Technical Contents

Engineering Guide: Sheet Metal Edging

Engineering Insight: Material Selection in Sheet Metal Edging

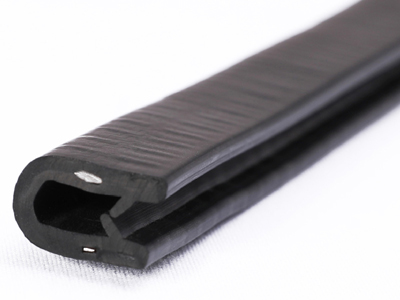

In industrial manufacturing, sheet metal edging is more than a finishing process—it is a critical engineering interface that impacts safety, durability, and long-term performance. The selection of edge protection materials, particularly rubber compounds, directly influences the functional lifespan of metal components exposed to mechanical stress, environmental degradation, and human contact. While off-the-shelf edging solutions are often marketed as universal, they frequently fail in demanding applications due to inadequate material science alignment with operational conditions.

Standard rubber edging profiles are typically formulated using generic elastomers such as natural rubber (NR) or low-grade SBR (styrene-butadiene rubber). These materials offer acceptable flexibility and initial adhesion but lack resistance to UV exposure, ozone, temperature extremes, and chemical agents. In environments such as automotive assembly lines, electrical enclosures, or outdoor infrastructure, these limitations lead to premature cracking, hardening, or delamination—compromising both safety and equipment integrity.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific material engineering. For instance, in high-temperature industrial enclosures, silicone rubber (VMQ) provides thermal stability up to 200°C, while maintaining flexibility and dielectric properties. In contrast, for heavy machinery with frequent impact exposure, thermoplastic polyurethane (TPU) delivers superior abrasion resistance and tensile strength. The failure of generic solutions often stems from a one-size-fits-all approach that neglects such nuanced performance requirements.

Adhesion methodology further differentiates engineered solutions from commodity products. Off-the-shelf edging often relies on pressure-sensitive adhesives (PSAs) with limited long-term bonding strength, especially under thermal cycling or vibration. In contrast, our formulations integrate co-extruded bonding layers or primers compatible with metal substrates, ensuring cohesive adhesion that survives years of operational stress.

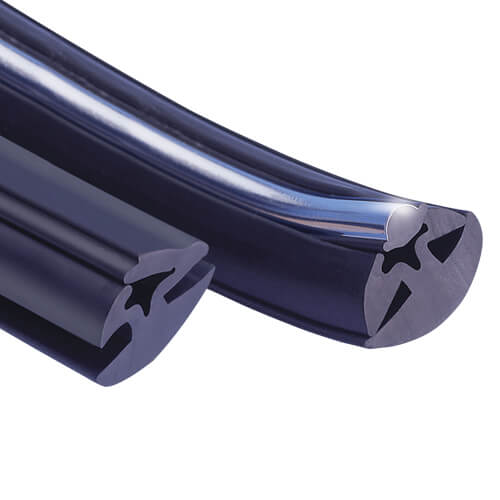

Another overlooked factor is compression set resistance. In dynamic applications where edging is repeatedly compressed—such as access panels or moving guards—low-grade rubber permanently deforms, losing its protective function. High-performance EPDM and chloroprene (CR) compounds maintain elastic recovery, preserving seal integrity and impact absorption over time.

The table below illustrates key performance characteristics across common rubber materials used in sheet metal edging:

| Material | Temperature Range (°C) | UV Resistance | Abrasion Resistance | Compression Set | Typical Application |

|---|---|---|---|---|---|

| NR (Natural Rubber) | -20 to +70 | Low | Moderate | High | Light-duty indoor use |

| SBR | -30 to +80 | Low | Moderate | High | General-purpose profiles |

| EPDM | -50 to +150 | Excellent | Good | Low | Outdoor enclosures, HVAC |

| CR (Neoprene) | -40 to +120 | Good | Good | Moderate | Industrial guards, marine |

| TPU | -40 to +100 | Moderate | Excellent | Low | High-wear machinery edges |

| VMQ (Silicone) | -60 to +200 | Excellent | Low | Low | High-temp electrical panels |

Material selection is not a secondary consideration—it is foundational to the reliability of sheet metal edging systems. At Baoshida, we engineer rubber solutions based on environmental exposure, mechanical demands, and lifecycle expectations, ensuring that every profile performs under real-world conditions. Off-the-shelf products may offer short-term cost savings, but they compromise long-term performance, safety, and total cost of ownership.

