Technical Contents

Engineering Guide: Rubber Sealing Strips For Doors

Engineering Insight: Material Selection in Rubber Sealing Strips for Doors

The performance of rubber sealing strips in door applications is fundamentally determined by material selection. While off-the-shelf sealing solutions are often marketed as universal fit products, they frequently fail to meet the mechanical, thermal, and environmental demands of real-world installations. This failure stems from a one-size-fits-all approach that neglects the engineered balance required between elasticity, compression set resistance, weatherability, and chemical stability.

Precision rubber seals must maintain consistent sealing force across variable conditions. Standard EPDM strips, for example, may suffice in temperate climates with minimal UV exposure. However, in environments with extreme temperature fluctuations (-40°C to +120°C), high ozone concentration, or prolonged solar radiation, such materials degrade rapidly. Cracking, hardening, and loss of resilience follow, leading to compromised sealing integrity and premature product failure.

Material science dictates that the polymer backbone, filler system, and cross-linking architecture must be tailored to the application. For instance, silicone rubber (VMQ) offers superior thermal stability and UV resistance but lacks the tensile strength and abrasion resistance required in high-cycle door mechanisms. Conversely, thermoplastic vulcanizates (TPVs) provide excellent processability and dynamic performance but may exhibit higher compression set in continuous compression scenarios.

At Suzhou Baoshida Trading Co., Ltd., we engineer rubber sealing strips using application-specific formulations. Our proprietary blends incorporate high-purity synthetic rubbers, nano-reinforced fillers, and advanced antioxidant packages to extend service life under stress. Each compound is validated through accelerated aging tests, compression set analysis, and dynamic fatigue cycles to ensure reliability.

Off-the-shelf products typically use reprocessed rubber content, inconsistent curing profiles, and minimal quality control. These compromises lead to dimensional instability and poor sealing performance. In contrast, precision-engineered seals maintain dimensional accuracy (±0.1 mm tolerance) and consistent durometer (Shore A 55–75), ensuring uniform compression and long-term sealing force retention.

The table below outlines key material properties for common rubber types used in door sealing applications.

| Material | Temperature Range (°C) | Shore A Hardness | Compression Set (22h @ 70°C) | Key Advantages | Limitations |

|---|---|---|---|---|---|

| EPDM | -40 to +125 | 55–75 | ≤25% | Excellent weather and UV resistance | Poor oil/fuel resistance |

| Silicone (VMQ) | -60 to +200 | 40–80 | ≤20% | Outstanding thermal stability | Low tensile strength |

| Nitrile (NBR) | -30 to +105 | 60–80 | ≤30% | Good oil and fuel resistance | Moderate weather resistance |

| TPV | -40 to +135 | 50–85 | ≤28% | High flexibility, recyclable | Higher compression set than EPDM |

Material selection is not a commodity decision—it is a critical engineering parameter. At Baoshida, we prioritize performance integrity over cost-driven shortcuts, ensuring our rubber sealing strips deliver precision, durability, and reliability in demanding door systems.

Material Specifications

Material Specifications for Precision Door Sealing Strips

Selecting the optimal elastomer for door sealing strips is critical for ensuring long-term performance under operational stressors including temperature extremes, chemical exposure, and mechanical compression. At Suzhou Baoshida Trading Co., Ltd., we engineer sealing solutions to stringent OEM specifications, prioritizing material integrity for automotive, industrial, and architectural applications. The three primary compounds deployed in high-performance door seals—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—exhibit distinct physicochemical profiles that dictate their suitability for specific environments.

Viton fluorocarbon rubber delivers exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. With a continuous service range of -20°C to +230°C and intermittent tolerance up to 300°C, it is the standard for engine compartment doors, aircraft access panels, and chemical processing facilities. Its low gas permeability and outstanding ozone resistance prevent premature hardening or cracking, though higher material costs necessitate strategic application where NBR or silicone would degrade rapidly. Compression set values typically remain below 25% after 70 hours at 150°C per ASTM D395, ensuring reliable sealing force retention.

