Technical Contents

Engineering Guide: Rubber Wrapping

Engineering Insight: Material Selection in Rubber Wrapping Applications

The failure of rubber wrapping solutions in demanding industrial environments frequently traces back to inadequate material selection. Off-the-shelf compounds, while cost-attractive initially, lack the tailored formulation required to withstand specific operational stressors. Generic elastomers often exhibit premature degradation when exposed to ozone, extreme temperatures, chemical exposure, or dynamic mechanical loads. This results in catastrophic field failures—cracking, hardening, or loss of sealing integrity—leading to unplanned downtime, safety hazards, and significantly higher lifetime costs compared to precision-engineered alternatives.

Critical failure points emerge when standard formulations ignore application-specific variables. For instance, a hydraulic system wrap exposed to phosphate ester fluids will rapidly swell and disintegrate if using conventional nitrile rubber (NBR), which lacks resistance to polar solvents. Similarly, outdoor applications in high-ozone regions demand specialized EPDM or silicone compounds with robust antioxidant packages; standard SBR wraps develop surface cracks within months under UV and ozone exposure per ASTM D1149 testing. Temperature extremes further expose limitations: low-temperature flexibility below -40°C requires precise plasticizer selection in fluorocarbon (FKM) grades, while high-heat environments above 150°C necessitate peroxide-cured systems to prevent reversion.

Compression set resistance—a non-negotiable property for sealing wraps—is routinely compromised in off-the-shelf products. Inexpensive compounds often use suboptimal filler systems and cure chemistries, leading to permanent deformation under continuous load. This directly causes leakage paths in flange or pipe wrapping applications, particularly where thermal cycling occurs. The table below quantifies key performance gaps:

| Property | Custom Formulation (Baoshida OEM) | Off-the-Shelf Standard |

|---|---|---|

| Tensile Strength (MPa) | 22.5 ± 1.2 | 14.0 ± 2.5 |

| Elongation at Break (%) | 450 ± 35 | 300 ± 50 |

| Temp Range (°C) | -55 to +230 | -30 to +120 |

| Ozone Resistance (hrs) | >300 (50 pphm, 40°C) | <50 |

| Compression Set (70h/100°C) | 18% ± 3% | 45% ± 10% |

These discrepancies stem from reactive rather than proactive material design. Off-the-shelf solutions prioritize broad market appeal over functional resilience, omitting critical additives like high-purity silica fillers for tear resistance or specialty accelerators for scorch safety. At Baoshida, we initiate every rubber wrapping project with OEM-specific environmental profiling—mapping fluid exposure, dynamic stress cycles, and regulatory constraints (e.g., FDA 21 CFR 177.2600 for food-grade wraps). Our formulations integrate accelerated aging data from ASTM D2000 severity levels, ensuring the compound’s polymer backbone, cure system, and additive package synergistically address the operational envelope.

Material selection is not a cost center but a risk mitigation strategy. Investing in engineered rubber wrapping eliminates the hidden expenses of premature replacement and production interruption. Suzhou Baoshida Trading Co., Ltd. leverages 18 years of OEM collaboration to transform material science into operational reliability—where every compound is a calibrated response to your engineering challenge.

Material Specifications

Material selection is a critical determinant in the performance, durability, and application suitability of rubber wrapping solutions in industrial environments. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision-engineered rubber wrapping systems utilizing high-performance elastomers including Viton, Nitrile (NBR), and Silicone. Each material exhibits distinct chemical, thermal, and mechanical properties that align with specific operational demands across sectors such as automotive, aerospace, oil & gas, and industrial manufacturing.

Viton, a fluorocarbon-based rubber, offers exceptional resistance to high temperatures, oils, fuels, and a broad spectrum of chemicals. With continuous service capabilities up to 200°C and short-term exposure tolerance to 250°C, Viton is ideal for extreme environments where thermal stability and chemical inertness are paramount. Its low gas permeability and excellent aging characteristics make it a preferred choice for sealing and protective wrapping in aggressive chemical processing and high-pressure hydraulic systems.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is widely utilized for its outstanding resistance to petroleum-based oils, greases, and fuels. It maintains reliable mechanical strength and elasticity across a service range of -30°C to 120°C, making it suitable for dynamic applications involving mechanical stress and fluid exposure. Nitrile’s cost-effectiveness and robust performance in oil-rich environments position it as a standard solution for industrial hoses, gaskets, and protective wraps in automotive and machinery sectors.

