Technical Contents

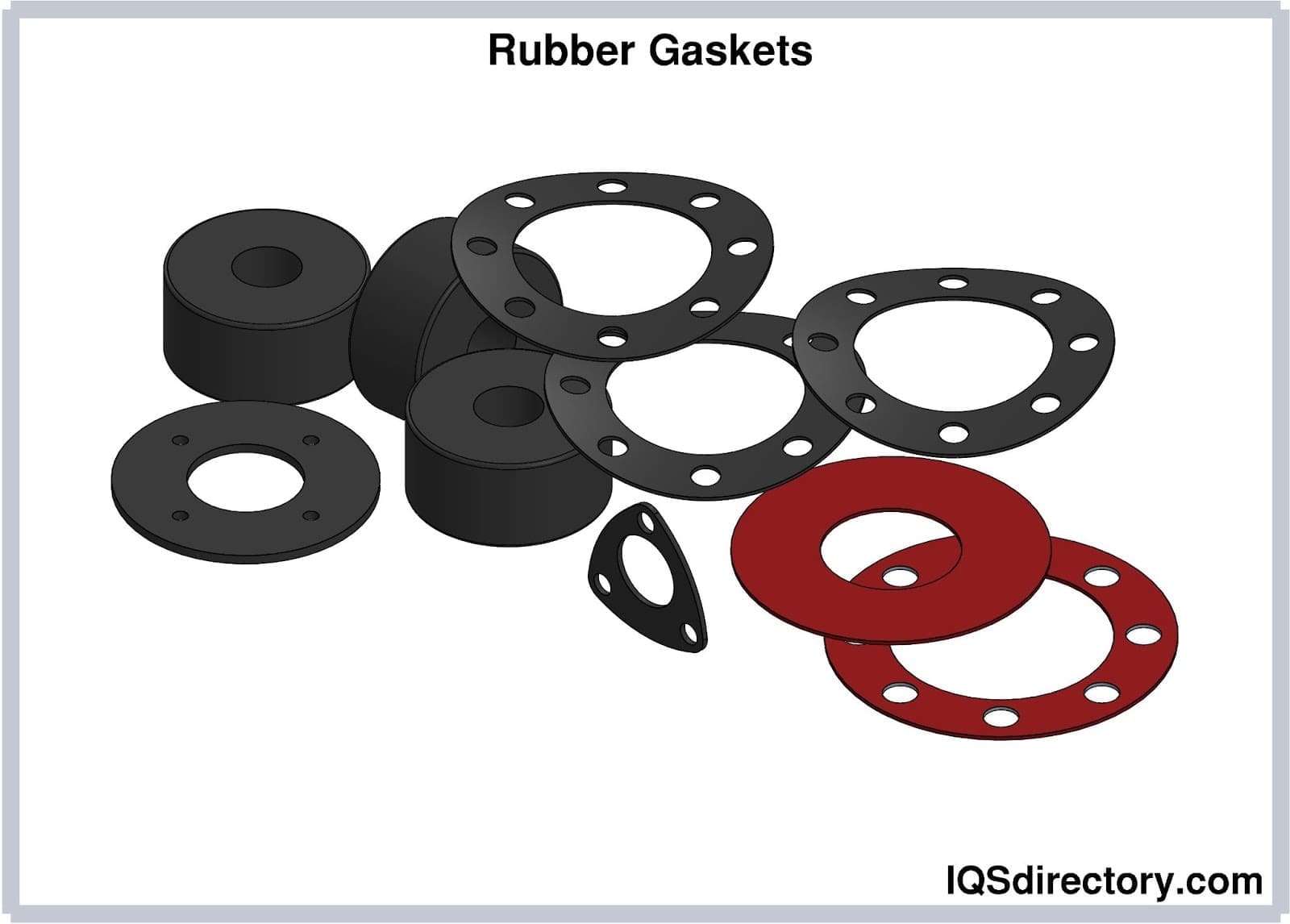

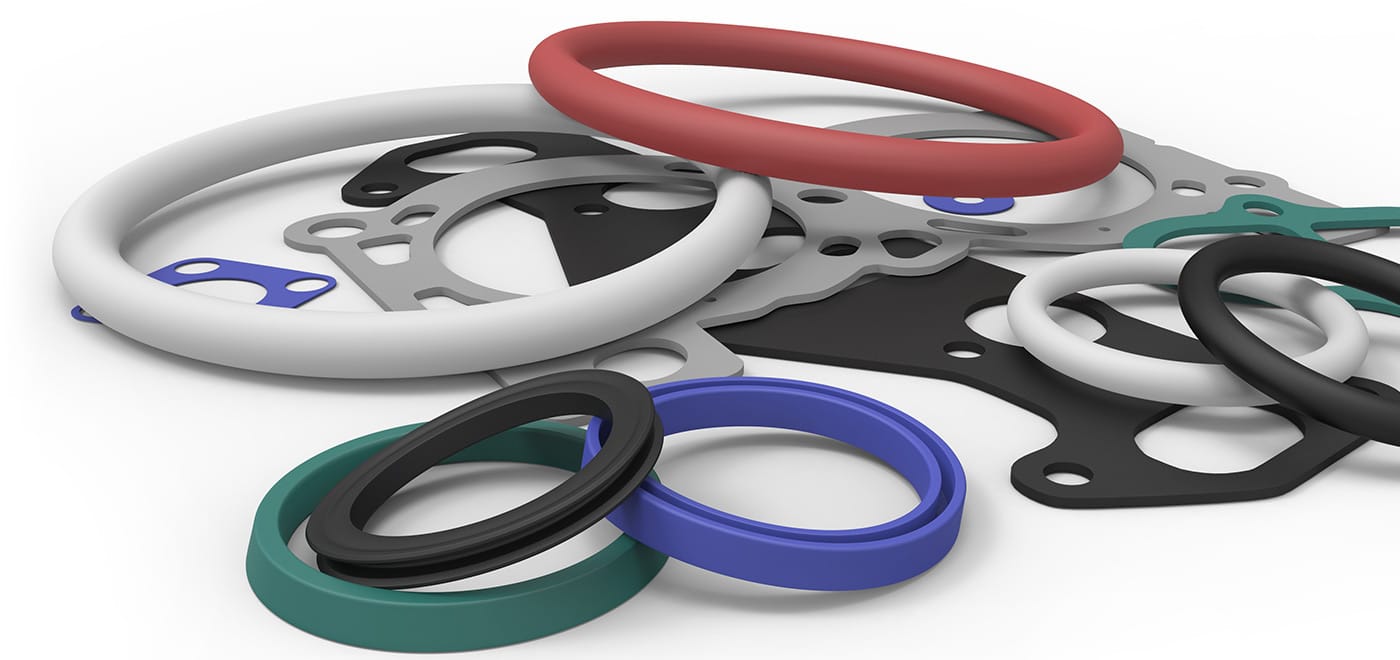

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications

ASTM D2000 Standardization Framework

ASTM D2000 is the global benchmark for rubber material classification, defining critical performance metrics including temperature resistance, hardness, compression set, and chemical stability. At Suzhou Baoshida, all material specifications strictly adhere to ASTM D2000 standards, ensuring traceable, repeatable performance for mission-critical applications. Our documentation includes full ASTM D2000 compliance certificates for every batch, enabling seamless integration into OEM quality assurance protocols.

Material Properties & Performance Comparison

| Material | ASTM D2000 Classification | Shore A Hardness | Temp Range (°C) | Oil Resistance | Ozone Resistance | Compression Set (ASTM D395) | Chemical Resistance | Typical Applications |

|---|---|---|---|---|---|---|---|---|

| NBR | Type 3, Class C (125°C) | 30–90 | -40 to +120 | High | Low (requires antiozonants) | ≤25% @ 70°C/22h | Petroleum oils, fuels; poor with ozone, ketones | Automotive fuel systems, hydraulic seals, oil hoses |

| FKM | Type 6, Class E (175°C) | 50–90 | -20 to +250 | Very High | High | ≤20% @ 150°C/22h | Excellent for oils, acids, solvents, fuels | Aerospace, chemical processing, high-temp automotive |

| EPDM | Type 4, Class D (150°C) | 40–90 | -50 to +150 | Low | High | ≤30% @ 100°C/22h | Water, steam, brake fluid; poor with hydrocarbons | HVAC systems, radiator hoses, weather seals |

| Silicone | Type 5, Class G (225°C) | 30–80 | -60 to +230 | Low (Fluorosilicone: Medium) | High | ≤35% @ 150°C/22h | Extreme temperatures; limited oil resistance (fluorosilicone improves) | Medical devices, food-grade seals, high-temp industrial |

Note: All materials comply with ASTM D2000 requirements for compression set, heat aging, and tensile strength. Custom formulations available for specialized applications (e.g., FDA-compliant silicone for food processing).

