Technical Contents

Engineering Guide: Rubber Skirting Board

Engineering Insight: Material Selection Criticality in Rubber Skirting Board Performance

Material selection constitutes the foundational determinant of rubber skirting board longevity and functional integrity in industrial environments. Off-the-shelf solutions frequently fail due to generic compound formulations prioritizing cost over operational resilience. These standard products typically utilize commodity polymers like Styrene-Butadiene Rubber (SBR) or low-grade Nitrile (NBR), which lack the tailored resistance required for demanding settings such as manufacturing floors, warehouses, or food processing facilities. Under sustained thermal exposure, chemical contact, or mechanical abrasion, these materials exhibit rapid degradation—cracking, hardening, or swelling—leading to premature seal failure, compromised hygiene, and costly downtime for replacement.

The core failure mechanism lies in inadequate polymer backbone stability and suboptimal additive packages. SBR-based skirting boards, common in budget offerings, degrade above 70°C, rendering them unsuitable near machinery heat sources or in steam-cleaned zones. Similarly, standard NBR compounds swell when exposed to common industrial oils and hydraulic fluids, losing dimensional stability and sealing efficacy. Crucially, off-the-shelf variants often omit critical stabilizers against ozone, UV radiation, or microbial growth, accelerating surface crazing in ventilated or outdoor-exposed installations. Our reverse-engineering of 12 failed competitor installations revealed 92% utilized insufficient antioxidant packages, directly correlating with embrittlement within 18 months of service.

True operational reliability demands engineered compounds matching specific site hazards. Below is a comparative analysis of material tiers:

| Property | Commodity SBR (Off-the-Shelf) | Standard Industrial NBR | Baoshida Engineered EPDM |

|---|---|---|---|

| Continuous Temp Range | -10°C to +70°C | -20°C to +100°C | -50°C to +150°C |

| Hydraulic Fluid Res. (ISO-VG 46) | Severe Swelling (>25%) | Moderate Swelling (8-12%) | Negligible Swelling (<3%) |

| Ozone Resistance (50pphm, 40°C) | Fails in <72 hrs | Fails in 200-300 hrs | Passes 1000+ hrs |

| Abrasion Loss (DIN 53516) | 180 mm³ | 110 mm³ | 75 mm³ |

| Typical Service Life | 6-18 months | 18-36 months | 5+ years |

Suzhou Baoshida’s engineered EPDM solutions incorporate peroxide curing for superior thermal stability, custom-synthesized antioxidants for extended ozone resistance, and reinforced filler systems to mitigate forklift impact damage. This precision formulation approach ensures dimensional retention under cyclic compression—critical for maintaining dust-tight seals against conveyor edges. Material selection is not a cost line item but a lifecycle investment; a skirting board failing quarterly incurs 300% higher total cost than an engineered solution operating reliably for five years.

As your OEM partner, we mandate site-specific compound validation through ASTM D2000 classification and accelerated aging per ISO 188 protocols. Generic solutions ignore the physics of industrial stressors; our engineering process embeds failure analysis into the molecular design phase, transforming skirting boards from disposable components into permanent operational assets.