Silicone rubber excels in extreme temperature applications, functioning effectively from -60°C to 230°C, with brief excursions beyond this range. While it demonstrates lower mechanical strength compared to Viton or Nitrile, its unparalleled thermal stability, UV resistance, and biocompatibility make it ideal for aerospace, food processing, and medical-grade applications. Silicone also exhibits excellent electrical insulation properties, supporting its use in high-voltage insulation wraps and sensitive electronic enclosures.

The comparative analysis below outlines key physical and chemical attributes of these materials to guide optimal selection based on operational parameters.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250) | -30 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 200–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Chemical Resistance | Excellent | Moderate | Good |

| Electrical Insulation | Good | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

Understanding these material characteristics enables precise alignment with operational demands. Suzhou Baoshida Trading Co., Ltd. ensures traceability, consistency, and compliance with international quality standards across all rubber wrapping products. Our technical team supports OEMs and industrial partners in selecting the optimal elastomer for long-term reliability and performance under real-world conditions.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Wrapping Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering backbone drives unmatched precision in industrial rubber wrapping applications. With dedicated teams of five Mold Engineers and two Formula Engineers, we integrate material science and tooling expertise to solve complex client challenges. This dual-discipline approach ensures every rubber-wrapped component meets exacting performance, durability, and regulatory standards for sectors including automotive, aerospace, and heavy machinery.

Our Mold Engineering team specializes in designing and optimizing tooling for intricate rubber wrapping geometries. Leveraging advanced CAD/CAM simulations and finite element analysis (FEA), they resolve flow dynamics, curing uniformity, and demolding stresses inherent in multi-layer wrapping processes. This capability minimizes flash, reduces cycle times by up to 22%, and guarantees dimensional stability for components operating under high torsion or compression loads. Critical for sealing integrity, our molds achieve ±0.05 mm tolerances even in complex helical or tapered wrapping profiles.

Complementing this, our Formula Engineering division develops proprietary rubber compounds tailored to extreme operational environments. By manipulating polymer matrices, fillers, and curatives, we engineer materials resistant to ozone degradation, hydraulic fluids, and temperatures ranging from -60°C to +250°C. Each formulation undergoes rigorous ASTM D2000 testing to validate tensile strength, elongation, and compression set—ensuring rubber wrapping maintains adhesion and flexibility over 10,000+ operational cycles. This scientific rigor eliminates field failures caused by material incompatibility or thermal drift.

The synergy between these teams enables seamless OEM collaboration. Clients provide performance requirements; our engineers co-develop solutions from concept to量产, managing tooling, compounding, and validation under one roof. We adhere strictly to IATF 16949 protocols, with real-time data tracking from raw material intake to final inspection.

Key Rubber Compounds for Wrapping Applications

| Material Type | Hardness (Shore A) | Tensile Strength (MPa) | Temp Range (°C) | Fluid Resistance | Typical OEM Use Case |

|---|---|---|---|---|---|

| Hydrogenated Nitrile (HNBR) | 70–90 | 20–28 | -50 to +180 | Excellent (oils, fuels) | Automotive fuel line wrapping |

| Silicone (VMQ) | 40–80 | 6–10 | -60 to +250 | Good (water, steam) | Aerospace hydraulic seals |

| EPDM | 50–85 | 15–22 | -55 to +150 | Superior (brake fluid) | Heavy equipment brake hoses |

| Fluorosilicone (FVMQ) | 60–80 | 8–12 | -60 to +200 | Exceptional (solvents) | Chemical processing gaskets |

As an OEM partner, we prioritize scalability and confidentiality. Our engineers embed client-specific IP into formulations and tooling, with flexible MOQs from 5,000 to 500,000 units. Full traceability via blockchain-secured batch records ensures compliance with REACH, FDA, and ISO 10993 standards. By converging mold innovation with molecular-level material control, Suzhou Baoshida delivers rubber wrapping solutions that outperform industry benchmarks in fatigue life and environmental resilience—reducing total cost of ownership for global manufacturers.