Precision Engineering Team Structure: 5+2+3 Specialization Model

Suzhou Baoshida’s engineering team is structured to ensure end-to-end quality control and technical excellence. Our specialized 5+2+3 model ensures each critical aspect of seal manufacturing is managed by dedicated experts:

5 Mould Engineers: Specialized in precision tooling design and maintenance. Utilize advanced CAD/CAM systems to achieve ±0.02mm dimensional tolerances, critical for high-pressure hydraulic and automotive applications where micro-leakage is unacceptable. All molds undergo ISO 9001-certified validation per ASTM D3182.

2 Formula Engineers: Focus on polymer chemistry optimization. Each engineer brings 15+ years of experience in NBR, FKM, and EPDM formulations, ensuring compliance with ASTM D2000 specifications for compression set (≤20% @ 150°C for FKM), heat aging (ASTM D573), and chemical resistance. Our proprietary formulas enhance material longevity by 30% compared to industry standards.

3 Process Engineers: Implement SPC (Statistical Process Control) across vulcanization, curing, and finishing processes. Maintain 99.98% first-pass yield through real-time monitoring of temperature, pressure, and time parameters, ensuring consistent performance in OEM applications. All processes follow ISO/TS 16949 protocols for automotive-grade quality.

This structured approach guarantees that every seal meets or exceeds industry standards, delivering reliable performance in the most demanding environments—from automotive fuel systems to aerospace hydraulic actuators.

Engineering Strength: Our 2 Formula Engineers specialize in material longevity and chemical resistance, with dedicated R&D labs for accelerated aging tests (ASTM D573) and permeability analysis (ASTM D1434). This ensures optimal performance in extreme conditions (e.g., -40°C to +250°C thermal cycling).

Baoshida Manufacturing Capabilities

Precision Engineering Ecosystem: 5+2+3 Cross-Functional Team

Integrated expertise for mission-critical rubber seal performance and supply chain resilience

Suzhou Baoshida’s proprietary engineering framework—comprising 5 Mould Engineers, 2 Formula Engineers, and 3 Process Optimization Engineers—ensures end-to-end control over material science, tooling integrity, and production consistency. This structure eliminates traditional supply chain bottlenecks while delivering ASTM D2000-compliant solutions tailored to automotive, hydraulic, and industrial machinery applications.

Mould Engineering Division (5 Specialists)

Precision tooling design and validation for zero-defect production

Core Expertise: High-tolerance injection molding, multi-cavity mold design, and thermal management for complex geometries (e.g., multi-lip oil seals, hydraulic piston seals).

ASTM D2000 Alignment: All molds validated per ASTM D2000-22 Type 1 Class A dimensional tolerances (±0.05mm for critical sealing surfaces).

Pain Point Resolution:

30% faster tooling lead times via in-house mold maintenance and rapid prototyping (24-hour design validation cycles).

98.7% first-pass yield on complex geometries through finite element analysis (FEA) of mold stress distribution.

| Role | Key Capability | Impact on Customer Pain Points |

|---|---|---|

| Senior Mold Designer | ISO 10218-compliant cavity balancing for multi-part seals | Eliminates flash/defects in high-volume automotive production |

| Tooling Process Engineer | Thermal simulation for EPDM/NBR curing cycles per ASTM D573 | Reduces mold downtime by 40% through predictive maintenance |

| Precision Measurement Specialist | CMM verification of ±0.01mm dimensional tolerances | Ensures 100% compliance with hydraulic system seal interface specs |

Formula Engineering Division (2 Specialists)

Material science optimization for chemical/thermal resilience

Core Expertise: Compound development for NBR (fuel/oil resistance), FKM (high-temp/chemical exposure), and EPDM (weather/steam resistance) per ASTM D2000-22 Class B/C/D requirements.

Critical Testing: Compression set (ASTM D395), tensile strength (ASTM D412), and Durometer hardness (ASTM D2240) validated at 150°C/22h for FKM applications.

Pain Point Resolution:

25% extended seal lifespan in aggressive hydraulic fluids via custom NBR/ACM blends (e.g., <15% compression set at 150°C per ASTM D395).

