Technical Contents

Engineering Guide: Ruber Sheet

Material Selection as Failure Prevention in Industrial Rubber Sheets

Off-the-shelf rubber sheets represent a significant risk in demanding industrial applications. Generic formulations prioritize cost reduction over performance specificity, leading to premature failure under operational stressors. At Suzhou Baoshida Trading Co., Ltd., our engineering analysis consistently reveals that mismatched material properties—such as inadequate temperature resistance, chemical incompatibility, or poor compression set—directly compromise system integrity. For instance, standard nitrile rubber (NBR) sheets exposed to ozone or hydraulic fluids beyond their formulation limits exhibit rapid surface cracking or swelling, causing seal leakage in hydraulic systems. This is not merely a maintenance inconvenience; it translates to unplanned downtime, safety hazards, and cascading costs far exceeding initial material savings.

The core issue lies in the absence of application-specific engineering. Industrial environments impose complex, simultaneous demands: dynamic mechanical loads, fluctuating temperatures, aggressive chemical exposure, and stringent regulatory requirements. Pre-manufactured sheets rarely account for these synergistic stressors. A sheet suitable for static gasketing in mild conditions may catastrophically fail in dynamic shaft sealing due to insufficient tensile strength or fatigue resistance. We observe recurring field failures where off-the-shelf ethylene propylene diene monomer (EPDM) sheets degrade when exposed to petroleum-based oils—a fundamental incompatibility overlooked during procurement. Such oversights stem from treating rubber as a commodity rather than a precision-engineered component.

Critical material properties must align with exact operational parameters. The table below illustrates how common rubber types perform under key industrial stressors, highlighting why generic solutions fail:

| Material | Temperature Range (°C) | Key Weakness | Typical Failure Mode in Mismatched Applications |

|---|---|---|---|

| NBR | -40 to +120 | Ozone, Brake Fluids | Swelling, loss of sealing force in hydraulic systems |

| EPDM | -50 to +150 | Petroleum Oils, Solvents | Hardening, cracking in fuel-handling equipment |

| FKM | -20 to +250 | Low-Temperature Flexibility | Brittleness below -20°C in cold-climate seals |

| CR | -30 to +100 | Heat Aging, Steam | Rapid compression set in high-temperature static seals |

These failure modes are preventable through rigorous material science. At Suzhou Baoshida, we deploy ASTM D2000-compliant compound development, tailoring polymer matrices, fillers, and curatives to the client’s fluid exposure, temperature cycles, and mechanical loads. For example, aerospace hydraulic seals require peroxide-cured FKM with reinforced thermal stability, not standard NBR. Similarly, food-grade applications demand FDA-compliant EPDM with zero extractables—unattainable in generic sheets.

Material selection is not a cost center but a risk mitigation strategy. Investing in engineered rubber sheets eliminates the hidden costs of replacement parts, production halts, and liability exposure. Suzhou Baoshida’s OEM partnership model integrates application diagnostics, custom compounding, and accelerated lifecycle testing to ensure each rubber sheet functions as a reliable system component—not a liability. Precision formulation is the only viable path to operational continuity in critical industrial environments.

Material Specifications

Suzhou Baoshida Trading Co., Ltd. provides high-performance industrial rubber sheets engineered for demanding applications across automotive, aerospace, chemical processing, and manufacturing sectors. Our precision-formulated rubber sheet materials—Viton, Nitrile, and Silicone—are designed to deliver consistent mechanical integrity, chemical resistance, and thermal stability under extreme operating conditions. Each material exhibits distinct polymer characteristics that make it suitable for specific industrial environments. This section outlines the technical specifications and performance attributes of these three elastomers to guide OEMs and industrial buyers in material selection.

Viton (FKM) is a fluorocarbon-based rubber renowned for its exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. With continuous service capabilities up to 230°C and intermittent exposure tolerance beyond 250°C, Viton sheets are ideal for sealing applications in engine compartments, fuel systems, and chemical processing equipment. Its low gas permeability and excellent aging resistance ensure long-term reliability in critical sealing roles. However, Viton exhibits lower flexibility at low temperatures and higher material cost compared to alternatives.

Nitrile (NBR) rubber is a copolymer of butadiene and acrylonitrile, offering superior resistance to aliphatic hydrocarbons, oils, and fuels. It is widely used in hydraulic systems, gaskets, and oil-handling equipment due to its excellent abrasion resistance and tensile strength. Nitrile sheets perform reliably in temperature ranges from -30°C to +100°C, with specialized high-acrylonitrile formulations extending upper limits to 125°C. While cost-effective and mechanically robust, Nitrile has limited resistance to ozone, UV radiation, and polar solvents, necessitating protective coatings or alternative materials in outdoor or chemical-exposure environments.

