Technical Contents

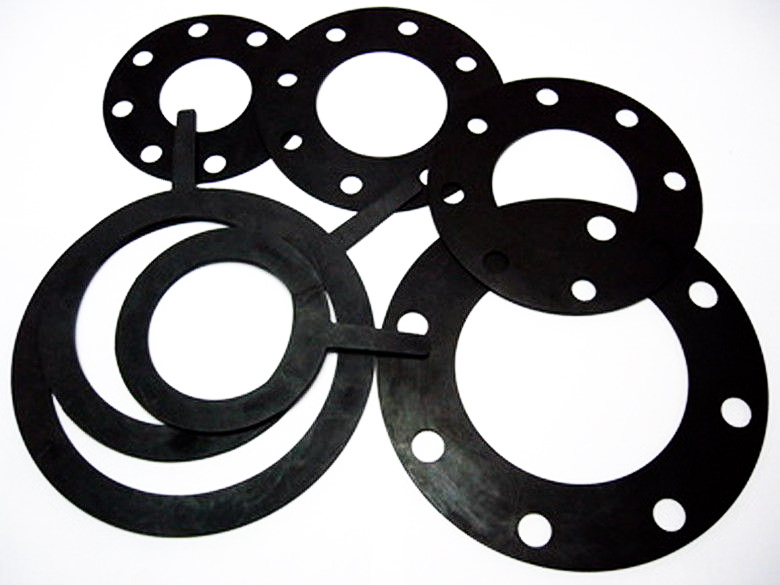

Engineering Guide: Sheeting Material

Engineering Insight Material Selection Imperatives for Industrial Sheeting Applications

Industrial rubber sheeting serves as a critical interface in countless OEM applications, from dynamic sealing systems to chemical containment barriers. Selecting the appropriate compound is not a commodity decision but a fundamental engineering requirement. Off-the-shelf generic sheeting materials frequently fail in demanding operational environments, leading to catastrophic system downtime, safety hazards, and significant financial losses. These failures stem from a critical mismatch between standardized material properties and the specific, often extreme, service conditions encountered in precision manufacturing, automotive, or chemical processing equipment. Generic sheeting typically targets broad market appeal with moderate performance across common parameters, sacrificing the tailored resilience required for high-stress industrial use. Consequences manifest as premature compression set in gaskets, chemical degradation in fluid handling systems, thermal runaway in high-temperature zones, or inadequate tensile recovery under cyclic loading. The cost of such failures—factoring in unplanned downtime, component replacement, and potential contamination—often dwarfs the initial savings from selecting a non-engineered solution. Understanding the precise interplay between polymer chemistry, filler systems, and curing mechanisms is paramount to avoiding these pitfalls.

Material failure analysis consistently reveals that generic compounds lack the targeted molecular architecture necessary for specific challenges. For instance, a standard NBR sheet may suffice for light oil resistance at room temperature but rapidly swells and loses mechanical integrity when exposed to modern synthetic lubricants or elevated temperatures common in engine compartments. Similarly, generic EPDM sheeting often exhibits inadequate resistance to ozone cracking in outdoor applications or insufficient steam resistance for sterilization cycles in pharmaceutical equipment. The core issue lies in the absence of purpose-driven formulation: engineered sheeting incorporates specialized monomers, high-purity fillers, and optimized cure systems to achieve precise performance thresholds. Critical factors such as compression set resistance, low-temperature flexibility, electrical resistivity, and flame retardancy cannot be adequately addressed by one-size-fits-all compounds. Batch-to-batch consistency, essential for OEM assembly line reliability, is also frequently compromised with generic materials due to variable raw material sourcing and less rigorous quality control protocols.

The performance gap between generic and engineered sheeting is quantifiable across key parameters essential for industrial reliability:

| Critical Parameter | Generic Off-the-Shelf Sheeting | Engineered OEM Sheeting | Performance Impact of Gap |

|---|---|---|---|

| Temperature Range (°C) | -30 to +120 | -55 to +150+ | Prevents thermal degradation in extreme environments |

| Compression Set (ASTM D395) | 40-50% after 70h @ 100°C | 15-25% after 70h @ 100°C | Ensures long-term sealing force retention |

| Chemical Resistance | Moderate (e.g., water, mild oils) | Custom-tailored (e.g., acids, fuels, solvents) | Eliminates swelling/degradation in aggressive media |

| Hardness Consistency (Shore A) | ±5 points | ±2 points | Guarantees dimensional stability in precision assemblies |

| Tensile Elongation (%) | 200-300 | 350-500+ | Provides critical flexibility under dynamic stress |

Achieving operational excellence demands moving beyond catalog specifications. Successful OEM integration requires collaborative material engineering—partnering with specialists who translate application stressors into precise compound formulations. At Suzhou Baoshida Trading Co., Ltd., we prioritize deep application analysis to develop sheeting solutions where molecular structure aligns with real-world demands, transforming a potential failure point into a reliable system component. The initial engineering investment in material selection directly correlates with extended service life, reduced total cost of ownership, and sustained operational integrity.

