Technical Contents

Engineering Guide: Rubber Play Tiles Outdoor

Engineering Insight: Material Selection in Outdoor Rubber Play Tiles

The performance and longevity of rubber play tiles in outdoor environments are directly governed by material selection at the formulation stage. Off-the-shelf solutions commonly fail due to reliance on generic rubber compounds not engineered for dynamic outdoor stressors. These stressors include UV radiation, thermal cycling, moisture exposure, mechanical abrasion, and biological growth—all of which accelerate degradation when suboptimal materials are used.

Standard consumer-grade rubber tiles often utilize reclaimed rubber or mixed post-industrial scrap with inconsistent cross-link density and filler content. While cost-effective, these materials lack the molecular stability required for sustained outdoor deployment. For instance, high aromatic oil content in low-grade SBR (Styrene-Butadiene Rubber) leads to surface blooming, hardening, and embrittlement under prolonged UV exposure. Additionally, inadequate vulcanization results in poor rebound resilience and increased susceptibility to compression set—critical flaws in high-traffic play zones.

At Suzhou Baoshida Trading Co., Ltd., we prioritize engineered EPDM (Ethylene Propylene Diene Monomer) and high-purity SBR compounds with controlled carbon black dispersion and UV-stabilized surface layers. These materials offer superior ozone resistance, color retention, and thermal stability across -40°C to +80°C operating ranges. The cross-link architecture is optimized via sulfur and peroxide co-curing systems to balance elasticity and durability.

A key differentiator lies in the integration of functional additives. Our formulations include hindered amine light stabilizers (HALS), micro-encapsulated biocides, and hydrophobic silica to mitigate algae formation and water ingress—common failure points in humid climates. Furthermore, controlled porosity in the cellular structure enhances drainage while maintaining impact attenuation, meeting ASTM F1292 and EN 1177 fall height safety standards.

Below is a comparative specification table highlighting critical performance parameters between standard off-the-shelf tiles and our engineered solution:

| Parameter | Off-the-Shelf Tile (Typical) | Baoshida Engineered Tile |

|---|---|---|

| Base Polymer | Mixed Reclaimed Rubber | Virgin EPDM / High-Purity SBR |

| UV Resistance (ASTM G154) | < 1,000 hrs to chalking | > 3,000 hrs no degradation |

| Tensile Strength (ASTM D412) | 3.5 – 5.0 MPa | 8.5 – 10.2 MPa |

| Elongation at Break | 120 – 180% | 280 – 350% |

| Compression Set (ASTM D395) | 28 – 35% after 70°C/22h | < 15% under same conditions |

| Color Fade Resistance (ΔE) | ΔE > 6 after 12 months | ΔE < 2 after 24 months |

| Slip Resistance (ASTM F2913) | Wet DCOF: 0.35 | Wet DCOF: 0.52 |

| Biocidal Protection | None | Silver-ion embedded layer |

Generic tiles frequently overlook system-level performance, focusing only on initial cost and ease of installation. However, lifecycle cost analysis reveals that premature replacement, safety non-compliance, and maintenance escalate total ownership expenses. Our engineered approach ensures dimensional stability, consistent impact absorption, and regulatory compliance over a 10+ year service life.

Material selection is not a commodity decision—it is a precision engineering imperative. For industrial and municipal applications, only purpose-formulated rubber compounds guarantee safety, durability, and long-term value.

Material Specifications

Material Specifications for Outdoor Rubber Play Tiles

Selecting the optimal elastomer for outdoor rubber play tiles requires rigorous evaluation of environmental resilience, mechanical performance, and safety compliance. At Suzhou Baoshida Trading Co., Ltd., we prioritize materials that withstand UV degradation, temperature extremes, and physical stress while meeting ASTM F1292 impact attenuation standards. Our engineered solutions focus on three premium polymers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each offers distinct advantages for playground applications, though suitability depends on regional climate, installation substrate, and longevity requirements.

Viton excels in extreme environments, resisting temperatures from -20°C to +250°C and exhibiting unparalleled resistance to ozone, UV radiation, and oxidation. Its high fluorine content ensures dimensional stability under prolonged sun exposure, critical for tiles in arid or high-altitude regions. However, Viton’s Shore A hardness typically ranges 70–85, which may compromise impact absorption if not compounded with specialized fillers. Tensile strength averages 15–20 MPa, but elongation at break is limited to 200–300%, potentially reducing flexibility in freeze-thaw cycles.

