipal, and residential applications. Our expertise lies in custom compounding, precision molding, and scalable production, ensuring every tile exceeds performance benchmarks in wear resistance, UV stability, and slip resistance.

Our rubber patio tiles are formulated using high-quality recycled and virgin rubber compounds, optimized for outdoor environments. Each batch undergoes rigorous quality control to ensure dimensional accuracy, consistent Shore A hardness, and resistance to weathering, compression set, and microbial growth. Whether deployed in public parks, rooftop terraces, or industrial walkways, our tiles provide reliable traction, impact absorption, and thermal resilience across a wide temperature range.

We invite procurement managers, construction firms, and OEM partners to engage directly with Mr. Boyce, our dedicated technical liaison, to discuss customization options, volume pricing, and technical specifications tailored to your project requirements. Mr. Boyce combines deep materials science knowledge with extensive supply chain experience, ensuring seamless collaboration from prototype to mass production. Contact him at [email protected] to request samples, review formulation data sheets, or initiate a technical consultation.

Below are the standard technical specifications for our most widely specified rubber patio tile series:

| Property | Test Method | Typical Value |

|---|---|---|

| Material Composition | Visual & FTIR Analysis | 70% Recycled EPDM, 30% Virgin SBR |

| Shore A Hardness | ASTM D2240 | 65 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 7.5 MPa |

| Elongation at Break | ASTM D412 | ≥ 200% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤ 20% |

| Density | ASTM D297 | 1.15 g/cm³ |

| Thickness Tolerance | ISO 3302 | ±0.5 mm |

| Dimensional Stability (100°C, 24 hrs) | ISO 1856 | ≤ 1.0% |

| Slip Resistance (Dry/Wet) | ASTM F2913 | R9/R10 |

| Operating Temperature Range | Internal Test | -40°C to +80°C |

| UV Resistance | ASTM G154 (1500 hrs) | No cracking, ≤ 10% color change |

All products are manufactured in compliance with ISO 9001 standards and are available in standard 500 mm × 500 mm × 20 mm configurations or custom sizes upon request. We support low minimum order quantities for prototyping and scalable production runs exceeding 50,000 units monthly.

Partner with Suzhou Baoshida to integrate scientifically engineered rubber solutions into your next outdoor surfacing project. Initiate the conversation today—contact Mr. Boyce at [email protected] for technical documentation, pricing, and sample fulfillment.

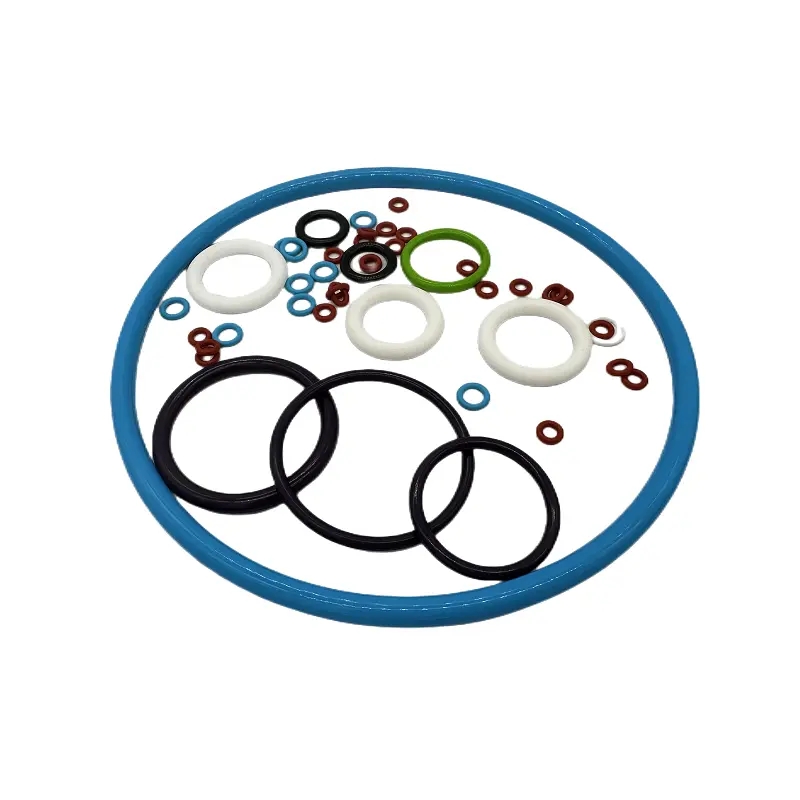

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).