Material Specifications

Suzhou Baoshida Trading Co., Ltd. provides high-performance industrial rubber sheeting materials engineered for demanding applications across automotive, aerospace, chemical processing, and manufacturing sectors. Our core sheeting solutions—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—are precision-formulated to meet rigorous operational standards, including resistance to extreme temperatures, aggressive chemicals, and mechanical stress. Each material offers distinct performance characteristics tailored to specific industrial environments.

Viton rubber sheeting exhibits exceptional resistance to high temperatures, ozone, and a broad spectrum of chemicals, including hydrocarbons, acids, and fuels. With continuous service capability up to 230°C (446°F) and intermittent exposure tolerance to 260°C (500°F), Viton is ideal for sealing and gasketing in high-temperature and chemically aggressive environments. Its low gas permeability and excellent aging properties make it a preferred choice in aerospace and oil & gas applications where reliability is critical.

Nitrile rubber sheeting, a copolymer of acrylonitrile and butadiene, delivers superior resistance to oils, greases, and aliphatic hydrocarbons. It maintains mechanical integrity under dynamic conditions, offering good abrasion resistance and tensile strength. Nitrile performs reliably in temperature ranges from -30°C to +100°C (-22°F to 212°F), with specialty grades extending low-temperature flexibility. This material is widely used in hydraulic systems, fuel handling, and industrial machinery where oil resistance is paramount.

Silicone rubber sheeting provides outstanding thermal stability and flexibility across an extended temperature range of -60°C to +200°C (-76°F to 392°F). It exhibits excellent resistance to UV radiation, ozone, and weathering, making it suitable for outdoor and high-purity applications. While not as resistant to petroleum-based fluids as Viton or Nitrile, silicone excels in electrical insulation, food-grade processing, and medical environments due to its inertness, low toxicity, and compliance with FDA and USP Class VI standards.

The following table summarizes key performance specifications for Viton, Nitrile, and Silicone sheeting materials:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 (up to 260 intermittent) | -30 to 100 (special grades to -50) | -60 to 200 |

| Hardness Range (Shore A) | 50–90 | 40–95 | 30–80 |

| Tensile Strength (MPa) | 12–20 | 10–30 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–600 |

| Fluid Resistance (Oils, Fuels) | Excellent | Excellent | Poor to Fair |

| Chemical Resistance (Acids, Ozone) | Excellent | Good | Good |

| Electrical Insulation | Fair | Fair | Excellent |

| FDA/USP Class VI Compliance | Limited grades | No | Yes (specific formulations) |

All sheeting materials are manufactured to precise thickness tolerances (0.5 mm to 10 mm standard) and are available in rolls or cut sheets. Custom durometers, colors, and reinforcement options are available upon request. Suzhou Baoshida ensures consistent quality through ISO-certified production and rigorous batch testing, supporting OEMs and industrial partners with reliable, application-optimized rubber solutions.

Manufacturing Capabilities

Engineering Excellence in Industrial Sheeting Material Development

Suzhou Baoshida Trading Co., Ltd. leverages integrated material science and precision tooling expertise to deliver mission-critical rubber sheeting solutions for demanding industrial environments. Our core strength resides in the seamless collaboration between dedicated Formula Engineering and Mould Engineering teams, ensuring every sheeting product meets exacting performance, durability, and dimensional specifications. With two specialized Rubber Formula Engineers and five advanced Mould Engineers, we eliminate traditional silos between material composition and manufacturing execution. This unified approach directly addresses common industry pain points such as premature material degradation, inconsistent thickness tolerance, and production inefficiencies during high-volume runs.

Our Formula Engineers possess deep expertise in polymer chemistry, compounding, and failure analysis. They develop proprietary formulations tailored to specific operational challenges—including extreme temperature exposure, chemical resistance, abrasion resistance, and critical sealing force requirements. Rigorous laboratory testing, including ASTM D2000 compliance validation, accelerated aging studies, and dynamic mechanical analysis (DMA), ensures formulations exceed baseline industry standards before prototyping. Concurrently, our Mould Engineering team applies finite element analysis (FEA) and precision CNC machining capabilities to design and fabricate tooling that guarantees ±0.05mm thickness uniformity and edge definition across large-format sheets. This synergy enables rapid iteration from concept to validated production, significantly reducing time-to-market for custom OEM solutions.