Nitrile butadiene rubber (NBR) offers an optimal balance of oil resistance, abrasion durability, and cost efficiency for general-purpose door seals. Operating effectively between -30°C and +120°C, NBR excels in automotive exterior door perimeters exposed to gasoline, hydraulic fluids, and weathering. Standard formulations achieve Shore A hardness of 60–90, allowing customization for compression load requirements. While inferior to Viton in extreme heat resistance, NBR’s tensile strength (15–25 MPa) and low-temperature flexibility make it ideal for mass-produced vehicle doors where fuel/oil contact is intermittent.

Silicone rubber (VMQ) provides unparalleled low- and high-temperature stability (-60°C to +200°C), UV resistance, and biocompatibility. Its inert nature suits cleanroom doors, medical facility entrances, and exterior architectural glazing where aesthetic retention and non-toxicity are mandatory. Silicone maintains elasticity across thermal cycles but exhibits lower tensile strength (6–10 MPa) and poor resistance to concentrated acids or hydrocarbons. Compression set is moderate (30–40% at 200°C), requiring precise cross-section design to sustain sealing pressure in static applications.

The comparative analysis below details critical parameters for OEM material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Hardness Range (Shore A) | 60–90 | 50–95 | 30–80 |

| Temp Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Fuel/Oil Resistance | Excellent | Good to Excellent | Poor |

| Compression Set (ASTM D395) | ≤25% @ 150°C | ≤30% @ 100°C | ≤40% @ 200°C |

| Key Limitations | Cost, Low-temp flexibility | Poor heat/ozone resistance | Low tensile strength, Solvent sensitivity |

| Primary Door Applications | Engine bays, Chemical plants | Automotive exterior, Industrial machinery | Cleanrooms, Medical facilities, Architectural glazing |

Suzhou Baoshida’s OEM team validates all formulations against ISO 3302 and SAE AS568 standards, ensuring dimensional stability and aging performance per client-specified duty cycles. Material selection must align with fluid exposure profiles, thermal loads, and regulatory frameworks—never solely on cost. Consult our engineering department for application-specific compound tailoring and accelerated lifecycle testing data.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our leadership in precision rubber sealing solutions for industrial and commercial applications. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we deliver technically advanced, application-specific sealing strips for doors that meet exacting performance and durability standards. Our integrated engineering approach ensures seamless coordination between material science and precision tooling, enabling optimized product development from concept to mass production.

Our rubber formula engineers possess deep expertise in elastomer chemistry, with a focus on EPDM, silicone, and thermoplastic vulcanizates (TPV). They develop custom rubber compounds tailored to specific environmental challenges such as UV resistance, ozone stability, low-temperature flexibility, and compression set performance. Each formulation is rigorously tested in-house to ensure compliance with international standards including ASTM D2000, ISO 3302, and RoHS. This scientific approach allows us to produce sealing strips that maintain long-term sealing integrity under dynamic stress, extreme temperatures (-40°C to +150°C), and continuous outdoor exposure.

Complementing our material expertise, our five mould engineers bring advanced capabilities in precision tool design and manufacturing. Utilizing CAD/CAM software (SolidWorks, AutoCAD, and UG NX), they design high-tolerance extrusion dies and custom moulds that ensure dimensional accuracy and consistent profile geometry. Our in-house tooling facility supports rapid prototyping, enabling fast turnaround for OEM clients requiring custom profiles. We specialize in complex cross-sectional designs, multi-durometer co-extrusions, and magnetic core integration for hermetic door sealing in cleanrooms and refrigeration units.

Our OEM engineering services are structured to support global manufacturers with full technical collaboration. From initial technical drawings and material selection to DFM analysis and sample validation, we provide end-to-end engineering support. Clients benefit from our ability to scale from prototype batches to high-volume production without compromising on quality or consistency. All processes are governed by ISO 9001-certified quality management systems, ensuring traceability, process control, and repeatable performance.