Nitrile rubber provides cost-effective performance for moderate climates, with a functional temperature range of -30°C to +120°C. It delivers superior abrasion resistance (Shore A 60–75) and high tensile strength (18–25 MPa), making it ideal for high-traffic zones. Elongation at break (250–400%) ensures adequate shock absorption, though UV resistance requires carbon black stabilization to prevent surface cracking. Nitrile’s vulnerability to ozone and limited high-temperature stability necessitate protective topcoats in tropical or polluted urban areas.

Silicone (VMQ) offers the broadest operational latitude (-60°C to +230°C) and inherent UV/ozone resistance without additives. Its Shore A hardness (40–70) and exceptional elongation (400–700%) provide superior cushioning for fall heights up to 3 meters. Silicone maintains elasticity across temperature extremes, preventing tile brittleness in winter or softening in summer. Drawbacks include lower tensile strength (6–10 MPa) and higher material costs, though its 25+ year service life often offsets initial investment.

The following table summarizes critical specifications for B2B decision-making:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -30 to +120 | -60 to +230 |

| Shore A Hardness | 70–85 | 60–75 | 40–70 |

| Tensile Strength (MPa) | 15–20 | 18–25 | 6–10 |

| Elongation at Break (%) | 200–300 | 250–400 | 400–700 |

| UV/Ozone Resistance | Excellent | Moderate* | Excellent |

| Key Limitation | Low flexibility | Degrades in UV | Lower tensile |

| Recommended Application | Desert/arid zones | Temperate climates | Extreme cold/heat |

*Requires carbon black stabilization for outdoor use.

For OEM partnerships, we emphasize compound customization: Viton formulations include peroxide curing for enhanced tear strength; Nitrile blends incorporate nano-silica for abrasion resistance; Silicone utilizes platinum-catalyzed systems for purity and color stability. All materials undergo accelerated weathering testing per ISO 4892-2 and meet EN 1177 safety thresholds. Suzhou Baoshida provides full technical documentation, including REACH/ROHS compliance certificates and lifecycle cost analysis, ensuring your outdoor play tiles deliver 15+ years of maintenance-free performance. Partner with us to optimize material selection for your specific geographic and regulatory requirements.

Manufacturing Capabilities

Engineering Excellence in Outdoor Rubber Play Tile Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the design and production of high-performance rubber play tiles for outdoor applications. With a dedicated team comprising five specialized mould engineers and two advanced formula engineers, we maintain full in-house control over material development, structural design, and manufacturing precision. This integrated approach ensures that every product meets rigorous functional, safety, and durability standards required in commercial playgrounds, schools, and public recreational spaces.