Material Specifications

Material Specifications for Sheet Metal Edging Applications

Selecting the appropriate elastomer for sheet metal edging is critical to ensuring longevity, sealing integrity, and resistance to operational stressors. At Suzhou Baoshida Trading Co., Ltd., our engineering team rigorously evaluates polymer formulations to match material properties with client-specific environmental and mechanical demands. The three primary elastomers deployed in industrial edging—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—exhibit distinct performance profiles under temperature extremes, chemical exposure, and dynamic loading. Precision in material selection directly impacts edge durability, preventing premature failure in automotive, aerospace, and heavy machinery assemblies.

Viton fluorocarbon rubber delivers exceptional resistance to high temperatures and aggressive chemicals, including fuels, oils, and acids. Its molecular stability supports continuous service up to 200°C, with short-term peaks at 250°C. Viton edging maintains sealing force under prolonged compression, making it ideal for engine compartments and hydraulic systems where hydrocarbon exposure is unavoidable. However, its higher cost necessitates justified application in extreme environments.

Nitrile rubber remains the industry standard for cost-sensitive applications requiring robust oil and fuel resistance. Optimized NBR compounds achieve hardness ranges of 50–90 Shore A, balancing flexibility with abrasion resistance during metal edge contact. While limited to -30°C to 120°C continuous service, NBR excels in transmission housings and industrial machinery where hydraulic fluid compatibility is paramount. Our proprietary low-temperature NBR variants extend operational limits to -50°C for cold-climate deployments.

Silicone rubber provides unmatched thermal stability from -60°C to 230°C and inherent flame resistance. Its inert composition meets FDA and USP Class VI standards, positioning it for medical and food-processing edging where purity is non-negotiable. Silicone’s low compression set ensures reliable sealing in cryogenic or high-heat static applications, though tensile strength limitations require careful design validation for dynamic edges.

The comparative analysis below details critical specifications per ASTM standards. All materials are formulated to ASTM D2000 classification M2BA 710 for baseline quality control.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 | -30 to +120 | -60 to +230 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Hardness Range (Shore A) | 60–90 | 50–90 | 30–80 |

| Fluid Resistance | Excellent (fuels, acids) | Excellent (oils, water) | Poor (fuels) |

| Compression Set (22h/150°C) | ≤20% | ≤25% | ≤20% |

| Key ASTM Standards | D1418, D2000 | D2000, D471 | D2000, D573 |

Material selection must align with fluid exposure, thermal cycling frequency, and edge geometry. Suzhou Baoshida’s OEM engineering team conducts application-specific validation testing to eliminate field failures. Contact our technical division for compound customization addressing unique edging challenges in your manufacturing process.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Solutions for Sheet Metal Edging

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the specialized domain of sheet metal edging applications. With a dedicated team comprising five experienced mould engineers and two senior rubber formula engineers, we deliver technically advanced, application-specific components that meet the rigorous demands of modern manufacturing environments. Our integrated engineering approach ensures seamless development from concept to production, with precision, durability, and performance at the core of every product.