We excel in transforming complex technical requirements into reliable sheeting products through our end-to-end OEM management process. Clients benefit from collaborative design reviews, material selection guidance based on fluid compatibility charts and mechanical property databases, and comprehensive validation reporting. Our facility supports low-volume prototyping through high-volume continuous production runs, maintaining strict ISO 9001:2015 process controls. Critical to our OEM success is the ability to document and transfer full material traceability, cure kinetics data, and dimensional certification packages—ensuring seamless integration into client assembly lines and audit readiness.

The following table illustrates key compound capabilities frequently deployed in our sheeting applications:

| Compound Type | Key Properties | Common Applications |

|---|---|---|

| Nitrile (NBR) | 50-90 Shore A Durometer; Oil/Fuel Resistance; -30°C to +100°C Operating Range | Hydraulic Seals, Fuel Hoses, Gaskets |

| EPDM | 40-80 Shore A Durometer; Ozone/Weather Resistance; -50°C to +150°C Operating Range | Weatherstripping, Roofing Membranes, Cooling System Components |

| Silicone (VMQ) | 30-80 Shore A Durometer; Extreme Temp Stability (-60°C to +230°C); Biocompatibility | Medical Device Components, High-Temp Insulation, Food Processing Seals |

| Neoprene (CR) | 40-70 Shore A Durometer; Flame Resistance; Moderate Oil Resistance | Electrical Insulation, Vibration Dampeners, Marine Seals |

This engineering-centric framework ensures Suzhou Baoshida delivers not merely sheeting material, but validated performance solutions. By embedding formula science and precision tooling expertise into every project phase—from initial specification consultation through production scaling—we mitigate technical risk and enhance product lifecycle reliability for global industrial OEMs. Our commitment is to be an extension of your engineering team, providing the scientific rigor and manufacturing precision required for success in today’s competitive markets.

Customization Process

Drawing Analysis: The Foundation of Precision Sheeting

At Suzhou Baoshida Trading Co., Ltd., the customization process for industrial rubber sheeting begins with rigorous drawing analysis. This initial phase ensures that every dimension, tolerance, and functional requirement is fully understood before any material development commences. Our engineering team evaluates technical drawings provided by the client, focusing on critical parameters such as thickness, width, length, surface finish, and any special geometrical features like grooves, perforations, or bonding zones. We also assess environmental exposure conditions—temperature range, chemical contact, dynamic stress, and UV/ozone resistance—to inform downstream material selection. This step is not merely interpretive; it is a collaborative dialogue. We often request clarification or suggest design optimizations to improve manufacturability and longevity, ensuring the final sheeting performs reliably under real-world operating conditions.

Formulation: Engineering Material for Application-Specific Demands

Once the design parameters are confirmed, our Rubber Formula Engineers initiate the formulation phase. This is where raw material science meets industrial application. Based on the environmental and mechanical requirements derived from the drawing analysis, we select the optimal base polymer—be it Nitrile (NBR) for oil resistance, EPDM for thermal and ozone stability, Silicone for extreme temperature performance, or Neoprene for balanced mechanical and chemical properties. Reinforcing fillers, plasticizers, vulcanizing agents, and anti-aging additives are then precisely compounded to achieve target hardness (Shore A), tensile strength, elongation at break, and compression set. Each formulation is documented and batch-traceable, adhering to ISO 9001 standards. Clients receive a full material data sheet for approval prior to prototyping, ensuring complete transparency and technical alignment.

Prototyping: Validating Performance Before Scale-Up

Prototyping serves as the critical validation bridge between design intent and mass production. Using pilot-scale calendaring or press-curing equipment, we produce limited quantities of the specified rubber sheeting. These samples undergo rigorous in-house testing, including dimensional inspection, hardness measurement, and application-specific performance trials such as fluid immersion or thermal cycling. Clients are encouraged to conduct field testing under actual operating conditions. Feedback is systematically collected and, if necessary, minor formulation or processing adjustments are implemented. This iterative approach minimizes risk and ensures product conformity before committing to full-scale manufacturing.

Mass Production: Consistency, Quality, and On-Time Delivery

Upon prototype approval, the project transitions to mass production. Our automated calendaring lines and continuous vulcanization systems ensure uniform thickness, consistent physical properties, and high throughput. Real-time quality monitoring, including laser-based thickness gauging and periodic mechanical testing, guarantees adherence to specifications. All batches are labeled with lot numbers for full traceability.