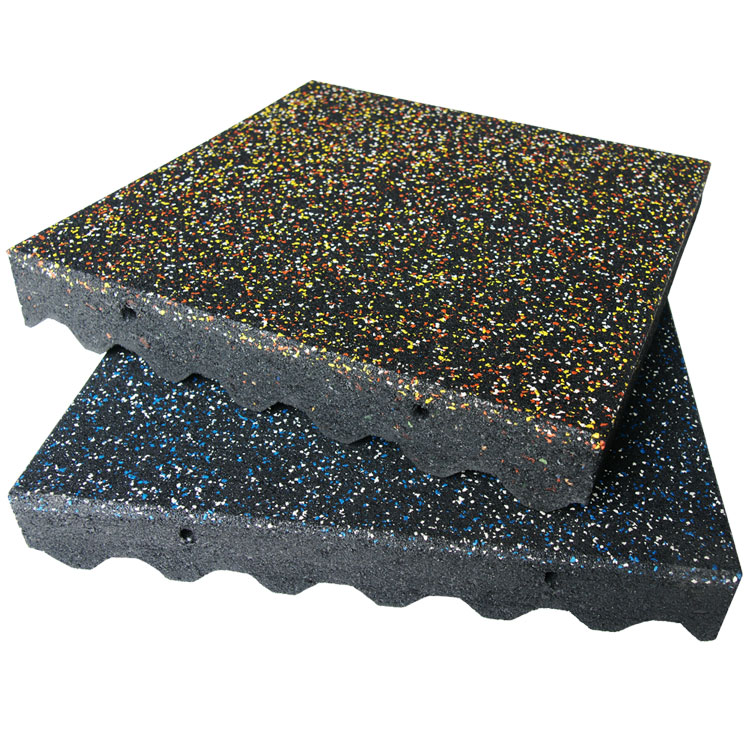

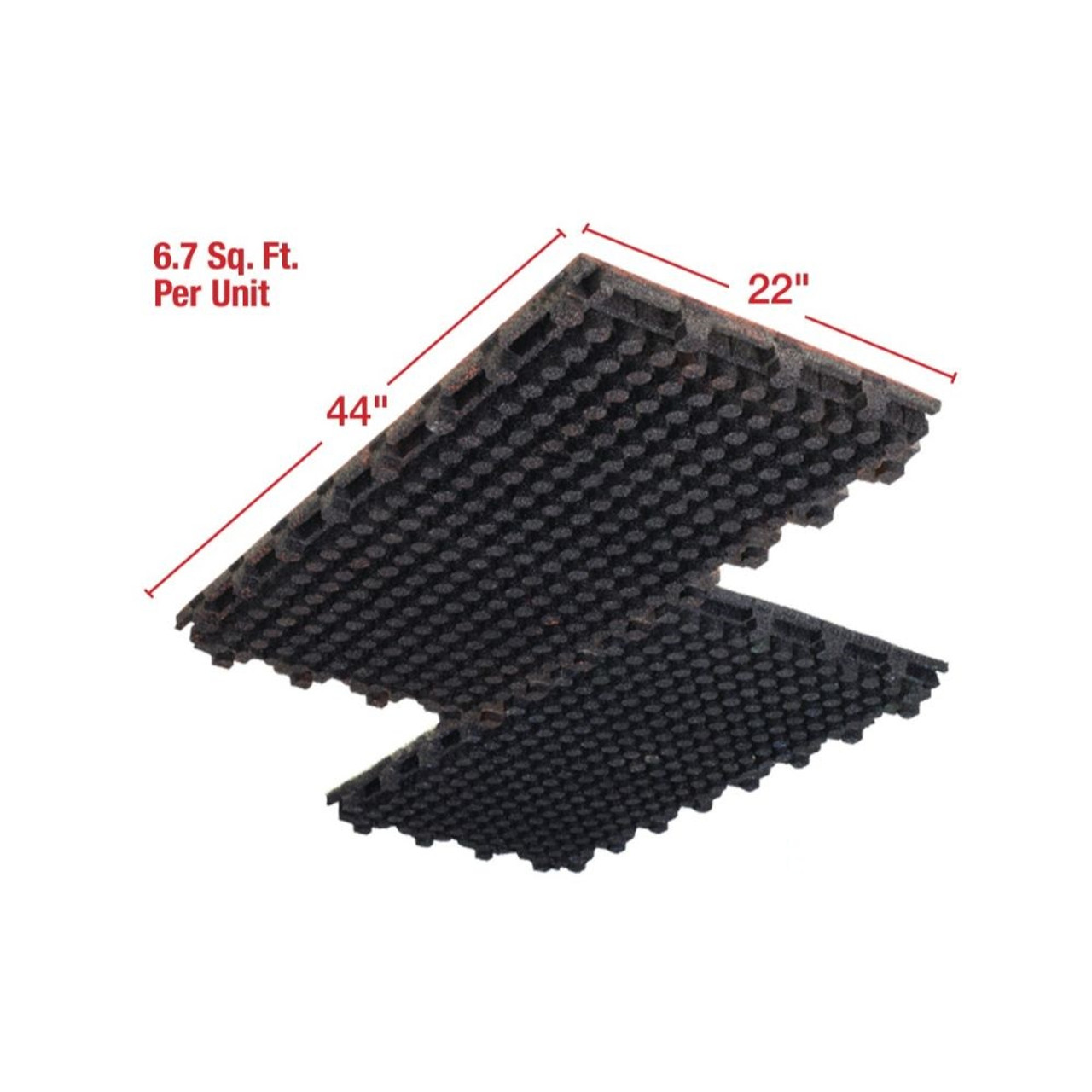

Our formula engineers focus exclusively on optimizing rubber compound formulations tailored to outdoor environmental stressors. Utilizing SBR (Styrene-Butadiene Rubber), EPDM granules, and recycled tire rubber, they engineer blends that deliver superior UV resistance, thermal stability, and long-term elasticity retention. These formulations are tested under accelerated weathering conditions to validate performance across temperature extremes (-30°C to +70°C), moisture exposure, and continuous UV radiation. The result is a non-toxic, slip-resistant, and impact-absorbing surface that complies with international safety standards, including ASTM F1292 for impact attenuation and EN 1177 for critical fall height protection.