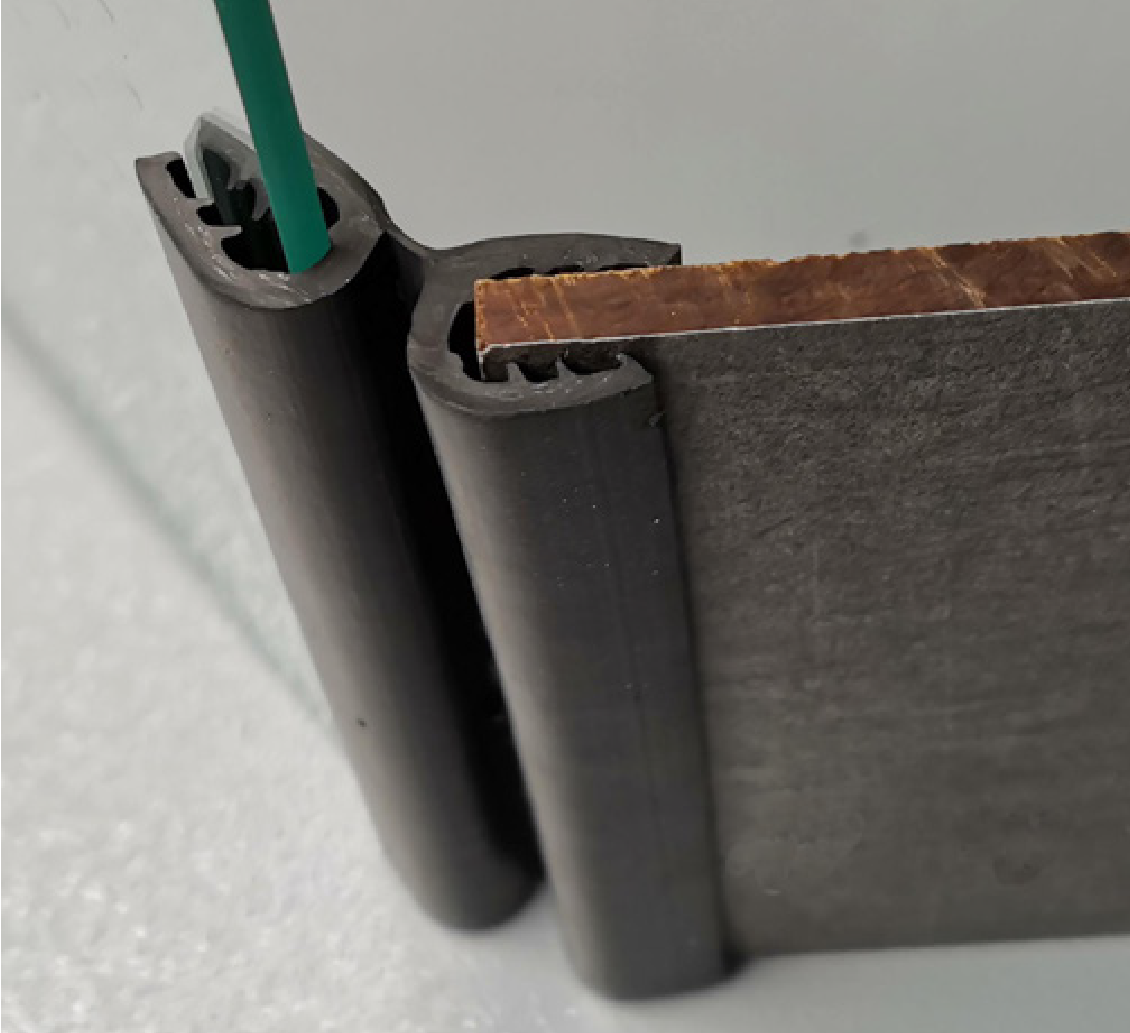

Our mould engineering team specializes in designing high-tolerance, long-life moulds tailored for complex rubber edging profiles. Utilizing advanced CAD/CAM software and CNC machining techniques, we develop custom moulds that support tight dimensional control and repeatable consistency across large production runs. This expertise is critical in sheet metal edging, where edge protection components must conform precisely to metal profiles while maintaining uniform thickness, flexibility, and adhesion characteristics.

Complementing our mould design strength is our in-house rubber formulation capability. Our two formula engineers possess deep expertise in polymer chemistry and material behavior under dynamic industrial conditions. They develop proprietary rubber compounds optimized for abrasion resistance, UV stability, temperature resilience, and adhesion to metal substrates. By controlling the formulation process internally, we ensure that each rubber profile maintains structural integrity and long-term performance when exposed to mechanical stress, environmental exposure, or chemical contact—common challenges in sheet metal handling and assembly.

We further reinforce our engineering strength with full OEM (Original Equipment Manufacturer) capabilities. This allows us to collaborate directly with industrial partners to co-develop custom edging solutions that integrate seamlessly into their production systems or end products. From prototyping and material testing to volume manufacturing and quality assurance, we provide end-to-end support, ensuring compliance with technical specifications and international quality standards.

Our technical proficiency is demonstrated through consistent delivery of rubber edging products that enhance product lifespan, improve safety, and reduce maintenance costs for clients across automotive, construction, appliance, and industrial equipment sectors.

Below is a summary of our core technical specifications and capabilities relevant to sheet metal edging applications:

| Parameter | Specification Capability |

|---|---|

| Durometer Range (Shore A) | 40–90 |

| Temperature Resistance | -40°C to +120°C (extended to +150°C on request) |

| Mould Tolerance | ±0.1 mm |

| Production Lead Time (Prototype) | 10–15 days |

| Standard Materials | EPDM, NBR, SBR, Silicone, Neoprene |

| Custom Compound Development | Yes (based on OEM performance requirements) |

| Adhesion to Metal Substrates | Available with PSA or co-extrusion options |

| Production Volume Capacity | 50,000+ meters/month |

Through a fusion of material science, precision engineering, and OEM collaboration, Suzhou Baoshida delivers reliable, high-performance rubber edging solutions engineered for industrial excellence.