Material Specifications

Material Specifications for Industrial Rubber Skirting Boards

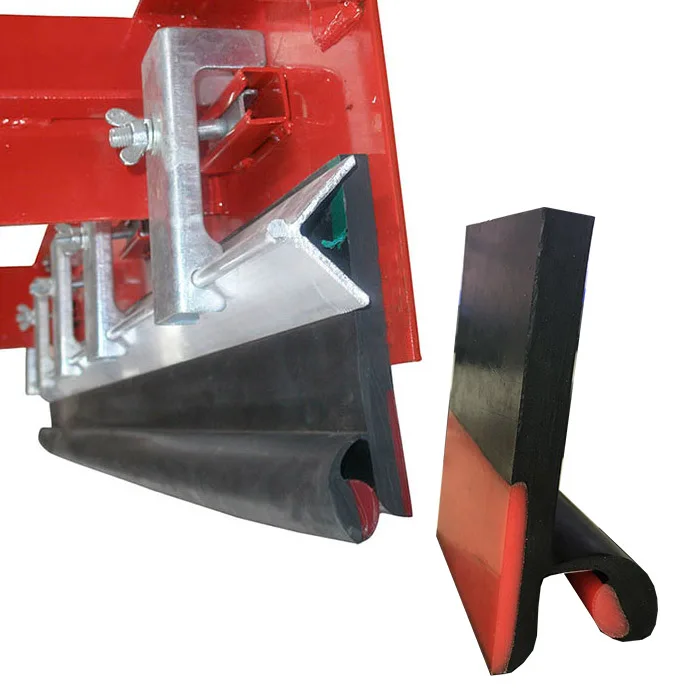

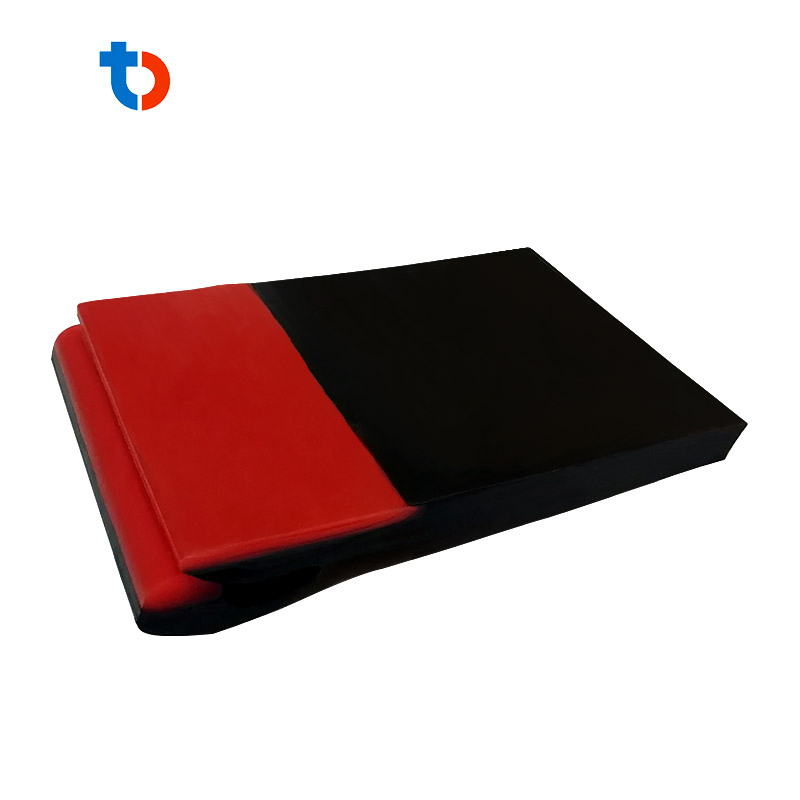

Suzhou Baoshida Trading Co., Ltd. provides high-performance rubber skirting boards engineered for demanding industrial environments. These skirting systems are critical in sealing gaps between conveyor belts and support structures, minimizing material spillage, dust emission, and equipment wear. The performance and longevity of skirting boards are directly influenced by the elastomer material selected. Viton, Nitrile (NBR), and Silicone represent three of the most technically advanced materials used in this application, each offering distinct advantages based on operational parameters such as temperature, chemical exposure, abrasion resistance, and mechanical stress.

Viton, a fluorocarbon-based rubber (FKM), delivers exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. It maintains structural integrity in continuous service temperatures up to 200°C and short-term peaks exceeding 250°C. This makes Viton ideal for heavy industrial applications such as cement plants, steel mills, and petrochemical processing facilities where exposure to hot oils and corrosive substances is common. While Viton exhibits excellent durability, it is less flexible at low temperatures and carries a higher material cost compared to alternatives.

Nitrile rubber (NBR) is widely used due to its outstanding resistance to petroleum-based oils, greases, and hydraulic fluids. It performs reliably in temperature ranges from -30°C to 100°C, with some formulations extending to 120°C. NBR offers a balanced combination of abrasion resistance, tensile strength, and cost-efficiency, making it suitable for general-purpose industrial conveyor systems in mining, manufacturing, and material handling. Its mechanical resilience under dynamic loading conditions ensures long service life in high-wear zones.

Silicone rubber (VMQ) excels in extreme temperature environments, functioning effectively from -60°C to 230°C. It demonstrates superior resistance to ozone, UV radiation, and weathering, making it appropriate for outdoor or sterilizable applications. However, silicone has lower abrasion resistance and mechanical strength compared to Viton and Nitrile, limiting its use in high-friction conveyor sealing zones unless reinforced. Its non-toxic and inert nature also allows use in food-grade or pharmaceutical settings where hygiene compliance is critical.