The following table outlines key technical specifications achievable through our engineering platform:

| Parameter | Typical Range/Value | Standard/Testing Method |

|---|---|---|

| Durometer (Shore A) | 40–90 | ASTM D2240 |

| Tensile Strength | ≥8 MPa (EPDM) | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤20% | ASTM D395 |

| Temperature Range | -40°C to +150°C (EPDM) | ASTM D1329 / ISO 188 |

| UV & Ozone Resistance | Excellent (Grade 1) | ASTM D1149 |

| Extrusion Tolerance | ±0.2 mm (critical dimensions) | ISO 3302 Class C2 |

| Custom Profile Complexity | High (multi-cavity, inserts) | CAD/CAM Designed |

This convergence of formulation science and precision engineering enables Suzhou Baoshida to deliver robust, high-performance rubber sealing strips that meet the exact functional and regulatory demands of modern door systems across transportation, construction, and industrial equipment sectors.

Customization Process

Customization Process for Precision Door Sealing Strips

At Suzhou Baoshida Trading Co., Ltd., our customization process for rubber sealing strips begins with rigorous drawing analysis. Engineering teams dissect OEM-provided CAD files and GD&T specifications to verify dimensional conformance, tolerance stacking, and interface compatibility with door hardware. Critical parameters such as cross-sectional geometry, insertion force requirements, and flange engagement depths undergo dimensional conformance verification. Material compatibility with adjacent substrates (e.g., anodized aluminum, painted steel) is assessed to prevent chemical degradation or adhesion failure. Any ambiguities in sealing pressure distribution or environmental exposure zones trigger immediate OEM consultation to eliminate design ambiguities before progression.

Formulation development follows, leveraging our ISO 17025-accredited polymer lab. Based on the operational environment defined in the drawing analysis phase, we select base polymers—typically EPDM for UV/ozone resistance in exterior applications or silicone for extreme temperature ranges. Reinforcement fillers, plasticizers, and curatives are precisely dosed to achieve target hardness (Shore A 50–80), compression set resistance (<25% per ASTM D395), and low-temperature flexibility (down to -50°C). Each compound undergoes dynamic mechanical analysis to simulate door cycling fatigue, ensuring the formulation meets the OEM’s lifecycle durability targets without compromising extrusion processability.

Prototyping employs multi-cavity aluminum tooling to produce functional samples within 15 business days. Samples undergo dimensional validation via CMM against the original drawing, followed by application-specific performance testing. This includes door closure force measurement, water ingress simulation per ISO 12216, and accelerated aging per SAE J2236. OEM feedback on sealing efficacy and installation ergonomics drives iterative refinements, with material adjustments documented in our traceable formulation log. Only after OEM sign-off on three consecutive prototype batches does the project advance.

Mass production integrates statistical process control at every extrusion and splicing station. Real-time monitoring of die temperature, line speed, and vulcanization parameters ensures batch-to-batch consistency. Each production run includes in-process hardness checks and final inspection for surface defects, dimensional drift, and splice integrity. Our ERP system links lot numbers to raw material certificates and test data, providing full traceability. Suzhou Baoshida’s OEM management team conducts quarterly process audits to maintain first-pass yield rates above 98.5% while accommodating volume scalability from 5,000 to 500,000 units monthly.

Key material specifications for door sealing strips are standardized across our product lines as follows:

| Property | Standard | Typical Range | Test Method |

|---|---|---|---|

| Hardness (Shore A) | ISO 7619-1 | 55–75 | ASTM D2240 |

| Tensile Strength | ISO 37 | ≥8.0 MPa | ASTM D412 |

| Elongation at Break | ISO 37 | ≥250% | ASTM D412 |

| Compression Set | ISO 815-1 | ≤22% (70°C/22h) | ASTM D395 |

| Temperature Range | ISO 188 | -50°C to +130°C | ASTM D573 |

| Density | ISO 2781 | 1.15–1.25 g/cm³ | ASTM D297 |

This structured workflow, anchored in material science and process discipline, ensures Suzhou Baoshida delivers sealing solutions that meet exact OEM functional and regulatory requirements while minimizing time-to-market.