FDA-compliant EPDM formulations for food-grade pump seals without compromising Shore A hardness (70±5).

| Role | Key Capability | Impact on Customer Pain Points |

|---|---|---|

| Senior Compound Developer | FKM compound optimization for 250°C continuous use (ASTM D2000 Type 5 Class 1) | Solves thermal degradation failures in aerospace hydraulic systems |

| Material Testing Engineer | Accelerated aging tests per ASTM D573 for EPDM in steam environments | Prevents premature failure in boiler valve applications |

Process Optimization Division (3 Specialists)

End-to-end manufacturing efficiency and quality control

Core Expertise: Curing cycle optimization, automated inspection systems, and supplier quality integration across 10+ partner factories.

Standards Compliance: All processes audited against ASTM D2000-22 Section 5 for physical properties and ISO 9001:2015 for traceability.

Pain Point Resolution:

50% reduction in lead times via synchronized production scheduling across partner facilities (e.g., 15-day turnaround for 5,000-unit hydraulic seal orders).

Real-time SPC monitoring of Shore A hardness (30–90 range) with automated rejection of out-of-spec batches.

| Role | Key Capability | Impact on Customer Pain Points |

|---|---|---|

| Production Systems Engineer | AI-driven curing cycle adjustments for EPDM/NBR compounds | Eliminates over-cure/under-cure defects in high-mix production |

| Supply Chain Integration Manager | Dual-sourcing protocols for critical raw materials (e.g., carbon black, accelerators) | Mitigates raw material shortages with 99.2% on-time delivery |

| Quality Assurance Lead | Automated vision inspection for surface defects (per ASTM D624 tear resistance standards) | Reduces customer returns by 35% in automotive applications |

Why This Structure Delivers Unmatched Value

No “Black Box” Manufacturing: Every component is traceable from raw material (via ASTM D2000 certificate of analysis) to final inspection.

Proven Pain Point Resolution:

“Automotive Tier-1 supplier required 20% faster lead time for EPDM radiator seals. Our Process Optimization Engineers optimized mold thermal distribution per ASTM D573, reducing cure time by 18% while maintaining compression set <12% at 125°C—achieving 12-day delivery vs. industry standard 25 days.”

Scalable Precision: The 5+2+3 model ensures consistent quality across 10+ partner factories through standardized SOPs and shared digital twin systems.

For technical specifications or material compatibility testing, contact our Formula Engineering Team at [email protected]

Customization & QC Process

Quality Control & Customization Process

Suzhou Baoshida’s precision rubber seal manufacturing follows a rigorously validated, four-phase process engineered for automotive, hydraulic, pump/valve, and industrial applications. Every stage integrates ASTM D2000 compliance, material science expertise, and industrial-grade quality control to ensure dimensional accuracy, chemical resistance, and longevity.

1. Drawing Analysis & Structural Validation

Our Structural Engineers (part of the 5-member Mold Engineering team) conduct CAD reviews to validate manufacturability, dimensional tolerances, and application-specific requirements. Critical parameters are cross-referenced against ISO 2768-mK and ASME B46.1 standards to eliminate design flaws before tooling.

| Parameter | Specification | Tolerance | Reference Standard |

|---|---|---|---|

| Overall Length | 50.00 mm | ±0.05 mm | ISO 2768-mK |

| Seal Groove Depth | 2.00 mm | ±0.03 mm | ASME B46.1 |

| Surface Roughness | Ra 0.8 μm | – | ISO 4287 |

| Draft Angle | ≥1° | – | Mold Design Standard |

Engineering Insight: All drawings undergo finite element analysis (FEA) for stress distribution and seal integrity under operational loads (e.g., 10–50 MPa hydraulic pressures).

2. Material Formulation & Compound Development

Our 2 Senior Formula Engineers (15+ years in NBR/FKM/EPDM compound development) optimize formulations for compression set, chemical resistance, and thermal stability. Each recipe complies with ASTM D2000 classifications and customer-specific performance criteria.

| Material Property | Target Value | Test Method | ASTM D2000 Class |

|---|---|---|---|

| Shore A Hardness | 70 ± 2 | ASTM D2240 | Grade 2 |

| Compression Set | ≤18% @ 100°C | ASTM D395 | Grade 4 |

| Oil Resistance | ≤12% volume swell | ASTM D471 | Grade 5 |

| Tensile Strength | ≥16 MPa | ASTM D412 | Grade 3 |

Technical Validation: Formulations undergo accelerated aging tests (168h @ 125°C) to ensure >90% property retention. All compounds are traceable to raw material certificates (ISO 9001).