Complementing material science expertise, our five mould engineers bring precision to geometric integrity and production scalability. Each mould is designed using CAD/CAM software and manufactured from high-grade steel with anti-corrosion treatment to ensure longevity and dimensional accuracy over tens of thousands of cycles. The engineering team optimizes flow dynamics during compression moulding to eliminate voids, ensure uniform density, and maintain consistent tile thickness—typically 20 mm, 25 mm, and 30 mm—critical for shock absorption and surface leveling.

We offer full OEM services, enabling clients to customize tile dimensions, surface textures, color profiles, and branding elements. Our engineers collaborate directly with partners to translate conceptual requirements into manufacturable designs, supporting prototyping, small-batch trials, and mass production with zero tooling markup costs for qualified projects. Rapid iteration cycles—typically 7–10 days from design to prototype—allow for agile development and fast time-to-market.

All rubber play tiles are engineered to interlock seamlessly, enabling easy installation and maintenance while resisting displacement under dynamic loads. With a service life exceeding 10 years under normal conditions, our tiles represent a durable, low-maintenance surfacing solution for outdoor environments.

The table below outlines key technical specifications of our standard outdoor rubber play tile series:

| Parameter | Specification |

|---|---|

| Material Composition | SBR + EPDM surface layer, recycled rubber core |

| Thickness Options | 20 mm, 25 mm, 30 mm |

| Density | 0.9–1.1 g/cm³ |

| Tensile Strength | ≥7.5 MPa |

| Elongation at Break | ≥200% |

| Shore A Hardness | 45–65 |

| Impact Attenuation (HIC) | ≤200 (ASTM F1292 compliant at 30 mm) |

| Slip Resistance (R10–R11) | DIN 51130 certified |

| Temperature Range | -30°C to +70°C |

| UV and Ozone Resistance | ASTM G154 passed |

| Available Colors | Customizable (standard: red, blue, green, black, yellow) |

Through the synergy of advanced material science and precision engineering, Suzhou Baoshida delivers technically superior, fully customizable rubber play tiles that meet the highest benchmarks in safety, performance, and longevity.

Customization Process

Customization Process for Industrial Rubber Play Tiles

At Suzhou Baoshida Trading Co., Ltd., our customization process for outdoor rubber play tiles integrates rigorous engineering protocols to ensure compliance with global safety standards and client-specific performance requirements. This four-phase workflow guarantees precision from concept to delivery, minimizing risk while optimizing material science for demanding outdoor environments.

Drawing Analysis

Initial engagement begins with comprehensive technical drawing review. Our engineering team validates dimensional tolerances, load-bearing specifications, and surface texture requirements against ISO 10137 (vibration criteria for playground surfaces) and ASTM F1292 (impact attenuation). Critical parameters include tile thickness variance (±0.5mm), interlocking geometry accuracy, and drainage channel design. Non-compliant elements trigger immediate client consultation to resolve conflicts between aesthetic intent and structural integrity, ensuring manufacturability before formulation proceeds.

Formulation Development

Based on validated drawings, our rubber chemists design proprietary polymer matrices using 80-100% post-consumer tire rubber (SBR/EPDM blends) or virgin compounds. Key variables include:

Hardness tuning via vulcanization accelerators (targeting 45-65 Shore A per EN 1177)

UV stabilizer concentration (≥1.2 phr HALS for 10,000+ hours QUV exposure)

Flame retardancy additives meeting ASTM E108 Class A

Each formula undergoes computational simulation for thermal stability and compression set resistance, with adjustments made to achieve ≤15% rebound resilience (critical for fall protection). All compounds are REACH-compliant and free of regulated phthalates.

Prototyping & Validation

Three functional prototypes are produced within 14 days using client-approved materials. These undergo accelerated lifecycle testing:

500+ hours of QUV-A weathering (ASTM G154)

Dynamic load testing at 2.5x operational weight (ISO 9001-certified lab)

Impact attenuation verification per ASTM F1292 (HIC ≤1000 at 6ft drop height)

Clients receive full test reports with spectral analysis of colorfastness (ΔE <2.0 after 1,000h exposure). Two revision cycles are included to refine texture, color consistency, or mechanical properties before tooling approval.