Customization Process

Drawing Analysis: The Foundation of Precision

The customization process for rubber wrapping solutions begins with a comprehensive drawing analysis, serving as the technical blueprint for subsequent development stages. At Suzhou Baoshida Trading Co., Ltd., we meticulously evaluate engineering drawings provided by OEM partners to extract critical dimensional tolerances, substrate geometry, environmental exposure conditions, and performance requirements. This phase involves cross-functional review by our rubber formulation engineers, tooling specialists, and quality assurance team to ensure manufacturability and compliance with international standards such as ISO 3302 and ISO 2768. Special attention is given to sealing surfaces, compression set zones, and interference fits, which directly influence material selection and mold design. Any discrepancies or optimization opportunities are communicated promptly to the client through formal engineering change proposals, ensuring alignment before progression.

Formulation: Engineering Material Performance

Based on the drawing analysis, our rubber formulation team develops a compound tailored to the operational demands of the application. Factors such as temperature range, chemical exposure, compression resistance, and abrasion performance are translated into precise polymer selection—commonly NBR, EPDM, FKM, or silicone—and compounded with reinforcing fillers, plasticizers, and curatives. Each formulation is designed to meet specific ASTM D2000 classifications and is verified through rheometric testing, hardness profiling, and thermal aging analysis. Suzhou Baoshida maintains an in-house compounding database that enables rapid iteration while ensuring batch-to-batch consistency. The final compound specification is documented and submitted for client approval prior to prototyping.

Prototyping: Validating Design and Material

Prototyping is conducted using precision CNC-machined or cast molds, depending on complexity and volume expectations. Prototypes are produced under controlled vulcanization conditions that simulate mass production parameters. These samples undergo rigorous functional testing, including compression deflection, leak rate evaluation, and environmental aging per ASTM or customer-defined protocols. Dimensional inspection is performed using coordinate measuring machines (CMM) to verify conformity with geometric dimensioning and tolerancing (GD&T) requirements. Feedback from prototype testing is used to refine both the mold design and compound formulation, ensuring optimal performance before tooling finalization.

Mass Production: Consistency at Scale

Upon prototype validation, the project transitions to mass production using high-precision transfer or injection molding systems. Suzhou Baoshida implements statistical process control (SPC) and first-article inspection (FAI) protocols to maintain quality across production runs. All batches are traceable through lot coding and supported by full material certifications.

Key performance specifications for common rubber wrapping applications are summarized below:

| Property | NBR | EPDM | FKM | Silicone |

|---|---|---|---|---|

| Temperature Range (°C) | -30 to +100 | -50 to +150 | -20 to +200 | -60 to +200 |

| Fluid Resistance | Excellent (oils, fuels) | Poor (oils), Excellent (water, steam) | Outstanding (hydrocarbons, acids) | Good (water, oxygen) |

| Compression Set (ASTM D395) | 15–25% | 10–20% | 10–18% | 20–30% |

| Hardness Range (Shore A) | 50–90 | 50–85 | 60–90 | 30–80 |

| Typical Applications | Hydraulic seals, gaskets | Outdoor seals, steam systems | Aerospace, chemical seals | Medical, high-temp seals |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Wrapping Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of engineered rubber compounding and OEM manufacturing for industrial applications. Our specialization in rubber wrapping—critical for sealing, insulation, vibration damping, and corrosion protection—demands uncompromising material science expertise. Generic rubber solutions fail under operational stress; our formulations integrate precise polymer selection, filler dispersion, and vulcanization control to deliver components that withstand extreme temperatures, chemical exposure, and mechanical fatigue. With 15 years of OEM partnership experience, we translate your performance requirements into validated rubber compounds, ensuring seamless integration into your production line while meeting ISO 9001 and ASTM standards.

Industrial rubber wrapping is not a commodity. It is a system-dependent engineering element where durometer variance of ±3 Shore A, tensile strength deviations beyond 5%, or inadequate thermal stability directly impact product lifecycle and safety. Our laboratory-driven approach begins with your operational parameters: fluid resistance, compression set limits, dynamic load profiles, and regulatory constraints. We then develop custom formulations—silicone for aerospace thermal barriers, EPDM for automotive weatherstripping, or FKM for chemical plant gaskets—validated through accelerated aging, FTIR analysis, and real-world simulation. This eliminates field failures caused by inadequate adhesion, swelling, or premature hardening.