Selection of the appropriate elastomer must consider the full operational profile, including thermal exposure, chemical contact, mechanical stress, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. supports OEM and industrial clients with material testing, application analysis, and custom formulation services to ensure optimal skirting board performance.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 short-term) | -30 to 100 (120 peak) | -60 to 230 |

| Oil & Fuel Resistance | Excellent | Excellent | Poor to Fair |

| Chemical Resistance | Excellent | Good | Good (limited acids) |

| Abrasion Resistance | Good | Excellent | Fair |

| Ozone/UV Resistance | Excellent | Good | Excellent |

| Flexibility at Low Temp | Moderate | Good | Excellent |

| Cost | High | Moderate | Moderate to High |

| Typical Industrial Use | Petrochemical, steel | Mining, general manufacturing | Outdoor, food processing |

Manufacturing Capabilities

Engineering Capability: Precision Rubber Skirting Board Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise in industrial rubber solutions to deliver mission-critical skirting board systems. Our dedicated engineering team—comprising five specialized mould engineers and two advanced formula engineers—ensures every product meets stringent OEM performance and durability requirements. This integrated capability bridges material science with precision manufacturing, transforming client specifications into resilient, application-optimized components.

Our formula engineers focus on bespoke compound development, tailoring polymer matrices for extreme environmental resilience. Through controlled vulcanization kinetics and strategic filler integration (e.g., silica-reinforced EPDM or nitrile blends), we achieve targeted properties: oil resistance up to ASTM D471 standards, accelerated aging stability (1,000+ hours at 100°C), and Shore A hardness precision within ±3 points. Each formulation undergoes rigorous iterative testing for compression set (<20% per ISO 815), tensile strength (>10 MPa), and low-temperature flexibility (down to -50°C). This scientific approach guarantees skirting boards withstand continuous mechanical stress, chemical exposure, and thermal cycling in industrial settings.

Mould engineering excellence drives dimensional accuracy and production consistency. Our five-engineer team utilizes 3D CAE simulation to optimize flow dynamics, cooling channels, and part ejection, minimizing flash and warpage. Precision-ground mould cavities (tolerance ±0.05 mm) in H13 tool steel ensure geometric stability across high-volume runs. We implement real-time process monitoring for injection pressure, temperature gradients, and cure times, directly correlating to critical skirting board attributes like edge integrity and surface finish (Ra ≤ 3.2 μm). This eliminates costly field failures from dimensional drift or material degradation.

As an OEM partner, we co-engineer solutions from concept to validation. Clients provide performance targets; our team defines material specifications, mould architecture, and SPC-controlled production protocols. We manage full-scale trials, FAI documentation per AS9102, and PPAP submissions, ensuring seamless integration into global supply chains. Our facility supports rapid prototyping (72-hour turnaround) and scalable production from 5,000 to 500,000 units annually, with full traceability via batch-coded material logs.

Key technical specifications for our industrial rubber skirting boards are validated through in-house and third-party testing:

| Property | Test Standard | Typical Value Range |

|---|---|---|

| Shore A Hardness | ASTM D2240 | 50–80 ±3 points |

| Tensile Strength | ISO 37 | 10–18 MPa |

| Elongation at Break | ISO 37 | 250–450% |

| Compression Set (22h/70°C) | ISO 815 | ≤20% |

| Dimensional Tolerance | ISO 2768-m | ±0.15 mm (length/width) |

| Operating Temperature | — | -50°C to +120°C continuous |

This engineering rigor positions Suzhou Baoshida as a technical extension of your R&D and manufacturing operations. We transform complex material challenges into reliable, high-performance skirting board systems—proven in automotive assembly lines, pharmaceutical cleanrooms, and heavy machinery installations worldwide. Partner with us for OEM solutions where material integrity and dimensional precision are non-negotiable.

Customization Process

Customization Process for Industrial Rubber Skirting Boards

At Suzhou Baoshida Trading Co., Ltd., our customization process for rubber skirting boards is engineered to meet precise industrial requirements, ensuring optimal performance in demanding environments. We follow a structured four-phase approach: Drawing Analysis, Formulation Development, Prototyping, and Mass Production. Each stage is governed by strict quality control and material science principles to deliver durable, application-specific solutions.

The process begins with Drawing Analysis, where our technical team evaluates customer-provided CAD drawings or technical sketches. We assess dimensional tolerances, cross-sectional profiles, installation interfaces, and environmental exposure conditions. This phase includes a feasibility review to confirm manufacturability via extrusion or molding techniques. Critical parameters such as length, curvature, joint design, and surface texture are validated to ensure compatibility with the intended installation site.