Silicone (VMQ) rubber excels in extreme temperature applications, maintaining elasticity from -60°C to +200°C, with short-term exposure up to 250°C. It is non-toxic, inherently flame-resistant, and exhibits excellent electrical insulation properties, making it suitable for medical, food-grade, and electronic applications. Silicone sheets also demonstrate good resistance to ozone and UV degradation, ensuring durability in outdoor environments. However, silicone has lower tensile strength and abrasion resistance compared to Nitrile or Viton, and it swells significantly in hydrocarbon oils, limiting its use in oil-exposed systems.

The following table compares key physical and chemical properties of Viton, Nitrile, and Silicone rubber sheets to facilitate informed material selection for industrial applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 100 (up to 125) | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Electrical Insulation | Good | Fair | Excellent |

| Water Resistance | Excellent | Good | Excellent |

Suzhou Baoshida Trading Co., Ltd. ensures all rubber sheet materials meet international quality standards with batch traceability and customizable thickness, hardness, and sheet dimensions to meet OEM specifications.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Sheet Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages integrated engineering expertise to deliver mission-critical rubber sheet solutions for industrial applications. Our core strength lies in the strategic synergy between dedicated Mould Engineering and Rubber Formulation disciplines. With five specialized Mould Engineers and two advanced Formula Engineers operating under one roof, we eliminate cross-departmental inefficiencies common in the industry. This unified structure ensures seamless translation of material science into precise physical geometry, directly addressing the root causes of performance failure in demanding environments such as hydraulic seals, vibration dampeners, and chemical barrier layers.

Our Formula Engineers focus on molecular-level control, optimizing polymer selection, filler dispersion, and crosslink density to achieve exact performance targets. Simultaneously, Mould Engineers refine cavity design, thermal management, and ejection systems to guarantee dimensional stability and surface integrity. This concurrent engineering approach reduces new product introduction (NPI) time by 30% while enhancing reproducibility. Critical parameters like compression set, tensile strength, and fluid resistance are validated through iterative lab-to-press validation cycles, not theoretical projections.

OEM partnerships benefit from our end-to-end capability, from initial compound development through precision molding and rigorous batch certification. We manage complex supply chains for specialty elastomers (NBR, EPDM, FKM, Silicone) and enforce strict process control protocols compliant with ISO 9001. Every sheet undergoes traceable quality documentation, including raw material lot tracking and real-time cure monitoring.

The table below summarizes our precision manufacturing specifications for industrial rubber sheets:

| Parameter | Standard Range | Precision Capability |

|---|---|---|

| Hardness (Shore A) | 30–90 | ±2 points |

| Thickness | 0.5–50 mm | ±0.1 mm (≤5mm) |

| Tensile Strength | 5–30 MPa | ±0.5 MPa |

| Elongation at Break | 150–800% | ±25% |

| Compression Set | ASTM D395 Method B | ≤15% (70°C, 22h) |

| Dimensional Tolerance | Custom Die-Cut | ±0.2 mm |

Material performance is never compromised for throughput. Our engineers select curing systems and processing aids to maintain integrity under extreme conditions—whether cryogenic exposure down to -50°C or continuous service at 200°C for FKM variants. OEM clients receive full technical dossiers including Durometer decay curves, fluid swell data, and FDA/USP Class VI documentation where applicable.

This engineering rigor translates to reduced field failures and extended service life for our clients’ end products. Suzhou Baoshida does not merely supply rubber sheets; we co-engineer reliability through science-driven manufacturing and uncompromising OEM collaboration. Batch-specific certificates of conformance and rapid technical support ensure seamless integration into your production workflow.

Customization Process

Customization Process for Industrial Rubber Sheets at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber sheet customization process is engineered for precision, performance, and scalability. We follow a structured four-phase approach—Drawing Analysis, Formulation, Prototyping, and Mass Production—to ensure every rubber sheet meets the exact mechanical, thermal, and chemical demands of your application.

The process begins with Drawing Analysis, where our engineering team evaluates customer-provided technical drawings, CAD files, or physical samples. We assess dimensional tolerances, surface finish requirements, hardness specifications, and environmental exposure conditions. This phase includes material compatibility checks, stress analysis, and identification of critical performance zones such as sealing edges or load-bearing areas. Our engineers collaborate directly with OEMs to validate design feasibility and recommend structural optimizations for manufacturability.

Following drawing validation, we proceed to Formulation Development. Our rubber chemists formulate compound recipes tailored to the operational environment—whether it involves exposure to oils, ozone, extreme temperatures, or dynamic mechanical stress. We select base polymers such as NBR, EPDM, silicone, neoprene, or FKM based on chemical resistance, flexibility, and longevity requirements. Additives including accelerators, fillers, plasticizers, and anti-aging agents are precisely dosed to achieve target physical properties. Each formulation is documented and archived for batch traceability and future replication.

Once the compound is finalized, we initiate Prototyping. Using precision cutting, compression molding, or calendering techniques, we produce small-batch samples under near-production conditions. These prototypes undergo rigorous testing, including tensile strength, elongation at break, compression set, hardness (Shore A), and fluid resistance per ASTM or ISO standards. Customers receive test reports and physical samples for field evaluation. Feedback is integrated into final adjustments before release to production.