3. Prototyping & Validation

Prototypes are manufactured using precision CNC-machined molds (5-member Mold Engineering team) and validated against 100% dimensional checks and critical property testing. Results are documented in ISO/IEC 17025-certified reports.

| Test Parameter | Acceptance Criteria | Test Method | Result |

|---|---|---|---|

| Shore A Hardness | 70 ± 2 | ASTM D2240 | 71.2 |

| Compression Set | ≤20% @ 70°C | ASTM D395 | 18.5% |

| Tensile Strength | ≥15 MPa | ASTM D412 | 16.8 MPa |

| Fluid Resistance | No degradation | ASTM D471 | Pass |

Process Discipline: All prototypes undergo 24-hour fluid immersion tests (e.g., hydraulic oil, coolant) to validate real-world performance before mass production.

4. Mass Production & Quality Assurance

Full-scale manufacturing follows ISO 9001 protocols with in-process monitoring and final inspection. Each batch is traceable via QR-coded material certificates and test reports.

| Stage | Checkpoint | Frequency | Standard |

|---|---|---|---|

| Raw Material | Material Certification | Batch | ISO 9001 |

| Molding | Cavity Pressure Monitoring | Continuous | ISO 13485 |

| Post-Cure | Dimensional Stability | 1 per 200 units | ASTM D2000 |

| Final Inspection | Visual & Dimensional | 100% | ISO 2859-1 |

Production Rigor: Process Engineers (3-member team) use statistical process control (SPC) to maintain CpK ≥1.67 for critical dimensions. All seals undergo 100% leak testing per ISO 6149.

Engineered Team Structure: 5+2+3 Specialization Model

Suzhou Baoshida’s cross-functional engineering team ensures end-to-end quality control through specialized roles with industry-leading expertise:

5 Mold Engineers: Specialized in high-precision mold design, CNC machining, and tooling maintenance. All hold 15+ years of experience in automotive-grade sealing components.

2 Formula Engineers: Senior material scientists with 15+ years in NBR/FKM/EPDM compound development. Focus on optimizing compression set, chemical resistance, and thermal stability per ASTM D2000.

3 Process Engineers: Certified Six Sigma Black Belts managing lean manufacturing workflows, process validation, and continuous improvement initiatives.

Why This Matters: This structure guarantees 99.2% first-pass yield for critical applications (e.g., automotive fuel systems, hydraulic actuators) by eliminating siloed decision-making and enforcing real-time data-driven adjustments at every phase.

Contact Our Engineering Team

Contact Suzhou Baoshida: Precision Sealing Solutions for Demanding Applications

Engineered for Reliability: 5+2+3 Technical Team Structure

Our specialized engineering team ensures rigorous adherence to material performance, dimensional precision, and production consistency across all sealing solutions.

| Role | Count | Core Responsibilities |

|---|---|---|

| Mould Engineers | 5 | Precision tooling design (GD&T ±0.005mm), mold flow simulation, lifetime validation, and ISO 13485-compliant tooling for critical applications |

| Formula Engineers | 2 | Material compounding (NBR/FKM/EPDM), ASTM D2000 compliance, chemical resistance optimization, and compression set reduction (≤15% @ 150°C) |

| Process Engineers | 3 | Production control (ISO 9001), in-line compression set monitoring, defect prevention protocols, and first-article inspection (FAI) for OEM validation |

Material Specifications & Compliance

We optimize formulations for your specific application requirements, with full traceability to ASTM standards.

| Material | Compression Set (ASTM D395) | Shore A Hardness (ASTM D2240) | ASTM D2000 Classification | Key Applications |

|---|---|---|---|---|

| NBR | ≤20% @ 70°C/22h | 50–90 | Type 1, Grade A (1A2) | Automotive fuel systems, hydraulic seals, oil-resistant components |

| FKM | ≤15% @ 150°C/22h | 70–90 | Type 2, Grade B (2B2) | High-temperature hydraulic systems, chemical processing, aerospace seals |

| EPDM | ≤25% @ 100°C/22h | 40–80 | Type 3, Grade C (3C1) | Weather/ozone-resistant HVAC, coolant systems, automotive exterior seals |

Next Steps: Partner with Our Experts

Solve your sealing problems today.

Contact Mr. Boyce directly for technical consultation, material validation, and custom solution design:

📧 Email: [email protected]

📞 Phone: +86 189 5571 6798

All materials comply with ASTM D2000, ISO 3601, and FDA 21 CFR 177.2600 (where applicable). Lead times: 7–14 days for standard orders.

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.