Customization Process

Customization Process for Precision Rubber Edging in Sheet Metal Applications

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber edging solutions for sheet metal components follow a rigorously defined customization pathway. This ensures seamless integration with client specifications while meeting stringent automotive, appliance, and machinery performance demands. The process begins with Drawing Analysis, where our engineering team dissects CAD files and technical schematics to identify critical parameters. We assess edge geometry, substrate material compatibility, environmental exposure conditions, and functional load requirements. This phase includes tolerance validation against ISO 2768-mK standards and verification of sealing or cushioning interfaces. Non-conformities are resolved through direct consultation with the client’s design team, eliminating downstream production risks.

Formulation Development immediately follows, leveraging our proprietary rubber compound database. Material selection prioritizes resistance to ozone, UV degradation, and chemical exposure per ASTM D2000 classifications. Key properties such as hardness, tensile strength, and compression set are calibrated to the application’s mechanical stresses. For instance, automotive door edging requires low-temperature flexibility down to -40°C, while industrial machinery guards demand high abrasion resistance. Below outlines typical compound specifications for common use cases:

| Property | Standard Test | Typical Range | Application Impact |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–80 | Balance of sealing force and flexibility |

| Temperature Range | ISO 188 | -50°C to +150°C | Operational stability in extreme climates |

| Tensile Strength | ASTM D412 | 8–15 MPa | Durability against mechanical stress |

| Compression Set (22h) | ASTM D395 | ≤25% | Long-term sealing integrity |

Prototyping utilizes CNC-machined molds to produce functional samples within 10–15 business days. Each prototype undergoes accelerated aging tests, adhesion validation per ASTM D429 Method B, and dimensional verification via CMM inspection at ±0.1 mm accuracy. Client feedback drives iterative refinements, with material adjustments made at the molecular level—such as increasing silica content for enhanced tear resistance—without compromising cycle time efficiency.

Mass Production commences only after formal sign-off on prototype performance. Our ISO 9001-certified manufacturing facility employs automated injection molding lines with real-time rheometer monitoring to ensure batch consistency. Every production run includes in-process checks for flash control, cure uniformity, and surface finish against Ra 3.2 μm tolerances. Final inspection packages provide traceability via batch-specific material certificates and dimensional reports, guaranteeing compliance with OEM documentation requirements. This end-to-end control minimizes scrap rates and accelerates time-to-market for high-volume sheet metal assemblies.

Contact Engineering Team

For industrial manufacturers seeking high-performance rubber edging solutions tailored to sheet metal applications, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in precision engineering and material science. Our rubber edging products are specifically formulated to meet the rigorous demands of industrial environments, offering superior abrasion resistance, thermal stability, and long-term durability. Whether your application involves edge protection for sheet metal panels, noise dampening in assembly lines, or impact resistance in transportation systems, our engineered rubber profiles deliver consistent, reliable performance.

At Suzhou Baoshida, we specialize in custom-formulated rubber compounds that integrate seamlessly with sheet metal fabrication processes. Our formulations include EPDM, NBR, SBR, and silicone, each selected based on operational requirements such as temperature range, chemical exposure, and mechanical stress. Our extrusion and vulcanization techniques ensure dimensional accuracy and bonding integrity, critical for maintaining edge integrity during handling, transport, and end-use.

We understand that industrial clients require more than just off-the-shelf components — they demand technical collaboration. Our engineering team works directly with OEMs and fabricators to optimize profile geometry, durometer hardness, and adhesion methods, ensuring compatibility with automated assembly systems and longevity in service. From prototyping to full-scale production, Suzhou Baoshida maintains ISO-compliant quality controls and batch traceability to support your supply chain reliability.

The following table outlines key technical specifications for our standard sheet metal rubber edging profiles:

| Property | Value | Test Method |

|---|---|---|

| Hardness (Shore A) | 50–80 ±5 | ASTM D2240 |

| Tensile Strength | ≥8.5 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Operating Temperature Range | -40°C to +120°C (up to +200°C intermittent) | ASTM D1329 |

| Compression Set (22h at 70°C) | ≤25% | ASTM D395 |

| Flame Resistance | UL94 HB compliant | UL94 |

| Adhesion to Metal Substrates | Strong bond with primed steel/aluminum | ASTM D429 |

All profiles can be supplied in continuous lengths or cut-to-size formats, with optional PSA (pressure-sensitive adhesive) backing, conductive fillers, or co-extruded dual-durometer designs for multi-functional performance.

To discuss your specific sheet metal edging requirements, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. With extensive experience in industrial rubber applications and global supply chain coordination, Mr. Boyce provides technical guidance and responsive support to ensure your project meets performance, timeline, and compliance goals. Reach out directly via email at [email protected] to initiate a technical consultation, request samples, or obtain a customized quotation. Partner with Suzhou Baoshida for engineered rubber solutions that enhance product durability and manufacturing efficiency.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).