Key production specifications are summarized below:

| Parameter | Range/Value | Testing Standard |

|---|---|---|

| Thickness Tolerance | ±0.1 mm (standard), ±0.05 mm (precision) | ASTM D3767 |

| Hardness Range | 30–90 Shore A | ASTM D2240 |

| Width Capability | Up to 1500 mm | Custom tooling available |

| Length Options | Rolls up to 50 m, cut sheets standard | Client-defined |

| Vulcanization Method | Hot air, steam, or continuous press | ISO 3300 |

| Common Polymers | NBR, EPDM, Silicone, CR, SBR | ASTM D1418 |

At Suzhou Baoshida, we integrate engineering precision with scalable manufacturing to deliver custom rubber sheeting that meets the exact needs of industrial OEMs worldwide.

Contact Engineering Team

Precision Partnership for Industrial Sheeting Material Solutions

Suzhou Baoshida Trading Co., Ltd. stands as your definitive engineering partner for mission-critical rubber sheeting materials. With over 15 years of specialized focus in elastomeric formulation and OEM collaboration, we resolve complex sealing, insulation, and wear challenges across automotive, aerospace, energy, and heavy machinery sectors. Our laboratory-driven approach ensures every sheeting compound meets exact dimensional tolerances, environmental resistance requirements, and performance specifications demanded by modern industrial applications. Unlike commodity suppliers, we integrate material science with manufacturing pragmatism—transforming your technical constraints into optimized production outcomes.

Critical performance parameters define the viability of rubber sheeting in demanding operational environments. The following table summarizes key properties achievable through our proprietary compounding processes, validated per ASTM D2000 and ISO 37 standards:

| Material Type | Hardness (Shore A) | Tensile Strength (MPa) | Temperature Range (°C) | Fluid Resistance Profile |

|---|---|---|---|---|

| NBR | 50–90 | 15–28 | -30 to +120 | Excellent for oils, fuels |

| EPDM | 40–80 | 10–22 | -50 to +150 | Superior ozone/weathering |

| SBR | 45–75 | 12–20 | -20 to +100 | Balanced general-purpose |

| Silicone | 30–80 | 5–12 | -60 to +230 | Extreme temp, biocompatible |

These specifications represent baseline capabilities; our engineering team routinely develops custom formulations exceeding standard benchmarks. Whether addressing dynamic compression set in hydraulic seals, flame retardancy for rail applications, or FDA-compliant food-grade surfaces, we deploy accelerated aging protocols and finite element analysis to validate real-world performance prior to tooling commitment. Our Suzhou-based production facility maintains ISO 9001 and IATF 16949 certification, with in-line spectrometry and rheometry ensuring batch-to-batch consistency within ±2% tolerance.

Initiate your project with engineered certainty. Contact Mr. Boyce, our dedicated OEM Manager, to discuss material selection, rapid prototyping, or volume production scheduling. Mr. Boyce possesses direct authority to allocate engineering resources for technical deep dives—providing compound datasheets, regulatory compliance documentation, and feasibility assessments within 72 hours of engagement. His team navigates complex supply chain variables to guarantee on-time delivery of sheeting materials cut to your precise thickness, width, and surface finish requirements.

Do not compromise on material integrity when system reliability is non-negotiable. Email Mr. Boyce at [email protected] with your application parameters, target cost structure, and volume projections. Specify reference code SHEET-ENG-2024 to expedite technical review. We respond to all qualified inquiries within one business day with a structured action plan—not generic sales literature. Suzhou Baoshida transforms elastomeric challenges into competitive advantages through chemistry, precision, and unwavering accountability. Your next-generation sheeting solution begins with an engineer-to-engineer dialogue. Act now to secure performance-grade materials engineered for operational endurance.

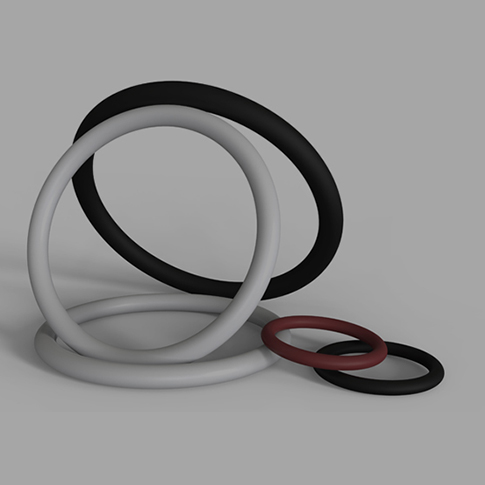

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).