Mass Production Oversight

Upon prototype sign-off, production commences at our ISO 13485-certified partner facilities under Suzhou Baoshida’s direct quality supervision. Every batch undergoes:

Real-time rheometer monitoring of cure kinetics (MH-ML variance ≤0.1 dNm)

Automated vision inspection for surface defects (0.1mm resolution)

Batch traceability via laser-etched QR codes linking to raw material COAs

Final shipment includes third-party test certificates for heavy metals (EN 71-3), slip resistance (ASTM F2913), and microbial resistance (ISO 22196). Lead time averages 25 days for 20ft container orders, with 99.2% on-time delivery performance.

Critical Performance Specifications

| Parameter | Test Standard | Target Range | Tolerance |

|————————–|——————|——————–|———–|

| Thickness | ASTM D2240 | 25-50mm | ±0.5mm |

| Impact Attenuation (HIC) | ASTM F1292 | ≤700 at 4ft height | ±3% |

| Tensile Strength | ASTM D412 | ≥7.5 MPa | ±0.3 MPa |

| UV Resistance (ΔE) | ISO 11341 | <1.5 after 2,000h | Q-SUN Xe-3|

| Flammability | ASTM E108 | Class A | Pass/Fail |

This end-to-end process ensures rubber play tiles meet stringent municipal safety codes while delivering 15+ year service life in extreme climates. Suzhou Baoshida maintains full technical accountability from polymer selection to container loading, providing OEM partners with auditable quality assurance at every stage.

Contact Engineering Team

For industrial manufacturers and commercial project developers seeking high-performance rubber play tiles for outdoor applications, Suzhou Baoshida Trading Co., Ltd. stands as a trusted leader in engineered rubber solutions. Our expertise lies in formulating durable, weather-resistant, and impact-absorbing rubber tiles that meet international safety standards while delivering long-term performance in playgrounds, schools, parks, and public recreational spaces. As your OEM partner, we combine advanced rubber compounding techniques with rigorous quality control to ensure every tile batch exceeds expectations in wear resistance, UV stability, and slip protection.

Our rubber play tiles are precision-manufactured using a blend of recycled and virgin EPDM or SBR rubber, vulcanized under controlled conditions to optimize mechanical strength and elasticity. Each tile is designed for interlocking installation, enabling rapid deployment and easy maintenance across variable substrates. With a focus on safety, our products consistently achieve critical fall height ratings up to 2.5 meters, making them ideal for high-traffic public installations where child safety and durability are non-negotiable.

We offer full customization in thickness, color composition, surface texture, and tile dimensions to meet specific project requirements and aesthetic preferences. Whether you require tiles for a municipal park upgrade or a large-scale educational campus development, our engineering team works closely with clients to deliver tailored formulations that balance performance, cost-efficiency, and regulatory compliance.

Below are the standard technical specifications for our most widely deployed outdoor rubber play tile series:

| Property | Specification |

|---|---|

| Material Composition | EPDM/SBR blend (virgin and recycled rubber) |

| Thickness Options | 20 mm, 25 mm, 30 mm, 40 mm, 50 mm |

| Tile Dimensions | 500 mm × 500 mm (custom sizes available) |

| Shore A Hardness | 65–75 |

| Tensile Strength | ≥7.5 MPa |

| Elongation at Break | ≥200% |

| Abrasion Resistance (DIN) | ≤120 mm³ volume loss |

| UV and Ozone Resistance | Compliant with ISO 4892-2 |

| Slip Resistance (R-value) | R10–R11 |

| Fall Height Rating | Up to 2.5 m (tested per EN 1177) |

| Temperature Range | -30°C to +70°C |

| Fire Performance | Class Bfl-s1 (EN 13501-1) |

All products undergo third-party testing and are supplied with full traceability documentation, including material safety data sheets (MSDS), CE declarations, and compliance certificates. Our production capacity supports large-volume orders with consistent turnaround times, backed by container-load logistics coordination for global delivery.

To discuss your next project or request a technical data sheet and sample kit, contact Mr. Boyce, OEM Project Manager at Suzhou Baoshida Trading Co., Ltd. Direct your inquiries to [email protected]. Include project scope, required quantities, and performance criteria to receive a tailored formulation proposal within 48 hours. Partner with us to deliver safer, smarter, and more sustainable outdoor play surfaces engineered for real-world conditions.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).