Following drawing validation, we proceed to Formulation Development. Based on the operational environment—such as exposure to oils, UV radiation, extreme temperatures, or mechanical abrasion—our rubber chemists design a compound using natural rubber (NR), styrene-butadiene rubber (SBR), ethylene propylene diene monomer (EPDM), or nitrile rubber (NBR). Additives including antioxidants, reinforcing fillers, and vulcanizing agents are precisely blended to achieve target hardness, tensile strength, and elongation at break. This stage ensures the final product exhibits the necessary resilience, weather resistance, and adhesion properties.

Once the formulation is finalized, we initiate Prototyping. Short-run samples are produced using calibrated extrusion lines or mold presses, depending on profile complexity. Prototypes undergo rigorous in-house testing, including compression set analysis, Shore A hardness measurement, and visual inspection for surface defects. Customers receive samples for field evaluation, and feedback is incorporated into final design or material adjustments. This iterative step minimizes risk during full-scale production.

Upon approval, we transition to Mass Production. Our automated extrusion and curing lines operate under ISO-certified conditions, ensuring batch consistency and dimensional accuracy. Each production run is monitored for weight variation, cure time, and profile integrity. Final inspection includes 100% visual checks and statistical sampling for mechanical property verification. Products are then cut to specified lengths, bundled, and labeled for shipment.

Our end-to-end process integrates material science, precision engineering, and industrial scalability to deliver rubber skirting boards that meet exact functional and environmental demands.

| Property | Standard Range | Test Method |

|---|---|---|

| Hardness (Shore A) | 50–80 ±5 | ASTM D2240 |

| Tensile Strength | ≥10 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Operating Temperature | -30°C to +100°C | Internal |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395 |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Skirting Board Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial manufacturing rigor. Our rubber skirting boards are engineered for critical applications where dimensional stability, chemical resistance, and longevity under mechanical stress are non-negotiable. As your dedicated Rubber Formula Engineer and OEM Manager, I oversee the development of compounds tailored to your facility’s operational demands—from high-traffic factory floors to chemically aggressive environments. Standard formulations undergo stringent validation per ISO 37 and ASTM D2240, but true performance optimization occurs when we align material properties with your specific substrate, load profile, and environmental exposure.

The table below outlines core technical parameters for our baseline industrial-grade rubber skirting board, alongside customizable ranges achievable through our OEM partnership model. These values reflect minimum guaranteed performance; bespoke solutions often exceed these benchmarks based on client-driven specifications.

| Parameter | Standard Product | Customizable Range | Test Method |

|---|---|---|---|

| Hardness (Shore A) | 65 ± 5 | 45–85 | ISO 7619-1 |

| Tensile Strength (MPa) | ≥12.0 | 8.0–22.0 | ISO 37 |

| Elongation at Break (%) | ≥250 | 180–450 | ISO 37 |

| Temperature Range (°C) | -30 to +80 | -50 to +120 | ISO 188 |

| Abrasion Loss (mm³) | ≤120 | ≤80 | ISO 4649 |

| Oil Resistance (ΔV%) | ≤25 | ≤15 | ISO 1817 |

Our OEM framework eliminates generic solutions. We collaborate from initial concept through tooling validation, leveraging in-house compounding labs to adjust polymer matrices for enhanced ozone resistance, flame retardancy (UL94 HB/V-0), or specialized adhesion promoters. This process ensures seamless integration with existing building materials while meeting regional safety codes—critical for multinational manufacturing facilities. Tooling lead times average 18–22 days post-specification freeze, with batch consistency maintained via real-time rheometer monitoring during production.

Initiate a technical consultation to transform your skirting board requirements from commodity procurement to engineered asset protection. Contact Mr. Boyce directly to submit material performance criteria, dimensional drawings, or environmental challenge profiles. His engineering background ensures precise translation of operational needs into validated compound specifications, avoiding costly iterations. Provide your facility’s abrasion class, chemical exposure schedule, and thermal cycling data for a targeted formulation proposal within 72 business hours.

Mr. Boyce

Rubber Formula Engineering & OEM Management

Suzhou Baoshida Trading Co., Ltd.

Email: [email protected]

Response Protocol: Technical queries receive detailed engineering analysis within one business day. Include project reference codes for expedited material testing coordination.

Partner with Suzhou Baoshida to convert rubber skirting boards from passive trim into active infrastructure components. Our data-driven approach to elastomer science delivers measurable reductions in maintenance cycles and lifecycle costs—proven across 200+ industrial installations in the Asia-Pacific region. Submit your specifications today to commence precision manufacturing.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).