The final phase, Mass Production, leverages our automated manufacturing lines and strict quality control protocols. Sheets are produced in thicknesses from 0.5 mm to 50 mm and widths up to 1,500 mm, with continuous vulcanization for uniform cross-linking. Every production batch is inspected for dimensional accuracy, surface defects, and consistency in physical properties. We support JIT delivery models and offer custom packaging, labeling, and certification documentation including MSDS and RoHS compliance.

Our end-to-end process ensures that each customized rubber sheet delivers optimal performance in demanding industrial environments—from automotive gaskets to chemical processing seals.

Typical Physical Properties of Custom Rubber Sheets (Example: NBR Base)

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–90 ±5 |

| Tensile Strength | ASTM D412 | ≥10 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤25% |

| Temperature Range | — | -30°C to +100°C (short-term +120°C) |

| Fluid Resistance (IRM 903) | ASTM D471 | Volume swell ≤25% after 70 hrs |

All specifications are adjustable based on customer requirements and application conditions.

Contact Engineering Team

Contact Suzhou Baoshida: Precision Rubber Engineering Solutions

Industrial rubber sheet performance directly impacts operational integrity, safety, and lifecycle costs across demanding manufacturing environments. Generic off-the-shelf materials frequently fail to address specific chemical exposures, thermal cycling, or mechanical stress profiles inherent in modern industrial processes. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber compounds developed through rigorous scientific methodology and validated OEM manufacturing protocols. Our formulations transcend standard commodity sheets by integrating precise polymer architecture, filler dispersion control, and vulcanization kinetics tailored to your application’s exact functional requirements. This commitment to molecular-level precision ensures consistent performance under extreme conditions—whether resisting ozone degradation in hydraulic systems, maintaining seal integrity at -50°C, or withstanding continuous exposure to aggressive solvents.

Our technical team collaborates directly with OEMs and Tier-1 suppliers to de-risk material selection through application-specific testing and failure mode analysis. We do not merely supply rubber; we co-engineer solutions that eliminate premature wear, reduce maintenance downtime, and extend service life. This begins with understanding your operational parameters: dynamic load specifications, fluid compatibility matrices, regulatory constraints (e.g., FDA, UL, ISO 188), and dimensional tolerances. Leveraging Suzhou Baoshida’s vertically integrated production ecosystem in Jiangsu Province, we deliver certified compounds with full traceability—from raw material batch records to final QC documentation—ensuring compliance with global quality standards.

The following table summarizes critical performance characteristics of our core industrial rubber sheet formulations. These values represent baseline capabilities; all properties are adjustable within technical boundaries through our custom compounding process.

| Material Type | Hardness Range (Shore A) | Temperature Range (°C) | Key Chemical Resistances | Typical Applications |

|---|---|---|---|---|

| Nitrile (NBR) | 40–95 | -30 to +120 | Oils, Fuels, Aliphatic Hydrocarbons | Hydraulic Seals, Fuel Hoses, Gaskets |

| EPDM | 30–90 | -50 to +150 | Steam, Ozone, Ketones, Brake Fluids | HVAC Components, Automotive Weatherstripping |

| Neoprene (CR) | 40–80 | -40 to +100 | Flame, Weathering, Mild Acids | Electrical Insulation, Conveyor Belts |

| Silicone (VMQ) | 30–80 | -60 to +230 | Extreme Temperatures, UV, Water | Medical Devices, Aerospace Seals, Food Processing |

Initiate a technical engagement with Suzhou Baoshida to transform your rubber sheet specifications from procurement line items into engineered performance assets. Contact Mr. Boyce, our dedicated OEM Manager, who possesses 14 years of experience in industrial elastomer applications and global supply chain optimization. Mr. Boyce will facilitate a structured consultation process including material data sheet review, feasibility assessment, and prototyping coordination—all without obligation. Provide your application details, performance targets, and volume requirements to receive a scientifically grounded proposal within 72 business hours.

Direct all technical inquiries and OEM partnership discussions to [email protected]. Include your company name, target application, and critical performance parameters to expedite our engineering response. Suzhou Baoshida operates under ISO 9001:2015 certification with manufacturing facilities audited for IATF 16949 compliance, ensuring your rubber components meet the highest benchmarks for industrial reliability. Do not compromise on material integrity—partner with an engineering-led supplier committed to solving your most complex elastomer challenges. Initiate your engineered solution today.

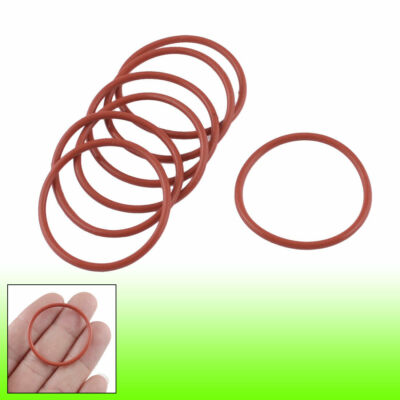

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).