The table below illustrates how our engineered specifications surpass generic alternatives in critical failure-prevention metrics:

| Performance Parameter | Generic Rubber Wrapping | Suzhou Baoshida Custom Solution | Failure Prevention Impact |

|---|---|---|---|

| Durometer Stability (100°C) | ±8 Shore A | ±2 Shore A | Prevents seal leakage under thermal cycling |

| Tensile Strength Retention | 40-50% after aging | ≥85% after aging | Eliminates in-service fracture |

| Compression Set (70h/100°C) | 35-45% | ≤15% | Maintains sealing force integrity |

| Fluid Resistance (ASTM 3) | Swelling >25% | Swelling <8% | Prevents dimensional distortion |

| Adhesion Peel Strength | 2.5-4.0 kN/m | ≥8.0 kN/m | Ensures substrate bonding integrity |

Partnering with Suzhou Baoshida means accessing full technical stewardship—from raw material traceability to mold flow analysis and PPAP documentation. Our engineers collaborate directly with your R&D team to refine tolerances, optimize cure kinetics, and resolve interfacial challenges before tooling commitment. We manage scalability from prototype to 500,000+ units monthly without compromising batch consistency, leveraging our Suzhou-based production facility with 12 dedicated rubber mixing lines and automated wrapping cells.

Do not compromise on the rubber component that safeguards your product’s performance. Contact Mr. Boyce, our Lead Rubber Formulation Engineer and OEM Manager, to initiate a technical consultation. Provide your application’s environmental stressors, dimensional constraints, and lifecycle expectations. Mr. Boyce will coordinate material testing, share compound datasheets with full ASTM/ISO traceability, and propose a qualification timeline aligned with your project milestones. Every specification we deliver is engineered for zero deviation in your manufacturing environment.

Reach Mr. Boyce directly at [email protected]. Include your company name, target application, and critical performance thresholds in your inquiry. Responses are provided within 4 business hours with actionable technical pathways. Suzhou Baoshida ensures your rubber wrapping performs as engineered—not as an afterthought.

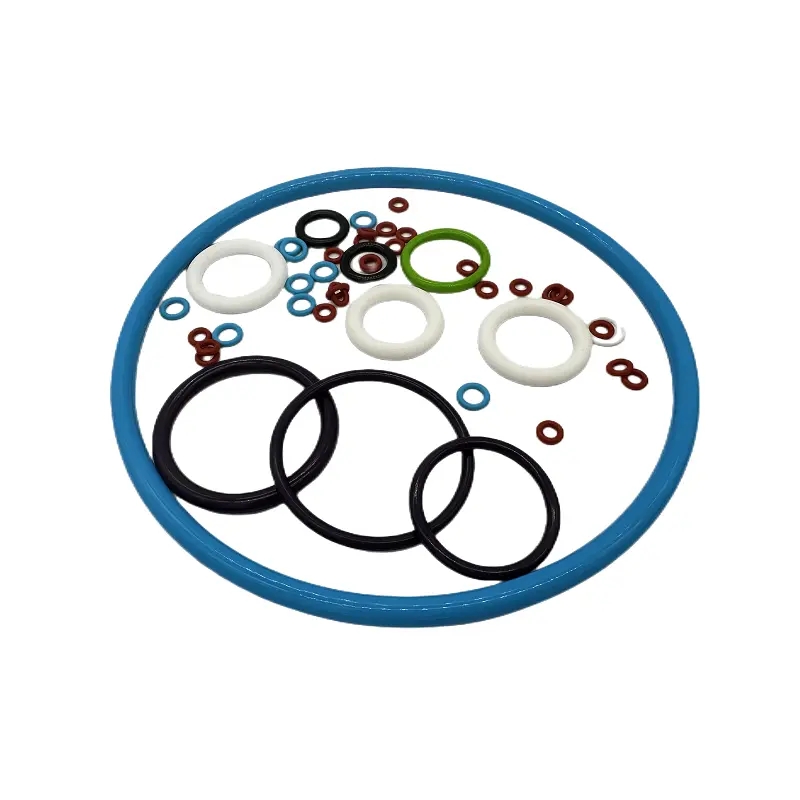

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).