Contact Engineering Team

For OEMs, automotive manufacturers, and industrial fabricators seeking high-performance rubber sealing strips for doors, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in precision rubber engineering. Our expertise lies in the development and supply of custom-engineered sealing solutions designed to meet exacting performance standards across automotive, construction, and transportation sectors. With advanced material science, rigorous quality control, and a commitment to on-time delivery, we support global clients in achieving optimal sealing performance, longevity, and environmental resistance.

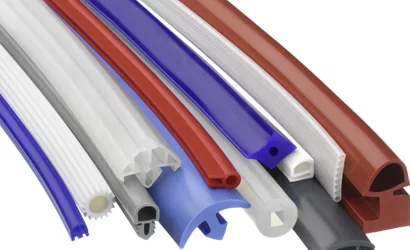

Our rubber sealing strips are formulated using premium-grade EPDM, silicone, neoprene, and thermoplastic rubber (TPR) compounds, selected based on application-specific requirements such as temperature range, UV exposure, compression set, and chemical resistance. Each profile is extruded with micron-level precision, ensuring dimensional consistency and seamless integration into door assemblies. Whether you require sponge rubber for compression sealing, hollow bulb profiles for weatherproofing, or co-extruded strips with rigid internal carriers for structural support, our engineering team collaborates closely with clients to deliver optimized solutions.

All manufacturing processes adhere to ISO 9001 standards, with in-house testing capabilities including tensile strength analysis, ozone resistance, thermal aging, and compression deflection testing. This ensures every batch meets or exceeds international performance benchmarks such as ASTM D2000, ISO 3302, and SAE J2236. Our facility in Suzhou is equipped with state-of-the-art extrusion lines, vulcanization chambers, and automated cutting systems, enabling high-volume production with tight tolerance control (±0.2 mm).

We understand that reliability in sealing directly impacts product safety, energy efficiency, and customer satisfaction. That is why we prioritize material transparency, process validation, and continuous improvement in every project. Our technical team provides full documentation, including material certifications, dimensional reports, and aging test data, to support your quality assurance protocols.

Below are representative specifications for our standard door sealing strip offerings:

| Property | EPDM Sponge | Silicone Solid | Neoprene Densified | TPR Co-Extruded |

|---|---|---|---|---|

| Hardness (Shore A) | 40 ± 5 | 50 ± 5 | 60 ± 5 | 55/75 (Dual Layer) |

| Temperature Range (°C) | -40 to +135 | -60 to +200 | -30 to +100 | -35 to +130 |

| Tensile Strength (MPa) | ≥1.8 | ≥4.0 | ≥9.0 | ≥7.5 |

| Elongation at Break (%) | ≥180 | ≥250 | ≥200 | ≥220 |

| Compression Set (22h @ 70°C) | ≤30% | ≤20% | ≤25% | ≤18% |

| Standard Colors | Black, Grey, White | Black, Red, Blue | Black, Brown | Custom RAL Available |

| Applications | Automotive Doors, Entry Systems | High-Temp Enclosures, Ovens | Industrial Doors, Marine | Sliding Doors, Appliances |

Partnering with Suzhou Baoshida means access to engineered rubber solutions backed by technical rigor and responsive service. To discuss your sealing requirements, request samples, or initiate a qualification batch, contact Mr. Boyce directly at [email protected]. We respond to all technical inquiries within 24 hours and support NDA-protected development projects. Let us help you achieve superior sealing performance—engineered precisely, delivered reliably.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).